Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Mk 13 Mod 0 stock

- Thread starter pmclaine

- Start date

Certificates that are being mailed out to people, and I've verified the authenticity of each stock. I still have 8 more stocks to look at and issue certificates for. Pretty crazy that another 18+ original Mk13 McMillan stocks have surfaced! I'll post a photo of the next 8 certificates when I'm done with them.This means that I only have about 20 unserialized certificates left to match up with original Mk13 McMillan stocks. As per usual, those will all be first come first served. I don't charge a single penny for these certificates (I even pay to have the certificates shipped to the stock owners), and they can add thousands of dollars in value to each original stock!

Thanks again to everyone who reached out to me with a stock from this newly discovered batch! I'm extremely happy to be able to help all of you out!

Thanks again to everyone who reached out to me with a stock from this newly discovered batch! I'm extremely happy to be able to help all of you out!

Little bit of progress being made on the latest Mk13 project. Huge thanks to @USMCSGT0331 for the extremely generous help with the cert. Truly appreciated.

Now back to scrounging for parts.

Now back to scrounging for parts.

Finished up some tweaking on my mod 3 today to get it a little closer to “clone correct”. Only other thing is the collar was installed with the latch cuts horizontal instead of vertically for some reason. I’m not sure if it can be rotated or not. Either way I’m super happy with it.

Attachments

Did you purchase one of the pre-made barrel journals to install on the barrel? Or did you get a barrel complete from @crazynoto? I've seen this happen before with the loose barrel journals that have the gate latches channels pre-cut into the journal. It looks like the barrel was installed on your receiver, the gunsmith screwed on a loose barrel journal, and then just said "good enough."Finished up some tweaking on my mod 3 today to get it a little closer to “clone correct”. Only other thing is the collar was installed with the latch cuts horizontal instead of vertically for some reason. I’m not sure if it can be rotated or not. Either way I’m super happy with it.

View attachment 8677032

The crazynoto barrels don't have the gate latch cuts in them, so a gunsmith installs the barrel like normal, then mounts the barreled action into a jig, and then cuts the vertical gate latches. Hell, even just flipping the barreled action upside-down to rest on the top picatinny rail would give a pretty good vertical alignment for the gate latch cuts. If the barrel was already installed and the gunsmith was fitted a pre-made pre-cut loose barrel journal, then he should have timed the barrel journal cuts vertically to the receiver.

The point is that a gunsmith should NEVER allow a barrel to leave his shop like that, they're very easy to time, no matter which way the journal was added to the barrel. I would have immediately sent the rifle back to have the barrel timed properly. This can be a lesson for other cloners, NEVER accept sub-par work from a gunsmith. This was very easy to prevent, and it's very easy to fix. It should have never left the shop looking like this.

Unfortunately, if your gunsmith marked the sides of the barrel with a caliber or other information, the markings will now be off if the barrel is turned and timed for your gate latch. So, you can easily have a gunsmith fix the problem, but if the barrel is marked horizontally as it sides now, the gunsmith will also have to fix the markings.

There's a few ways to do this, either put the barrel on a lathe and turn down the back end to get rid of the markings, and then blend that turned down area into the rest of the barrel to keep the same profile. Or the markings can be spot welded and cleaned up. The latter will show through bluing and parkerizing, and can be seen in raw steel. But it won't matter if you powder coat or paint the barrel. The gunsmith will have to be extremely careful to take his time spot welding the markings if you go this route because the high heat can ruin the barrels tempering.

I hope this information helps and I hope that you can get it fixed. It doesn't take a crazy amount of rounds to burn out a .300WM barrel. So, shoot the shit out of that barrel, order a new Mod 3 barrel from crazynoto WITHOUT the pre-cut gate latch channels, and then have a different gunsmith install the new barrel and properly do the vertical gate latch cuts.

I am actually planning another run of mk13 mod 3 barrels. I am only planning on doing this if I get at least 20 requests with deposits to proceed (due to the amount of work to manufacture / modify the barrels).

This time a new blank will be utilized that I will supply. Previously I had issues with the variation of the taper of the barrel blanks that were customer supplied to me, only 50% - 60% of the barrels were able to be modified properly to my standards. Additionally I had to continuously adjust the lathe settings per barrel to find the "sweet spot" to complete the modification, this adde hours to each individual barrel set up.

I will be ordering custom blanks that will have a max material condition to properly complete the modification. The barrel will be delivered to you with the collar installed and suppressor profiling complete, and extra material length on the breach / crown ends for your gunsmith. The barrels will have NO chambering, breach end threading, gate latch cuts, alignment pin, or muzzle crown this is up to you or your gunsmith to complete during the building process.

It is looking like the completed price for the barrels will be right around $1k , I will be collecting a $450 deposit each barrel ordered.

Lilja's lead time for the barrel blanks is 10-12 weeks after I take delivery my lead time will be 4-6 weeks for the modifications, hopefully these lead times will be slightly shorter and not slightly longer.

Please PM me with if you are interested with the subject "MK13 mod 3 barrel" and your basic information (name phone number), and quantity. If you PM'd me before please send another PM with that information.

I will not be collecting any deposits unless there is enough interest, I will post a running tally of who is interested (screen name and qty) so we can keep track to make sure no one is accidentally missed and that the quantities are correct. If you decide you are no longer interested please PM me and I will remove you from the list.

Please keep in mind this is a side hobby in addition to my profession and it may take me 24-48 hours to respond to PM's and update the list. If anyone has any additional questions please feel free to reach out to me. So we don't clutter up this thread I will start a new one for the barrel pre order if I receive enough interest/ PM's.

Thanks

5/15/25 update I currently have 12+13 people interested in barrels.

This time a new blank will be utilized that I will supply. Previously I had issues with the variation of the taper of the barrel blanks that were customer supplied to me, only 50% - 60% of the barrels were able to be modified properly to my standards. Additionally I had to continuously adjust the lathe settings per barrel to find the "sweet spot" to complete the modification, this adde hours to each individual barrel set up.

I will be ordering custom blanks that will have a max material condition to properly complete the modification. The barrel will be delivered to you with the collar installed and suppressor profiling complete, and extra material length on the breach / crown ends for your gunsmith. The barrels will have NO chambering, breach end threading, gate latch cuts, alignment pin, or muzzle crown this is up to you or your gunsmith to complete during the building process.

It is looking like the completed price for the barrels will be right around $1k , I will be collecting a $450 deposit each barrel ordered.

Lilja's lead time for the barrel blanks is 10-12 weeks after I take delivery my lead time will be 4-6 weeks for the modifications, hopefully these lead times will be slightly shorter and not slightly longer.

Please PM me with if you are interested with the subject "MK13 mod 3 barrel" and your basic information (name phone number), and quantity. If you PM'd me before please send another PM with that information.

I will not be collecting any deposits unless there is enough interest, I will post a running tally of who is interested (screen name and qty) so we can keep track to make sure no one is accidentally missed and that the quantities are correct. If you decide you are no longer interested please PM me and I will remove you from the list.

Please keep in mind this is a side hobby in addition to my profession and it may take me 24-48 hours to respond to PM's and update the list. If anyone has any additional questions please feel free to reach out to me. So we don't clutter up this thread I will start a new one for the barrel pre order if I receive enough interest/ PM's.

Thanks

5/15/25 update I currently have 12+13 people interested in barrels.

Last edited:

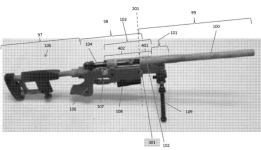

Second picture below is a new barrel compared to an original take off. All dimensions were taken from the original barrel and an original blue print.

Last edited:

have one of these on my mk13-3 and can attest to the quality. If you want the most historically accurate mk13-3 - this is 100% the route you want to take.

Just like @ilikebmxbikes said in his post above, these are the absolute best Mk13 Mod 3 barrels that collectors/cloners can possibly get! If any of you need a Mod 3 barrel, contact @crazynoto asap and get one the list. Who knows if this will be the last run or not, so grab 1 or 2 while you still can!Second picture below is a new barrel compared to an original take off. All dimensions were taken from the original barrel and an original blue print.

View attachment 8677694View attachment 8677695View attachment 8677696View attachment 8677697

If you already have a built rifle, it's still a good idea to get in on this deal and pick up an extra barrel. It's pretty easy to shoot out a .300WM barrel, so having a spare barrel or two on hand and ready to go is a great backup option to have. And if this turns out to be the last run of these barrels, any loose barrels will drastically increase in price over the coming years. Just a few other things to think about.

It was extremely surprising when @crazynoto found his original Mod 3 barrel, since it's currently the only original Mk13 Mod 3 barrel in private hands. He sent me tons of photos and we spent countless hours going over the smallest of details. That analysis paid off because we discovered exactly how the original Mod 3 barrels were made! This isn't just a look-alike or something that's close to the originals, it's an EXACT reproduction of the original Mod 3 barrels! This is the only place to get one, and @crazynoto has gone through great lengths to order the barrel blanks in the exact specs he needs to make these clone barrels.

Once a gunsmith installs this clone Mod 3 barrel on your rifle and does the vertical gate latch cuts, it will be a 100% reproduction of the finished original military barrels. The barrel blanks come with the barrel journal already installed, so @crazynoto has already taken care of the most difficult part of the barrel that needs to be precisely duplicated.

Please ask any questions in this thread. If anyone needs a Mod 3 barrel or 2, don't pass up this opportunity!

I’ve been waiting over 2 years for this, let’s go!!I am actually planning another run of mk13 mod 3 barrels. I am only planning on doing this if I get at least 20 requests with deposits to proceed (due to the amount of work to manufacture / modify the barrels).

This time a new blank will be utilized that I will supply. Previously I had issues with the variation of the taper of the barrel blanks that were customer supplied to me, only 50% - 60% of the barrels were able to be modified properly to my standards. Additionally I had to continuously adjust the lathe settings per barrel to find the "sweet spot" to complete the modification, this adde hours to each individual barrel set up.

I will be ordering custom blanks that will have a max material condition to properly complete the modification. The barrel will be delivered to you with the collar installed and suppressor profiling complete, and extra material length on the breach / crown ends for your gunsmith. The barrels will have NO chambering, breach end threading, gate latch cuts, alignment pin, or muzzle crown this is up to you or your gunsmith to complete during the building process.

It is looking like the completed price for the barrels will be right around $1k , I will be collecting a $450 deposit each barrel ordered.

Lilja's lead time for the barrel blanks is 10-12 weeks after I take delivery my lead time will be 4-6 weeks for the modifications, hopefully these lead times will be slightly shorter and not slightly longer.

Please PM me with if you are interested with the subject "MK13 mod 3 barrel" and your basic information (name phone number), and quantity. If you PM'd me before please send another PM with that information.

I will not be collecting any deposits unless there is enough interest, I will post a running tally of who is interested (screen name and qty) so we can keep track to make sure no one is accidentally missed and that the quantities are correct. If you decide you are no longer interested please PM me and I will remove you from the list.

Please keep in mind this is a side hobby in addition to my profession and it may take me 24-48 hours to respond to PM's and update the list. If anyone has any additional questions please feel free to reach out to me. So we don't clutter up this thread I will start a new one for the barrel pre order if I receive enough interest/ PM's.

Thanks

Finally got my Mk13 action back into a stock. Traded the original stock back to someone who had been issued that S/N, was happy to link them back up!

Frank Greene noted that 3 different chambers were used by the military on the 300 WinMag rifles (each differed from SAMMI spec). Here’s my random question regarding the freebore on Mk 13 chambers. When Crane went from the Mk 248 Mod 0 chamber (190 grain SMK) to the Mk 248 Mod 1 chamber (220 grain SMK), did they change the free bore spec?

-I think the A191 chamber (circa 1993-94?) has a .108" freebore, but maybe the later chambers had a longer freebore? Did the freebore spec change over time? (PT&G offers different reamers). I know the Mk 248 Mod 1 ammo is too hot, but was curious if the freebore changed when they adopted the 220 SMK bullets (circa 2009):

-I think the A191 chamber (circa 1993-94?) has a .108" freebore, but maybe the later chambers had a longer freebore? Did the freebore spec change over time? (PT&G offers different reamers). I know the Mk 248 Mod 1 ammo is too hot, but was curious if the freebore changed when they adopted the 220 SMK bullets (circa 2009):

Mk13 mod 3 barrel order list final call

Username:

Randomguy qty1

0812guns qty 2

CoeJro qty1

Banman19 qty1

Chris22215 qty1

TheFlyingNerd qty1

Werk125 qty 3

BEJ762 qty1

Telfehunden qty1

HarryBC qty1

Mike Sullivan qty2

Not on forum:

Jeff N qty2

Jon K qty1

Please PM me if I missed your name or qty

I will start collecting deposits in a week or so.

Username:

Randomguy qty1

0812guns qty 2

CoeJro qty1

Banman19 qty1

Chris22215 qty1

TheFlyingNerd qty1

Werk125 qty 3

BEJ762 qty1

Telfehunden qty1

HarryBC qty1

Mike Sullivan qty2

Not on forum:

Jeff N qty2

Jon K qty1

Please PM me if I missed your name or qty

I will start collecting deposits in a week or so.

Last edited:

Update:

Local smith corrected the barrel timing to get the supressor cuts vertically as they should be and looks a lot better now. I cant imagine how funky a mk11 can would’ve looked sideways at the end of this thing. Picked up a 8-32 NXS while he had it and I’m happy to have it back home.

Local smith corrected the barrel timing to get the supressor cuts vertically as they should be and looks a lot better now. I cant imagine how funky a mk11 can would’ve looked sideways at the end of this thing. Picked up a 8-32 NXS while he had it and I’m happy to have it back home.

Last edited:

What am I looking at here?

Rubber oring gasket in the rear?

States 26” long… what suppressor and experimental setup was this

Rubber oring gasket in the rear?

States 26” long… what suppressor and experimental setup was this

Attachments

Thought about those two already, I could be wrong, but imo, I think the surefire OTB mount goes over/sleeves over a longer run of barrel, which the skinnier portion of barrel exposed before it jets off into bull barrel thickness is too short IMO and the the OPS suppressor profile lends itself to a tapered fit, and if you look at the side profile there are no tapers. Perhaps an early early version of it.Looks like an expiremental barrel where a surefire like sleeve collar muzzle device would be attached or maybe an ops inc style suppressor.

Something I don’t want to bother Ron about lol.

Mk13 mod 3 barrel order list final call and deposit collection.

Username:

Randomguy qty1. $ Deposit received

0812guns qty 2. $ Deposit pending

CoeJro qty1 $ Deposit received

Banman19 qty1 $ Deposit received

Chris22215 qty1. $ Deposit received

TheFlyingNerd qty1. $ Deposit received

Werk125 qty 3. $ Deposit received

BEJ762 qty1. $ Deposit received

Telfehunden qty1. $ Deposit received

HarryBC qty1. $ Deposit received

Henry Morgan qty1. $Deposit received

Molonlave qty 1. $ Deposit received

03duce qty1. $ Deposit pending

Utah45 (Jeffery N) qty 2. $ Deposit received

KFT101 qty1. $ Deposit received

Mike Sullivan qty2. $ Deposit received

lapua_guy. Qty1. ---out---

JMAR Qty1. $ Deposit received

Not on forum:

Jon Kilmer qty1 ----out-----

Please PM me if I missed your name or qty amount

You can start sending your deposits in.

I would like to have all of them collected within the next 10 to 14 days please PM (preferred) and or text for deposit payment info, (USPS MO , zelle, PayPal F&F, cash app)

Username:

Randomguy qty1. $ Deposit received

0812guns qty 2. $ Deposit pending

CoeJro qty1 $ Deposit received

Banman19 qty1 $ Deposit received

Chris22215 qty1. $ Deposit received

TheFlyingNerd qty1. $ Deposit received

Werk125 qty 3. $ Deposit received

BEJ762 qty1. $ Deposit received

Telfehunden qty1. $ Deposit received

HarryBC qty1. $ Deposit received

Henry Morgan qty1. $Deposit received

Molonlave qty 1. $ Deposit received

03duce qty1. $ Deposit pending

Utah45 (Jeffery N) qty 2. $ Deposit received

KFT101 qty1. $ Deposit received

Mike Sullivan qty2. $ Deposit received

lapua_guy. Qty1. ---out---

JMAR Qty1. $ Deposit received

Not on forum:

Jon Kilmer qty1 ----out-----

Please PM me if I missed your name or qty amount

You can start sending your deposits in.

I would like to have all of them collected within the next 10 to 14 days please PM (preferred) and or text for deposit payment info, (USPS MO , zelle, PayPal F&F, cash app)

Last edited:

Soo... Are the Mk13s sold on CMP complete fabrications of what mk13 mod3s are supposed to be?

Just looking at these 4 every single one is different. My guess is they found the receivers and bolts and built these hodgepodges from whatever spare parts they could scrape up. Some poor people are paying the same prices for these as complete untouched rifles yet what they are getting is cobbled together parts with probably less historical provenance than most high-end clone builds built on genuine return stocks.

Either that or the Mod 3 just has more varience then we understand and truly was a in between for the Mod 0 and 5 using parts of both?

Just looking at these 4 every single one is different. My guess is they found the receivers and bolts and built these hodgepodges from whatever spare parts they could scrape up. Some poor people are paying the same prices for these as complete untouched rifles yet what they are getting is cobbled together parts with probably less historical provenance than most high-end clone builds built on genuine return stocks.

Either that or the Mod 3 just has more varience then we understand and truly was a in between for the Mod 0 and 5 using parts of both?

I seem to recall a discussion on this a while back when one of the Mod 5’ish rifles hit the auction. If I recall correctly, the general understanding was they’d been used as a suppressor host during development and testing. Hence the threaded barrel and muzzle device. Also, the backwards bipod absolutely drives me nuts.

Thread on a painted one:

www.snipershide.com

www.snipershide.com

And thread/link to the analysis on the threaded barrel ones:

www.snipershide.com

www.snipershide.com

Another MK13 on CMP auction opened 1/22/24

Yet another...G65 serial number range....well marked bolt....with case......nice parts but no wear on camo painted......

And thread/link to the analysis on the threaded barrel ones:

Another MK13 on the CMP Auction

It looks like another MK13 has made the block. The one last year fetched around 18k. Any guessers on this one? Current listing

Guess we all agree they were parts/ test guns. Still cool guns just for the original mod 3 receivers/ bolts.

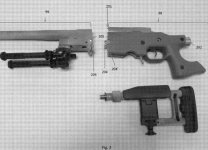

When I was super into the Mod0/5 several years ago I had pics of another MK 13 mod 5ish that I have never seen a single person post or talk about. It was a mod 5 converted to be a take down rifle. The pics I had were super neat, but my old computer blew up.

When I was super into the Mod0/5 several years ago I had pics of another MK 13 mod 5ish that I have never seen a single person post or talk about. It was a mod 5 converted to be a take down rifle. The pics I had were super neat, but my old computer blew up.

Attachments

Alright, that’s cool. I wonder if it was just tech of the time, but why build something so covert like that and not offer a suppressor?

It's only made from Mk13 parts because that's likely just what they had in house at crane. I'm not sure exactly how long the barrel is but it looks like 14 inches or so which when paired with .300 winmag is probably rather spicy and would be hard to suppress meaningly. The designer mentioned that he would prefer it to be in a different caliber like .308. Although this in 2016 and there are probably better options now. I'd imagine if they were to ever pursue it they would have a smaller caliber with a suppressor included in the kit.Alright, that’s cool. I wonder if it was just tech of the time, but why build something so covert like that and not offer a suppressor?

SEAL Team 3 Chris Kyles Mk13. Allegedly his go-to most lethal gun.

Got the MK13/15 stuff out today to reorganize storage.

Finally done, no idea when I can get a round down the barrel but I can't wait.

Seal Team 2 return stock, G prefix action. Scope is questionable but I may swap out in the future.

Seal Team 2 return stock, G prefix action. Scope is questionable but I may swap out in the future.

Nice looking rifle. My kit was scrubbed of all markings when I got it. What markings did you receive with yours to identify it?Finally done, no idea when I can get a round down the barrel but I can't wait.

Seal Team 2 return stock, G prefix action. Scope is questionable but I may swap out in the future.

View attachment 8730364

You got a pic of the entire kit? Here’s mineFinally done, no idea when I can get a round down the barrel but I can't wait.

Seal Team 2 return stock, G prefix action. Scope is questionable but I may swap out in the future.

View attachment 8730364

Last edited:

I've asked around and everyone I've talked to went off the TM2 in the magwell as seal team 2. One guy thought it may be an army training rifle but didn't really elaborate why. Under the monogram J in the right light you can see old dope written but I haven't been able to get a photo of it.Nice looking rifle. My kit was scrubbed of all markings when I got it. What markings did you receive with yours to identify it?

I really need to build out the rest of the employment kit. I know it's buried in here somewhere but does anyone have the list handy?

Chris at Redbull Armory did the build if anyone was wondering.

And a few more of the build and what came with it.

Soo... Are the Mk13s sold on CMP complete fabrications of what mk13 mod3s are supposed to be?

Just looking at these 4 every single one is different. My guess is they found the receivers and bolts and built these hodgepodges from whatever spare parts they could scrape up. Some poor people are paying the same prices for these as complete untouched rifles yet what they are getting is cobbled together parts with probably less historical provenance than most high-end clone builds built on genuine return stocks.

Either that or the Mod 3 just has more varience then we understand and truly was a in between for the Mod 0 and 5 using parts of both?

View attachment 8723685View attachment 8723686View attachment 8723691

I believe the last CMP MK13-3 was a MK13-5 development rifle. Or at least the parts suggest. It has a mk13-2 MARS rail on it and older navy lug.

This isnt one of his service rifles. He used MK13-0, MK13-3, MK13-5 and TAC338 primarily. The rifle above was the rifle scanned while making his statue. Not sure if its a personal rifle or the exact story on it.

I snagged a Mod 5 deployment kit with the G R700 trigger, blank, and 40ds of BH 2400 I believe about a year ago. Pics belowWhat’s the going price on the mod 5 chassis now days?

My kit finished up this year. The kit was sterilized when received, but based on what was in the case I believe it was an Army rifle. So built out as so.

Attachments

That scope isMy kit finished up this year. The kit was sterilized when received, but based on what was in the case I believe it was an Army rifle. So built out as so.

By far the best one I could have put on itThat scope is

Dang thats fine!Posted this in bolt too so I apologize for the double post but it might appeal to the historically minded too.

Noticed a neat sale on Ebay.

http://www.ebay.com/itm/Navy-SEAL-us...YAAOSwSlBY3TlJ

[IMG2=JSON]{"data-align":"none","data-size":"full","src":"http:\/\/i1005.photobucket.com\/albums\/af178\/pmclaine\/mk13%20mod%200_zpsz7ycqvoe.jpg"}[/IMG2]

Ive seen the McMillan return stocks from the M40s but didnt realize that the big gun parts made it into our world. Nice to build a tribute or clone that has some legit history.

Not my sale, I stick to affordable calibers, but it seemed like an item people on here would find use for if they knew about it.

The post I got that from said that was his service rifle sourced from his wife Marra. Interestingly it looks a lot like the CMP ones so maybe he was issued an early prototype. Or it is a stateside clone he commissioned after he got out trying to replicate his service guns.I believe the last CMP MK13-3 was a MK13-5 development rifle. Or at least the parts suggest. It has a mk13-2 MARS rail on it and older navy lug.

This isnt one of his service rifles. He used MK13-0, MK13-3, MK13-5 and TAC338 primarily. The rifle above was the rifle scanned while making his statue. Not sure if its a personal rifle or the exact story on it.

The post I got that from said that was his service rifle sourced from his wife Marra. Interestingly it looks a lot like the CMP ones so maybe he was issued an early prototype. Or it is a stateside clone he commissioned after he got out trying to replicate his service guns.

It was an amalgamation of parts. Most likely a personal rifle with some parts borrowed from the armory.

Not sure if this will work well or flop... I started a thread to more closely match up issued chassis’ / stocks and MARS / MIRS rails (or even optics). Most were DRMO’d or sourced separately leaving us with mismatched parts.

https://www.snipershide.com/shooting/threads/mk13-swap-thread.7263781/

The best approach is probably to post what you have to trade, rather than what you want, to avoid someone faking paint jobs / etc. Hopefully others find it useful.

https://www.snipershide.com/shooting/threads/mk13-swap-thread.7263781/

The best approach is probably to post what you have to trade, rather than what you want, to avoid someone faking paint jobs / etc. Hopefully others find it useful.

This one is getting closer, still need a few things: old Leupold Ultra rings and the action bolts, but hope to send it off to Red Bull soon, for Chris to finish later this year or early 2026.

Early grey stock from 1990s is underneath the tan paint. Unique recoil lug seen here (Badger Ordnance part).

Remington C-prefix action from early 1990s.

Early grey stock from 1990s is underneath the tan paint. Unique recoil lug seen here (Badger Ordnance part).

Remington C-prefix action from early 1990s.

Last edited:

Had it on the 1k quickly this weekend, but had a rough issue with dope, user error probably on prior turret reset. #fail

Similar threads

- Replies

- 0

- Views

- 3K