Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Any structural engineers around?

- Thread starter Garvey

- Start date

Why do some "experts" always ask other people for advice so they can tell them they did it the right way and don't need any advice?

Idk don’t you know you should ask a German EE.Why do some "experts" always ask other people for advice so they can tell them they did it the right way and don't need any advice?

Engineer design said it would work...

But they didn't install it right.

Oof...

It will hold burn that 6011 rod in deep and show these pussies how us farmers get the job done!!!

Urban Dictionary: Askhole

Askhole: A person who [constantly] asks for your advice, yet ALWAYS does the [complete] [opposite] of what you told them to do.

Been pretty happy with Bryant and Carrier the last 7 years residential. Normally run high seer stuffSame here, been a dealer for 25 years. There equipment is shit and we are changing brands. The newer dual wall climate changer air handlers aren’t bad. We’ve always used a lot of Carrier on our Commerical side and looking at switching to them for residential.

I remember that, KC walkway collapse. I also think it made Engineering Disasters.

Engineer design said it would work...

But they didn't install it right.

Oof...

The last place I expected a group full of pussies, saying "govern me harder daddy" was Sniper's Hide.

I have been burning rods, and MIG wire, for 26 years, every week. Did any of you ever think I asked questions, and allowed shitty looking welds to be in pics, wasn't just to fuck with you?

For those that are slow. Once again. These beams, as is, were county road bridge beams, on public roads. Now that they are trussed, they are stronger than they were. For those that do not understand trusses, go research some geometry information, followed by some truss building information.

2 1/2" X .188" wall pipe in tension, on top of 10" I-beam. Really, what would break it? A locomotive? I don't have one of those, and there are no tracks going to where this bridge will be.

There were probably 5 of these minimum on an 18'-20' wide bridge. Possibly flat timber deck, but more than likely corrugated steel. They were on some type of foundation(you dont have), and had something keeping them together(you dont have), acting as a unit instead of singular beam, and to keep it from rolling(you dont have). Youre the master though. I could give a fuck less about you getting a visit, the first time is ask for forgiveness. Hate to see a fella fuck up his tractor, but go right on ahead. Maybe not the first trip, but it will happen. Professionals be damned, this man is a genious, and the worlds best welder.

1-No one said call the government and get permission, we said contact a structural engineer.The last place I expected a group full of pussies, saying "govern me harder daddy" was Sniper's Hide.

I have been burning rods, and MIG wire, for 26 years, every week. Did any of you ever think I asked questions, and allowed shitty looking welds to be in pics, wasn't just to fuck with you?

For those that are slow. Once again. These beams, as is, were county road bridge beams, on public roads. Now that they are trussed, they are stronger than they were. For those that do not understand trusses, go research some geometry information, followed by some truss building information.

2 1/2" X .188" wall pipe in tension, on top of 10" I-beam. Really, what would break it? A locomotive? I don't have one of those, and there are no tracks going to where this bridge will be.

2-So you have been welding for 26 years, but can somehow still make a shitty weld in the flat position but you did it to just fuck with us so you could redo it later?

3-as states before previous use is completely irrelevant unless you build an identical bridge with the same spans. So exactly how much extra strength did your cockamamie truss add? Be precise.

4- you said it was 2 3/8 pipe and 8” wf beam. Have you already forgotten what material sizes you are using? You also mentioned a 14” beam on a trailer. How that is relevant to your 8” beam for the bridge I have yet to figure out.

And from a previous post it appears you have forgot which rod you have been using to weld with.

Sorry to be a bitch.........Don't forget about the use of 2/0 cable for the AC supply........That makes all the difference.........1-No one said call the government and get permission, we said contact a structural engineer.

2-So you have been welding for 26 years, but can somehow still make a shitty weld in the flat position but you did it to just fuck with us so you could redo it later?

3-as states before previous use is completely irrelevant unless you build an identical bridge with the same spans. So exactly how much extra strength did your cockamamie truss add? Be precise.

4- you said it was 2 3/8 pipe and 8” wf beam. Have you already forgotten what material sizes you are using? You also mentioned a 14” beam on a trailer. How that is relevant to your 8” beam for the bridge I have yet to figure out.

And from a previous post it appears you have forgot which rod you have been using to weld with.

Ah yes I forgot that using 2/0 cable makes up for setting for machine 50 amps too low.Sorry to be a bitch.........Don't forget about the use of 2/0 cable for the AC supply........That makes all the difference.........

I legit almost want to go outside, fire my machine up, weld this exactly how he says he did, and see if I can get it to break off with a hammer. I have a rusty piece of 8” wf beam and rusty 2 3/8 pipe sitting outside right now

You should! You will be surprised how strong that red oxide is.Ah yes I forgot that using 2/0 cable makes up for setting for machine 50 amps too low.

I legit almost want to go outside, fire my machine up, weld this exactly how he says he did, and see if I can get it to break off with a hammer. I have a rusty piece of 8” wf beam and rusty 2 3/8 pipe sitting outside right now

If he's really in Texas, lots of oil drillers will give away the 2 1/2-3 inch drill rod when the ends go to shit.

I have a few hundred feet of it I use for whatever around here.

Damn sure better than that heavy wall fence pole he's *trying" to make a truss out of.

30 seconds and here is the image I asked for in the first reply on page 1

Note blue water, vague idea of how spars should work, and tractor in correct position given all we know.

I have a few hundred feet of it I use for whatever around here.

Damn sure better than that heavy wall fence pole he's *trying" to make a truss out of.

30 seconds and here is the image I asked for in the first reply on page 1

Note blue water, vague idea of how spars should work, and tractor in correct position given all we know.

Breather still above waterIf he's really in Texas, lots of oil drillers will give away the 2 1/2-3 inch drill rod when the ends go to shit.

I have a few hundred feet of it I use for whatever around here.

Damn sure better than that heavy wall fence pole he's *trying" to make a truss out of.

30 seconds and here is the image I asked for in the first reply on page 1

Note blue water, vague idea of how spars should work, and tractor in correct position given all we know.

View attachment 7828046

I don't know how deep the water is ?Breather still above water

He said something about 12'.....but is that the ditch depth or water depth at bottom of ditch ?

No matter, I say my childish level paint image foretells the future well enough

I have played with bridges on my place and concluded that used semi flat beds made the most sense.

But ended up lifting my truck and just fording...

But ended up lifting my truck and just fording...

Last edited:

#1 out of the shop. Both were blocked 3" off the floor. This one had no deflection before adding the truss. It is cambered uphill now.

View attachment 7827739

Story and “bridge” both seem 100% legit. Im sure it’ll at least support your mom when she comes to visit for HalloweenThe last place I expected a group full of pussies, saying "govern me harder daddy" was Sniper's Hide.

I have been burning rods, and MIG wire, for 26 years, every week. Did any of you ever think I asked questions, and allowed shitty looking welds to be in pics, wasn't just to fuck with you?

For those that are slow. Once again. These beams, as is, were county road bridge beams, on public roads. Now that they are trussed, they are stronger than they were. For those that do not understand trusses, go research some geometry information, followed by some truss building information.

2 1/2" X .188" wall pipe in tension, on top of 10" I-beam. Really, what would break it? A locomotive? I don't have one of those, and there are no tracks going to where this bridge will be.

Switch all the .308 trusses to 6.5 trusses for that long a water crossing.

Last edited:

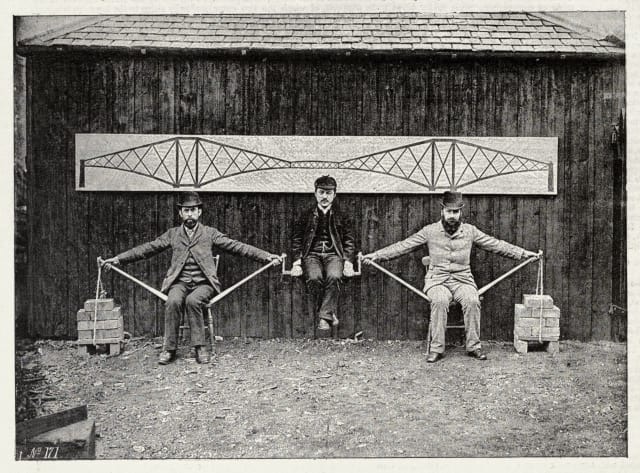

How engineers properly design a bridge. Notice the absence of gooseneck trailers....

From late 1800s, Forth Bridge in Scotland if you wanna look er up. Was the longest span in the world (over 500 meters) for a few years.

From late 1800s, Forth Bridge in Scotland if you wanna look er up. Was the longest span in the world (over 500 meters) for a few years.

So there I was in 1800, looking for a gooseneck trailer to pull with my sooperduty.

The reason that failed was because the construction company substituted one continuous threaded rod for two separate ones. Kinda like how we have two separate beams of different sizes being stuck together for this project.I remember that, KC walkway collapse. I also think it made Engineering Disasters.

How engineers properly design a bridge. Notice the absence of gooseneck trailers....

From late 1800s, Forth Bridge in Scotland if you wanna look er up. Was the longest span in the world (over 500 meters) for a few years.

View attachment 7828117

And this is what happens to people who don't listen to advice.

That's actually a really cool (and famous) photograph in engineering history... So the two guys on the stools are "Fowler and the other one"... the engineers who designed the Forth bridge. In the middle is a Japanese engineer who was studying (and wanted to illustrate) the cantilever principle.How engineers properly design a bridge. Notice the absence of gooseneck trailers....

From late 1800s, Forth Bridge in Scotland if you wanna look er up. Was the longest span in the world (over 500 meters) for a few years.

View attachment 7828117

Very cool and thanks for posting! Haven't seen that in years.

Sirhr

They look related.

Wow.

Hate I missed this one.

It is odd because I had a former friend from high school call me about a VERY similar project a few weeks back except he also wanted to pull (in addition to large tractors) fully-loaded semis across the bridge during peanut season. He was looking at some old W8s of questionable age and tensile strength (likely not 50 ksi). Just kind of funny such a similar question came up.....in a place I didn't think it would (a shooting forum).

I am NOT an engineer.

My only background is that I've fabricated structural steel as my profession since 1998.

We do not fabricate DOT bridges, but we have done several pedestrian bridges and the occasional civilian automotive bridge (on private property). I say that to say I'm certainly no bridge expert, but you do pick up a few things over the years that might translate.

I apologize if any of this was covered by others since the first few posts of this thread.

1. We don't really know the actual member sizes. W10x33 to W10x45 make up your 10" x 8" family and I have no idea what wide flange member size has a 5" flange.....not even in a current AISC manual.

2. I can only assume the material is 36 KSi steel due to age (pulled from an old REPLACED roadway bridge per your original description)

3. Two, differing-size/family members (of questionable age and tensile strength) were welded together in what appears to be very close to where bearing on the creek bank ends.

4. I will not second guess your welding abilities......

5. Did I miss if there was any upward camber in the girders?

6. I think I gathered from your post that the actual unsupported clear span was 28'.

7. Since this steel was from a replaced bridge, did corrosion or some type or vibration from the continual loading/unloading of traffic over the bridge weaken the steel? I know that may be stretching it in your mind, but it is something that comes to my mind when I think of reusing old steel from a bridge. I'm not smart enough to answer those questions, but a SE could. In one close-up photo I saw, the steel looked pretty rough.....but again, perhaps an unfair assumption.

In the oldest AISC Manual I can put my hands on (ASD 9th Edition), the allowable uniform load tables for a single 36 ksi W10x45 (that is laterally supported, mind you) stops at 24' and you are trying to span 28'.....not with a single, continuous piece, but with two pieces of differing size welded end to end. I know you are trying to stiffen the member with all of the pipe you welded to the girders, but it still seems dicey in my opinion.....guessing at dead load, guessing at live load, guessing at material strength and condition.

I want to reiterate that I'm not an SE and I could be referencing the wrong tables above, but in my gut this whole scenario seems very dicey.....and this is coming from a guy who has great respect for people who build things for themselves and solve problems by thinking outside of the box.

I would strongly suggest you just pick up the phone and try to establish contact with a local engineer. A 30 minute conversation could be very enlightening and may flesh out a few things you haven't thought about. It certainly couldn't hurt.

Long story short: you could proceed full steam ahead and be just fine.....until your not.....and that is what concerns me.

Hate I missed this one.

It is odd because I had a former friend from high school call me about a VERY similar project a few weeks back except he also wanted to pull (in addition to large tractors) fully-loaded semis across the bridge during peanut season. He was looking at some old W8s of questionable age and tensile strength (likely not 50 ksi). Just kind of funny such a similar question came up.....in a place I didn't think it would (a shooting forum).

I am NOT an engineer.

My only background is that I've fabricated structural steel as my profession since 1998.

We do not fabricate DOT bridges, but we have done several pedestrian bridges and the occasional civilian automotive bridge (on private property). I say that to say I'm certainly no bridge expert, but you do pick up a few things over the years that might translate.

I apologize if any of this was covered by others since the first few posts of this thread.

1. We don't really know the actual member sizes. W10x33 to W10x45 make up your 10" x 8" family and I have no idea what wide flange member size has a 5" flange.....not even in a current AISC manual.

2. I can only assume the material is 36 KSi steel due to age (pulled from an old REPLACED roadway bridge per your original description)

3. Two, differing-size/family members (of questionable age and tensile strength) were welded together in what appears to be very close to where bearing on the creek bank ends.

4. I will not second guess your welding abilities......

5. Did I miss if there was any upward camber in the girders?

6. I think I gathered from your post that the actual unsupported clear span was 28'.

7. Since this steel was from a replaced bridge, did corrosion or some type or vibration from the continual loading/unloading of traffic over the bridge weaken the steel? I know that may be stretching it in your mind, but it is something that comes to my mind when I think of reusing old steel from a bridge. I'm not smart enough to answer those questions, but a SE could. In one close-up photo I saw, the steel looked pretty rough.....but again, perhaps an unfair assumption.

In the oldest AISC Manual I can put my hands on (ASD 9th Edition), the allowable uniform load tables for a single 36 ksi W10x45 (that is laterally supported, mind you) stops at 24' and you are trying to span 28'.....not with a single, continuous piece, but with two pieces of differing size welded end to end. I know you are trying to stiffen the member with all of the pipe you welded to the girders, but it still seems dicey in my opinion.....guessing at dead load, guessing at live load, guessing at material strength and condition.

I want to reiterate that I'm not an SE and I could be referencing the wrong tables above, but in my gut this whole scenario seems very dicey.....and this is coming from a guy who has great respect for people who build things for themselves and solve problems by thinking outside of the box.

I would strongly suggest you just pick up the phone and try to establish contact with a local engineer. A 30 minute conversation could be very enlightening and may flesh out a few things you haven't thought about. It certainly couldn't hurt.

Long story short: you could proceed full steam ahead and be just fine.....until your not.....and that is what concerns me.

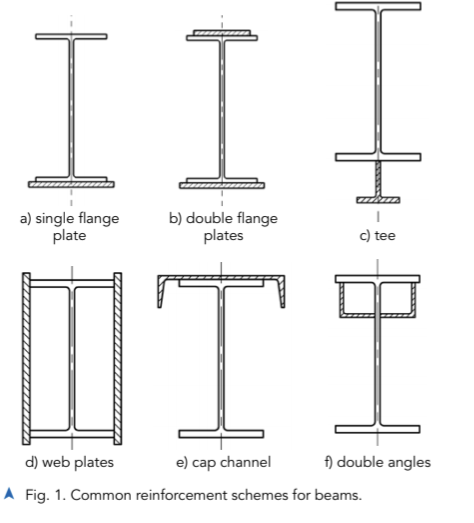

I'd love to see a basic FEA of this thing. My guess is that this railing which is being passed off as a truss is going to impart some, uh, interesting loads onto the top flange of the I-beam.

There are a number of generally accepted ways of strengthening a I-beam, but this ain't one of 'em.

There are a number of generally accepted ways of strengthening a I-beam, but this ain't one of 'em.

Last edited:

Why was the original bride replaced to begin with? Fatigued steel and concrete?

Saggy tits ?Why was the original bride replaced to begin with? Fatigued steel and concrete?

Sorry - not an engineer. My dad the plumbing contractor had little good to say about them so I chose a different path.

Our church bought some adjacent land on the other side of a creek behind the church and wanted to build a temporary pedestrian bridge to connect the two parcels. Somebody donated a couple of huge steel beams. These weren't small beams- I remember walking across the creek on one and thinking about how it was like walking on a sidewalk compared to walking the top of a 2x6 wall -some maybe 10 or 12 inches wide? A crew of volunteers put in some very (VERY) rudimentary timber "footings" a good 5 feet from either bank on which to rest the ends. Got a crane to come lift the beams in place and laid down some 2x6 decking and put up some railings.

Maybe a 20 foot span footing to footing, six foot drop to the normal water level (running maybe six inches deep at the time - summer). It was under the forest canopy and far enough off the road that nobody noticed, which is just as well since no one thought to even wonder if permits might be required.

I wish I had pictures or could remember beam dimensions and such, but the bridge disappeared. There was a storm, and the next day somebody went to cross the bridge and it was gone. I think they found one beam about 50 yards down stream, not sure if they ever found the other. Whole thing just washed clean away.

Moral of the story - the foundation is more important than the bridge itself. It's been mentioned here once or twice but bears repeating. Check out Matthew 7:24-27 - and Yes - that was the sermon the next Sunday!

Our church bought some adjacent land on the other side of a creek behind the church and wanted to build a temporary pedestrian bridge to connect the two parcels. Somebody donated a couple of huge steel beams. These weren't small beams- I remember walking across the creek on one and thinking about how it was like walking on a sidewalk compared to walking the top of a 2x6 wall -some maybe 10 or 12 inches wide? A crew of volunteers put in some very (VERY) rudimentary timber "footings" a good 5 feet from either bank on which to rest the ends. Got a crane to come lift the beams in place and laid down some 2x6 decking and put up some railings.

Maybe a 20 foot span footing to footing, six foot drop to the normal water level (running maybe six inches deep at the time - summer). It was under the forest canopy and far enough off the road that nobody noticed, which is just as well since no one thought to even wonder if permits might be required.

I wish I had pictures or could remember beam dimensions and such, but the bridge disappeared. There was a storm, and the next day somebody went to cross the bridge and it was gone. I think they found one beam about 50 yards down stream, not sure if they ever found the other. Whole thing just washed clean away.

Moral of the story - the foundation is more important than the bridge itself. It's been mentioned here once or twice but bears repeating. Check out Matthew 7:24-27 - and Yes - that was the sermon the next Sunday!

Top flange will be in compression. If I learned one thing, it is that metal very rarely fails in compression. There are plenty of other places in this project that will fail before the top of this beam buckles under compression.I'd love to see a basic FEA of this thing. My guess is that this railing which is being passed off as a truss is going to impart some, uh, interesting loads onto the top flange of the I-beam.

There are a number of generally accepted ways of strengthening a I-beam, but this ain't one of 'em.

View attachment 7829495

I'm not 100% sure, but I think his intent is to invert the beams from the as-photographed position so that the "truss framing" is pointing towards the creek. This assumption is based off his statement of using "milled utility poles" as the driving surface.

I assume he would have no room to anchor the milled poles to the top flange if the truss framing was facing upwards, hence the inverted orientation.

I assume he would have no room to anchor the milled poles to the top flange if the truss framing was facing upwards, hence the inverted orientation.

Next question, how do you plan on reinforcing the WF beam at the footing connections to Keep it from rocking side to side where the flange meets the web? You know it’s not super hard to rock flanges back and forth with a shockingly small amount of leverage. Same has to be said if you plan on anchoring the drive surface to the top flanges.

And they are being replaced with some sweet little sugar titsSaggy tits ?

Holy shit, you think you have steep enough of an angle on that rigging?

Little pro tip- squirt out all you boom and get some leverage instead of flat booming.

No sense in digging out the big rigging if you don’t need it.Holy shit, you think you have steep enough of an angle on that rigging?

Little pro tip- squirt out all you boom and get some leverage instead of flat booming.

I’m well aware of how boom angle works.

Have you run a 25 ton carry deck very much?

OnceNo sense in digging out the big rigging if you don’t need it.

I’m well aware of how boom angle works.

Have you run a 25 ton carry deck very much?

.... for a career.

For how many years again?

I retired Nov 17th 2017.... for a career.

For how many years again?

Little over 30 years with IUOE 18

Similar threads

Precision Rifle Gear

Tango Innovations FIRE4000 WMLRF Initial Impressions

- Replies

- 330

- Views

- 25K

- Replies

- 11

- Views

- 2K