Yes. I believe so. If I have my chamber terminology correct, the upper part of the previous photo is the end of the neck area, and the part just below the lip in the bottom is the freebore before you see the lands and grooves (leade?). Here are some additional snaps. This is from an AI-AT .260 Bartlein barrel (Gradous) with about 1800-2000ish rounds through.Where did you take that picture at? Is that at the case mouth junction? That's what it looks like to me. Let me know.

Before attacking the Carbon ring

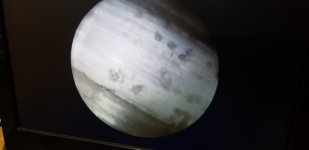

After soaking the chamber with a nylon 9mm brush wrapped in a patch soaked with Boretech C4 Carbon remover for about 45 min:

I bought some CLR in case the C4 didn't get it out. But the Boretech C4 worked like a champ. I just left the patch/brush w/ C4 in the chamber for a while and then gave it a few twists by hand, patched it out and then re-scoped it and viola!

Last edited: