Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

AR15 Cycling Issues

- Thread starter mkrem

- Start date

18". Yes, it's correct for 20" but not so much for 18", apparently.Sorry what barrel is this we’re talking about? That’s a YUGE gas port; actually mil-spec for a 20” rifle length port is thereabouts.

I replied here because I have the exact same problem, with a BA barrel as well, that mkrem had. Seemed better to contribute here than start a new thread.How many users with problem ARs does this thread have? Talk about confusing. LOL

The OP is mkrem. Check. Has @mkrem got it sorted out?

I'd start a new thread and just post the link in a comment here.I replied here because I have the exact same problem, with a BA barrel as well, that mkrem had. Seemed better to contribute here than start a new thread.

Yeah, that's up there like the other guy said. Not meaning to question you, but assuming that's accurate, I doubt in your case if that's it unless it's a 20 in. barrel with rifle length gas system. . How did you measure it?I did measure my port, it's 0.093".

What is the length and gas length?

@ShoeboxI did measure my port, it's 0.093".

Mine started as a normally functioning PSA 16" milspec rifle. The only change being the BA barrel, gas block, and tube. Nothing particularly fancy. The only variable truly was the barrel, and it stopped running reliably no matter what parts I threw at it. The only thing left is the gas port.

Not enough info. What have you tried, what is your current parts list, what ammo tested, ejection pattern, so on and so forth? While a gas port diameter of 0.093" is usually for a 20" barrel rifle length gas using a roughly 5.4oz buffer. However, 0.093" can still work for a rifle length gas 18".

I've already tried everything suggested in this thread and more, there's no reason to start another. I'm just giving my input. It would be redundant to post the same question with the same problem.I'd start a new thread and just post the link in a comment here.

Last edited:

It can, but doesn't in this case. I didn't give more info, because as I said, I'm just giving my own input and experience with my BA barrel.@Shoebox

While a gas port diameter of 0.093" is usually for a 20" barrel rifle length gas using a roughly 5.4oz buffer. However, 0.093" can still work for a rifle length gas 18".

It's a relatively simple machine. There are only so many things it could be and there's always an answer.I've already tried everything suggested in this thread and more,

================

Port size

Block alignment

Tube port alignment with the block

Tube ID

Tube insertion in the key.

Key mounting on the carrier

Carrier glide in the receiver.

Lug lockup and un-lockup.

SOOPER tight gas rings

Buffer too heavy.

Spring too strong

Binding in the tube

I'm just poking around (guessing?)and I probably missed something, but in here somewhere is the answer.

It's not even my gun and it bugs ME that it won't run right

Last edited:

I'd start a new thread and just post the link in a comment here.

Lol so I already have a thread here. I have posted this question so many places I forget where I've made a thread and where I haven't.@Shoebox

Not enough info. What have you tried, what is your current parts list, what ammo tested, ejection pattern, so on and so forth?

AR new barrel cycling issues

Hello all, I've been reading here for a while, but this is my first post. I've read several other threads with similar issues, but every situation is different, so I figured I'd ask about my own situation. Currently equipped: PSA upper and lower receivers BA 18" Stainless .223 Wylde...

Haha. Funny, I quit trying to read my hijacked thread.How many users with problem ARs does this thread have? Talk about confusing. LOL

The OP is mkrem. Check. Has @mkrem got it sorted out?

To answer your question, BA drilled out the gas port. I have not had a chance to test it yet.

Yeah, it got confusing for sure.Haha. Funny, I quit trying to read my hijacked thread.

To answer your question, BA drilled out the gas port. I have not had a chance to test it yet.

I for one would like to see you get it worked out as is, for the satisfaction.It did dawn on me that a mid length gas system could be part of the issue on a 14.5” barrel. May just need to swap the barrel And change to a carbine length.

Going to test it with the drill gas port first.

No, that's not an issue.It did dawn on me that a mid length gas system could be part of the issue on a 14.5” barrel. May just need to swap the barrel And change to a carbine length.

I was thinking, when that was posted; sure seems as 12.5-14.5 w/mid-length is the new hotness. Don't usually hear many complaints about that setup.No, that's not an issue.

@mkremYeah, it got confusing for sure.

Even though I am self confessedly bad for it myself, I don't like thread hijacking. The only reason I kept on it in this case, was because the same topic was being discussed. What was helpful to Shoebox was also helpful to the OP. At least that's how I was looking at it

Shit happens.@mkrem

Even though I am self confessedly bad for it myself, I don't like thread hijacking. The only reason I kept on it in this case, was because the same topic was being discussed. What was helpful to Shoebox was also helpful to the OP. At least that's how I was looking at it

Well, drilling out the gas port did nothing to help my issue. I believe I am going to pick up an FN HF 14.5" barrel and see what happens.

Well that's disappointing to hear.Well, drilling out the gas port did nothing to help my issue. I believe I am going to pick up an FN HF 14.5" barrel and see what happens.

Had to re-read the beginning of the thread to see what the original problem was. I'm stumped, I've had that exact same combination of parts, right down to the 14.5" Faxon Gunner and it ran perfect from the get go.

Last edited:

Well, drilling out the gas port did nothing to help my issue. I believe I am going to pick up an FN HF 14.5" barrel and see what happens.

....well, that is an unfortunate situation, but I daresay that it does reveal that the issue wasn't the BA barrel as OP originally imagined. Just switching the brand of barrel is not a guarantee the actual issue will be resolved. Good luck.

What size did you drill it from and to? And how did you measure it? Just askingWell, drilling out the gas port did nothing to help my issue. I believe I am going to pick up an FN HF 14.5" barrel and see what happens.

BA drilled it out. I don't know what they drilled it to.What size did you drill it from and to? And how did you measure it? Just asking

I'm the OP. I know it probably won't resolve the issue, but i wanted an FN CHF barrel anyways so why not? It is also a carbine length gas system so that is a change i can test. I also ordered a new Aero upper, new Aero buffer tube assembly, and new Failzero BCG. Because screw money, i'm tired of messing with this gun. Hope one of these parts solves the issue!....well, that is an unfortunate situation, but I daresay that it does reveal that the issue wasn't the BA barrel as OP originally imagined. Just switching the brand of barrel is not a guarantee the actual issue will be resolved. Good luck.

I am extremely jealous of you right now if that is the case!!!Had to re-read the beginning of the thread to see what the original problem was. I'm stumped, I've had that exact same combination of parts, right down to the 14.5" Faxon Gunner and it ran perfect from the get go.

Forgive me bud for coming off in what might quite understandably be construed as the wrong way, but when you can, can you please post a pic of the gas port after they drilled it? An angle that shows the inside of the port would be greatly appreciated if you would.What size did you drill it from and to? And how did you measure it? Just asking

Yes, no problem. I am going to try the other replacement parts first before swapping barrels. If those don't fix the issue, i'll send pics as well as try to measure the gas port.Forgive me bud for coming off in what might quite understandably be construed as the wrong way, but when you can, can you please post a pic of the gas port after they drilled it? An angle that shows the inside of the port would be greatly appreciated if you would.

If the barrel porting was altered, the issue is elsewhere or is a combination of factors. Unrelated to this specific example, I built an upper that ran exceptionally well for me, but the new owner complained of constant issues with lock back. After minor troubleshooting the issue was located in the lower receiver.

None of these new parts worked. In fact, changing to the 14.5 FN barrel with the carbine gas system only made the cycling issue worse. It wouldn't even chamber another round after firing. gas port size is .066-.069. My 14.5 BA barrel w/ mid-length system mic's .082-.085 after BA opened it up. I'm done with this rifle. Who can I send it to that is an expert with this shit?I'm the OP. I know it probably won't resolve the issue, but i wanted an FN CHF barrel anyways so why not? It is also a carbine length gas system so that is a change i can test. I also ordered a new Aero upper, new Aero buffer tube assembly, and new Failzero BCG. Because screw money, i'm tired of messing with this gun. Hope one of these parts solves the issue!

Forgive me bud for coming off in what might quite understandably be construed as the wrong way, but when you can, can you please post a pic of the gas port after they drilled it? An angle that shows the inside of the port would be greatly appreciated if you would.

I don't know. Evil spirits?None of these new parts worked. In fact, changing to the 14.5 FN barrel with the carbine gas system only made the cycling issue worse. It wouldn't even chamber another round after firing. gas port size is .066-.069. My 14.5 BA barrel w/ mid-length system mic's .082-.085 after BA opened it up. I'm done with this rifle. Who can I send it to that is an expert with this shit?

Send it to Chad at SOTAR/School of the American Rifle- let him measure everything and troubleshoot- for one of his YT vids. The only way to do better would be if he made the video for SH.None of these new parts worked. In fact, changing to the 14.5 FN barrel with the carbine gas system only made the cycling issue worse. It wouldn't even chamber another round after firing. gas port size is .066-.069. My 14.5 BA barrel w/ mid-length system mic's .082-.085 after BA opened it up. I'm done with this rifle. Who can I send it to that is an expert with this shit?

Yeah, that boy has massive experience and every conceivable piece of equipment known to man.Send it to Chad at SOTAR/School of the American Rifle- let him measure everything and troubleshoot- for one of his YT vids. The only way to do better would be if he made the video for SH.

Obviously it's not magic. There's an answer in here somewhere. He'd figure it out. Which is a good thing because the mystery is killin me.

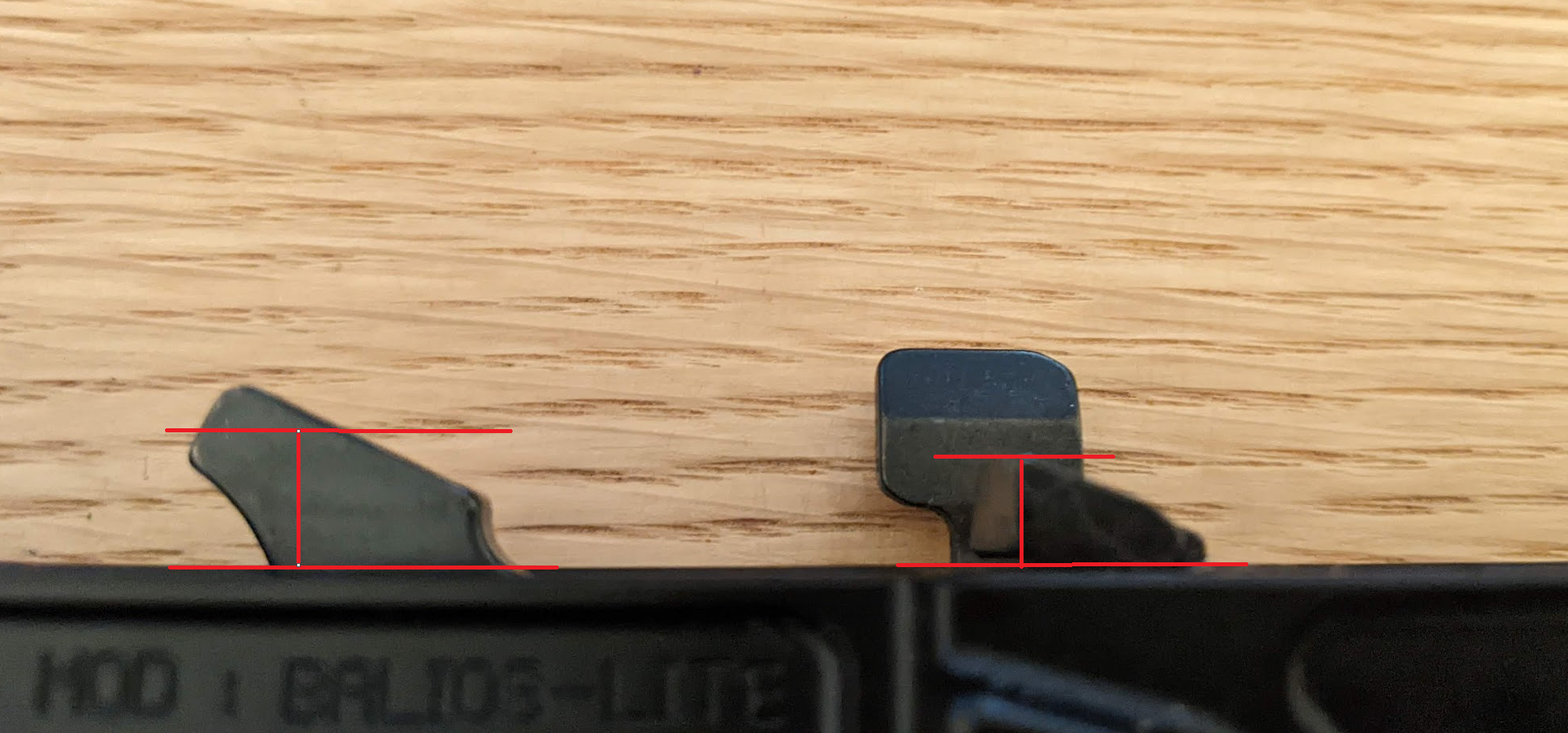

If you have before and after sizes, it's pretty much certain that it was drilled out, but what I don't understand is how the finish is still in the inside of the port. Which is why I asked for the pics. When I drilled both of mine it left the inner surface of the port bare metal. Visibly a silver metallic color. Yours is still black.

Edit: Maybe it's carbon.

Last edited:

I’d say it’s carbon. I shot it prior to taking the picturesIf you have before and after sizes, it's pretty much certain that it was drilled out, but what I don't understand is how the finish is still in the inside of the port. Which is why I asked for the pics. When I drilled both of mine it left the inner surface of the port bare metal. Visibly a silver metallic color. Yours is still black.

Edit: Maybe it's carbon.

Send it to Chad at SOTAR/School of the American Rifle- let him measure everything and troubleshoot- for one of his YT vids. The only way to do better would be if he made the video for SH.

How do I go about reaching out to him?

Seeing how I've been rudely butting in through this whole thread, why break the trend now?How do I go about reaching out to him?

Check HERE

I'd also point him to this thread as I'm sure he gets a lot people with requests. That way he can see all the stuff that's already been tried. You seem to have a real zinger here. You've replaced practically the whole rifle.

If there's no abnormal receiver or buffer tube wear, the bolt catch and hammer would basically be the only places left that I can think of that would cause drag along the underside of two (or more) different BCGs that you've tested. Wear marks on either of these parts wouldn't be a good indicator of excessive drag.

Since Aero Precision won't let you send in the receivers is to check the dimensions between the bottom of the BCG ramp and the bottom of the upper receiver and the height of the bolt catch at rest and the height of the hammer when depressed to the top of the lower receiver. It'll give you something to do while you wait for a response from Chad. The only way to tell if it's a the trigger hammer or bolt catch is to swap the parts or have some way to measure to see if the trigger pin holes were drilled in the correct location.

Since Aero Precision won't let you send in the receivers is to check the dimensions between the bottom of the BCG ramp and the bottom of the upper receiver and the height of the bolt catch at rest and the height of the hammer when depressed to the top of the lower receiver. It'll give you something to do while you wait for a response from Chad. The only way to tell if it's a the trigger hammer or bolt catch is to swap the parts or have some way to measure to see if the trigger pin holes were drilled in the correct location.

I assume you've seen this before. One of those would certainly explain it, but boy would that be a major league mess up on Aero's part. Maybe slightly crooked when mounted for machining if that's it?The only way to tell if it's a the trigger hammer or bolt catch is to swap the parts or have some way to measure to see if the trigger pin holes were drilled in the correct location.

I didn't think of this, but it definitely makes sense.

EDIT: Doesn't it seem like something that severe would be able to be felt when charging the BCG? Well. Maybe not.

....after roughly 2-1/2 months and unknown amount of money expended, it might be time to just purchase a complete platform from a vendor of your choice.None of these new parts worked. In fact, changing to the 14.5 FN barrel with the carbine gas system only made the cycling issue worse. It wouldn't even chamber another round after firing. gas port size is .066-.069. My 14.5 BA barrel w/ mid-length system mic's .082-.085 after BA opened it up. I'm done with this rifle. Who can I send it to that is an expert with this shi

Of the 6 random lowers I grabbed and measured tonight (2qty Aero Lowers, 1 BCM Lower, 1 DD Lower, 1 Balios Lite Gen 1 lower, 1 Balios Lite Gen 2 lower). - sample size of 3 Geissele SD-C, sample size 3 of Geissele SD-E, the difference for trigger hammer height to top of lower receiver in depressed position (past cocked) ranged from 0.232" to 0.235". Trigger hammer height in cocked position ranged from 0.353" to 0.358". The bolt catch heights (BCM, DD, Forward Controls Design ABC/R v2s) ranged from 0.199" to 0.210"

Of the 6 random uppers I grabbed and measured tonight (BCM Upper with BCM BCG, Daniel Defense DDM4V5, 2A Armament Balios lite Gen 1 upper with Faxon Low mass BCG, 2A Armament Balios Lite Gen 2 with Faxon Low mass BCG, Aero Precision upper with Brownells TiN Low mass BCG, Aero Precision upper with Ballistic Advantage labeled BCG - Measurements from BCG ramp to bottom edge of upper receiver ranged from 0.262" to 0.2785"

Of the 6 random uppers I grabbed and measured tonight (BCM Upper with BCM BCG, Daniel Defense DDM4V5, 2A Armament Balios lite Gen 1 upper with Faxon Low mass BCG, 2A Armament Balios Lite Gen 2 with Faxon Low mass BCG, Aero Precision upper with Brownells TiN Low mass BCG, Aero Precision upper with Ballistic Advantage labeled BCG - Measurements from BCG ramp to bottom edge of upper receiver ranged from 0.262" to 0.2785"

I assume you've seen this before. One of those would certainly explain it, but boy would that be a major league mess up on Aero's part. Maybe slightly crooked when mounted for machining if that's it? Yup, that would do it. Wouldn't be the first time it has happened. I've had to return 3 different Aero lowers (on separate occasions) that had the rear takedown pin holes drilled slightly off (this was around early 2018 and early 2019). The way I was able to tell was because there were no rear takedown pins (tried 6 different pins) that could pass through both the lower and the upper receiver rear lug (6 different stripped uppers and 5 different completed uppers). Never did attempt to install triggers on those before getting a replacement but I wouldn't have been surprised if the trigger pin holes were slightly too far forward in those lowers.

I didn't think of this, but it definitely makes sense.

EDIT: Doesn't it seem like something that severe would be able to be felt when charging the BCG? Well. Maybe not.

Yeah I assume it would be felt if it was that severe but if it was magazine feed lip rubbing, it'd be super noticeable (even if it was from feed lip gap being like 0.005" too narrow with minor rubbing because you can tell from the weird scratchy feel).

I can't feel the difference at all in drag between the upper with the shallowest upper depth to BCG ramp (0.262") paired with the lower with the tallest cocked hammer height (0.358") and the upper with the deepest upper to BCG ramp (0.2785) and shortest cocked hammer height (0.353"). All of the combos of uppers and lower will easily have a gap between the top of bolt catch to ramp and the triggers can depress below the BCG ramp leaving a gap.

Considering the OP tried different mags and didn't note any wear on the magazine feed lips, bolt catch and trigger hammer are the only things left that can be measured with simple tools. If the Geissele hammer is too tall or can't depress far enough that could cause it or if the bolt catch is way too tall relative to where the BCG ramp is.

Here's all the military's recommendations for buffers, springs, ammo etc. They sure managed to turn he M16 into a novel of fixes, bandaids and a zillion different calibers after essentially changing every design feature for the worse. Fortunately I only have 2 short barrels in 300AAC, 11.5 and 7.5 with no issue, one 18" match rifle, and everything else is AR10 and the big calibers. I never realized the cluster fuck of ammo and buffers and assorted picky things that plaque ARs, although at least 9 times out of 10 is something really simple and stupid causing an issue.I was thinking, when that was posted; sure seems as 12.5-14.5 w/mid-length is the new hotness. Don't usually hear many complaints about that setup.

- CQBR type 1: Made from M4A1 uppers by shortening the barrels and opening gas ports, no longer produced, STD carbine buffer in use in host lowers at time of fielding.

- CQBR type 2: NSWC assembled with contracted and /or overhauled parts complete with all accessories to current standards at time of build, will work with H, H2 or H3 balanced to ammo requirements:

- H okay with M193/M855.

- H2 needed for MK 262/R2LP and will feed and fire M193/M855.

- H3 may be needed for an extreme case, or when the gas port is eroded but the barrel still groups.

- CQBR type 2A: NSWC assembled with contracted and /or overhauled parts, naked without any accessories or buffer. The buffer in the host carbine would be used or upgraded as necessary via the supply system same as type 2.

- CQBR type 3: Colt-contracted upper complete with all accessories. NO buffer supplied. The buffer in the host carbine would be used or upgraded as necessary via the supply system same as type 2.

- CQBR type 3A: Colt-contracted upper naked without any accessories or buffer supplied. The buffer in the host carbine would be used or upgraded as necessary via the supply system same as type 2.

- MK18 type 1: NSWC assembled carbine with contracted and/or overhauled parts complete with all accessories to current standards at time of build; will work with H or H2 and could have shipped with either. Units will balance buffer to ammo requirements:

- H okay with M193/M855. (All shipboard MK 18s should have H buffers as this was the standard at the time of assembly.)

- H2 needed for MK 262/R2LP and will run M193/M855.

- H3 may be needed for an extreme cases or when the gas port is eroded but the barrel still groups.

- MK18 type 2: Colt-contracted carbine complete with all accessories (H buffer supplied). Units will balance buffer to ammo requirements same as Mk 18 type 1.

- MK18 Mod 1: Similar to the changes found in the SOPMOD Block II kit, the Mod 1 features a gas block end without a front sight and a railed handguard, by Daniel Defense, that extends all the way to the base of the flash hider to provide more accessory rail space for the user.

- MK18 Mod 2: Simultaneously with USASOC's adoption of the Upper Receiver Group, Improved (URG-I), which featured the Geissele Automatic's MK16 rail with M-LOK interface, Special Operations community had requested Geissele to develop a 9.3-inch rail for their MK18 Mod 2's. In 2019, there were requirements for a 10.5-inch rail instead, because reevaluation found 11.5-inch barrels to work better than 10.3-inch series, and thus a longer rail is needed. Together with the regular 14.5-inch uppers, these are often unofficially dubbed "SOPMOD Block 3" by operators.

Last edited:

I will try to take these measurements tonight. Thanks for the specific instructions!If there's no abnormal receiver or buffer tube wear, the bolt catch and hammer would basically be the only places left that I can think of that would cause drag along the underside of two (or more) different BCGs that you've tested. Wear marks on either of these parts wouldn't be a good indicator of excessive drag.

Since Aero Precision won't let you send in the receivers is to check the dimensions between the bottom of the BCG ramp and the bottom of the upper receiver and the height of the bolt catch at rest and the height of the hammer when depressed to the top of the lower receiver. It'll give you something to do while you wait for a response from Chad. The only way to tell if it's a the trigger hammer or bolt catch is to swap the parts or have some way to measure to see if the trigger pin holes were drilled in the correct location.

View attachment 7860897View attachment 7860891

TBH, I kind of wrote this issue off because I can’t find any signs of significant wear on either of these parts or the bcg.

I appreciate everyone not giving up on this rifle! Hopefully I come to a solution soon. I am going to try to reach out to Chad today and hopefully he is able to take this rifle in!

What is your interpretation of this data? Clearly you are far more qualified in these things than I am.Of the 6 random lowers I grabbed and measured tonight (2qty Aero Lowers, 1 BCM Lower, 1 DD Lower, 1 Balios Lite Gen 1 lower, 1 Balios Lite Gen 2 lower). - sample size of 3 Geissele SD-C, sample size 3 of Geissele SD-E, the difference for trigger hammer height to top of lower receiver in depressed position (past cocked) ranged from 0.232" to 0.235". Trigger hammer height in cocked position ranged from 0.353" to 0.358". The bolt catch heights (BCM, DD, Forward Controls Design ABC/R v2s) ranged from 0.199" to 0.210"

Of the 6 random uppers I grabbed and measured tonight (BCM Upper with BCM BCG, Daniel Defense DDM4V5, 2A Armament Balios lite Gen 1 upper with Faxon Low mass BCG, 2A Armament Balios Lite Gen 2 with Faxon Low mass BCG, Aero Precision upper with Brownells TiN Low mass BCG, Aero Precision upper with Ballistic Advantage labeled BCG - Measurements from BCG ramp to bottom edge of upper receiver ranged from 0.262" to 0.2785"

Those ranges don't seem to me to be enough to decisively cripple function like this. Maybe 0.262" to 0.2785", but even that doesn't seem like a huge variance. Isn't there some wiggle room in the tolerances? Or is that your point?

All honest questions.

Similar threads

- Replies

- 15

- Views

- 821

- Replies

- 47

- Views

- 1K