I'm over it, looking for an exit.But the weather sure is nice here isn’t it..

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

American Rifle Company New Archimedes Action, New Xylo Chassis, and major Mausingfield revision

- Thread starter karagias

- Start date

Does anyone else struggle w/ the bolt stop as much as i do? I thought I saw an iteration w/ a tear drop shaped actuator, but these "in the wild" photos dont have that. Now just wondering if i made that up, or if design was changed for some reason.

It's pretty stiff at 1st. open/close it for awhile and it'll loosen/smooth out. Still kinda tough when you have optics mount right above it (at least on my Nucleus), but if you can get the correct leverage on it, pretty easy to twist.

The original design had a "teardrop" look. But i think it was changed for production.

The original Nucleus prototypes had that but I think they interfered with rear scope rings or opened unintentionally due to inertia (kind of doubtful), so it was changed to a round knob.Does anyone else struggle w/ the bolt stop as much as i do? I thought I saw an iteration w/ a tear drop shaped actuator, but these "in the wild" photos dont have that. Now just wondering if i made that up, or if design was changed for some reason.

Does anyone else struggle w/ the bolt stop as much as i do? I thought I saw an iteration w/ a tear drop shaped actuator, but these "in the wild" photos dont have that. Now just wondering if i made that up, or if design was changed for some reason.

The one on both of my Nukes was a bit tough to use at first. I took it apart and cleaned and lubed it and it's a whole different animal now. You could probably just clean it installed and be 98% as effective as taking it apart as well.

Xylo question:

What magazines fit the long action?

ARC website says 3.78"

MDT website offers 3.715" and 3.85"

Magpul offers 3.7"

I'm guessing the 3.78" is a cartridge length, not magazine length and the MDT 3.85" is the right one but I'm going to ask because this isn't clear at all and magazines are expensive...

What magazines fit the long action?

ARC website says 3.78"

MDT website offers 3.715" and 3.85"

Magpul offers 3.7"

I'm guessing the 3.78" is a cartridge length, not magazine length and the MDT 3.85" is the right one but I'm going to ask because this isn't clear at all and magazines are expensive...

Xylo question:

What magazines fit the long action?

ARC website says 3.78"

MDT website offers 3.715" and 3.85"

Magpul offers 3.7"

I'm guessing the 3.78" is a cartridge length, not magazine length and the MDT 3.85" is the right one but I'm going to ask because this isn't clear at all and magazines are expensive...

You’re correct. Like the KRG Bravo and MDT ACC, it takes CIP-length (3.85in) magazines, which correspond to 3.78in COAL.

I ordered January 25th and received action 00028.

I also have the TT Special and FWIW, there is a bit of forward bolt travel under spring tension just before I can rotate the bolt handle down to the closed position. In my example it's intermittent and it's caused by the spring-loaded rotation lockout plunger in the cocking piece shroud, I gotta say I'm not a fan.

Just received #47 and I can attest to not being able to close the bolt once my TT special was installed. I mocked it up in a chassis and while it is better it’s still unacceptable. I’m waiting to hear back from ARC.

I also have the TT Special and FWIW, there is a bit of forward bolt travel under spring tension just before I can rotate the bolt handle down to the closed position. In my example it's intermittent and it's caused by the spring-loaded rotation lockout plunger in the cocking piece shroud, I gotta say I'm not a fan.

I ordered January 25th and received action 00028.

I also have the TT Special and FWIW, there is a bit of forward bolt travel under spring tension just before I can rotate the bolt handle down to the closed position. In my example it's intermittent and it's caused by the spring-loaded rotation lockout plunger in the cocking piece shroud, I gotta say I'm not a fan.

Do you have a Nucleus? Curious any difference.

Same deal and I sent the FFL paperwork myself... Oh well, keeps me from buying X,Y or Z trigger while the rest of you figure out which one works.I haven’t heard anything for a week and I think my FFL sent the paperwork...

Do you have a Nucleus? Curious any difference.

I also have a Nucleus with a TT and it does not hang up this bad.

I have a Nucreus from the first batch released and have never had any troubles with a TriggerTech Special OR Diamond, the only triggers I’ve ever run. Ive also never experienced any of the light strike issues. If I sit at the couch and get really picky I pick up a little effort on closing but have not noticed it on the line of fire.

Anxiously awaiting Archimedes #70 inbound on Friday and have a Special waiting for it....I’m not worried....yet.

Anxiously awaiting Archimedes #70 inbound on Friday and have a Special waiting for it....I’m not worried....yet.

ARC just sent an email pertaining to Long Action rails. There's a minor defect near the front (muzzle end). It should still work, just advise not to lock down any ring/mount on that specific spot/slot. That one rail is chamfered. They will send out new rails...hope they send me the correct 30MOA rail.

Last edited:

Just received #47 and I can attest to not being able to close the bolt once my TT special was installed. I mocked it up in a chassis and while it is better it’s still unacceptable. I’m waiting to hear back from ARC.

ARC just sent an email pertaining to Long Action rails. There's a minor defect near the front (muzzle end). It should still work, just advise not to lock down any ring/mount on that specific spot/slot. That one rail is chamfered. They will send out new rails...hope they send me the correct 30MOA rail.

Sadly, seems expected and not too surprising to see that ARC's new designs have issues and need another iteration or three to make them right. They had issues with Nucleus as well and that action don't' seem fully sorted yet. Still seeing/hearing of people working on spring weights or bolt close feel. And did ARC ever resolve their magazine issues? Hopefully ARC can figure it all out and resolve Nucleus & Archimedes issues before their attention switches to creating another new action next year.

Sadly, seems expected and not too surprising to see that ARC's new designs have issues and need another iteration or three to make them right. They had issues with Nucleus as well and that action don't' seem fully sorted yet. Still seeing/hearing of people working on spring weights or bolt close feel. And did ARC ever resolve their magazine issues? Hopefully ARC can figure it all out and resolve Nucleus & Archimedes issues before their attention switches to creating another new action next year.

If someone was surprised, I feel sorry for them. Its not like it was a secret though. Still not the best way to operate. I'd be happy to see it all worked out for what they have released and the XL Archimedes come out in 2021. I think I'll be in the market for a big boomer by then...

I bought the Nucleus (0005 short action and 0002 long action) and didn't mind the delays, trigger springs, bolt heads, etc. I bought an Archimedes, and am patiently waiting for my action to ship, warts and all. I certainly don't expect everyone to be as patient as me though.

That makes me happy. Sometimes I really have to wonder how much of this is picking nits and how much is truly a problem. I noticed a little extra effort to close on my Nucleus but it never bothered me and after a couple hundred rounds wore in nicely. Original spring and all. Never a misfire and the first two hundred rounds through it were at a shooting school. I always take some of these gripes with a grain of salt and have to wonder how much of it is truly a problem and how much of it is “user error”. Guess I’ll find out soon enough.

That makes me happy. Sometimes I really have to wonder how much of this is picking nits and how much is truly a problem. I noticed a little extra effort to close on my Nucleus but it never bothered me and after a couple hundred rounds wore in nicely. Original spring and all. Never a misfire and the first two hundred rounds through it were at a shooting school. I always take some of these gripes with a grain of salt and have to wonder how much of it is truly a problem and how much of it is “user error”. Guess I’ll find out soon enough.

I just updated the Sear Engagement thread. They are aware of the issue and working on the solution. It's definitely not nit-picking as I experienced it with my Mausingfield as well. It was straight up shit to run it with a Huber trigger. Clunky, took a lot of force to close the bolt. With a TT, the bolt almost closes itself. It made all the difference in the world. If I wanted to compromise I'd just have a 700 action.

-Dan

I don’t claim to be a professional shooter or anything, I’ve got a nucleus, never an issue with it with original spring. Looking forward to getting a barrel spun up. Hopefully I won’t have an issue, Hope you other guys get your actions squared away quickly.

Just caught that update. Thank you.I just updated the Sear Engagement thread. They are aware of the issue and working on the solution. It's definitely not nit-picking as I experienced it with my Mausingfield as well. It was straight up shit to run it with a Huber trigger. Clunky, took a lot of force to close the bolt. With a TT, the bolt almost closes itself. It made all the difference in the world. If I wanted to compromise I'd just have a 700 action.

-Dan

I hate to say it but I’m done. I’ve been through this with the Nucleus, Barloc...surely the Archimedes would be ready. I’m sending mine back. ARC is becoming the Delorian of actions.

Archimedes

Just the Archimedes.Do you have a Nucleus? Curious any difference.

Dear American Rifle Company customer:

You are receiving this message because the Archimedes action that you have just received from us or will receive very soon has a minor problem that we must remedy. If you have not received your action yet but have paid for it in full, shipping will be delayed by about five to seven business days while we correct the problem.

So what’s wrong.

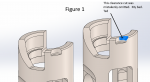

The bolt shroud locking pin is not disengaging the bolt body making it difficult to close the bolt. This is because the bolt body is missing a helical relief cut. See Figure 1. The Archimedes prototypes did not require this cut because they did not have closing cams machined into the forward end of the receiver. Since prototyping, we decided to incorporate 0.050” of forward camming to aid in closing the bolt over tight or slightly oversized brass. Unfortunately, we failed to include the helical relief cut that enables the bolt shroud to disengage the bolt before bolt rotation begins. The action will work without the relief cut but the effort required to make it work depends on the relationship between the cocking piece and the trigger assembly. A relationship that does not cock on close might seem to work fine but one that does cock on close will require a forceful push forward to close the bolt.

The fix is very straight forward, but it does require you to send your bolt to us so that we can replace it with one that has the relief cut. We will email a shipping label to you making the return process as painless as we can. You can also simply remove the bolt should locking pin and its spring, but we don’t recommend this because do so will allow the bolt should to easily rotate when the bolt is retracted. We really want you to send your bolt back to us so we can take care of this properly.

We have also noticed that the aft end of the Archimedes bolt may be rubbing the upper sear of some triggers. Thus far, we have very few confirmed occurrences of this, one of which was with a Tubb T7 trigger, but we will be reducing the diameter of the aft end of the bolt by about 0.020” thus adding an additional 0.010” of clearance between the bottom of the cocking piece and the top of the trigger assembly, most likely the upper sear. A bolt having the reduced aft diameter has already been successfully tested for strength.

Lastly, as some of you have already noticed, the cocking piece of the Archimedes is engraved with a couple of number, such as 780/055. These signify some important dimensions of the cocking piece that will enable us to offer you variation that will improve (depending on your preference) your tactile experience when closing the bolt. Most of our customers seem to prefer smooth and bump-free bolt-closing rotation. It’s worth noting that an action exhibiting bump-free closing will not cock-on-close at all. However, nearly all major brands of bolt-action rifles cock-on-close and do so for a very good reason, it improves ignition reliability while reducing the effort to open the bolt. But the heart wants what it wants, and we aim to deliver what it wants. Therefore, during testing, we determined that sear interface protrusion of 0.055 inches (see Figure 2) will result in bump-free bolt-closing when used with Remington, Trigger Tech, Timney, and Jewell triggers. This may not always be the case. We know triggers vary, even triggers of the same type from the same manufacturer. The parts of the action also vary. Thus, if you happen to be using a 780/055 cocking piece and a trigger from one of the aforementioned companies, and you are experiencing some cock-on-close, you can replace your cocking piece with one having 0.010 or 0.020 inches less sear interface protrusion, 780/045 and 780/035 respectively. We are offering various cocking pieces so that you can time you action without having to grind either the cocking piece or sear. We currently have cocking pieces with having sear interface protrusions of .035, .045, .055, and .065 inches in stock. That will likely cover all of the popular triggers but we will make more sizes if necessary.

One of our customers recently sent his Archimedes action back to us along with his Bix’n Andy Tac Sport Pro trigger. We found that a 780/035 cocking piece was necessary to provide bump-free bolt closing.

As we learn more about trigger-cocking piece compatibility, we will compile data and make it available on our web site.

Oh yeah, and there’s one more thing. If you have received a long action Archimedes, we will be sending you a new Picatinny rail for it. We screwed up one of the recoil slots. No need to send your defective rail back to us. Keep it as a back up or just keep using it and keep your new one as the backup. We will continue to send long actions with defective rails to get you shooting sooner than later. We’ll send the new rails as soon as we have them, probably within the next month or two.

Sorry about the speed bumps. The absence of the helical relief cut is really the only major issue and correcting that is our number one priority. We seriously appreciate your business and apologize for the inconvenience and delay these issues may cause.

As always, thanks for your business, support, and interest in firearms.

Sincerely,

Ted

President

American Rifle Company

You are receiving this message because the Archimedes action that you have just received from us or will receive very soon has a minor problem that we must remedy. If you have not received your action yet but have paid for it in full, shipping will be delayed by about five to seven business days while we correct the problem.

So what’s wrong.

The bolt shroud locking pin is not disengaging the bolt body making it difficult to close the bolt. This is because the bolt body is missing a helical relief cut. See Figure 1. The Archimedes prototypes did not require this cut because they did not have closing cams machined into the forward end of the receiver. Since prototyping, we decided to incorporate 0.050” of forward camming to aid in closing the bolt over tight or slightly oversized brass. Unfortunately, we failed to include the helical relief cut that enables the bolt shroud to disengage the bolt before bolt rotation begins. The action will work without the relief cut but the effort required to make it work depends on the relationship between the cocking piece and the trigger assembly. A relationship that does not cock on close might seem to work fine but one that does cock on close will require a forceful push forward to close the bolt.

The fix is very straight forward, but it does require you to send your bolt to us so that we can replace it with one that has the relief cut. We will email a shipping label to you making the return process as painless as we can. You can also simply remove the bolt should locking pin and its spring, but we don’t recommend this because do so will allow the bolt should to easily rotate when the bolt is retracted. We really want you to send your bolt back to us so we can take care of this properly.

We have also noticed that the aft end of the Archimedes bolt may be rubbing the upper sear of some triggers. Thus far, we have very few confirmed occurrences of this, one of which was with a Tubb T7 trigger, but we will be reducing the diameter of the aft end of the bolt by about 0.020” thus adding an additional 0.010” of clearance between the bottom of the cocking piece and the top of the trigger assembly, most likely the upper sear. A bolt having the reduced aft diameter has already been successfully tested for strength.

Lastly, as some of you have already noticed, the cocking piece of the Archimedes is engraved with a couple of number, such as 780/055. These signify some important dimensions of the cocking piece that will enable us to offer you variation that will improve (depending on your preference) your tactile experience when closing the bolt. Most of our customers seem to prefer smooth and bump-free bolt-closing rotation. It’s worth noting that an action exhibiting bump-free closing will not cock-on-close at all. However, nearly all major brands of bolt-action rifles cock-on-close and do so for a very good reason, it improves ignition reliability while reducing the effort to open the bolt. But the heart wants what it wants, and we aim to deliver what it wants. Therefore, during testing, we determined that sear interface protrusion of 0.055 inches (see Figure 2) will result in bump-free bolt-closing when used with Remington, Trigger Tech, Timney, and Jewell triggers. This may not always be the case. We know triggers vary, even triggers of the same type from the same manufacturer. The parts of the action also vary. Thus, if you happen to be using a 780/055 cocking piece and a trigger from one of the aforementioned companies, and you are experiencing some cock-on-close, you can replace your cocking piece with one having 0.010 or 0.020 inches less sear interface protrusion, 780/045 and 780/035 respectively. We are offering various cocking pieces so that you can time you action without having to grind either the cocking piece or sear. We currently have cocking pieces with having sear interface protrusions of .035, .045, .055, and .065 inches in stock. That will likely cover all of the popular triggers but we will make more sizes if necessary.

One of our customers recently sent his Archimedes action back to us along with his Bix’n Andy Tac Sport Pro trigger. We found that a 780/035 cocking piece was necessary to provide bump-free bolt closing.

As we learn more about trigger-cocking piece compatibility, we will compile data and make it available on our web site.

Oh yeah, and there’s one more thing. If you have received a long action Archimedes, we will be sending you a new Picatinny rail for it. We screwed up one of the recoil slots. No need to send your defective rail back to us. Keep it as a back up or just keep using it and keep your new one as the backup. We will continue to send long actions with defective rails to get you shooting sooner than later. We’ll send the new rails as soon as we have them, probably within the next month or two.

Sorry about the speed bumps. The absence of the helical relief cut is really the only major issue and correcting that is our number one priority. We seriously appreciate your business and apologize for the inconvenience and delay these issues may cause.

As always, thanks for your business, support, and interest in firearms.

Sincerely,

Ted

President

American Rifle Company

Attachments

Ted, can we just send our action in with our preferred trigger so we don't end up having to buy an additional piece if needed?

Last edited:

Ted, can we just send our action in with our preferred trigger so we don't end up having to buy an additional piece if needed?

^This^

Definitely. that actually makes things much easier for us and I am glad that you brought it up. Also, if you have the capability of modifying a cocking piece, you can also order a 0.055" or 0.065" protrusion and grind for desired bolt closing characteristics. But sending in you trigger is the way to go if you want bump-free close. Also, bear in mind that current increments are only 0.010" which means that you may have up to that amount of pin drop-on-close. But that's OK because that's hard to feel. With a slight drop on close arrangement, if you open the bolt without having pulled the trigger, you'll feel the bolt slightly lift the striker before it fully unlocks.Ted, can we just send our action in with our preferred trigger so we don't end up having to buy an additional piece if needed?

Ted

That is awesome to agree too. I have a "short action" that arrived today as a long action, which is fine since I have a long action order and hopefully it will be fulfilled with the short action. Would you be willing to allow me to send two triggers when I send back my "short" long action and fit to the other order I have as well?Definitely. that actually makes things much easier for us and I am glad that you brought it up. Also, if you have the capability of modifying a cocking piece, you can also order a 0.055" or 0.065" protrusion and grind for desired bolt closing characteristics. But sending in you trigger is the way to go if you want bump-free close. Also, bear in mind that current increments are only 0.010" which means that you may have up to that amount of pin drop-on-close. But that's OK because that's hard to feel. With a slight drop on close arrangement, if you open the bolt without having pulled the trigger, you'll feel the bolt slightly lift the striker before it fully unlocks.

Ted

Thanks

ben

How does the bolt fit in the rear of the action with .020 turned off? Does it allow any additional lateral movement that isn't there now?

No but reducing the diameter back there as he said should^^^^^ I dont think that little relief cut is gonna fix that

Yes, I just hope that it doesn't induce binding. My action is working great with a TT diamond trigger. I think I'll wait a bit before sending it in for replacement.No but reducing the diameter back there as he said should

Called my FFL, my action hasn't been delivered so it must be getting fixed before it ships.

Thanks for this post. That's helpful and it's about what I am expecting. Please use our sales email to contact us and we will send a shipping label immediately so that we can fix this.On my example, the TriggerTech Special sear contacts the large-diameter portion of the bolt body even when the action is cycled gently while inverted.

Clean the area:

View attachment 7150791 View attachment 7150792

Apply a very thin layer of grease:

View attachment 7150793

And the results:

View attachment 7150794 View attachment 7150795

Ted

If you are happy with the way your action is functioning, you don;t have to send it to us. This will not be a problem with every action and user. It depends on which trigger is used and how the action is cycled. If it feels good to you, keep shooting. Should you ever choose to replace the trigger and experience a problem because of it, we can address it at that time.Yes, I just hope that it doesn't induce binding. My action is working great with a TT diamond trigger. I think I'll wait a bit before sending it in for replacement.

Ted

Yes but I don't think there is an advantage in doing so simply because bolt body remains extremely strong after the rework is complete and the machining is straight forward either way.Hi Ted,

Is cutting or grinding a flat similar to the patch around the bolt handle pivot pin an option instead of turning the diameter down?

Ted

No. We are not reducing the diameter of the bolt that engages the aft portion of the receiver. The clearance between the bolt and the receiver remains the same.How does the bolt fit in the rear of the action with .020 turned off? Does it allow any additional lateral movement that isn't there now?

You guys ask great questions.

Ted

Ted, can we just send our action in with our preferred trigger so we don't end up having to buy an additional piece if needed?

Yeah, I need my actions to work with Tubb T7T and BnA tac sport and Geiselle 700

Yes but I don't think there is an advantage in doing so simply because bolt body remains extremely strong after the rework is complete and the machining is straight forward either way.

Ted

It seems like fixturing and milling a slot/flat would take less time than truing and turning the OD of the bolt body. Or rather, just swapping bolt bodies and cocking pieces with parts with the work already incorporated.

I don't have an action right in front of me but with a removable bolt handle and bolt head, it might be as simple as putting the bolt body in a collet closing lathe and using a tool post grinder to cut through the nitride.

Pretty easy if that is the case. Milling a flat would probably need a jig to line it up with some other feature. Still simple but possibly a bit more work.

Pretty easy if that is the case. Milling a flat would probably need a jig to line it up with some other feature. Still simple but possibly a bit more work.

Here is a before and after photo of the rework as well as a couple of photos of the setup for the curious among you. Premium carbide endmills get through the nitriding without any trouble. We'll probably go through two or three of them to get this done but we're used to spending money on cutting edges. Someday I'd like to buy an endmill dispenser (Walter CNC grinder) but it will take much greater volume to justify the $400,000+ investment for one of those, unless of course we get into the chamber reamer business, or maybe even the end mill business. Imagine buying premium carbide directly from the factory using an awesome website like McMaster-Carr. Opportunity is knocking folks.

Anyway, the rework is going well. We should be able to send parts out for finishing tomorrow via UPS next day and have them back here by Wednesday in which case we'll resume shipping on Thursday. I hope things go well and that happens.

Ted

Anyway, the rework is going well. We should be able to send parts out for finishing tomorrow via UPS next day and have them back here by Wednesday in which case we'll resume shipping on Thursday. I hope things go well and that happens.

Ted

Attachments

Similar threads

- Replies

- 2

- Views

- 505

- Replies

- 12

- Views

- 677

- Replies

- 0

- Views

- 322

- Replies

- 0

- Views

- 231

- Replies

- 5

- Views

- 1K