Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

AMP Press now in stock!!

- Thread starter Dthomas3523

- Start date

This press is for masochists……

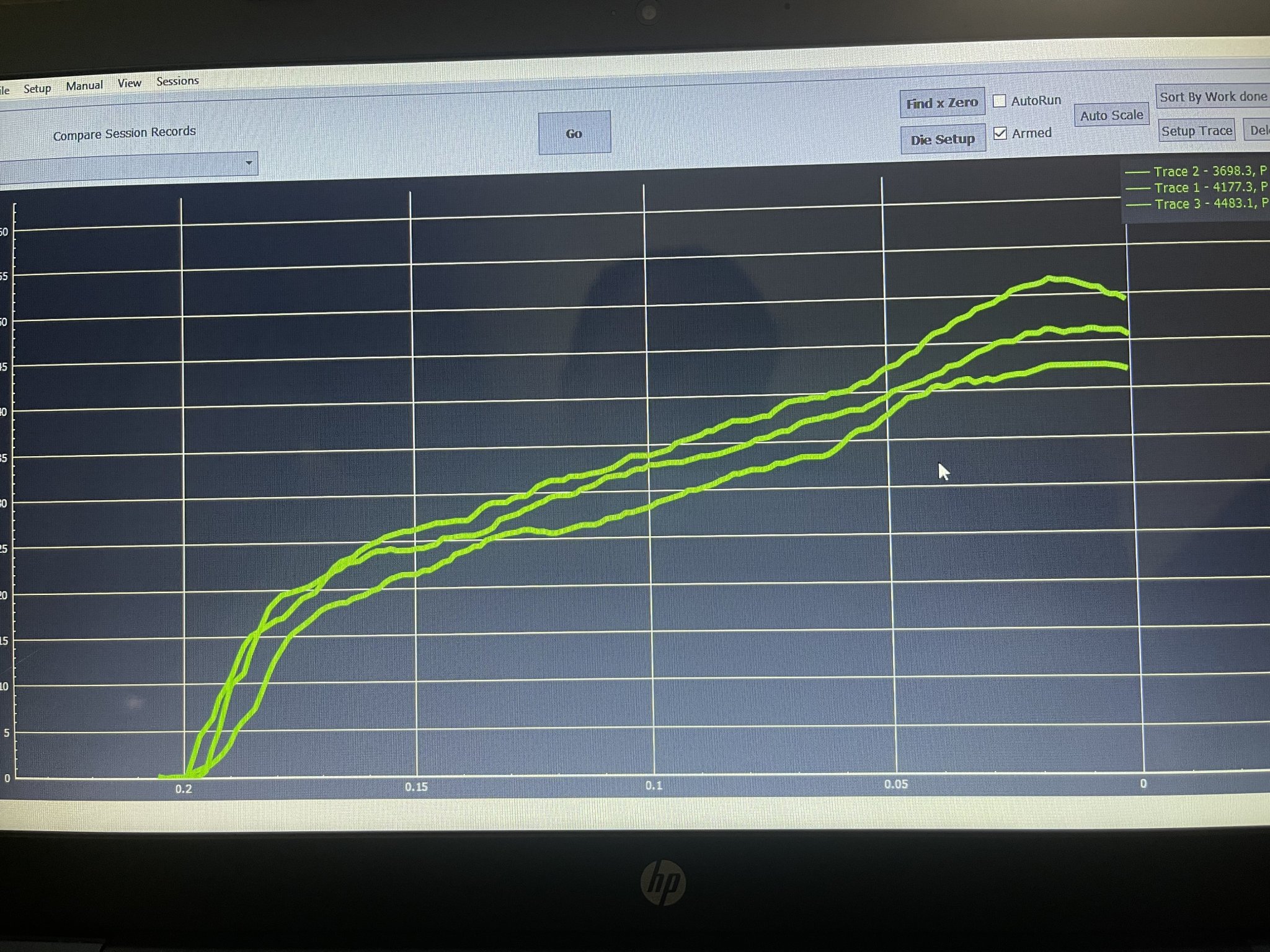

Definitely will show you how consistent or not things are. This is fired hornady 6gt, not cleaned, not annealed, not neck turned. This is “acceptable” IMO. But I’d like to see better.

Definitely will show you how consistent or not things are. This is fired hornady 6gt, not cleaned, not annealed, not neck turned. This is “acceptable” IMO. But I’d like to see better.

Those are some very pretty dies.Wilson makes some micro dies for Sinclair. A bit pricey. Though very well made and most of all repeatable. But, it still a Wilson die. So there’s no difference. Got these when it went on sale plus used a coupon code.

View attachment 7668655

This would drive me absolutely insane.

It’s quite possibly the worst mistake I’ve every made.

It’s quite possibly the worst mistake I’ve every made.

I mean, are you putting your hand on the press, and as you begin pushing down you just start repeating...

No squiggly line!

No squiggly line!

I mean, are you putting your hand on the press, and as you begin pushing down you just start repeating...

No squiggly line!

No squiggly line!

Almost exactly what I’m doing.

It’s quite possibly the worst mistake I’ve every made.

Day 1: Has 500 pieces of good brass

Day 8: Has 10 pieces of good brass

Would like to see a comparison of how the ammo shoots in terms of SD and ES when sorted by what the graph puts out. This is one of the most intriguing pieces of reloading gear that has come out in a while. The want is really high with this thing!

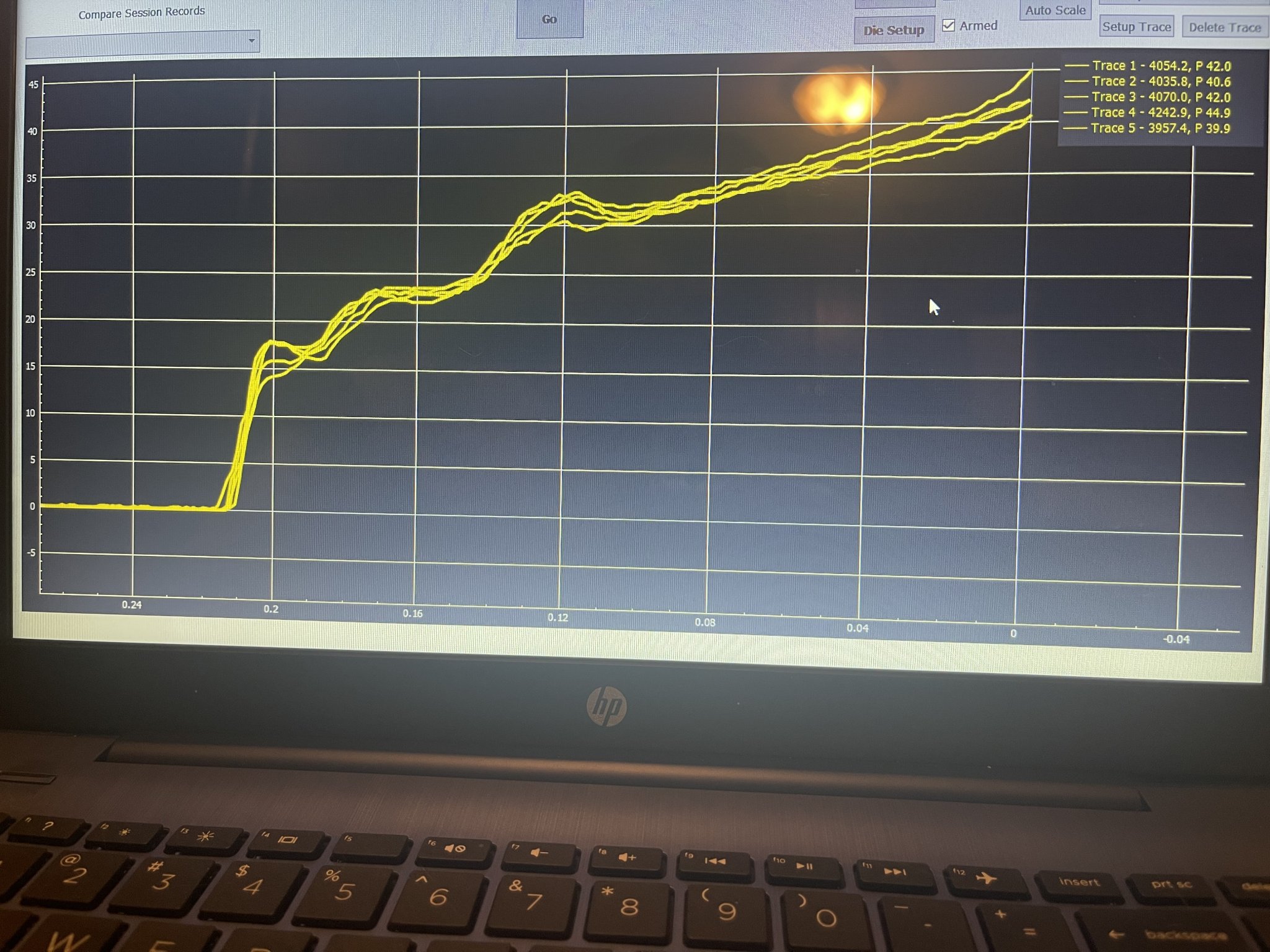

So, just messing around, I did 10 each:

Lapua 6br virgin - mandrel/chamfer

Hornady 6gt virgin - mandrel/chamfer

Hornady 6gt virgin - IDOD neck turned to .009 wall/sized down/mandrel/chamfer

All three had a Peak Force ES of 10/11. The Hornady non turned was 49-60lbs. The turned Hornady and lapua 6br were down in the 30-40lb area.

The interesting part:

Lapua Total work = 851lb ES

Hornady non turned = 795lb ES

Hornady turned = 696 ES

The lapua and non turned Hornady had graphs that were linear ish with increasing force until seated. The turned Hornady however show a “wavy” graph. Even though it exhibited more consistent Total Work used.

So, now we move onto live fire. See if there is correlation to the Total Force used. People have been separating by Peak Force for years with hydro presses and such. Results have been inconclusive if sorting by Peak Force works.

My theory is the less Total Force used, the better release the bullet will have. Will that show up on chrono and paper? We’ll see.

Lapua 6br virgin - mandrel/chamfer

Hornady 6gt virgin - mandrel/chamfer

Hornady 6gt virgin - IDOD neck turned to .009 wall/sized down/mandrel/chamfer

All three had a Peak Force ES of 10/11. The Hornady non turned was 49-60lbs. The turned Hornady and lapua 6br were down in the 30-40lb area.

The interesting part:

Lapua Total work = 851lb ES

Hornady non turned = 795lb ES

Hornady turned = 696 ES

The lapua and non turned Hornady had graphs that were linear ish with increasing force until seated. The turned Hornady however show a “wavy” graph. Even though it exhibited more consistent Total Work used.

So, now we move onto live fire. See if there is correlation to the Total Force used. People have been separating by Peak Force for years with hydro presses and such. Results have been inconclusive if sorting by Peak Force works.

My theory is the less Total Force used, the better release the bullet will have. Will that show up on chrono and paper? We’ll see.

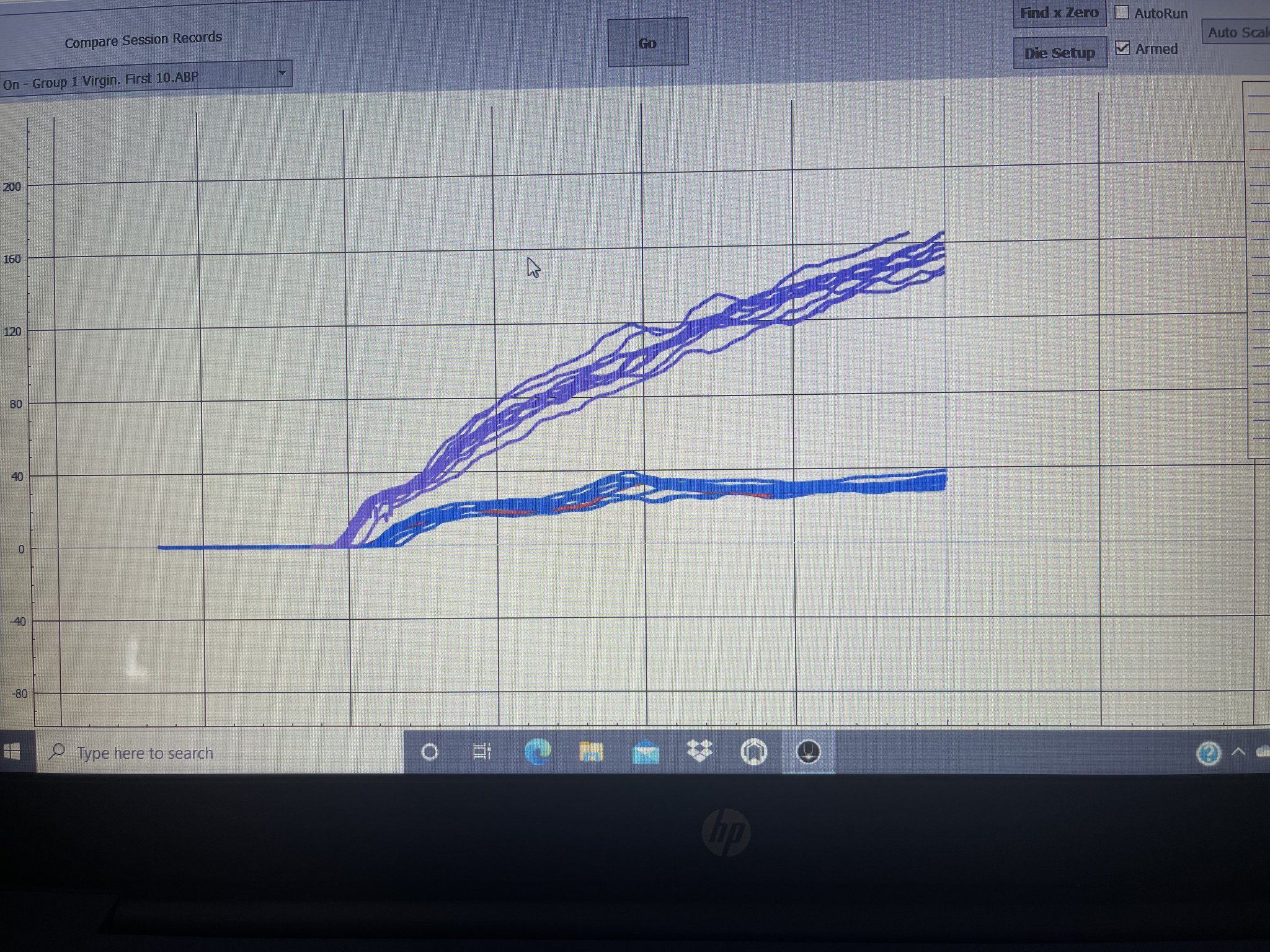

Ok so it seems the left scale is force, what is the bottom scale?This is why you buy lapua brass….View attachment 7668887

thank you for your service….So, now we move onto live fire. See if there is correlation to the Total Force used. People have been separating by Peak Force for years with hydro presses and such. Results have been inconclusive if sorting by Peak Force works.

This reminds me of what I tell people all the time:

Do you know why I hit myself on the head with a hammer?

Because it feels so good when i stop...

Do you know why I hit myself on the head with a hammer?

Because it feels so good when i stop...

This reminds me of what I tell people all the time:

Do you know why I hit myself on the head with a hammer?

Because it feels so good when i stop...

If you have the right mindset, it’s a good tool.

If you’re the type who will get paralyzed when something doesn’t “look” like you expected, just send AMP $1400 and tell them to keep the press. It’s cheaper.

I’m seeing a lot of things that validate what I though prior. I’m also seeing things that aren’t as clean cut as I thought.

Just loading out the box vs brass prep:

Interesting that you're not getting the initial spikes like in the video.

Maybe I missed it, but what was his linear neck tension measurement? 0,001”, 0.002”, 0.003”?

It might have an effect on the initial spike measurement.

It might have an effect on the initial spike measurement.

Interesting that you're not getting the initial spikes like in the video.

Initial spikes are *likely* due to chamfer aggressiveness (or lack of chamfer).

Have to really visualize what’s going on with bullet and neck during the graph.

Bullet has to overcome the initial resistance of the top of neck.

After, as the bullet is progressing in the neck, it has less and less resistance “beneath” the bullet as since they neck is smaller under the bearing surface than it is on the surface.

Once bearing surface starts passing wherever the neck sizing stopped, pressure will decrease (if you get to that point before achieving desired seating depth).

Anyone use on big cartridges?

Will it handle .338LM?

It’ll handle anything you can get a chamber type die for.

I’ll be using it on lapua bolt face cartridges.

Initial spikes are *likely* due to chamfer aggressiveness (or lack of chamfer).

Have to really visualize what’s going on with bullet and neck during the graph.

Bullet has to overcome the initial resistance of the top of neck.

After, as the bullet is progressing in the neck, it has less and less resistance “beneath” the bullet as since they neck is smaller under the bearing surface than it is on the surface.

Once bearing surface starts passing wherever the neck sizing stopped, pressure will decrease (if you get to that point before achieving desired seating depth).

When I watched the video, I wondered if he had chamfered the case mouth or not. I don't recall him mentioning it.

There's a big difference in feel with the RCBS type tool vs a VLD chamfer.

In fact, I've got a long, tapered reamer I used to use until it just became too much for my hands.

The long reamer gave the smoothest seating feel.

The biggest issue was controlling the depth of the chamfer.

In Cortina’s video with the Finley’s they talk about the importance of consistent trim length and chamfer. If all of your cases are the same you will see the force line begin at the exact same distance mark for each case…if you see variability here that should direct you to your trimming and chamfering processes. (Bullet variation will also show here but as long as your using quality components I plan to ignore that factor)

Mine should be arriving on Tuesday and I can’t wait.

Mine should be arriving on Tuesday and I can’t wait.

In Cortina’s video with the Finley’s they talk about the importance of consistent trim length and chamfer. If all of your cases are the same you will see the force line begin at the exact same distance mark for each case…if you see variability here that should direct you to your trimming and chamfering processes. (Bullet variation will also show here but as long as your using quality components I plan to ignore that factor)

Mine should be arriving on Tuesday and I can’t wait.

Yea, it’s all about realistic expectations. I’m within .002 variance on trimmed cases with Henderson trimmer (verified via caliper). And I see up to .004 or so difference in the start point on the graph if I zoom in.

I’m *assuming* that’s due to length of chamfer and bullet variation. I have 21st century trimming attachment arriving next week. Will see if that is more consistent (I’m not worried about this slight variation on the graph. Just testing)

Does this help eliminate velocity flat spots?

Does this help eliminate velocity flat spots?

Shooting more than one shot already fixed that…..

I'll second this, it was a noticeable change in feel even on a Dillon 550 when seating.When I watched the video, I wondered if he had chamfered the case mouth or not. I don't recall him mentioning it.

There's a big difference in feel with the RCBS type tool vs a VLD chamfer.

In fact, I've got a long, tapered reamer I used to use until it just became too much for my hands.

The long reamer gave the smoothest seating feel.

The biggest issue was controlling the depth of the chamfer.

I have an original RCBS Trim Mate case prep center. Replacing the 45 degree chamfer toolhead with their VLD tool made a huge difference.

I notice, you are moving the die when the ram is still moving.

I wonder if you should wait until all ram movement is completed?

I notice, you are moving the die when the ram is still moving.

I wonder if you should wait until all ram movement is completed?

That’s not me, just sharing.

I notice, you are moving the die when the ram is still moving.

I wonder if you should wait until all ram movement is completed?

The cycle is complete on the down stroke. The up is his returning the ram.

Won’t hurt it.

Here is what I would like to see if it is possible, load a bunch of dummy rounds with the primer pocked drilled out.

Record each individual rounds seating data then using the press with the round upside down press the bullet out with a rod through the primer

pocket to record the variation of the bullet being pressed out.

You can also leave a few sit for a month then press them out and see if the bullets welded to the case.

Record each individual rounds seating data then using the press with the round upside down press the bullet out with a rod through the primer

pocket to record the variation of the bullet being pressed out.

You can also leave a few sit for a month then press them out and see if the bullets welded to the case.

Yes, the zeroing of the start should be an OPTION.

Though, please don't take anything away, but ADD options.

Last edited:

Wouldn't that itself change the bullet seating dynamics, by allowing the compression force build up in the case to disappear?Here is what I would like to see if it is possible, load a bunch of dummy rounds with the primer pocked drilled out.

I do understand your test though, would be neat to see.

Not sure I understand your question but if you mean air compression, I doubt it would matter.Wouldn't that itself change the bullet seating dynamics, by allowing the compression force build up in the case to disappear?

I do understand your test though, would be neat to see.

I simply would like to see what the load variance is getting the bullet moving in the case.

I’m finding things quite interesting with my press. Things you think are very consistent (same careful process piece to piece of brass) end up looking like a seismograph.

Will he range testing more to confirm, but stumbling upon some processes that are very consistent (and much less work than you’d think).

Will he range testing more to confirm, but stumbling upon some processes that are very consistent (and much less work than you’d think).

You’re gonna make a write up on all the secret sauce discoveries for us, right?Will he range testing more to confirm, but stumbling upon some processes that are very consistent (and much less work than you’d think).

You’re gonna make a write up on all the secret sauce discoveries for us, right?

Possibly. Like most things…..some of it flies in the face or established “never do that.”