First, I love my B14-R steel, wouldn’t trade it. I’ve had light strikes, received a new pin and striker spring assembly, and have had no failures to fire. Cycling issues I’ve only blamed on me until this weekend when I tested CCI SV. After 20 rounds to season the bore, and while firing a 20 round group to compare to the last 20 round group of GECO Bolt Rifle, the action became difficult to close occasionally, and I had one failure to extract after firing. I dropped the mag, closed the bolt and it extracted the second time fine. Examining the case, nothing unusual. All cases appeared to have far lighter strikes, indicating tougher brass. The groups were comparable, but with these hiccups I don’t trust this ammo for match use in this rifle. I think I was getting residue build-up in the chamber, but I will do a rim thickness comparison.

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Bergara B14R Issues & Solutions

- Thread starter 357Max

- Start date

I cant say that I feel lucky about my B14R.... Mine has never given me problems and that is what I expect from any

product. I don't buy a freezer and expect or accept a non functional ice maker. I expect my B14R to extract unfired cartridges

if I ever have any. Mine has worked great from the very first day.

I changed the bolt knob to a Vudoo style due to personal preference. It is longer, bigger in diameter and the knurling is less

aggressive. I did the #6-32 spring plunger trigger mod because I'm a trigger freak and I enjoy working on things. Had I

been happy with an 11 ounce trigger weight and didn't think I could squeeze more out of it, I could have easily left it alone.

But I pushed a little to far and a #8-32 plunger crashed into the safety spring / ball detent arrangement.

Now I have a Jewell HVR.... It is very nice and set to 4 oz.

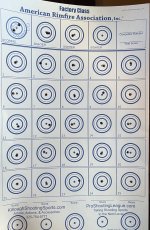

The target below was shot last year with the factory trigger set to it's minimum. About 36 ounces. I think the gun is a

very good value. It went to Lapua and shot .32 ctc. at 50 meters, not yards. I think I paid $975.00 for this steel version.

While working on my trigger, I was limited to photographs. After I went overboard with an #8-32 plunger, I was able to take mine

apart and get some actual dimensions. I have been helping Deputy Dan with his trigger mod and that allowed me to see what kind

of questions other people may have or problems they may run into. So far the issue has been the #6 threads intrudes into the

safety spring pocket by .011". The pocket is about .010" larger than the spring so mathematically, the spring can move out of the

way except for the last .001". The spring is also smaller near the middle than at it's end by about .003" so that is added clearance

and explains why my trigger worked fine.

The third photo is of my trigger. It has a .136 diameter drill going past the spring pocket and the spring and ball retract just fine.

If you have any interference between the #6 - 32 plunger and the safety spring, no more than .005" inch material need be removed.

Mine worked with a standard plunger though it was on the brink. The photo #5 is of my #8-32 and that is where I went

overboard.

In the process of looking into Dan's issues, I asked him to send my some photographs taken in a particular way. Basically straight

on, at the object. In his case the trigger sear shown in photo #6. With a photo taken that way, I can zoom up on it 40 / 60 times and get actual measurements off of the computer screen. IE: .001" at 60 times zoom is .060" Conversely, .060" on the screen is .001" in real life.

The process is much easier than you may imagine.

All I need is a known value for scale. In his case I used the depression around the part number 32790.

After zooming on his sears, I was able to estimating the size of the radii, and doing some math using hard dimensions from

my trigger I was able to estimate his good bearing surface. Later described as useable sear surface because after the sear radii have gotten past a certain point, they are past the flat surface and on tangent points only.

I hope people that used a #4-40 set screw will reevaluate HOW they are getting any trigger weight under

the factory published 36 ounces. I feel they are getting lower trigger weights because the rounded sears create a line of

contact and only friction is holding the FP back. You can all look at YOUR sears and see that they don't have sharp, crisp edges.

I equated it to being like a wet water melon seed between your finger and thumb. As soon as the pressure on it gets

out of balance, it shoots across the room. And pokes someone's eye out !!

I still feel the $5.00 mod is a good thing to do until you get $200.00 / $300.00 for a really good trigger.

What are you going to do with the original trigger once you get a TTD? Throw it out?

I sent Dan a link today shown in RED... it is about forces applied at angles and how the angles change force requirements.

I feel the #4-40 folks have unknowingly set up a situation that lowers the trigger weight but is unsafe.

I'm not the trigger police, I'm just throwing it out there so you may ask how it's working??

I feel the last sketch illustrates what is happening with the set screw approach and how the force is lowered.

I know people will say that my trigger doesn't look like that, I have overlap !! Photo #8 was only an exaggerated illustration

to convey an idea. Photo #7 looks like it has adequate overlap, It is Dan's trigger and he has been getting ADs. But if you take

note of the radii and their center points, they are nearly in line with each other. His flat bearing area is .0016"

Dan's sketch shows actual displacement.

In prior posts I have tried to dispel the notion about friction decreasing as the surface area changes.... It doesn't.

I have illustrated that the sears have rounded edges and not sharp edges like I feel they should have.

I'm asking anyone that gets a lower trigger weight with a set screw to ask themselves HOW that is happing??

Do you get a lower trigger weight if you turn the screw in by one quarter of a turn?? Why not? Why does the weight only

go down as you reach the radii? It's not a friction issue.... we covered that. As the surface area reduces, the unit load goes up

thus keeping the frictional value the same. See purple link

www.womackmachine.com

www.womackmachine.com

www.theifod.com

www.theifod.com

I have stuck my neck way out here in the hopes of helping some of you guy's out.....

I hope you will consider this information.

All my best

product. I don't buy a freezer and expect or accept a non functional ice maker. I expect my B14R to extract unfired cartridges

if I ever have any. Mine has worked great from the very first day.

I changed the bolt knob to a Vudoo style due to personal preference. It is longer, bigger in diameter and the knurling is less

aggressive. I did the #6-32 spring plunger trigger mod because I'm a trigger freak and I enjoy working on things. Had I

been happy with an 11 ounce trigger weight and didn't think I could squeeze more out of it, I could have easily left it alone.

But I pushed a little to far and a #8-32 plunger crashed into the safety spring / ball detent arrangement.

Now I have a Jewell HVR.... It is very nice and set to 4 oz.

The target below was shot last year with the factory trigger set to it's minimum. About 36 ounces. I think the gun is a

very good value. It went to Lapua and shot .32 ctc. at 50 meters, not yards. I think I paid $975.00 for this steel version.

While working on my trigger, I was limited to photographs. After I went overboard with an #8-32 plunger, I was able to take mine

apart and get some actual dimensions. I have been helping Deputy Dan with his trigger mod and that allowed me to see what kind

of questions other people may have or problems they may run into. So far the issue has been the #6 threads intrudes into the

safety spring pocket by .011". The pocket is about .010" larger than the spring so mathematically, the spring can move out of the

way except for the last .001". The spring is also smaller near the middle than at it's end by about .003" so that is added clearance

and explains why my trigger worked fine.

The third photo is of my trigger. It has a .136 diameter drill going past the spring pocket and the spring and ball retract just fine.

If you have any interference between the #6 - 32 plunger and the safety spring, no more than .005" inch material need be removed.

Mine worked with a standard plunger though it was on the brink. The photo #5 is of my #8-32 and that is where I went

overboard.

In the process of looking into Dan's issues, I asked him to send my some photographs taken in a particular way. Basically straight

on, at the object. In his case the trigger sear shown in photo #6. With a photo taken that way, I can zoom up on it 40 / 60 times and get actual measurements off of the computer screen. IE: .001" at 60 times zoom is .060" Conversely, .060" on the screen is .001" in real life.

The process is much easier than you may imagine.

All I need is a known value for scale. In his case I used the depression around the part number 32790.

After zooming on his sears, I was able to estimating the size of the radii, and doing some math using hard dimensions from

my trigger I was able to estimate his good bearing surface. Later described as useable sear surface because after the sear radii have gotten past a certain point, they are past the flat surface and on tangent points only.

I hope people that used a #4-40 set screw will reevaluate HOW they are getting any trigger weight under

the factory published 36 ounces. I feel they are getting lower trigger weights because the rounded sears create a line of

contact and only friction is holding the FP back. You can all look at YOUR sears and see that they don't have sharp, crisp edges.

I equated it to being like a wet water melon seed between your finger and thumb. As soon as the pressure on it gets

out of balance, it shoots across the room. And pokes someone's eye out !!

I still feel the $5.00 mod is a good thing to do until you get $200.00 / $300.00 for a really good trigger.

What are you going to do with the original trigger once you get a TTD? Throw it out?

I sent Dan a link today shown in RED... it is about forces applied at angles and how the angles change force requirements.

I feel the #4-40 folks have unknowingly set up a situation that lowers the trigger weight but is unsafe.

I'm not the trigger police, I'm just throwing it out there so you may ask how it's working??

I feel the last sketch illustrates what is happening with the set screw approach and how the force is lowered.

I know people will say that my trigger doesn't look like that, I have overlap !! Photo #8 was only an exaggerated illustration

to convey an idea. Photo #7 looks like it has adequate overlap, It is Dan's trigger and he has been getting ADs. But if you take

note of the radii and their center points, they are nearly in line with each other. His flat bearing area is .0016"

Dan's sketch shows actual displacement.

In prior posts I have tried to dispel the notion about friction decreasing as the surface area changes.... It doesn't.

I have illustrated that the sears have rounded edges and not sharp edges like I feel they should have.

I'm asking anyone that gets a lower trigger weight with a set screw to ask themselves HOW that is happing??

Do you get a lower trigger weight if you turn the screw in by one quarter of a turn?? Why not? Why does the weight only

go down as you reach the radii? It's not a friction issue.... we covered that. As the surface area reduces, the unit load goes up

thus keeping the frictional value the same. See purple link

Angle Problems in Fluid Power Applications - Womack Machine Supply Company

Womack Machine Supply Company Angle Problems in Fluid Power Applications reference page

Friction is Independent of Surface Area

Leonard da Vinci sketches of his work on friction What is Friction? Friction is the resistance to motion of one object relative to another. It is not a fundamental force like gravity or the electro…

www.theifod.com

www.theifod.com

I have stuck my neck way out here in the hopes of helping some of you guy's out.....

I hope you will consider this information.

All my best

Attachments

-

7-21-21-A.jpg520.8 KB · Views: 186

7-21-21-A.jpg520.8 KB · Views: 186 -

ROUNDED SEARS AND #4-40 SET SCREW WILL REDUCE TRIGGER WEIGHT BUT IS UNSAFE.jpg260.8 KB · Views: 165

ROUNDED SEARS AND #4-40 SET SCREW WILL REDUCE TRIGGER WEIGHT BUT IS UNSAFE.jpg260.8 KB · Views: 165 -

DANS SEAR OVER LAP AT 41 X UPDATED.jpg280.2 KB · Views: 167

DANS SEAR OVER LAP AT 41 X UPDATED.jpg280.2 KB · Views: 167 -

Contact DAN.jpg355.9 KB · Views: 177

Contact DAN.jpg355.9 KB · Views: 177 -

#8-32 PLUNGER DOG BONED FOR SAFETY SPRING CLEARANCE #6 PLUNGER NEEDS .005 INCH OR LESS OFF OF...jpg293.3 KB · Views: 169

#8-32 PLUNGER DOG BONED FOR SAFETY SPRING CLEARANCE #6 PLUNGER NEEDS .005 INCH OR LESS OFF OF...jpg293.3 KB · Views: 169 -

DIRECT MEASURE INTERFERANCE .0110 INCH.jpg290.6 KB · Views: 165

DIRECT MEASURE INTERFERANCE .0110 INCH.jpg290.6 KB · Views: 165 -

DIRECT MEASURE INTERFERANCE WITH SPRING AND BALL PERFECT FUNTION.jpg381.9 KB · Views: 178

DIRECT MEASURE INTERFERANCE WITH SPRING AND BALL PERFECT FUNTION.jpg381.9 KB · Views: 178 -

B14R first BP150 target Sept 2021.jpg489.5 KB · Views: 203

B14R first BP150 target Sept 2021.jpg489.5 KB · Views: 203

Disagree on sear loading and friction vs contact area. It’s been my experience that reducing sear engagement surfaces reduces pull weight all on its own, without reducing spring strength. Think this way- sliding a flat bottom safe vs one with feet. The feet have far higher lbs per square inch of load, yet the reduced contact area makes it far easier to slide.

But then, I seem to be alone in my views on using Molybdenum Disulfide Grease on my sear contact points and totally against the Ronsonol lighter fluid crowd.

But then, I seem to be alone in my views on using Molybdenum Disulfide Grease on my sear contact points and totally against the Ronsonol lighter fluid crowd.

It sounds like, it's been your experience that while pulling the trigger, as the sears start losing the overlap, you simultaneously

loses trigger weight ????? I have super sized some sears below. The sketch is NOT what happens.

I'm suggesting that the load stay's constant and as your UNIT area goes down, the UNIT pressure goes up.

100 pounds on 100 sq in = 1 pound per sq in. 100 pounds on 50 sq in = 2 pounds per sq in. And so on.

The units can be anything, unit inches, unit millimeters. I use inches as the UNIT to make it easy to follow.

I use the smallest dollop of Krytox on my sears too.

I thought I had read that some trigger companies say to use Ronsonol lighter fluid to clean the unit. Is that what you mean??

The sketch below is WHAT DOESNT HAPPEN.... the frictional load of 16 ounces doesn't get cut in half when the surface

area is cut in half as the cartoon below would suggest. If it did, your 16 ounce trigger would get weaker as you pulled it.

How would your trigger scale deal with trigger that had a decreasing weight??

The sears start with a certain frictional load, say 16 ounces. When half of the lower sear slides off the upper sear, the

surface area DOES get cut in half but the load per square inch at the contact area DOUBLES. It is that doubling that

keeps the frictional load constant. It also works while a percentage of the sears start to disengage, I'm using HALF and

DOUBLING to keep the example clear and simple and avoid a bunch of math that most people tend to shy away from.

If you were to weigh yourself on a scale you would get a value. If you stepped on two separate scales, the load is split

between them and each scale would read half of your weight.

The diagram shows a constant load. With one pillar, the load is spread over a certain amount of surface area.

If you tried to slide the blue pillar it would require a certain amount of force.

The next one has two pillars and the same load is distributed between them. The surface area has been doubled

but the load on each pillar is cut in half. ( A shared load ) So the load per square inch is cut in half.

Now if you tried to move both pillars with twice the surface area and half of the unit load, the force to move the

pillars would be the same force as it took to move the single pillar.

If you have one pillar the total friction is μN. If you have two pillars each supports half of the weight, and thus exert half the normal force, so the total friction is μN/2 + μN/2 = μN.

If you have one pillar the total friction is μN. If you have two pillars each supports half of the weight, and thus exert half the normal force, so the total friction is μN/2 + μN/2 = μN.

Below is stuff from the net....

""Frictional force increases ... When the contact area is made smooth then the molecular forces between surfaces increases this gives rise to friction.""

Anyone who has wrung gage blocks together has felt the increased friction from the molecular forces.

""Since pressure equals force divided by the area of contact, it works out that the increase in friction generating area is exactly offset by the reduction in pressure; the resulting frictional forces, then, are dependent only on the frictional coefficient of the materials and the FORCE holding them together.""

Steel on steel static c.f. is .8 dry and .16 lubricated ( Machinist Handbook 23rd edition pg. 2202 )

Friction is Independent of Surface Area – THE IFOD

loses trigger weight ????? I have super sized some sears below. The sketch is NOT what happens.

I'm suggesting that the load stay's constant and as your UNIT area goes down, the UNIT pressure goes up.

100 pounds on 100 sq in = 1 pound per sq in. 100 pounds on 50 sq in = 2 pounds per sq in. And so on.

The units can be anything, unit inches, unit millimeters. I use inches as the UNIT to make it easy to follow.

I use the smallest dollop of Krytox on my sears too.

I thought I had read that some trigger companies say to use Ronsonol lighter fluid to clean the unit. Is that what you mean??

The sketch below is WHAT DOESNT HAPPEN.... the frictional load of 16 ounces doesn't get cut in half when the surface

area is cut in half as the cartoon below would suggest. If it did, your 16 ounce trigger would get weaker as you pulled it.

How would your trigger scale deal with trigger that had a decreasing weight??

The sears start with a certain frictional load, say 16 ounces. When half of the lower sear slides off the upper sear, the

surface area DOES get cut in half but the load per square inch at the contact area DOUBLES. It is that doubling that

keeps the frictional load constant. It also works while a percentage of the sears start to disengage, I'm using HALF and

DOUBLING to keep the example clear and simple and avoid a bunch of math that most people tend to shy away from.

If you were to weigh yourself on a scale you would get a value. If you stepped on two separate scales, the load is split

between them and each scale would read half of your weight.

The diagram shows a constant load. With one pillar, the load is spread over a certain amount of surface area.

If you tried to slide the blue pillar it would require a certain amount of force.

The next one has two pillars and the same load is distributed between them. The surface area has been doubled

but the load on each pillar is cut in half. ( A shared load ) So the load per square inch is cut in half.

Now if you tried to move both pillars with twice the surface area and half of the unit load, the force to move the

pillars would be the same force as it took to move the single pillar.

If you have one pillar the total friction is μN. If you have two pillars each supports half of the weight, and thus exert half the normal force, so the total friction is μN/2 + μN/2 = μN.

If you have one pillar the total friction is μN. If you have two pillars each supports half of the weight, and thus exert half the normal force, so the total friction is μN/2 + μN/2 = μN.Below is stuff from the net....

""Frictional force increases ... When the contact area is made smooth then the molecular forces between surfaces increases this gives rise to friction.""

Anyone who has wrung gage blocks together has felt the increased friction from the molecular forces.

""Since pressure equals force divided by the area of contact, it works out that the increase in friction generating area is exactly offset by the reduction in pressure; the resulting frictional forces, then, are dependent only on the frictional coefficient of the materials and the FORCE holding them together.""

Steel on steel static c.f. is .8 dry and .16 lubricated ( Machinist Handbook 23rd edition pg. 2202 )

"" Friction is Not Dependent on Surface Area ""

""A fascinating property of friction is that it is not dependent on the surface area in contact between two objects. This seems counter-intuitive. Here’s why this is the case: “Although a larger area of contact between two surfaces would create a larger source of frictional forces, it also reduces the pressure between the two surfaces for a given force holding them together. Since pressure equals force divided by the area of contact, it works out that the increase in friction generating area is exactly offset by the reduction in pressure; the resulting frictional forces, then, are dependent only on the frictional coefficient of the materials and the FORCE holding them together. ""Friction is Independent of Surface Area – THE IFOD

Attachments

Last edited:

At least one trigger company and several agencies I’ve read of recommended only using Ronsonol lighter fluid to clean/lube their triggers.It sounds like it's been your experience that while pulling the trigger, as the sears start losing the overlap, you simultaneously

loses trigger weight . I have super sized some sears below.

I'm suggesting that the load stay's constant and as your unit area goes down, the unit pressure goes up.

100 pounds on 100 sq in = 1 pound per sq in. 100 pounds on 50 sq in = 2 pounds per sq in. And so on.

I use the smallest dollop of Krytox on my sears too.

I thought I had read that some trigger companies say to use Ronsonol lighter fluid to clean the unit. Is that what you mean??

Below is stuff from the net....

""Frictional force increases ... When the contact area is made smooth then the molecular forces between surfaces increases this gives rise to frction.""

Anyone who has wrung gage blocks together has felt the increase in friction from the molecular forces.

""Since pressure equals force divided by the area of contact, it works out that the increase in friction generating area is exactly offset by the reduction in pressure; the resulting frictional forces, then, are dependent only on the frictional coefficient of the materials and the FORCE holding them together.""

"" Friction is Not Dependent on Surface Area ""

""A fascinating property of friction is that it is not dependent on the surface area in contact between two objects. This seems counter-intuitive. Here’s why this is the case: “Although a larger area of contact between two surfaces would create a larger source of frictional forces, it also reduces the pressure between the two surfaces for a given force holding them together. Since pressure equals force divided by the area of contact, it works out that the increase in friction generating area is exactly offset by the reduction in pressure; the resulting frictional forces, then, are dependent only on the frictional coefficient of the materials and the FORCE holding them together. ""

If you have one pillar the total friction is μN. If you have two pillars each supports half of the weight, and thus exert half the normal force, so the total friction is μN/2 + μN/2 = μN. Source

Friction is Independent of Surface Area – THE IFOD

As a test I cleaned a mirror laying flat. Next day I sprayed it with Ronsonol and didn’t touch it for 24 hours. There was zero residue the following day, complete evaporation. Draw your finger across the glass and you left no marks either where the fluid had been, or where it hadn’t been.

Running dry triggers seems like a good way to keep selling triggers.

I have never done any testing with lighter fluid myself and truly given the subject very little thought. I have some really

nice products that I favor, one of them is EEZOX. It is a cleaner / lube. Out of the can it has a very low viscosity. That allows

it to seep into small spaces. After a short time, the carrier evaporates and what is left is a thin oil film. Super Lube Oil with PTFE

is a low viscosity oil that I may use in my triggers. I don't think that running your trigger dry will shorten it's useable life span.

It is moving very slowly and never generates any heat. I still feel compelled to point out the table below. The static c.f. of dry

steel is .78 and the static c.f. of steel with some basic lube, castor oil is .15

With your sear overlap being so short, I would ignore the .15 altogether. So the question we all must ask ourselves is, do you think

you want to run a dry trigger or a trigger with an oil film on it ??

What type of road do you prefer driving on? Dry .70 ..... Wet .40 ...... or Ice 0.03

The CF is why I put one drop of low viscosity lube on my sears.

Another great general product is KROIL, it has a low viscosity also.

As a side bar.... as a general oil protectant, I use cheap mineral oil from Walmart on the steel and the wood. If you look

at the ingredients of many products you will see Mineral oil near the top of the list.

nice products that I favor, one of them is EEZOX. It is a cleaner / lube. Out of the can it has a very low viscosity. That allows

it to seep into small spaces. After a short time, the carrier evaporates and what is left is a thin oil film. Super Lube Oil with PTFE

is a low viscosity oil that I may use in my triggers. I don't think that running your trigger dry will shorten it's useable life span.

It is moving very slowly and never generates any heat. I still feel compelled to point out the table below. The static c.f. of dry

steel is .78 and the static c.f. of steel with some basic lube, castor oil is .15

With your sear overlap being so short, I would ignore the .15 altogether. So the question we all must ask ourselves is, do you think

you want to run a dry trigger or a trigger with an oil film on it ??

What type of road do you prefer driving on? Dry .70 ..... Wet .40 ...... or Ice 0.03

The CF is why I put one drop of low viscosity lube on my sears.

Another great general product is KROIL, it has a low viscosity also.

As a side bar.... as a general oil protectant, I use cheap mineral oil from Walmart on the steel and the wood. If you look

at the ingredients of many products you will see Mineral oil near the top of the list.

Your bottom diagram on sear engagement makes my point. Not from the view of a moving sear, but of one with different engagement. The less engagement, the lighter the pull weight. Not a human perception, an instrument reading.

As for lubes/protection, we all have our go-to products.

I cut a barrel into small pieces, fully degreased, and treated each with what I could find locally, and samples folks from RFC sent from across the country. Tacked to a board, and hung from a soffit a half mile from the Atlantic for 3 months. Winners were Corrosion-X HD, STP oil treatment, and regular Corrosion-X. Ronsonol was as bad as the control piece, and the Kroil piece was a lump of wet rust.

As for lubes/protection, we all have our go-to products.

I cut a barrel into small pieces, fully degreased, and treated each with what I could find locally, and samples folks from RFC sent from across the country. Tacked to a board, and hung from a soffit a half mile from the Atlantic for 3 months. Winners were Corrosion-X HD, STP oil treatment, and regular Corrosion-X. Ronsonol was as bad as the control piece, and the Kroil piece was a lump of wet rust.

Did you read the information from the internet ??

The sketch is supposed to illustrate that as your sear is in full contact with the upper sear, you have a friction force. Lets call it 16 oz.

The 10 lb weight being in contact with the 100% of the sear. Call it one square inch of area.

If you maintain the 10 lb weight and you slide half of the sear out from under it, the surface area is cut in half but the load per square in doubles.

That still creates a frictional force of 16 oz.

Doesn't sound like you see it that way..... People should look it up and decide for themselves.

A man convinced against his will, Is a man of the same opinion still !!

Kroil is great stuff for it's label uses. Loosens Frozen Metal Parts.....

It say's nothing about being a good rust preventative.

The sketch is supposed to illustrate that as your sear is in full contact with the upper sear, you have a friction force. Lets call it 16 oz.

The 10 lb weight being in contact with the 100% of the sear. Call it one square inch of area.

If you maintain the 10 lb weight and you slide half of the sear out from under it, the surface area is cut in half but the load per square in doubles.

That still creates a frictional force of 16 oz.

Doesn't sound like you see it that way..... People should look it up and decide for themselves.

A man convinced against his will, Is a man of the same opinion still !!

Kroil is great stuff for it's label uses. Loosens Frozen Metal Parts.....

It say's nothing about being a good rust preventative.

"" Friction is Not Dependent on Surface Area ""

""A fascinating property of friction is that it is not dependent on the surface area in contact between two objects. This seems counter-intuitive. Here’s why this is the case: “Although a larger area of contact between two surfaces would create a larger source of frictional forces, it also reduces the pressure between the two surfaces for a given force holding them together. Since pressure equals force divided by the area of contact, it works out that the increase in friction generating area is exactly offset by the reduction in pressure; the resulting frictional forces, then, are dependent only on the frictional coefficient of the materials and the FORCE holding them together. ""As noted earlier I had a spare Bergara trigger so I modified it by tapping the rear hole to #6-32 and running in a plunger-set-screw (hereinafter just referred to as “screw”) to adjust the sear. While nobody else seems to have reported a problem, when I ran the screw down the shaft I encountered problems. It seems the threads from the screw must have been interfering with the safety spring. By all accounts it shouldn’t happen, but in my case it was interfering, and without further modification (to the screw) it was unsafe.

By unsafe - if I ran the screw to the point of pushing the trigger off the sear and then backed it off just a bit, the safety wouldn’t work at all - jammed. As I gradually backed out the screw to enable the safety to function, I was getting Accidental Discharges (AD) with flipping the safety, and occasionally when locking the bolt, though depending on how far in the screw was positioned I had some failures to even cock the gun. By the time I eliminated any interference with the safety, the screw wasn’t engaging the trigger/sear at all

Ultimately I dog-boned the screw - I’ve attached a pic of an 8-32 screw AirGunShawn did, because mine is fugly! But it works.

The pic "Contact" shows the trigger (silver) in contact with the sear (black), though that's NOT the dog-boned screw that’s sticking out the back of the housing. At this position, with the dog-boned screw, I get no interference with the safety, no AD and no failure to cock. If I rotate the screw much more the trigger drops. At this amount of trigger-sear contact I was getting a pretty consistent 16 oz trigger pull (Wheeler Trigger Pull Scale). Just to be safe I backed out the screw about another quarter of a turn (so the trigger is not on the hairy-edge of the sear as it is in the pic!) and I’m now getting a reasonably consistent 20-22 oz pull.

This seems to be the sweet spot. Note I’m not using any other screws - none in the front (appears to control over-travel) nor the regular/factory trigger adjustment screw.

I finally got it out to the range and I really like it at this weight. NO ADs or failures of any sort - unless you count the one time I had my finger barely touching the trigger and the guy in the next lane let go a round out of what might have been a Howitzer. I jumped. And fired. And still landed a pretty decent shot relative to my POA.

What I can’t explain is how others got significantly lower trigger weights, but then I’m happy with mine where it’s at, so I'm not going to mess with it anymore.

But I can caution that if you’re going to modify the trigger with the #6-32 screw you’ve got to work through resolving any AD issues, and possibly some sort of interference with the safety - issues that in my case were resolved by dog-boning the set screw.

By unsafe - if I ran the screw to the point of pushing the trigger off the sear and then backed it off just a bit, the safety wouldn’t work at all - jammed. As I gradually backed out the screw to enable the safety to function, I was getting Accidental Discharges (AD) with flipping the safety, and occasionally when locking the bolt, though depending on how far in the screw was positioned I had some failures to even cock the gun. By the time I eliminated any interference with the safety, the screw wasn’t engaging the trigger/sear at all

Ultimately I dog-boned the screw - I’ve attached a pic of an 8-32 screw AirGunShawn did, because mine is fugly! But it works.

The pic "Contact" shows the trigger (silver) in contact with the sear (black), though that's NOT the dog-boned screw that’s sticking out the back of the housing. At this position, with the dog-boned screw, I get no interference with the safety, no AD and no failure to cock. If I rotate the screw much more the trigger drops. At this amount of trigger-sear contact I was getting a pretty consistent 16 oz trigger pull (Wheeler Trigger Pull Scale). Just to be safe I backed out the screw about another quarter of a turn (so the trigger is not on the hairy-edge of the sear as it is in the pic!) and I’m now getting a reasonably consistent 20-22 oz pull.

This seems to be the sweet spot. Note I’m not using any other screws - none in the front (appears to control over-travel) nor the regular/factory trigger adjustment screw.

I finally got it out to the range and I really like it at this weight. NO ADs or failures of any sort - unless you count the one time I had my finger barely touching the trigger and the guy in the next lane let go a round out of what might have been a Howitzer. I jumped. And fired. And still landed a pretty decent shot relative to my POA.

What I can’t explain is how others got significantly lower trigger weights, but then I’m happy with mine where it’s at, so I'm not going to mess with it anymore.

But I can caution that if you’re going to modify the trigger with the #6-32 screw you’ve got to work through resolving any AD issues, and possibly some sort of interference with the safety - issues that in my case were resolved by dog-boning the set screw.

Attachments

Shot my first 50/50 match. Used SK LR match.

I don’t have one of those fancy front rests, so just used my shmedium bag on a block of wood up front and a squeeze bag rear.

It was windy and switchey. Didn’t think I was doing that great, but turns out I won the match.

I still haven’t had any failures since the mods in this thread. Still Loving the Huber 1.5# 2 stage.

Round count is just above 3500 now.

Only planned change is a scope switch to an XTR3 3.3-18 x 50 SCR-2 mil. The reticle is very fine & should be perfect on the B14r

My score was 698/12x combined.

Second place was a CZ 457 Lilja @ 687/8x

Don’t really know if that is a good score, but everyone was bitching about the wind.

I don’t have one of those fancy front rests, so just used my shmedium bag on a block of wood up front and a squeeze bag rear.

It was windy and switchey. Didn’t think I was doing that great, but turns out I won the match.

I still haven’t had any failures since the mods in this thread. Still Loving the Huber 1.5# 2 stage.

Round count is just above 3500 now.

Only planned change is a scope switch to an XTR3 3.3-18 x 50 SCR-2 mil. The reticle is very fine & should be perfect on the B14r

My score was 698/12x combined.

Second place was a CZ 457 Lilja @ 687/8x

Don’t really know if that is a good score, but everyone was bitching about the wind.

Had this (to me) somewhat unique ejection failure yesterday. I had cleaned my bore and was seasoning it with a different ammo type from the same manufacturer. The rifle turned into a malfunctioning beast, at least 4 examples of the fired case landing transverse behind the magazine, 2 or 3 fired cases lodged on the left wall facing rearward, and then this one. I was surprised there was that much of a recess for the case!

Mentioned on FB and was immediately assailed by suggestions to stake the ejector, but have never seen this idea supported by either Bergara or it’s importers.

Thus far I’ve done nothing but wipe everything down, blast it with the air compressor, and run 2 mags of snap caps. I’ve felt the tension which is about what the OP describes. I have a quantity of other guns to compare to, but the stand-out is the number of successful designs with the C-style spring that tensions both tensioner and extractor the same. I’m wondering why Bergara decided to diverge from that.Have you ever messed with the spring tension on the non ejector port side claw?

My barreled action was made in 2021 and the ejector was very snug so staking it wouldn’t have solved anything. The assist spring did the trick on the weaker tensioned claw.Thus far I’ve done nothing but wipe everything down, blast it with the air compressor, and run 2 mags of snap caps. I’ve felt the tension which is about what the OP describes. I have a quantity of other guns to compare to, but the stand-out is the number of successful designs with the C-style spring that tensions both tensioner and extractor the same. I’m wondering why Bergara decided to diverge from that.

Haven’t the opportunity yet.You said you changed ammo, did you go back see if the other was OK? Different lot could act different

View attachment 7855783

Had this (to me) somewhat unique ejection failure yesterday. I had cleaned my bore and was seasoning it with a different ammo type from the same manufacturer. The rifle turned into a malfunctioning beast, at least 4 examples of the fired case landing transverse behind the magazine, 2 or 3 fired cases lodged on the left wall facing rearward, and then this one. I was surprised there was that much of a recess for the case!

Mentioned on FB and was immediately assailed by suggestions to stake the ejector, but have never seen this idea supported by either Bergara or it’s importers.

Stuff like this became "normal" on mine. I think the slots in the barrel are either too narrow or not narrow enough.

If the slots were cleared out, the jamed round might fall out. If the slots were more narrow, it would not get in in the first place.

Another problem is created by the over stroke of the bolt to the rear. That opens up a rat hole behind the mag where brass finds its way and prevents the bolt from going forward.

When you compare the action design of the B14R to the Vudoo, you can see the Vudoo guys were a little more intelligent with their design.

The bolt does not over throw to the rear, and the absence of false bolt lugs makes for fewer places for brass to hide.

I'll be posting some acuracy testing vids on my YouTube channel shortly where to our surprize, by B14R was more accurate than a RimX, Vudoo Anschutz 54, CZ452 and a TacSol 1022. So accuracy was really good.

But for the reliability issues... I was in a match recently where it jammed in 9 our of 10 stages... With that, I replaced it with a Vudoo, which I was hoping to avoid as it is over priced. I was really hoping that the Bergara would fit the bill for less money, but it fell short.

I hope the factory works out the kinks because if they do, it will make for a great value.

So Saturday I removed the left extractor, checked the spring size against extras in my parts box, and while I couldn’t find one I liked, I did find one in a reverse helix that slid inside, so I just cut to length, slathered in my moly grease, and reassembled. It ended up slightly less strong than the right side.Stuff like this became "normal" on mine. I think the slots in the barrel are either too narrow or not narrow enough.

If the slots were cleared out, the jamed round might fall out. If the slots were more narrow, it would not get in in the first place.

Another problem is created by the over stroke of the bolt to the rear. That opens up a rat hole behind the mag where brass finds its way and prevents the bolt from going forward.

When you compare the action design of the B14R to the Vudoo, you can see the Vudoo guys were a little more intelligent with their design.

The bolt does not over throw to the rear, and the absence of false bolt lugs makes for fewer places for brass to hide.

I'll be posting some acuracy testing vids on my YouTube channel shortly where to our surprize, by B14R was more accurate than a RimX, Vudoo Anschutz 54, CZ452 and a TacSol 1022. So accuracy was really good.

But for the reliability issues... I was in a match recently where it jammed in 9 our of 10 stages... With that, I replaced it with a Vudoo, which I was hoping to avoid as it is over priced. I was really hoping that the Bergara would fit the bill for less money, but it fell short.

I hope the factory works out the kinks because if they do, it will make for a great value.

Took it out for testing and couldn’t make it fail, even when running drills. Tried both types of ammo, so looks like I’m back up and running. Interesting side note, my mag alignment on this rifle was so perfect it would feed fired cases. Doesn’t quite do that anymore, but I’m satisfied with the functionality.

Got a match pending so hopefully it’ll behave.

Here’s a tl;drTagging this post as I am a proud new owner of a b-14r carbon barrel.

If you are having extraction issues (brass popping back into the chamber area) check the tension on the claws. If you’re having said issues more than likely the non ejection port claw is too loose meaning not enough spring tension.

So what's the final consensus, is it worth getting one? Do they fair well long distance or in NRL matches? I'm seeing a ton of conflicting info everywhere.

Sort of like the idea of being able to swap a rimfire barreled action into my ACC

Sort of like the idea of being able to swap a rimfire barreled action into my ACC

Last edited:

So what's the final consensus, is it worth getting one? Do they fair well long distance or in NRL matches? I'm seeing a ton of conflicting info everywhere.

Sort of like the idea of being anle

To swap a rimfire barreled action into my ACC

I love mine. The steel barrel is very accurate & with a few simple mods it's 100% reliable. The hard part was figuring out what exactly needed tweaking. SK LR match or Eley 10X is sub moa @100y for 6 x 5's when the wind is mild.

I currently have a 4.5 - 27 G2 Razor on it with 40moa worth of cant = 28 mils on the dial. Every type ammo I've tried falls apart before 500y, but it's fun playing at distance. RWS is suppose to have some new ammo out this year geared towards 22 ELR.

I wouldn't get the Carbon barrel version as its not a carbon wrapped barrel. Its just a sleeve slid over a skinny steel barrel. Would also be harder to get it to balance.

Here is what it looks like in a ACC. Pic from this thread (not my rifle). It would look fine if there was a suppressor on it.

While it has its quirks I’ve yet to hear anyone say it flat out sucks. I see them at matches all the times and everyone I personally know with one does well with it. 99.99% of the time it’s going to be the Indian and not the arrow. Obviously ammo selection matters and just spending time with it at the range. One of the PRS clubs I shoot with has a loaner B14R. It has mileage on it and can hang with the custom stuff.So what's the final consensus, is it worth getting one? Do they fair well long distance or in NRL matches? I'm seeing a ton of conflicting info everywhere.

Sort of like the idea of being anle

To swap a rimfire barreled action into my ACC

I saw a few minutes ago Eagle eye shooting did a 24” barrel and a 21 3/4” that were shooting ridiculous groups on his YouTube channel. Shame bergara doesn't just sell the actions.While it has its quirks I’ve yet to hear anyone say it flat out sucks. I see them at matches all the times and everyone I personally know with one does well with it. 99.99% of the time it’s going to be the Indian and not the arrow. Obviously ammo selection matters and just spending time with it at the range. One of the PRS clubs I shoot with has a loaner B14R. It has mileage on it and can hang with the custom stuff.

Well the good thing is that they sell barreled actions. You can always ditch the factory barrel and pick your own stock/chassis. Close enough I suppose.I saw a few minutes ago Eagle eye shooting did a 24” barrel and a 21 3/4” that were shooting ridiculous groups on his YouTube channel. Shame bergara doesn't just sell the actions.

Biggest thing I think EVERYONE (myself included) forgets occasionally, is ALL guns are owned and shot by people. We all know someone who could break a hammer. Likewise there are those who don’t check for loose screws, clean out factory goo, test different ammo, know how to clean properly, etc. Bear all this in mind when evaluating a product by other’s “experience”.So what's the final consensus, is it worth getting one? Do they fair well long distance or in NRL matches? I'm seeing a ton of conflicting info everywhere.

Sort of like the idea of being able to swap a rimfire barreled action into my ACC

Mine is a 2019, has been restocked, has connected at 507 yds, has competed favorably and less than favorably against Rim-X, Vudoo, Christiansen, etc. out to 401yds. Every dog has it’s day, and the rifle rarely fails the shooter- it’s usually the opposite.

Buy with confidence, the gun is up to the task.

Last edited:

I have taken mine out to 200 yards and I would say it competes with my RimX. The action isn’t as smooth and the magazines are not as nice as the RimX. As far as accuracy is concerned, I don’t think it will hold you back. This is a 25 shot target that I shot shorty after getting my new chassis at 50 yards and 13 mph wind off of a bipod and rear bag. I pulled a few shots due to lack on concentration. I haven’t gotten the rifle back out since getting the RimX back.So what's the final consensus, is it worth getting one? Do they fair well long distance or in NRL matches? I'm seeing a ton of conflicting info everywhere.

Sort of like the idea of being able to swap a rimfire barreled action into my ACC

Nothing to complain about there. I’d love a RimX barreled by Desert Precision Gunworks but that’s a little out of my price range for sure, the RimX mags definitely seem nicer than the V22 mags.I have taken mine out to 200 yards and I would say it competes with my RimX. The action isn’t as smooth and the magazines are not as nice as the RimX. As far as accuracy is concerned, I don’t think it will hold you back. This is a 25 shot target that I shot shorty after getting my new chassis at 50 yards and 13 mph wind off of a bipod and rear bag. I pulled a few shots due to lack on concentration. I haven’t gotten the rifle back out since getting the RimX back. View attachment 7874300

My RimX is Desert Precision Gunworks. He puts together a nice barreled action. The RimX mags are best best 22 mags out there IMO. Loading them is a breeze and they feed well and reliably. Had a Keystone before and they are very nice as well. My brother has it now and it has been flawless for both of us. I don’t think you can go wrong with Vudoo, RimX or Bergara honestly.Nothing to complain about there. I’d love a RimX barreled by Desert Precision Gunworks but that’s a little out of my price range for sure, the RimX mags definitely seem nicer than the V22 mags.

I just discovered Kenny, if everything he builds is as good as what’s in his videos he ought to stay real busy it looks like he does some really great work.My RimX is Desert Precision Gunworks. He puts together a nice barreled action. The RimX mags are best best 22 mags out there IMO. Loading them is a breeze and they feed well and reliably. Had a Keystone before and they are very nice as well. My brother has it now and it has been flawless for both of us. I don’t think you can go wrong with Vudoo, RimX or Bergara honestly.

It’s just weird how the bergara is so different action so action as far a second how smooth they run, seen several guys filing the bolt to run smoother.

It just seems like Vudoo owners go through a huge checklist when it doesn’t shoot right. Did you shoot 5000 rounds through it first to season the barrel? Lol I’m teasing. My friends all shoot Vudoos. I have to bust their balls every once in a while since I’m the odd man out with a RimX.My RimX is Desert Precision Gunworks. He puts together a nice barreled action. The RimX mags are best best 22 mags out there IMO. Loading them is a breeze and they feed well and reliably. Had a Keystone before and they are very nice as well. My brother has it now and it has been flawless for both of us. I don’t think you can go wrong with Vudoo, RimX or Bergara honestly.

Honestly even if you didn’t go through him there are good prefits out on the market. You can DIY at home.I just discovered Kenny, if everything he builds is as good as what’s in his videos he ought to stay real busy it looks like he does some really great work.

Well I shoot a budget built 10/22 now so screw all y’allIt just seems like Vudoo owners go through a huge checklist when it doesn’t shoot right. Did you shoot 5000 rounds through it first to season the barrel? Lol I’m teasing. My friends all shoot Vudoos. I have to bust their balls every once in a while since I’m the odd man out with a RimX.

Saw where a guy put a ball bearing on top of the extractor spring to add preload if that’s what you’re talking about adding to.My barreled action was made in 2021 and the ejector was very snug so staking it wouldn’t have solved anything. The assist spring did the trick on the weaker tensioned claw.

I'm definitely not on the level of Shawn so I probably screwed something up but I used the 6-32 4.5 lb plunger at first. I found that I had a very fine line between failing to cock (maybe because the trigger was pushed forward?) and a situation where the plunger would push the trigger forward when pulled but not far enough to fire. It would move at about 11oz but then hang up and require another 4-5 Oz of trigger pull to fire. I ended up swapping to a fixed set screw and now it pulls at 11 Oz with less travel. I have tossed the gun around and slammed the butt down without any misfires and my safety still works.Shawn: No luck getting time to work on the trigger this week - BUT - for the benefit of the folks that haven't been part of our private messages --

I ran the #6-32 spring-plunger screw in until the trigger dropped and the backed it out about 120 to 135* but after recocking the safety was stuck. While it "should't be" it seems the screw is interfering with the safety. If I back the screw out far enough to free up the safety my trigger pull is about 20-24 oz BUT several times I would get trigger fall just working the safety lever, so pretty unsafe.

Basically I could get a trigger fall almost any time the screw was in contact with the trigger with a few operations of the safety.

Without any adjustment screw - back, front, or bottom - the trigger pull is about 2.75 lbs/44 oz. And no amount of manipulation of the safety causes the trigger to fall.

Has anybody else tried the #6-32 screw? If so - what has been your experience??

My current plan - hopefully I'll get time this weekend - is to take a stab at the dog bone fix mentioned elsewhere with regard to the #8 screw - filing some of the threads off the section of the screw that might interfere with the safety spring.

We'll see . . .

Best thing though - I can always just revert back to the original trigger without these extra adjustment screws. Actually, in that case I might just drop in the TriggerTech Special from my Remington 700 and put the Bergara trigger in the Remington since the 308 is NOT getting much use these days!

I did manage to flatten or break the firing pin while test firing though so I need a new one of those now...it's always something (b14r fired brass on the left).

Jeff

Attachments

I shore would like to know what you made the shims out of, and what glue you used. I can see that helping a lot ! Taking some of the slop out will stop the jamming while feeding...Here is what we did to fix the feeding problem. A little piece of plastic glued to the mag. Zero issues since and have put a good number of rounds through it.View attachment 7614622

I used a hot glue gun to create pretty much the same thing. And by heating up a butter knife with a torch, I could make the "shim" thinner until I got the fit I wanted.I shore would like to know what you made the shims out of, and what glue you used. I can see that helping a lot ! Taking some of the slop out will stop the jamming while feeding...

Bump so I can more quickly find this thread.

My b14r ran fine after staking the ejector, but has developed the fteject issue again.

Looking at the spring fix on the left side extractor claw this time around.

My b14r ran fine after staking the ejector, but has developed the fteject issue again.

Looking at the spring fix on the left side extractor claw this time around.

So my B14R has started to dribble an occasional extracted case into the chamber vs ejecting it. Maybe one in 20 or so but enough to be distracting. I've read here (and elsewhere) that I need a new spring for the inside shell holder/claw. Has anyone found a better aftermarket spring or should I just call Bergara CS for a replacement? Thanks in advance! Tried searching but it's like drinking from a fire hose.

I have had or had ejection issues with some brands of ammo

Lots of folks stake the ejector I found a post where they changed the ejector side extractor spring ( some also file a little of the bevel out and make it a tad straighter ) I replaced the spring in mine and it seems to have fixed it

Lots of folks stake the ejector I found a post where they changed the ejector side extractor spring ( some also file a little of the bevel out and make it a tad straighter ) I replaced the spring in mine and it seems to have fixed it

357max , half way

www.snipershide.com

www.snipershide.com

Bergara B14R Ejector/Extraction Issues

Hi Guys, I just picked up my B14R, and dropped into a spare MPA Chassis. Took it to the range and had some issues, and thought I would ask everyone if anyone has had this issue and fixed it, or has any ideas. First off, this would happen 3-4 times per magazine of 5-rounds. I would fire the...

I had installed an extra spring (inside the factory spring) on the tensioner. That worked for a couple of matches, then had a single failure to eject. Decided a bolt cleaning may have been in order, and during tear-down, found the left-right extractor springs And the firing-pin return spring are all similar sizes, but of different wire and therefore different strengths.So my B14R has started to dribble an occasional extracted case into the chamber vs ejecting it. Maybe one in 20 or so but enough to be distracting. I've read here (and elsewhere) that I need a new spring for the inside shell holder/claw. Has anyone found a better aftermarket spring or should I just call Bergara CS for a replacement? Thanks in advance! Tried searching but it's like drinking from a fire hose.

I discarded the extra spring I added, and swapped the light left extractor spring for the medium weight firing pin return spring.

So far, so good

Thanks, good to know the interchangeability aspect. I sent Bergara CS an email over the holiday. Hopefully I can get a spring set from them. Worse case, I'll spec out the factory springs and order some upgrades on McMaster Carr.I had installed an extra spring (inside the factory spring) on the tensioner. That worked for a couple of matches, then had a single failure to eject. Decided a bolt cleaning may have been in order, and during tear-down, found the left-right extractor springs And the firing-pin return spring are all similar sizes, but of different wire and therefore different strengths.

I discarded the extra spring I added, and swapped the light left extractor spring for the medium weight firing pin return spring.

So far, so good

As guns are assembled by hand, I’m wondering if human error placed the mid weight spring on the firing pin, can’t say as I don’t have multiples to examine.Thanks, good to know the interchangeability aspect. I sent Bergara CS an email over the holiday. Hopefully I can get a spring set from them. Worse case, I'll spec out the factory springs and order some upgrades on McMaster Carr.

I love mine, and don’t mind doing whatever it takes to make it even better.

Agreed. It's worth the effort. My Vudoo is smoother but I like the B14R better in many ways.As guns are assembled by hand, I’m wondering if human error placed the mid weight spring on the firing pin, can’t say as I don’t have multiples to examine.

I love mine, and don’t mind doing whatever it takes to make it even better.

I Love mine. Had it with me last time at the range working with my new 6ARC barrel.Agreed. It's worth the effort. My Vudoo is smoother but I like the B14R better in many ways.

While waiting for the ARC to cool I was just playing in the wind with the B14R (8mph + from 9 & gusty). Was trying to shoot fast to stay between gusts @100y with SK LR match.

The B14R hurts a lot of FUD feelings this time of year. When they walk down to the 100 berm to check groups on their hunting rigs and realize a 22LR smoked their groups in the wind

I got my B14R in February of 2020. Serial number ends in -19. I staked my ejector over a year ago when I got a MPA chassis for it and had the action out of the stock. I probably have 7500 plus rounds through the gun. Last match I had a failure to eject. Today sighting in a new scope I had 3 FTEs in about 100 rounds. At the range I pulled the bolt out and noticed the left side claw spring felt very wimpy compared to right side extractor claw. Came home and googling came across this thread. I tested cycling empty cases and am not seeing them drag across the next round in the mag or the mag itself. I think I will beef up the left side claw with some detent spring and see if my problem goes away.The B14R hurts a lot of FUD feelings this time of year. When they walk down to the 100 berm to check groups on their hunting rigs and realize a 22LR smoked their groups in the wind, priceless!

357max thanks for the info and good write up.

I got my B14R in February of 2020. Serial number ends in -19. I staked my ejector over a year ago when I got a MPA chassis for it and had the action out of the stock. I probably have 7500 plus rounds through the gun. Last match I had a failure to eject. Today sighting in a new scope I had 3 FTEs in about 100 rounds. At the range I pulled the bolt out and noticed the left side claw spring felt very wimpy compared to right side extractor claw. Came home and googling came across this thread. I tested cycling empty cases and am not seeing them drag across the next round in the mag or the mag itself. I think I will beef up the left side claw with some detent spring and see if my problem goes away.

357max thanks for the info and good write up.

My B14R SN: ends in -20. My ejector has some backlash. About .003" side to side and .020" for and aft. I have never staked it. The left side bolt finger

has a rate of about 75% of the right side. I have 100% ejection and zero issues with it. Though not as pretty as my V22 was, it is more accurate. I put my

B14R in my Vudoo MDT LSS chassis and a Trigger Tech Diamond and it made no difference at all. So, I kept my Bergara in it's stock configuration.

Later I did swap out the trigger to a Jewell HVR. Currently set to 6 ounces. I also have the old square cut slot in my bold. I wish I had the revised

round bottom slot but it has yet to cause any problems. My tolerance for FTE would be near ZERO in any gun. Or FT extract from a match chamber.

I have ZERO issues with that as well. I think I paid $975.00 for mine and it has been a great value.

As for post #186.... I tried putting in a long nose spring plunger into the rear screw hole. That was to defeat most of the factory torsion spring weight.

Mine worked well but Dan had issue's . That forced me to open the trigger up and I found that adding a #4-40 set screw is ill advised. The MIM trigger

blade and other parts are soft and the sear surfaces are rounded over. They don't appear to have been finish ground. I thought of a way to do the mod safely for the average person but that is a different post.

Attachments

Last night I put the detent spring in to stiffen the left side extractor. I'd say it is about 80% as strong as the right now. Interestingly now I have the empties contacting the empty mag feed lips. Couple passes with a needle file and I shaped the lips where the empty does not make contact. I am noticing now even if I very gently move the bolt to the rear it takes a good bit of force to eject and the empty flies right out

Attachments

Last edited:

Similar threads

- Replies

- 17

- Views

- 994

- Replies

- 3

- Views

- 827

- Replies

- 15

- Views

- 695