I was shooting Copper jacketed bullets covered with JB bore paste [pushed slowly by 9 gr. Bullseye] to try to break in a couple barrels;

a) Douglas 260 with factory bluing inside the bore that fouled too fast

b) a Midway Addams and Bennett 243 barrel that fouls fast.

I got this idea form Greg Langelius on an internet list 10 or 12 years ago.

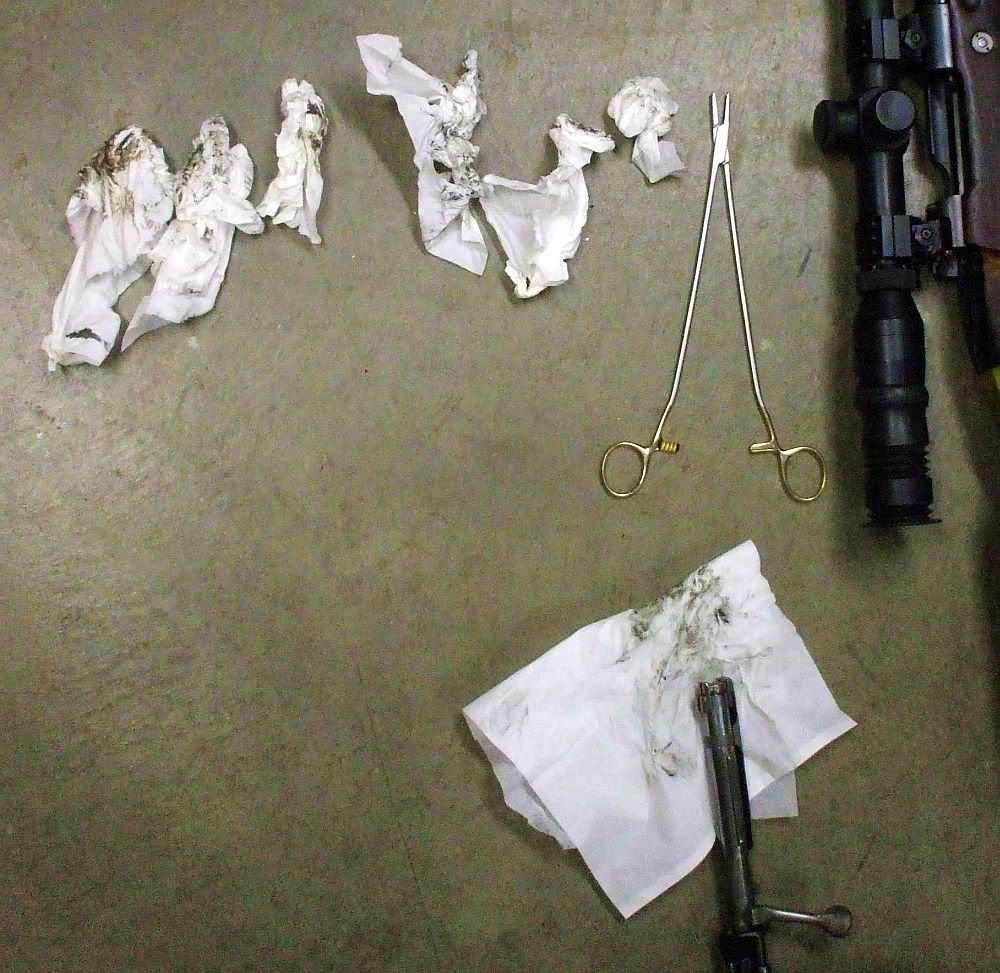

After 20 some rounds in each rifle, the JB bore paste was all over the empty cases and all over the bolt lugs.

The bolt lugs are a male shape, and can be wiped off with a Kleenex with a couple twists of the wrist in a few seconds.

But getting the female shape of the receiver clean is harder. My old technique of poking into the lug abutments with a Q-tip is slow and ineffective.

Someone gave me a 10" pair of locking forceps.

I poked a Kleenex inside the lug race, poked in the open forceps behind, locked onto the Kleenex, twisted both 10 times, pulled out the Kleenex, and it was dirty. I repeated this 5 more times until the Kleenex came out clean.

Now the bolt slides in and out nicer. I did not know I had such a smooth action.

Forceps are cheap, and handy for cleaning with Kleenex down inside holes:

http://www.amazon.com/Papa-JohnS-Toolbox-Forceps-Straight/dp/B0009UD7RY