Everybody anneals their brass multiple times during the manufacturing process to reduce the likely hood of splitting during forming.If that is so, it of makes you wonder then why Laupa anneals their brass before shipping. You can see that on the necks of virgin brass

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

AMP really worth the extra $$$$$$

- Thread starter Ruslow

- Start date

Went back and had a look through the thread in case exhaustion was getting the better of me, and you've posted zero groups in this thread.I’ve posted several of my groups here. Bro if you’re not going to read the thread don’t just barge in on some obscure outlier statistics point.

What does having a firearms license have to do with math?For you being allowed to own a gun for only 6 years now, you sure have learned it all very quickly.

Went back and had a look through the thread in case exhaustion was getting the better of me, and you've posted zero groups in this thread.

You’re stupid and blind? Literally posted one last night.

Not in this thread you didn't.You’re stupid and blind? Literally posted one last night.

Not in this thread you didn't.

Attachments

You're talking about others, "posting groups to see how good they shoot" and then call a graph a group? But I'm stupid? Amazing. Let's see the actual group.

Quoted for posterity.@Rio Precision Gunworks since you’re so smart and know everything maybe you could post some of your groups on here so we can see how good you really are something besides tapping the keyboard? I posted my last two outtings…..

You're talking about others, "posting groups to see how good they shoot" and then call a graph a group? But I'm stupid? Amazing. Let's see the actual group.

This entire thread is geared towards talking about sd and es. So yeah that’s what I’m talking about and I assume you don’t have anything better or you’d be posting it.

Thanks for trying to help your butt buddy by arguing semantics and having no proof you can reload or shoot better.

Here are some of my recent, “groups”.

In that first, "group", my ammo went from 70 degrees in the car, to freezing on the bench.

There is a hurt feelings thread in the pit you may be interested in .

Swipes ? That's funny coming from the most self-important know it all on the forum .

"So, let's stop that and you learn us something."...I can teach you proper English if you like .

I do find it funny that you are sticking up for troll #2 . The point is , like you he is a know it all troll with Very little experience, just a big mouth .

Still waiting for you to drop some knowledge. Explain how I'm wrong. The difference is, I don't take swipes. I'll explain exactly what I'm saying. You just don't like that you've been slapped around with actual explanations several times over your career on this forum. From your incorrect understanding of "tension" to agreeing with the "metal absorbs water" and lately your misunderstanding of how sd/es interact. All those years of "experience" and so little understanding.

Not to mention quite a large amount of jealousy with Erik Cortina that's pretty weird.

One of the best ways to know someone doesn't have the knowledge they claim......they always bring up how long they've done something or how much "experience" they have. Yet never actually explain anything.

So, drop some of that knowledge you've gained through all this experience you keep bringing up.

Last edited:

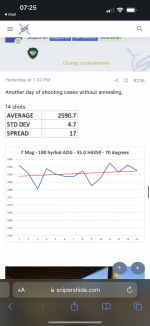

View attachment 8338170View attachment 8338168

Here are some of my recent, “groups”.

In that first, "group", my ammo went from 70 degrees in the car, to freezing on the bench.

Decent reloads and a respectable number of shots for as. Let’s see what captain know it all @Rio Precision Gunworks has for us and we’ll take a time stamp so you don’t cherry pick something from last year.

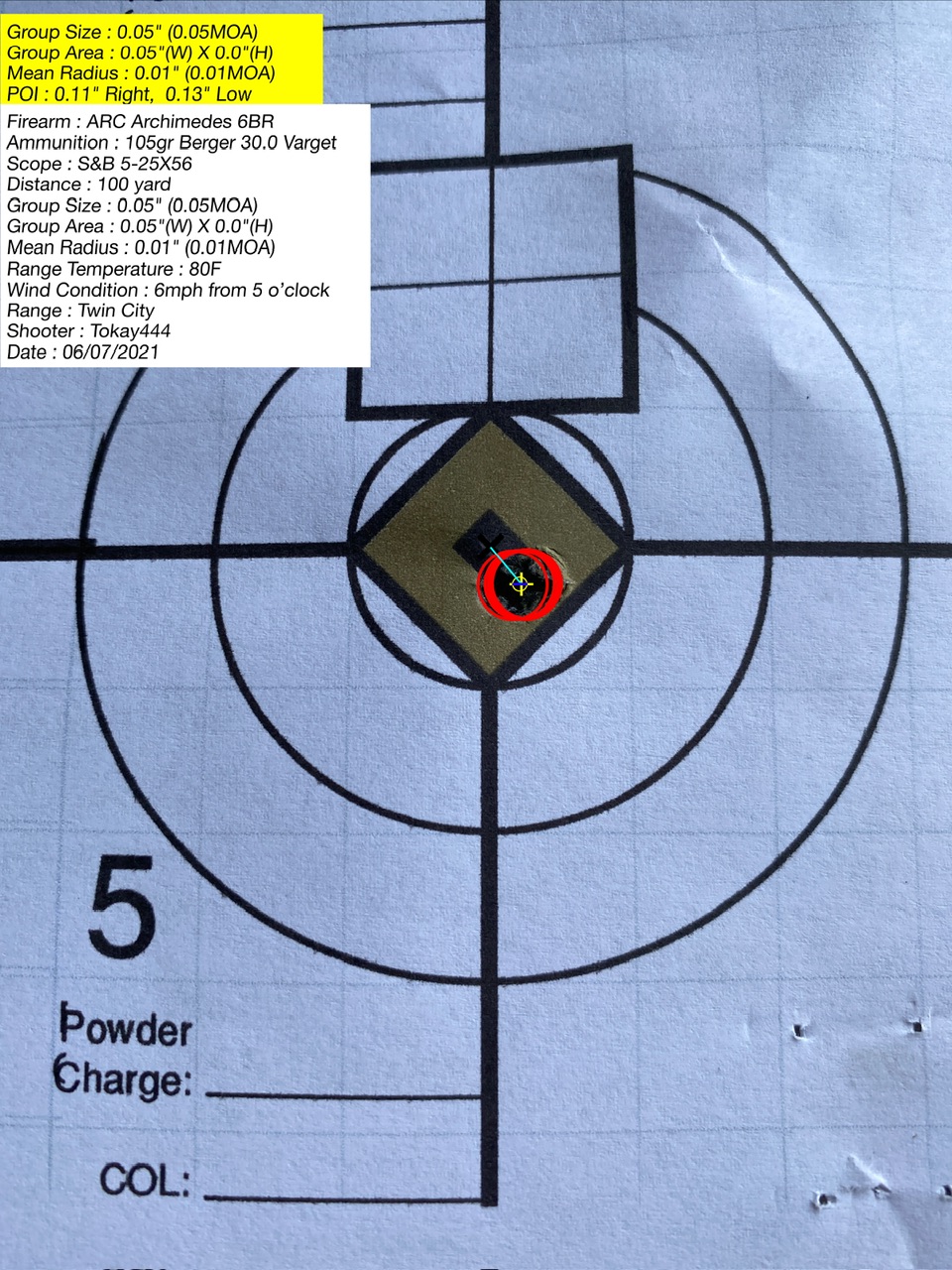

Here’s an actual group, but I’ve only been, “allowed” to have gun for “five years”, so clearly I don’t know what I’m doing.

I’ve been around firearms my whole life.

I’ve been around firearms my whole life.

So do you anneal every time and if so, what annealer?I have a lot more. Cold clean bore on this barrel can easily be 60-80fps slower than the average, but I always leave it in, since it’s part of the, “group”.

View attachment 8338179

Here’s an actual group, but I’ve only been, “allowed” to have gun for “five years”, so clearly I don’t know what I’m doing.

View attachment 8338198

I’ve been around firearms my whole life.

That comment probably wasn’t towards you then. we’re all shooting single hole groups at 100 yards on our best day. It means nothing to compare a single group on paper that’s why we’re talking sd and es

I anneal every firing. I've just transitioned from molten salt which was extremely consistent, and had the added excitement of the element of danger, to an AMP. I could do two cases in salt for every one I do in the AMP, but the AMP is much cleaner, safer, has less setup time, and I don't have to wash brass afterwards.So do you anneal every time and if so, what annealer?

I have a lot more of those as well, but I digress.That comment probably wasn’t towards you then. we’re all shooting single hole groups at 100 yards on our best day. It means nothing to compare a single group on paper that’s why we’re talking sd and es

If I don’t anneal I find 5-7 reloads is all I get at full power before the brass is not ductile enough to maintain the same neck tension. That’s the whole point of annealling. I don’t know how shooters do 10-20 reloads on the same case without hardening the brass. Lapua brass isn’t cheap enough to throw away after a half dozen firings if it can be consistent for many more.Gotcha. So you introduced an unknown variable in your reloading setup to “aid reliability…. No tight chambering rounds”

I can afford the amp just fine. I’m asking why people are just arbitrarily doing it for seemingly no reason or articulable improvement in accuracy, like you just told me above (except to chamber rounds??)

Uh.... we anneal it every time. That's howIf I don’t anneal I find 5-7 reloads is all I get at full power before the brass is not ductile enough to maintain the same neck tension. That’s the whole point of annealling. I don’t know how shooters do 10-20 reloads on the same case without hardening the brass. Lapua brass isn’t cheap enough to throw away after a half dozen firings if it can be consistent for many more.

My question was rhetorical for you guys that get it. The foot stomping attention whores were the target of my leading question. Text is a difficult medium for elegantly shitting on dim bulbs.Uh.... we anneal it every time. That's how

I’m getting under 7sd with 5-6x fired brass through a supressor. I think the neck tension is okay. Just checked the brass I sized and 15/15 are at .335 the exact size of my whidden bushing. Never annealed - if there was a ductility issue, we would expect it to have more spring-back to the original size?

I think it is somewhat well-established you can easily get 10+ firing from Lapua without any issues? the amp testing at least did that without issue. I buy enough brass for 10 firings on a barrel then I throw the barrel and brass away - won't your primer pockets give out at some point around 15-20 anyways? is hardening the neck really that good if you continue to the point you have inconsistent ignition, believing the brass is? fine? at some point you need to toss the brass before it opens up.

I think it is somewhat well-established you can easily get 10+ firing from Lapua without any issues? the amp testing at least did that without issue. I buy enough brass for 10 firings on a barrel then I throw the barrel and brass away - won't your primer pockets give out at some point around 15-20 anyways? is hardening the neck really that good if you continue to the point you have inconsistent ignition, believing the brass is? fine? at some point you need to toss the brass before it opens up.

@Rio Precision Gunworks first. he's seen this already and not posted anything.Wonder what @Haney's, "groups" and actual groups look like...

I would love to see someone anyone shoot 10 five shot groups in a row and count every shot, not well I pulled that one or that is a flier I won't count that one and see what they average. I would be willing to bet most could not average under a MOA and yet there are so many all over the internet posting tiny benchrest type groups they shot off a bi pod and rear squeeze bag LOL.

you'd be right outside of most of the higher level competition circles

those higher level competitors would take your money tho easily

those higher level competitors would take your money tho easily

Here’s 4x5 shots and a 10 shot on the last target, as I’m moving seating depth from .025” jam to .010” jam, and then reshooting 10 shots at .025” jam, with freezing cold hands.I would love to see someone anyone shoot 10 five shot groups in a row and count every shot, not well I pulled that one or that is a flier I won't count that one and see what they average. I would be willing to bet most could not average under a MOA and yet there are so many all over the internet posting tiny benchrest type groups they shot off a bi pod and rear squeeze bag LOL.

And then this is a second confirmation group of 10 shots.

That's a shame about that one flier!Here’s an actual group, but I’ve only been, “allowed” to have gun for “five years”, so clearly I don’t know what I’m doing.

View attachment 8338198

I’ve been around firearms my whole life.

4 shot attention span.

That's a shame about that one flier!

We need a sarcasm font or something. It's hard to convey via textMy question was rhetorical for you guys that get it. The foot stomping attention whores were the target of my leading question. Text is a difficult medium for elegantly shitting on dim bulbs.

My AMP arrived today. As previously stated, I have 5 AMP annealed 300PRC cases and 5 that I flame annealed using my Giraud. If anyone has the ability to hardness test them, I'll gladly box them up and send them along.

Well if you have the equipment and are such an expert why don't you do a little testing for us then??? I can send some amp annealed brass and I'm sure someone else here will send some other flame annealed and we can see.

Now why on earth would You trust Me to test anything for You

I tested MY cases using MY flame method as well as Induction heating over two decades ago and am perfectly satisfied with the results . I had the Leading Metallurgist supervising those tests ,so as to be certain of the Data obtained would be correct . There are labs which will do metallurgy evaluations ,look for one in your area .

All anyone needs is a certifiable Metal tester and you can do them yourself . Ideal ductility measurement is 14-15 HV . Over 17 is too hard .

https://www.ebay.com/itm/325875178183?hash=item4bdfac9ac7:g:W9kAAOSwAk1lR4A6

https://www.mcssl.com/store/websterinstrument

https://digitalmicrometers.co.uk/types-of-hardness-testers

Extremely light forces must be accurately applied, and the resultant impressions must be precisely measured under high magnification.

Having and using an Optical Comparator gives precision beyond human capability and defines absolute numbers .

Well, this is what you said....Now why on earth would You trust Me to test anything for You

I tested MY cases using MY flame method as well as Induction heating over two decades ago and am perfectly satisfied with the results . I had the Leading Metallurgist supervising those tests ,so as to be certain of the Data obtained would be correct . There are labs which will do metallurgy evaluations ,look for one in your area .

All anyone needs is a certifiable Metal tester and you can do them yourself . Ideal ductility measurement is 14-15 HV . Over 17 is too hard .

https://www.ebay.com/itm/325875178183?hash=item4bdfac9ac7:g:W9kAAOSwAk1lR4A6

https://www.mcssl.com/store/websterinstrument

https://digitalmicrometers.co.uk/types-of-hardness-testers

Extremely light forces must be accurately applied, and the resultant impressions must be precisely measured under high magnification.

Having and using an Optical Comparator gives precision beyond human capability and defines absolute numbers .

Ex E6 said:

Funny reading all the experts favoring Amp over any other methods of ductility restoration in cartridge brass .

Wonder how many actually have had their cases tested ?. Yep the ONLY way to verify one particular method over another is VERIFICATION ,using BASELINE samples . SO how many have done this or had their cases sent to a metallurgist testing facility and how good was the equipment that shop used ??. Please share results ,as well as tests materials manufacturers lots !.

Can't help wonder after having used Boeing's facilities for decades ,as to what other shops equipment budgets expenditures are or were ??.

I'm not questioning everyone and what they are doing. You are the one doing that and you are the one claiming to have access to the equipment. I'm totally fine with my process without sending it off but since we apparently have someone right here with the expertise and equipment to evaluate brass, I'd be happy to send it so you can post the results. I noticed you didn't post any details about your own results, or anything worthwhile.

@Rio Precision Gunworks since you’re so smart and know everything maybe you could post some of your groups on here so we can see how good you really are something besides tapping the keyboard? I posted my last two outtings…..

@Rio Precision Gunworks

Oh, so glad to see the standard SH pissing contest is alive and well.

So…maybe a Texas Cage Match to settle the issue.

You guys are hilarious

So…maybe a Texas Cage Match to settle the issue.

You guys are hilarious

Still waiting for you to drop some knowledge. Explain how I'm wrong. The difference is, I don't take swipes. I'll explain exactly what I'm saying. You just don't like that you've been slapped around with actual explanations several times over your career on this forum. From your incorrect understanding of "tension" to agreeing with the "metal absorbs water" and lately your misunderstanding of how sd/es interact. All those years of "experience" and so little understanding.

Not to mention quite a large amount of jealousy with Erik Cortina that's pretty weird.

One of the best ways to know someone doesn't have the knowledge they claim......they always bring up how long they've done something or how much "experience" they have. Yet never actually explain anything.

So, drop some of that knowledge you've gained through all this experience you keep bringing up.

I see you have no problem telling lies .I'm not questioning everyone and what they are doing.

I know at your age Biden moments are more frequent, but if you have any loved ones (big if, I know) ask them to keep you off the internet while you’re experiencing them.

This is a continuation of an earlier video where Alex interviews Lou Murdica and (eventually) discuss the AMP and how to test the annealing process. In the video Lou is testing annealed vs unannealed and showing, through 20-shot groups, why he anneals with an AMP after every firing. Apologies if you've seen this prior.

Well, this is what you said....

Ex E6 said:

Funny reading all the experts favoring Amp over any other methods of ductility restoration in cartridge brass .

Wonder how many actually have had their cases tested ?. Yep the ONLY way to verify one particular method over another is VERIFICATION ,using BASELINE samples . SO how many have done this or had their cases sent to a metallurgist testing facility and how good was the equipment that shop used ??. Please share results ,as well as tests materials manufacturers lots !.

Can't help wonder after having used Boeing's facilities for decades ,as to what other shops equipment budgets expenditures are or were ??.

I'm not questioning everyone and what they are doing. You are the one doing that and you are the one claiming to have access to the equipment. I'm totally fine with my process without sending it off but since we apparently have someone right here with the expertise and equipment to evaluate brass, I'd be happy to send it so you can post the results. I noticed you didn't post any details about your own results, or anything worthwhile.

Well as long as you're happy ,little else matters .

Yes I did MY testing in 1997 ,using various headstamp pieces of brass . I ran #20 of #8 brands of 30/06 including LC & RWS . New and once fired along with #20 range pickups for variable allowances and setting parameters . Funny thing because I used both Induction as well as flame ,splitting the groups into half or #10 each ** .

I used the Range pickups as guinea pigs ,varying the temp as well as dwell ,so as to ascertain the " Correct Temp " for restoring ductility and retaining some neck spring aka tension . In other words Not over cooking it . 750 Deg. F didn't do shit ,neither did 850 F. . When I approached 950 Deg. F. necks began to exhibit favorable tenancies as well as softening to a desirable HV number . 1200 Deg. F. was the Proper Temp* . As cases dropped into a metal tray ,necks dented in many cases . By accident I found out that by resizing just the once after partial annealing or ductility restoration ,that neck tension was Perfect . Across the board regardless of case manufacturer ,numbers aligned as closely as I was able to measure with New Unfired Brass . I used #7 New cases and tore down brand new loaded ammo for those ,as cases weren't available by themselves in all instances .

I also sacrificed #6 Pieces of 8X57 cases at various stages of temp and dwell attempted restoration . Our Metallurgist cut those cases and put them under extreme magnification using the High power optical comparator or metallurgical microscope . I made the illumination solution so as to offset high contrast . Using two well known methods , #1 Darkfield illumination and #2 Nomarsky Prism .

Our conclusion was as follows ; NO restructuring or lattice aka grain had been formed in any of the brass test cartridges or sacrificed save for #1 8X57 , as I cooked that in the oven annealer for #30 minutes at 900 Deg. F. and about 70% showed finer more uniform grained appearance.

The case was Worthless ,as it was way way too soft and unusable . It was however Annealed in the true sense of the meaning .

As I know of NO practical method of continually cooling a brass cartridge case , from the shoulder to it's base while cooking neck and shoulder for #30 minutes at 900 Deg. F. is why I state Ductility restoration instead of annealing .

Bottom line without reservation ** Regardless of method used Flame or Induction heated ,provided each method is done correctly makes ZERO difference to the case in regards to accuracy or neck tension .

IF one is allowing their case necks to turn cherry red ,they've gotten too hot ( But NOT ruined ( simply resize them twice .

I set dwell time for case specific temp ,less for larger caliber more for smaller caliber . It's just the opposite of what one would think but larger cases require less time to Heat to correct temperature . Color is Blue flash smoke to orange and off the flame ,as the witness mark replicates Lapua cases perfectly and brass doesn't looked like it was baked all day in an easy oven by your granddaughter .

What I can tell anyone is , It's far better to restore neck shoulder ductility then not ,regardless of method used . You can plainly see MY cases started out UGLY in real life ,as perhaps 80 years to the weather before being cleaned ultrasonically and flame ductility restored .

I've gotten #28 near full power reloads on 1942-43 original .30 Cal M2 once fired cases ,that I cleaned and induced neck shoulder ductility too and haven't lost a single case . Not even a torn rim and I'm still reloading those cases and hopefully will for another #20 reloads .

I've gotten #48 reloads out of MY 7.62X51mm LC match cases and retired them as I found #2 were thinner than I liked . I run most of MY Old cases through My M1 Garands and M14's . I do run additional AR10 style DPMS 7.62X51mm as well as 6.5 CM along with several AR-15 platform semi's and keep ammo separated ,as chambers are Not same .

Whatever works for any of you is OK by Me ,one simply can't pull the wool over this old Wolf's hide ; I've been in far to many herds

Attachments

Ok cool. So then you agree annealing (or whatever you'd like to call it), is a good thing to do and you say there is no difference in Induction vs flame so long as both are done properly. I'm inclined to agree, but doing proper flame annealing and doing so the same for each case seems like a hard goal to achieve day in and day out.Well as long as you're happy ,little else matters .

Yes I did MY testing in 1997 ,using various headstamp pieces of brass . I ran #20 of #8 brands of 30/06 including LC & RWS . New and once fired along with #20 range pickups for variable allowances and setting parameters . Funny thing because I used both Induction as well as flame ,splitting the groups into half or #10 each ** .

I used the Range pickups as guinea pigs ,varying the temp as well as dwell ,so as to ascertain the " Correct Temp " for restoring ductility and retaining some neck spring aka tension . In other words Not over cooking it . 750 Deg. F didn't do shit ,neither did 850 F. . When I approached 950 Deg. F. necks began to exhibit favorable tenancies as well as softening to a desirable HV number . 1200 Deg. F. was the Proper Temp* . As cases dropped into a metal tray ,necks dented in many cases . By accident I found out that by resizing just the once after partial annealing or ductility restoration ,that neck tension was Perfect . Across the board regardless of case manufacturer ,numbers aligned as closely as I was able to measure with New Unfired Brass . I used #7 New cases and tore down brand new loaded ammo for those ,as cases weren't available by themselves in all instances .

I also sacrificed #6 Pieces of 8X57 cases at various stages of temp and dwell attempted restoration . Our Metallurgist cut those cases and put them under extreme magnification using the High power optical comparator or metallurgical microscope . I made the illumination solution so as to offset high contrast . Using two well known methods , #1 Darkfield illumination and #2 Nomarsky Prism .

Our conclusion was as follows ; NO restructuring or lattice aka grain had been formed in any of the brass test cartridges or sacrificed save for #1 8X57 , as I cooked that in the oven annealer for #30 minutes at 900 Deg. F. and about 70% showed finer more uniform grained appearance.

The case was Worthless ,as it was way way too soft and unusable . It was however Annealed in the true sense of the meaning .

As I know of NO practical method of continually cooling a brass cartridge case , from the shoulder to it's base while cooking neck and shoulder for #30 minutes at 900 Deg. F. is why I state Ductility restoration instead of annealing .

Bottom line without reservation ** Regardless of method used Flame or Induction heated ,provided each method is done correctly makes ZERO difference to the case in regards to accuracy or neck tension .

IF one is allowing their case necks to turn cherry red ,they've gotten too hot ( But NOT ruined ( simply resize them twice .

I set dwell time for case specific temp ,less for larger caliber more for smaller caliber . It's just the opposite of what one would think but larger cases require less time to Heat to correct temperature . Color is Blue flash smoke to orange and off the flame ,as the witness mark replicates Lapua cases perfectly and brass doesn't looked like it was baked all day in an easy oven by your granddaughter .

What I can tell anyone is , It's far better to restore neck shoulder ductility then not ,regardless of method used . You can plainly see MY cases started out UGLY in real life ,as perhaps 80 years to the weather before being cleaned ultrasonically and flame ductility restored .

I've gotten #28 near full power reloads on 1942-43 original .30 Cal M2 once fired cases ,that I cleaned and induced neck shoulder ductility too and haven't lost a single case . Not even a torn rim and I'm still reloading those cases and hopefully will for another #20 reloads .

I've gotten #48 reloads out of MY 7.62X51mm LC match cases and retired them as I found #2 were thinner than I liked . I run most of MY Old cases through My M1 Garands and M14's . I do run additional AR10 style DPMS 7.62X51mm as well as 6.5 CM along with several AR-15 platform semi's and keep ammo separated ,as chambers are Not same .

Whatever works for any of you is OK by Me ,one simply can't pull the wool over this old Wolf's hide ; I've been in far to many herds

I'm not sure what you are referring to with the whole "can't pull the wool over my eyes" stuff. I don't know who you think is trying to do that but I know sometimes old people feel as though others are trying to fool them when they aren't, so maybe that's that's about

?

But I am.This can’t be true he not using a zero press!

Similar threads

- Replies

- 24

- Views

- 3K

- Replies

- 33

- Views

- 2K