@spife7980 and I both told you to clean it and asked about your chamber for a reason.Tell me more about this carbon ring stuff.

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Help Needed - Sticky Bolt CLOSE

- Thread starter roosterpig

- Start date

-

- Tags

- .308 win reloading sticky bolt

Gracias. Devising a plan to identify and clean it now. Gonna try to hook an old cleaning rod to a drill with some good solvent.@spife7980 and I both told you to clean it and asked about your chamber for a reason.

Its eaten hundreds of rounds of FGMM and dozens of various other factory loads. It’s due for a good cleaning.

I guess I can’t just beat on it like an AR.

I will heed this advice and make a lot of passes.Please don't use a drill.

Do you recommend a particular cleaning product? Or combination of products?

Appreciate it!

Yeah, don't use a drill. Just use a nylon brush and a good solvent then patch it out.I will heed this advice and make a lot of passes.

Do you recommend a particular cleaning product? Or combination of products?

Appreciate it!

10-4 thank you.Yeah, don't use a drill. Just use a nylon brush and a good solvent then patch it out.

Not necessarily.. I just started loading 175SMK for my Criterion barrel. FGMM 175s chamber fine at an average 2.800" COAL. I made some reloads that were 2.800" COAL and they were sticky closing the bolt. Headspace wasn't the issue. Took out the FP and ejector and tried again.. Found out I had to seat them to around 2.780" to get the bullet out of the lands. So the profile on my SMKs are different than the ones used by Federal in their FGMM.At 2.800" COAL the bullet ogive is miles from the lands in a Rem 700. If those marks are from the chamber something is seriously wrong.

THIS is very very interesting.Not necessarily.. I just started loading 175SMK for my Criterion barrel. FGMM 175s chamber fine at an average 2.800" COAL. I made some reloads that were 2.800" COAL and they were sticky closing the bolt. Headspace wasn't the issue. Took out the FP and ejector and tried again.. Found out I had to seat them to around 2.780" to get the bullet out of the lands. So the profile on my SMKs are different than the ones used by Federal in their FGMM.

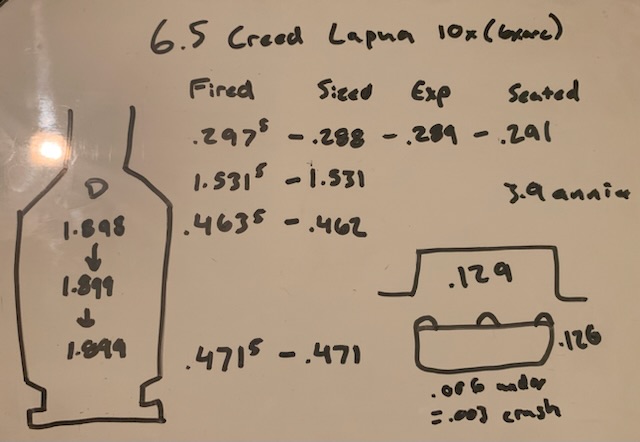

Measure your brass. That will tell you if your issue is with the case or not. Compare fired dimensions to sized, they should all get smaller.

After that find the distance to the lands with your bullets in your barrel. Once you know where those are you can avoid jamming it.

After that find the distance to the lands with your bullets in your barrel. Once you know where those are you can avoid jamming it.

Are the marks all the way round or just one side.THIS is very very interesting.

If one side do they line up with ejection port

Do the marks go away if you hold the cartrage centered while ejecting

No drill!Gracias. Devising a plan to identify and clean it now. Gonna try to hook an old cleaning rod to a drill with some good solvent.

Its eaten hundreds of rounds of FGMM and dozens of various other factory loads. It’s due for a good cleaning.

I guess I can’t just beat on it like an AR.

For carbon ring I use CLR on a patch and soak 15-20 mins, then patch out and clean well with solvent. Do not leave any behind or get in you action.

Leave no oil in chamber as you want the brass to grip the walls.

Below is the ring that I get. Some folks get one near the lands but I have no experience with that.

Carbon ring build up not only forms between the case neck mouth and the chamber's second shoulder, but it also builds up in the throat area up to the lands. . . especially if one is not cleaning the bore often enough. Normal cleaning usually takes care of that and still leave the "carbon ring".No drill!

For carbon ring I use CLR on a patch and soak 15-20 mins, then patch out and clean well with solvent. Do not leave any behind or get in you action.

Leave no oil in chamber as you want the brass to grip the walls.

Below is the ring that I get. Some folks get one near the lands but I have no experience with that.

View attachment 8095530

To get the the carbon ring out of my rifle, I've found that a little bit of short stroking with a nylon brush (a heavy duty blue bore brush) and a little iosso bore cleaner on it gets the job done nicely.

Thanks. I added a couple of the nylon brushes and the tube of paste from Iosso to my midway cart.Carbon ring build up not only forms between the case neck mouth and the chamber's second shoulder, but it also builds up in the throat area up to the lands. . . especially if one is not cleaning the bore often enough. Normal cleaning usually takes care of that and still leave the "carbon ring".

To get the the carbon ring out of my rifle, I've found that a little bit of short stroking with a nylon brush (a heavy duty blue bore brush) and a little iosso bore cleaner on it gets the job done nicely.

I’m going to try this again tonight with fresh brass, fresh projo, and get some answers. Thanks for following up.Are the marks all the way round or just one side.

If one side do they line up with ejection port

Do the marks go away if you hold the cartrage centered while ejecting

Use brake or carb cleaner to remove all oils?No drill!

For carbon ring I use CLR on a patch and soak 15-20 mins, then patch out and clean well with solvent. Do not leave any behind or get in you action.

Leave no oil in chamber as you want the brass to grip the walls.

Below is the ring that I get. Some folks get one near the lands but I have no experience with that.

View attachment 8095530

I use KG gun solvent but brake cleaner is fine. Put some on a patch and keep it off everything else.Use brake or carb cleaner to remove all oils?

You can use a marker on a piece previously scuffed too. Just give the bullet a coating with the marker.I’m going to try this again tonight with fresh brass, fresh projo, and get some answers. Thanks for following up.

Sounds like you're on the right track learning about headspace and carbon ring.. Lot of good videos out there from reputable folks, I'm always learning something new.THIS is very very interesting.

For my issue.. I decided to make a video... My FGMM is circa 2016. Pulled one bullet, just one so it's a limited test, but the base to ogive (BTO) on the bullet was .631", my box of 175gr SMKs have a BTO of around .660", almost 30 thou diff. So my issue is explained by the differing bullet profile and an apparent short distance to lands. Rifle is a Remage 308 with a McRee Precision match barrel. Here's the video:

Ran it through twice. Definite markings on the shoulder. What was suspected ejection markings are somewhat confirmed here with the long running marks in the sharpie on the projo.You can use a marker on a piece previously scuffed too. Just give the bullet a coating with the marker.

Attachments

I’ve run about 30 trimmed patches, soaked with No. 9. She’s cleaner than when we started. Waiting for my long brushes to arrive from midway. None at LGS unfortunately. Also got one .338 cal brush for the chamber.@spife7980 and I both told you to clean it and asked about your chamber for a reason.

Sounds like you're on the right track learning about headspace and carbon ring.. Lot of good videos out there from reputable folks, I'm always learning something new.

For my issue.. I decided to make a video... My FGMM is circa 2016. Pulled one bullet, just one so it's a limited test, but the base to ogive (BTO) on the bullet was .631", my box of 175gr SMKs have a BTO of around .660", almost 30 thou diff. So my issue is explained by the differing bullet profile and an apparent short distance to lands. Rifle is a Remage 308 with a McRee Precision match barrel. Here's the video:

Woah your action is smooth like glass. Awesome. This Remington is… uh… less distinguished.

The ejector and firing pin are removed.. It's the best way to feel what's going on because you don't have the ejector jamming the round to one side, or the pressure of the firing pin assembly pushing back.Woah your action is smooth like glass. Awesome. This Remington is… uh… less distinguished.

Makes sense. I was wondering if your knob was made of lead lol.The ejector and firing pin are removed.. It's the best way to feel what's going on because you don't have the ejector jamming the round to one side, or the pressure of the firing pin assembly pushing back.

Well we have moved around here a bit in this thread. Do you have a headspace tool to measure with and a piece of fired brass to compare with you sized brass.Ran it through twice. Definite markings on the shoulder. What was suspected ejection markings are somewhat confirmed here with the long running marks in the sharpie on the projo.

Refresh my memory, is the bolt sticky only after firing or does it close hard on the round?

Hey Max. Happy Monday.Well we have moved around here a bit in this thread. Do you have a headspace tool to measure with and a piece of fired brass to compare with you sized brass.

Refresh my memory, is the bolt sticky only after firing or does it close hard on the round?

Closing hard on the round. Have not fired any of the reloads.

Waiting for midway to deliver headspace comparator head. 9 mil case wasn’t quite as repeatable as I’d like.

Assuming that you are using 7/8x14 dies, half a turn should get you about 35 thousands. Doing the math:Knocked the shoulder back another 7 thou. Full half turn of the die.

Still difficult to chamber. Not as difficult as it originally was. But not smooth like a factory load.

I’m beginning to wonder if these old RCBS dies from my dad are old/worn/rusted and cleaned enough to be out of spec. I guess the headspace gauge will help with that.

one divided by fourteen equals 0.0714 so one turn is 0.714

0.0714 divided by one half a turn is 0.0357.

But a half-turn got you only 7 thou, not 35 thou. Something is strange. Your shell holder dimension measured from the bottom of the case to the top of the shell holder may be unusually thick - perhaps it is a different brand? Another thought, you said the dies are old. Maybe they expect a different shell holder.

Also your measurement of FGMM was 2.209 and for your cases it was 2.216 - that is 7 thou difference and that is plenty enough to make it hard to close the bolt handle - 2 thou is enough. Check your shellholder, is it the right one for 308? If RCBS, it should be a #3. See if you can find or borrow different dies and shell holder.

I don't know what to make of that "belling" on the case mouth. My first reaction is that the chamber is too short but I just don't believe it. If you want to test that theory, trim a case to 2.000 or 1.995, FL size, check for belling in the die, chamber, check again for belling in the chamber. If it is gone then there is something strange about your die or your chamber.

Hey Bax.Assuming that you are using 7/8x14 dies, half a turn should get you about 35 thousands. Doing the math:

one divided by fourteen equals 0.0714 so one turn is 0.714

0.0714 divided by one half a turn is 0.0357.

But a half-turn got you only 7 thou, not 35 thou. Something is strange. Your shell holder dimension measured from the bottom of the case to the top of the shell holder may be unusually thick - perhaps it is a different brand? Another thought, you said the dies are old. Maybe they expect a different shell holder.

Also your measurement of FGMM was 2.209 and for your cases it was 2.216 - that is 7 thou difference and that is plenty enough to make it hard to close the bolt handle - 2 thou is enough. Check your shellholder, is it the right one for 308? If RCBS, it should be a #3. See if you can find or borrow different dies and shell holder.

I don't know what to make of that "belling" on the case mouth. My first reaction is that the chamber is too short but I just don't believe it. If you want to test that theory, trim a case to 2.000 or 1.995, FL size, check for belling in the die, chamber, check again for belling in the chamber. If it is gone then there is something strange about your die or your chamber.

Awaiting a real headspace comparator to get a more definitive measurement. Who knows how good the wobbly spent 9mm case was doing

It’s an RCBS #3.

Considering buying new dies. But not until I verify this isn’t just a headspace issue due to my early onset dumbassnes.

If you have a fired and unsized case, reset the dies like the instructions said to. Then size a case. Then disassemble your bolt. Remove the firing pin and ejector. With the bolt out, stick the sized case under the lip on the bolt face. Insert bolt and case into the reciever and see how far the bolt will close. Do not force it. You can also cover the sized case with a sharpie to see were the case is hanging up. If the bolt will not close and there are no marks on the case, turn your die in an 1/8 of a turn until the bolt will close under it's own weight. Don't force it. Google wheeleraccurace click test for a video of what I'm trying to say.

Last edited:

I’ll be tinkering at the bench tonight. Will try this.If you have a fired and unsized case, reset the dies like the instructions said to. Then size a case. Then disassemble your bolt. Remove the firing pin and extractor. With the bolt out, stick the sized case under the lip on the bolt face. Insert bolt and case into the reciever and see how far the bolt will close. Do not force it. You can also cover the sized case with a sharpie to see were the case is hanging up. If the bolt will not close and there are no marks on the case, turn your die in an 1/8 of a turn until the bolt will close under it's own weight. Don't force it. Google wheeleraccurace click test for a video of what I'm trying to say.

Honestly, never taken the bolt apart so that’ll be a fun YouTube how to.

Thanks!

Everything is pointing to that shoulder not pushing back far enough.Hey Max. Happy Monday.

Closing hard on the round. Have not fired any of the reloads.

Waiting for midway to deliver headspace comparator head. 9 mil case wasn’t quite as repeatable as I’d like.

Closes ok with factory? No resistance?

Yes sir. No resistance at all with factory FGMM.Everything is pointing to that shoulder not pushing back far enough.

Closes ok with factory? No resistance?

To remove the firing pin, use a boot lace loop(foot laced in boot) to pull back the firing pin then unscrew it. The ejector needs a pin punch to remove. It is spring loaded so watch out. You can use a piece of brass hooked under the extractor to compress the ejector.

@roosterpig here you go. We probably should have done this from the start. *** Wear eye protectionTo remove the firing pin, use a boot lace loop(foot laced in boot) to pull back the firing pin then unscrew it. The ejector needs a pin punch to remove. It is spring loaded so watch out. You can use a piece of brass hooked under the extractor to compress the ejector.

Always another tool to buy. Time for some punches.

Try a small nail. Make sure to grind the tip flat.Always another tool to buy. Time for some punches.

I’m sure I could get the roll pin OUT. It’s the getting it back in that worries me w/o roll pin punches.Try a small nail. Make sure to grind the tip flat.

Hey Spife. Missed your reply earlier. Will definitely be measuring bump as soon as headspace comparator comes in from midway. Thanks for the pic. Good stuff.Measure your brass. That will tell you if your issue is with the case or not. Compare fired dimensions to sized, they should all get smaller.

View attachment 8095519

After that find the distance to the lands with your bullets in your barrel. Once you know where those are you can avoid jamming it.

1. Don't switch dies just yet.

2. The case mouth belling could be caused by having your decapping stem too deep. The expander can have a flare at the top of the expander.

3. If you can't screw the die in deep enough with cam over, trim the top of the shell holder.

4. Once you get close to proper shoulder setback, the brass will actually lengthen a couple of thousands just before its correct.

2. The case mouth belling could be caused by having your decapping stem too deep. The expander can have a flare at the top of the expander.

3. If you can't screw the die in deep enough with cam over, trim the top of the shell holder.

4. Once you get close to proper shoulder setback, the brass will actually lengthen a couple of thousands just before its correct.

Measure both cases and find out where the difference is.Tinkering with this RCBS gauge. Interesting finding… some loads fit and some don’t.

Cool little tool.

I’m not certain that the case mouth is belled. Attached pic of sized piece and a piece with seated projectile.1. Don't switch dies just yet.

2. The case mouth belling could be caused by having your decapping stem too deep. The expander can have a flare at the top of the expander.

3. If you can't screw the die in deep enough with cam over, trim the top of the shell holder.

4. Once you get close to proper shoulder setback, the brass will actually lengthen a couple of thousands just before its correct.

Also attached pic of expander.

Will know a lot more when this comparator arrives

Attachments

That expander ball looks to me like it could be part of the problem. Most expander balls tend to produce issues, particularly for those new to reloading. Expander ball have to be set up just right to work properly and can be very finicky. One of the things I don't like about them is even when they work as designed, as they pull through the neck they tend to impart a lot of runout on the neck.I’m not certain that the case mouth is belled. Attached pic of sized piece and a piece with seated projectile.

Also attached pic of expander.

Will know a lot more when this comparator arrives

To solve this issue, I no longer use an expander ball in my sizing dies (no expander ball, no spindle with decapper . . . decapping is done with a different die as my first operation before annealing and cleaning). After sizing the case, the neck is compressed to a smaller diameter, of course. Then I use a expander mandrel to size the neck to the neck tension I'm after. I've always got very good results doing this way. It's extras steps that a sizing die with expander ball and decapper provides, but if you're after good results, speed is not as important.

FYI: In you're first pictures, I thought maybe you still had a burr on the outside of the case mouth. I often check for such a thing by simply running my fingernail lightly along the neck up past the case mouth and if there's a burr, it can easily be felt.

BTW, when you get your comparator, keep in mind that it's a "comparator" that you can compare YOUR various measurements. What I get with my comparator can be very different that what you get with yours. It's NOT a precision instrument. So, if you're measuring from a fired case from base to the shoulder datum and getting 1.604 and someone tells you it should be 1.630, don't be alarmed. The best way to tell how your comparator compares to an accurate measurement is best done by using your comparator on a go or no-go gauge, where you can see the difference. Again, the comparator is comparing your own measurements and is plenty accurate in that way for you needs.

Thanks for the info. I decap using a Lee universal decapping die (so that I can once clean the brass before resizing and not get sizing die as dirty), and just figured I’d let the expander stay in the resizing die so it’s thing since I don’t have an expander mandrel.That expander ball looks to me like it could be part of the problem. Most expander balls tend to produce issues, particularly for those new to reloading. Expander ball have to be set up just right to work properly and can be very finicky. One of the things I don't like about them is even when they work as designed, as they pull through the neck they tend to impart a lot of runout on the neck.

To solve this issue, I no longer use an expander ball in my sizing dies (no expander ball, no spindle with decapper . . . decapping is done with a different die as my first operation before annealing and cleaning). After sizing the case, the neck is compressed to a smaller diameter, of course. Then I use a expander mandrel to size the neck to the neck tension I'm after. I've always got very good results doing this way. It's extras steps that a sizing die with expander ball and decapper provides, but if you're after good results, speed is not as important.

FYI: In you're first pictures, I thought maybe you still had a burr on the outside of the case mouth. I often check for such a thing by simply running my fingernail lightly along the neck up past the case mouth and if there's a burr, it can easily be felt.

BTW, when you get your comparator, keep in mind that it's a "comparator" that you can compare YOUR various measurements. What I get with my comparator can be very different that what you get with yours. It's NOT a precision instrument. So, if you're measuring from a fired case from base to the shoulder datum and getting 1.604 and someone tells you it should be 1.630, don't be alarmed. The best way to tell how your comparator compares to an accurate measurement is best done by using your comparator on a go or no-go gauge, where you can see the difference. Again, the comparator is comparing your own measurements and is plenty accurate in that way for you needs.

Instead of reloading, they should call this hobby “Rabbit Hole Drilling”. Always finding another needed tool.

Note taken on the comparator. Just hoping I can get proficient enough to start seeing a .002 difference between once fired brass and resized brass.

The bullet seating die being set to low can buldge out the shoulder.

YOU HAVE SOLVED MY PROBLEM.The bullet seating die being set to low can buldge out the shoulder.

Set up the seating die by inserting a piece of sized brass, lowering the die to the brass, and then adjusting the seating stem to 2.800 COAL.

It feeds!

I can’t thank all of you enough for the support. Learned best practices for shoulder bumping, seating, cleaning. All in one thread. Thank you everyone!

I use the same decapping die. I works great.Thanks for the info. I decap using a Lee universal decapping die (so that I can once clean the brass before resizing and not get sizing die as dirty), and just figured I’d let the expander stay in the resizing die so it’s thing since I don’t have an expander mandrel.

Yup, a "rabbit hole" indeed . . . especially if you really get into precision reloading.Instead of reloading, they should call this hobby “Rabbit Hole Drilling”. Always finding another needed tool.

If you have a good caliper (not one of the cheap one's), it'll be a breeze.Note taken on the comparator. Just hoping I can get proficient enough to start seeing a .002 difference between once fired brass and resized brass.

Similar threads

- Replies

- 5

- Views

- 185

- Replies

- 15

- Views

- 740

- Replies

- 21

- Views

- 862

- Replies

- 16

- Views

- 1K