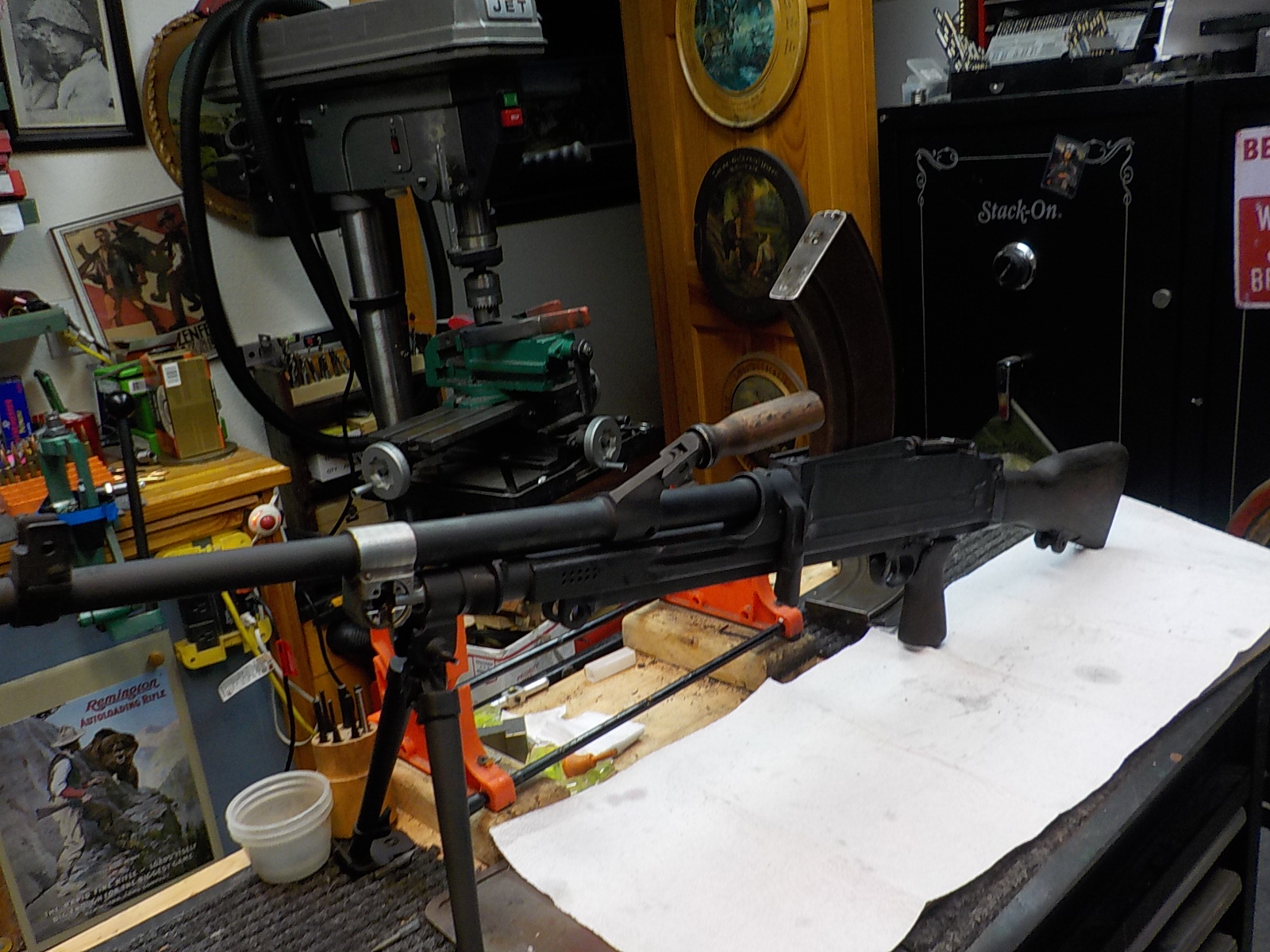

OK, last two days nothing but problems and headaches...but I got it all sorted out and everything works. First, the above mentioned problem with the scope not fitting in the rings. Fixed. My mag catch came yesterday. Slipped right in, fit perfect, done in five seconds. Now to go out and sight in the scope. Wasn't looking forward to it. I knew the rings were mounted in the correct position as I test fired using a Nikon scope, no problem. The No.32 has an arcane zeroing procedure. It involves special tools. I've done this before for my No. 4T Enfield sniper. Basically, you adjust the crosshairs by removing the knobs (turrets) and adjusting a "lead" screw. Once that is done, you install the turrets at the zero. The turrets have minimal adjustment once you re-install them. Anyway, the scope wasn't too far off so it should be no problem making the adjust. However, I was having problems getting the gun to shoot semi-auto. There were a miscellany of problems...gun wouldn't cycle enough to extract and eject the empty, gun would cycle, but the striker wouldn't catch the sear for the next shot, gun would cycle, but would double and then stop. So the scope goes on the back burner...it was only shooting a foot high and 6 inches to the left so it would be no problem making the correction and I could deal with it for now by just holding low and to the right.

So my first reaction is that the springs just need some fine tuning. Shortening the recoil spring should help the gun cycle. Shortening the striker spring should make it easier for the striker to move far enough back to catch the sear. These springs work together and it is a trick getting the right balance. Fortunately, I had quite a bit of spring on hand and could cut and re-cut with abandon. Well, after about 50 rounds I still basically had a single shot rifle. So, I quit for the day and started again this morning. I now moved my theory from springs to just not enough gas pressure. I tried opening up the gas block, and a myriad of other things but I still had a single shot rifle that would feed, fire, extract, eject, but the striker would not catch. Then it dawned on me...a blinding glimpse of the obvious. I had exactly the same problem when I built my semi-auto Sten gun. And I went thru exactly the same frustrating process...until I realized the disconnector was too low. Same problem here. I had taken too much off the disconnector when I radiused it so the striker could move over it smoothly. So, out to the barn and welded a glob of metal on top of the disconnector...literally a blob of metal. Took it inside and cleaned it up a little so the striker could ride over it, took it outside and...Bam, Bam Bam. Fixed. I ordered a new disconnector for $10. The blob disconnector will do for now. I also milled a new striker and need to heat treat that. Shooting video to follow in a couple of days