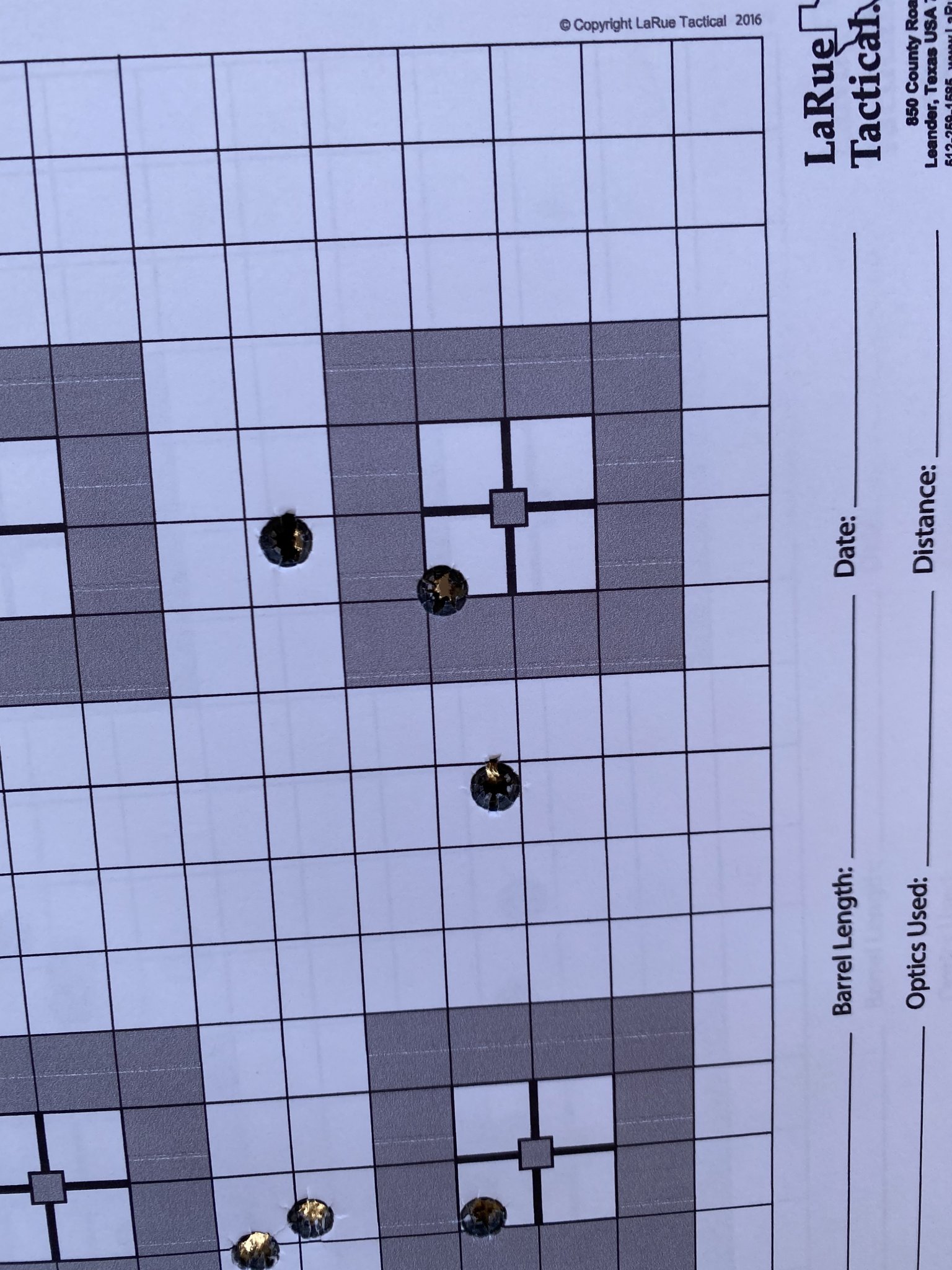

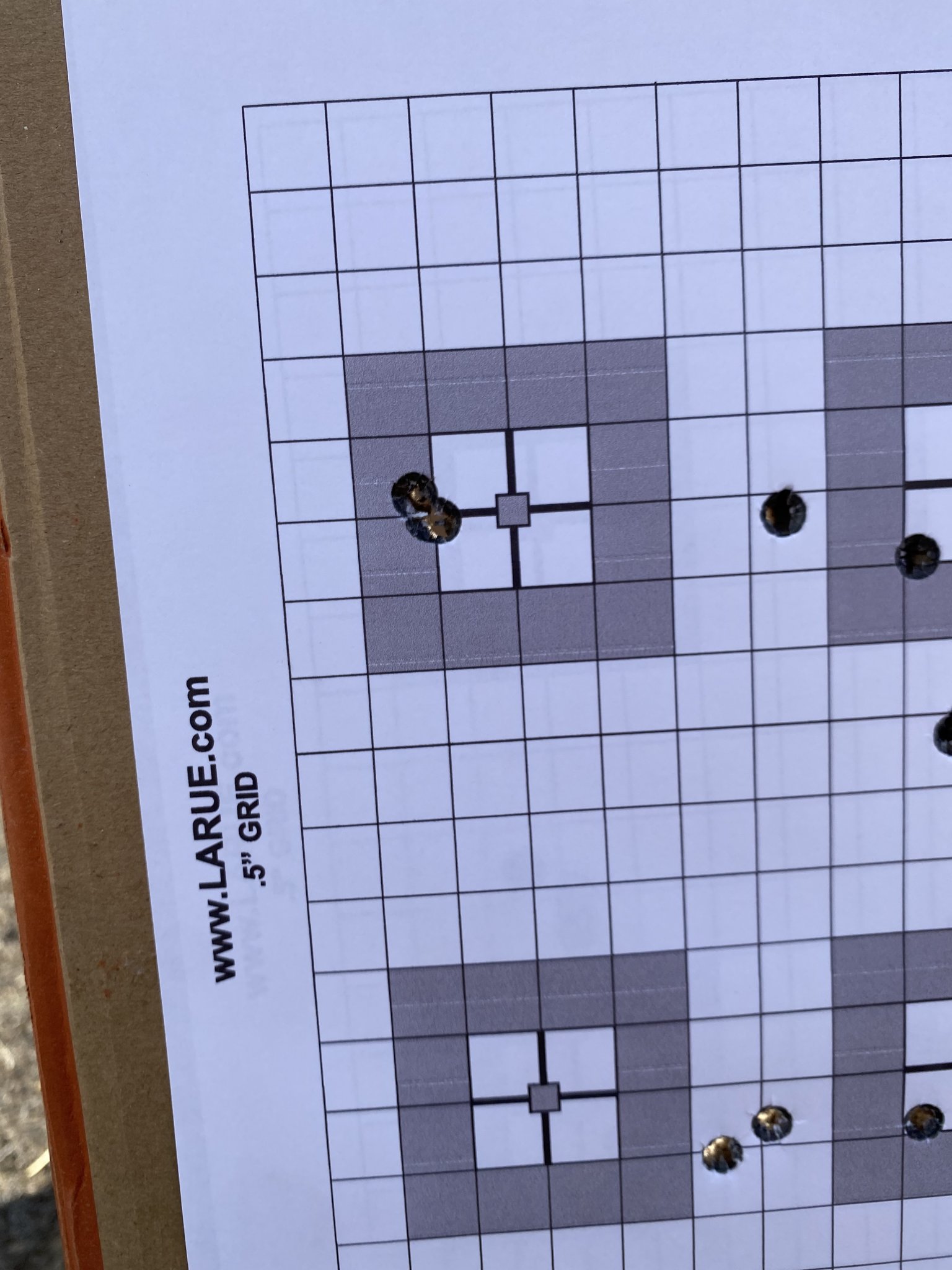

hey guys, Recently got an AMP annealing machine for my reloading, its slick. I had a pet load for my 300 PRC that shoots pretty good, and duplicated it, same brass prep, same charge, seating depth etc… Well I got an AZTEC code of 150, and went to the range to find out it shoots pretty bad. I use a .3070 expander mandrel, and the group on the left (.2MOA ish) is the old blow torch method of annealing.

Now i’m kind of confused has anybody seen the same issues? After I grouped the two on the right top and bottom (forgive the crap pictures I took it in the sun and couldn’t see the groups / framing on my iPhone) I was scratching my head so I shot the old load and it grouped fine. I chrono’d the loads and they both were the same average and same SD.

Now i’m kind of confused has anybody seen the same issues? After I grouped the two on the right top and bottom (forgive the crap pictures I took it in the sun and couldn’t see the groups / framing on my iPhone) I was scratching my head so I shot the old load and it grouped fine. I chrono’d the loads and they both were the same average and same SD.