I’ve been a maker for about 3-4 years now. I don’t have tons of experience and unfortunately I don’t get to heat and beat anymore now that I’m active duty. (Gave my coal forge away when I joined to a good friend). I do however have my propane forge and grinder here with me in NC and love building. I mainly do it for friends and through word of mouth. And I don’t care to sell a whole lot because I don’t like deadlines and timelines. But here is some of my work! Any other makers on here, I’d love to chat!

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Sidearms & Scatterguns Anyone else here making knives?

- Thread starter Slambert008

- Start date

Thank you! I’m working on my very first tomahawk right now. 1/4” 80crv2 steel. 9” OALNice looking blades!

Nice! Im really digging that fixed blade tanto! What kind of steel are you using and is there a finish on the blades? Some look like a black oxide.Thank you! I’m working on my very first tomahawk right now. 1/4” 80crv2 steel. 9” OAL

I use O1, 80crv2, and I’m branching out into some 1095, and 1084. But I only use carbon steels. Don’t have the proper equipment/ kiln for heat treating stainless at the moment. The dark look is a forced patina. Done with acid etching. I’ve used some gun blue on them as wellNice! Im really digging that fixed blade tanto! What kind of steel are you using and is there a finish on the blades? Some look like a black oxide.

The tanto i made for a friend who is in Kuwait at the moment. I’ll show some of them in sheaths

How well does the edge hold up using carbon steel? Also, I'd like to purchase a fixed Tanto if your time and schedule would allow.

I carry the leopard wood knife with the white splits in it daily, it’s only been sharpened once in over 6 months. It’s O1. Let me see what my time is looking like. I leave country in 2 monthsHow well does the edge hold up using carbon steel? Also, I'd like to purchase a fixed Tanto if your time and schedule would allow.

I started making knives back in 2015. I initially wanted to get into long before that, but I detoured through the kydex world for several years instead.

Knives are my creative outlet now and it’s nice that it is a hobby that at least pays for itself. I don’t forge anything yet, strictly stock removal. It can be therapeutic to stand in front of the grinder for a while and not think about anything else.

Knives are my creative outlet now and it’s nice that it is a hobby that at least pays for itself. I don’t forge anything yet, strictly stock removal. It can be therapeutic to stand in front of the grinder for a while and not think about anything else.

Attachments

-

E7913F27-1A26-4829-B711-C920D9F4D807.jpeg745 KB · Views: 93

E7913F27-1A26-4829-B711-C920D9F4D807.jpeg745 KB · Views: 93 -

1720B61E-F066-4840-9AED-0F67C7CA37B1.jpeg911.6 KB · Views: 99

1720B61E-F066-4840-9AED-0F67C7CA37B1.jpeg911.6 KB · Views: 99 -

C17F6D49-BF1A-42A3-998F-13CF403C8E67.jpeg736.1 KB · Views: 96

C17F6D49-BF1A-42A3-998F-13CF403C8E67.jpeg736.1 KB · Views: 96 -

B217F832-C064-4875-B58E-F2E858F83672.jpeg1.1 MB · Views: 88

B217F832-C064-4875-B58E-F2E858F83672.jpeg1.1 MB · Views: 88 -

FC46BD31-F0F5-4A14-BD85-2677CB3FCCCD.jpeg651.8 KB · Views: 105

FC46BD31-F0F5-4A14-BD85-2677CB3FCCCD.jpeg651.8 KB · Views: 105

You have beautiful work! I really like the one in the second to last photoI started making knives back in 2015. I initially wanted to get into long before that, but I detoured through the kydex world for several years instead.

Knives are my creative outlet now and it’s nice that it is a hobby that at least pays for itself. I don’t forge anything yet, strictly stock removal. It can be therapeutic to stand in front of the grinder for a while and not think about anything else.

Thanks! Your work is very nice as well. That’s my Happy Dagger, and has become my ‘flagship’ blade. It makes for a great edc/ defensive knife and people seem to really love it.

I completely feel you on the “business” side of making. I got to a point where I was overwhelmed with people wanting to order stuff and so I just quit taking orders for the most part. Now I mostly just make what I want to make and sell them. Not having anyone’s money in my hand makes the deadlines not be an issue.

I completely feel you on the “business” side of making. I got to a point where I was overwhelmed with people wanting to order stuff and so I just quit taking orders for the most part. Now I mostly just make what I want to make and sell them. Not having anyone’s money in my hand makes the deadlines not be an issue.

Good looking blades....

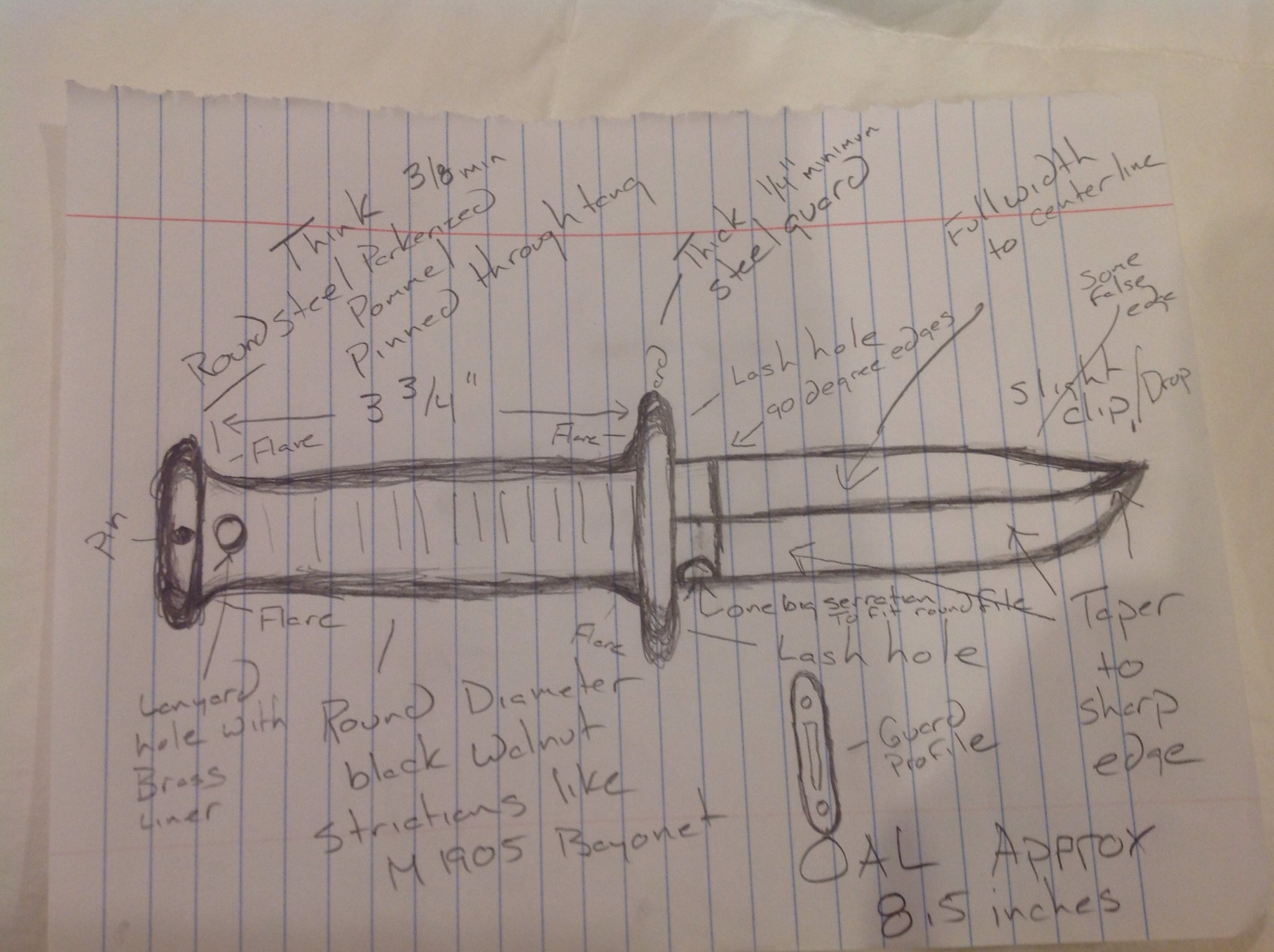

Was talking to a guy here about building me something like this....

Sent him a couple of busted up Garand stocks to use the WWII walnut for the scales/handle.

I dont know things went tits up for some reason when it seemed things were going well.

Was talking to a guy here about building me something like this....

Sent him a couple of busted up Garand stocks to use the WWII walnut for the scales/handle.

I dont know things went tits up for some reason when it seemed things were going well.

Same here. I build stuff, and if people like it I sell it! But I do have a few orders. I never take deposits for that reason. If I finish it and they don’t want it, it’s usually easy enough for me just to sell it to someone else.Thanks! Your work is very nice as well. That’s my Happy Dagger, and has become my ‘flagship’ blade. It makes for a great edc/ defensive knife and people seem to really love it.

I completely feel you on the “business” side of making. I got to a point where I was overwhelmed with people wanting to order stuff and so I just quit taking orders for the most part. Now I mostly just make what I want to make and sell them. Not having anyone’s money in my hand makes the deadlines not be an issue.

Do you have a page? Like Instagram or somethingThanks! Your work is very nice as well. That’s my Happy Dagger, and has become my ‘flagship’ blade. It makes for a great edc/ defensive knife and people seem to really love it.

I completely feel you on the “business” side of making. I got to a point where I was overwhelmed with people wanting to order stuff and so I just quit taking orders for the most part. Now I mostly just make what I want to make and sell them. Not having anyone’s money in my hand makes the deadlines not be an issue.

Thanks! And you had it all spec’d out for him I see. That’s not at all my style of building or I might take it on. But maybe you’ll find someone to do it for you one day! Did he send your Garand stocks back?Good looking blades....

Was talking to a guy here about building me something like this....

View attachment 7290458

Sent him a couple of busted up Garand stocks to use the WWII walnut for the scales/handle.

I dont know things went tits up for some reason when it seemed things were going well.

Those are some great looking knives. This is something that I’ve been interested in starting for a number of years, but I don’t have my own place, so I’ve been hesitant to start amassing the tools. (I think) I’d like to get into forging knives using coal or propane, but I don’t have a lot of mechanical background.

For those of you who make knives, especially the guys who are newer at it, what has the learning curve been like, and how has the cost been? Are you more inclined to purchase or use less expensive tools as you’re learning the art, or will those only lead to frustration, so might as well buy once, cry once?

Thanks, and keep posting the great pieces that you’re making.

For those of you who make knives, especially the guys who are newer at it, what has the learning curve been like, and how has the cost been? Are you more inclined to purchase or use less expensive tools as you’re learning the art, or will those only lead to frustration, so might as well buy once, cry once?

Thanks, and keep posting the great pieces that you’re making.

I have everything nice, except for a grinder. I will be buying a nice 2x72 in a year or so. I have multiple grinders but none compare to a 2x72 built specifically for knife bevel grinding. You can buy a decent propane forge for $2-300 or there are lots of DIY videos and forums online. The learning curve is different for everyone. But I believe every knife I produce is better than the last. Not saying 3-4 knives ago was pure sh$%, but I’m constantly learning new little tricks and techniques to make the final product that much better. The main advice I have is, just jump into it head first and get started on something. The long you wait, the longer it will take for you to “be good” at building knives.Those are some great looking knives. This is something that I’ve been interested in starting for a number of years, but I don’t have my own place, so I’ve been hesitant to start amassing the tools. (I think) I’d like to get into forging knives using coal or propane, but I don’t have a lot of mechanical background.

For those of you who make knives, especially the guys who are newer at it, what has the learning curve been like, and how has the cost been? Are you more inclined to purchase or use less expensive tools as you’re learning the art, or will those only lead to frustration, so might as well buy once, cry once?

Thanks, and keep posting the great pieces that you’re making.

I will say this, the Hide Fighter Steve Woods made based on input from the forum is a pretty popular blade, it would be cool do another

Hide K-Bar or something

Hide K-Bar or something

My first purchase was an Atlas Knife Company single burner propane forge. And I love it. I’m limited to around 13” OAL blades. But it’s a very nice and consistent forge. Only upgrade I’d recommend to it is a proper high temp thermometer until you learn how to associate metal color with metal temperature

That’s beautiful. And years beyond my skill. But, I don’t make a production knife eitherI will say this, the Hide Fighter Steve Woods made based on input from the forum is a pretty popular blade, it would be cool do another

Hide K-Bar or something

Very nice work well done.When I was a younger man I made quite a few custom knives and martial arts weapons but im not up to it anymore when I get a chance I will post some pics.I’ve been a maker for about 3-4 years now. I don’t have tons of experience and unfortunately I don’t get to heat and beat anymore now that I’m active duty. (Gave my coal forge away when I joined to a good friend). I do however have my propane forge and grinder here with me in NC and love building. I mainly do it for friends and through word of mouth. And I don’t care to sell a whole lot because I don’t like deadlines and timelines. But here is some of my work! Any other makers on here, I’d love to chat! View attachment 7290167View attachment 7290169View attachment 7290170View attachment 7290171View attachment 7290173View attachment 7290174View attachment 7290178View attachment 7290179View attachment 7290182View attachment 7290183

Thank you! And I would love to see them. I like looking at other builders work more than my own.Very nice work well done.When I was a younger man I made quite a few custom knives and martial arts weapons but im not up to it anymore when I get a chance I will post some pics.

These

are QUITE nice, spike-ish on that end nice and the photo reps it nicely with the dodged areas on the perimeters, darks complimenting the dark scales...knives and pic, great. ?

are QUITE nice, spike-ish on that end nice and the photo reps it nicely with the dodged areas on the perimeters, darks complimenting the dark scales...knives and pic, great. ?

Thats an awesome looking knife. I’m using 80crv2Here is a bowie fighter I made about 20 years ago out of 1/4" D2 steel.My camera is not the best but the handle is a pretty emerald green.I like that camp ax your working on what kind of steel did you use ?

Thanks! And you had it all spec’d out for him I see. That’s not at all my style of building or I might take it on. But maybe you’ll find someone to do it for you one day! Did he send your Garand stocks back?

I bought a Randall Fireman.

It's like a stainless steel reinforcing bar with a sharp edge.

Last edited:

I do, I am @jbcustomcutlery on Instagram and I believe it’s the same on Facebook.Do you have a page? Like Instagram or something

I’m not on face space. But I’ll add you on IG!I do, I am @jbcustomcutlery on Instagram and I believe it’s the same on Facebook.

I live just a handful of miles from a couple of Master Bladesmiths, Audra Draper (first female Master), and Ed Fowler. I have knives from each of them. Both are high carbon steel knives. Stainless steel working knives are for people who don't take care of their stuff.

You are correct there!I live just a handful of miles from a couple of Master Bladesmiths, Audra Draper (first female Master), and Ed Fowler. I have knives from each of them. Both are high carbon steel knives. Stainless steel working knives are for people who don't take care of their stuff.

All of those are nice. I bet the axes are handy. That’s why I’m wanting to build one. I don’t like buy store sold items like that anymore! I feel like they’re cheap and break easily.Here are a couple of skinners that I made out of D2.

Would you have any interest in making me a Molle compatible Kydex sheath for the Randall Fireman I posted ?

Or does anyone no anyone making good Kydex custom sheaths.

and truth be told I want some assurances I get my knife back if I have to send it to someone unknown. References and personal satisfaction experiences would be good to hear.

Or does anyone no anyone making good Kydex custom sheaths.

and truth be told I want some assurances I get my knife back if I have to send it to someone unknown. References and personal satisfaction experiences would be good to hear.

Thank's bro when you make something like the ax you are making you can make it customized to fit your hand and it feels like it is part of your hand when using it.There is also a-lot of self satisfaction in making it.Please keep me updated on your ax and take your time with it so it is a perfect fit for you.All of those are nice. I bet the axes are handy. That’s why I’m wanting to build one. I don’t like buy store sold items like that anymore! I feel like they’re cheap and break easily.

I understand that. I don’t make the sheaths but one of my really good buddies down the street makes them for me. You’re welcome to send it to me and I can get it done for you. I’ll PM you some credentialsWould you have any interest in making me a Molle compatible Kydex sheath for the Randall Fireman I posted ?

Or does anyone no anyone making good Kydex custom sheaths.

and truth be told I want some assurances I get my knife back if I have to send it to someone unknown. References and personal satisfaction experiences would be good to hear.

I will for sure! I’m going to put it on my friends 2x72 for the initial grinds so it will look a little more professional! I’ll post pictures hereThank's bro when you make something like the ax you are making you can make it customized to fit your hand and it feels like it is part of your hand when using it.There is also a-lot of self satisfaction in making it.Please keep me updated on your ax and take your time with it so it is a perfect fit for you.

That 2x72 will take some steel off real quick make sure you got some water close to keep the heat down and away from your hands.And don't let that 2x72 grab that ax out of your hand and send it flying.I miss my 2x72 I use to use it to get all kinds of work done quickly.What handle material do you plan on using.

I plan on using G10 for the handle. Black with grey liners. Also going to put the same texture on it as that grey knife I posted in the OP. This 2x72 has variable speed. Never use it too high.That 2x72 will take some steel off real quick make sure you got some water close to keep the heat down and away from your hands.And don't let that 2x72 grab that ax out of your hand and send it flying.I miss my 2x72 I use to use it to get all kinds of work done quickly.What handle material do you plan on using.

I’ll keep you updated on it for sureThat should look real nice on that ax.

Here a nice one built by Doug Hartsook. He’s built a few that I’ve owned.

I really like that! Beautiful Damascus workHere a nice one built by Doug Hartsook. He’s built a few that I’ve owned.View attachment 7291306View attachment 7291307View attachment 7291312

You are smart to make what YOU like and feel like building. I finally quit taking my knives to shows because no matter how many varieties of knives I took, I got more idiots making excuses why they didn't buy after fingering the knives... I could have 4 different blade lengths, four different colors of scabbards, and when someone would say, "I really was hoping for a 4.5" blade just like this one", I would pull a 4.5" blade from under the table, only to hear something like "yeah, but I wanted a scabbard with a little darker of brown for the leather.." I wish he would just say "I don't have the money", or "I'm not buying, I'm just looking today".

In any case, like you I finally settled on making what I wanted for the art and relaxation of making something. It was far more satisfying.

In any case, like you I finally settled on making what I wanted for the art and relaxation of making something. It was far more satisfying.

My wife’s grandfather made this from an old file in 1952 though. Pretty neat and I’ll keep it until I’m gone.

Knives seem to be very personal..

The user wants something very specific.

Likewise builders like to build with their ideal features in mind.

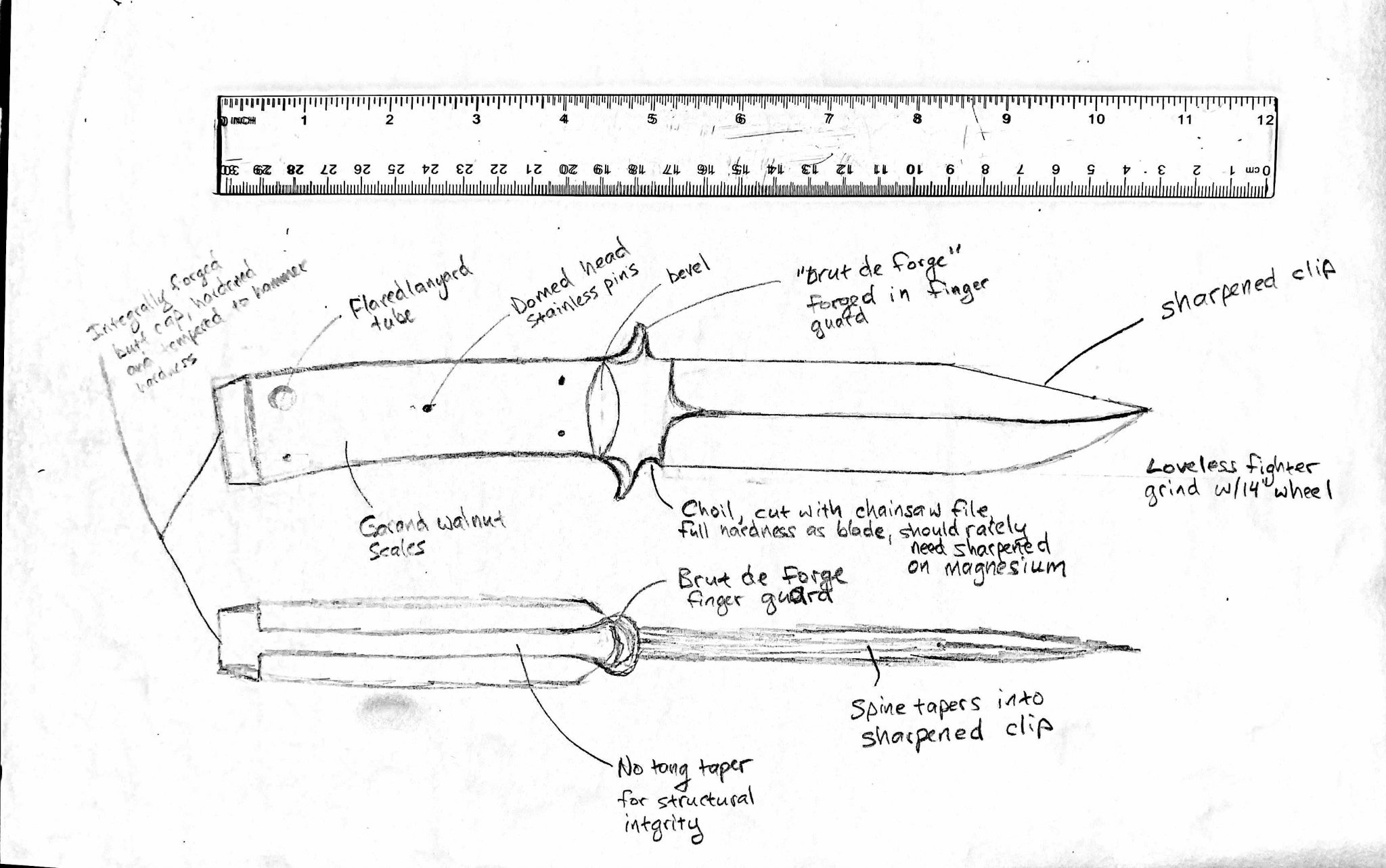

I like my knives to be pretty spartan, drop or working clip, a manageable size, pommel suitable for some light hammering, spine suitable for some battoning, 90 degree edges for striking a fire steel/fire starting.

The maker I was talking to had issues with some of my ideas, particularly the "hammering" of the pommel.

He took my ideas and came up with what would work with his skills/desires as a builder.

He came back with this....

My original sketch to compare...

If anything he added some bling to my spartan desires.

I liked it and we parted with an agreement if he built it Id buy it but than I never heard anymore so I kind of moved on. He builds really nice knives and I hope he is finding success. Who knows I may get contact one of these days stating "Hey your knife is done, pay me $X and Ill send it".

Just an interesting side note on how when it comes to knives the user/builder really have to be in unison on their ideas.

The user wants something very specific.

Likewise builders like to build with their ideal features in mind.

I like my knives to be pretty spartan, drop or working clip, a manageable size, pommel suitable for some light hammering, spine suitable for some battoning, 90 degree edges for striking a fire steel/fire starting.

The maker I was talking to had issues with some of my ideas, particularly the "hammering" of the pommel.

He took my ideas and came up with what would work with his skills/desires as a builder.

He came back with this....

My original sketch to compare...

If anything he added some bling to my spartan desires.

I liked it and we parted with an agreement if he built it Id buy it but than I never heard anymore so I kind of moved on. He builds really nice knives and I hope he is finding success. Who knows I may get contact one of these days stating "Hey your knife is done, pay me $X and Ill send it".

Just an interesting side note on how when it comes to knives the user/builder really have to be in unison on their ideas.

Last edited:

Similar threads

- Replies

- 68

- Views

- 6K

- Replies

- 60

- Views

- 3K

- Replies

- 4

- Views

- 276

Precision Rifle Gear

Tango Innovations FIRE4000 WMLRF Initial Impressions

- Replies

- 330

- Views

- 24K