Here's my new project rifle for gunsmithing school. I am going to document as best as I can, all my work done to this rifle over the next year or so.

For now, just a new bolt knob, aluminum firing pin shaft and SS pin, upgraded spring, and aluminum anodized shroud.

Base rifle, got for $350

Upgraded firing pin, shaft, spring, and aluminum shroud

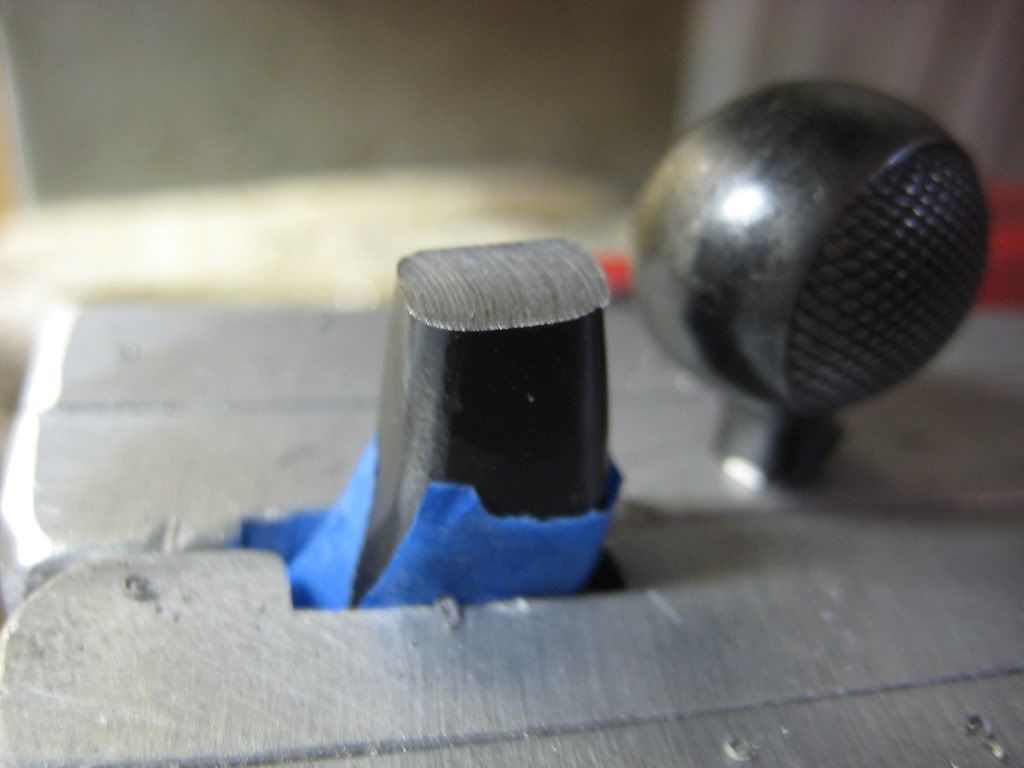

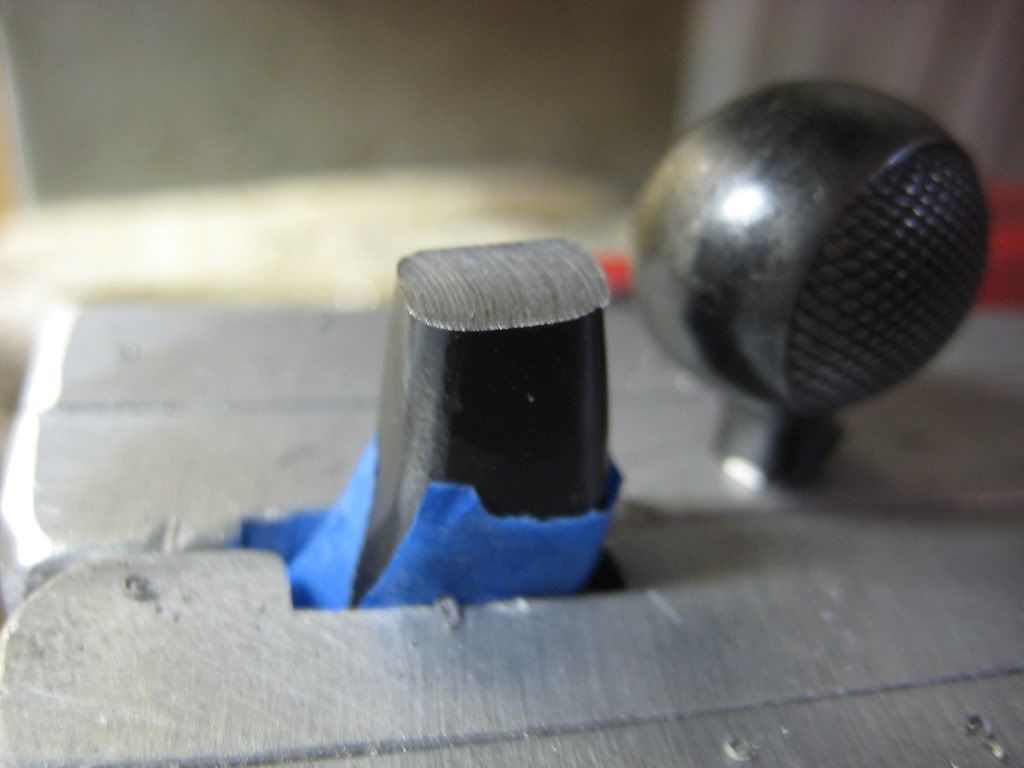

Bolt knob prep

10-32 hardened steel stud installed

My sako extractor jig I made.

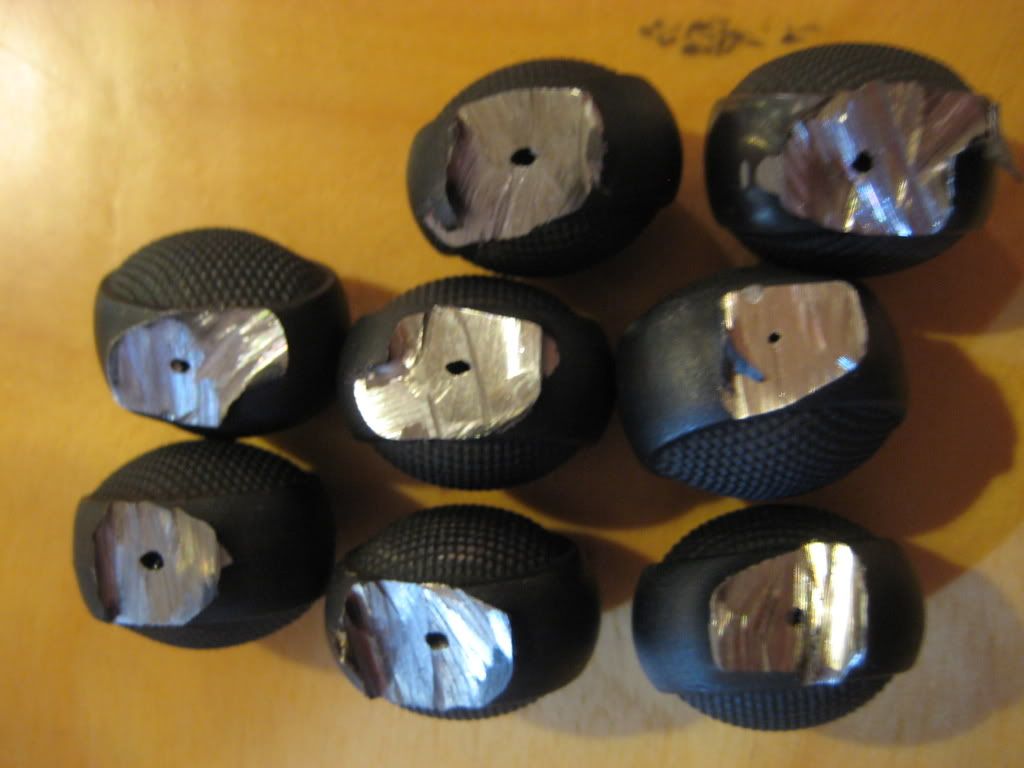

Phoenix 4 groove knob, not tapped and screwed on yet

Next will be a Sako style extractor, then blasting and Cerakote

Total price so far: $351

Hope you enjoy this project as it comes along.

For now, just a new bolt knob, aluminum firing pin shaft and SS pin, upgraded spring, and aluminum anodized shroud.

Base rifle, got for $350

Upgraded firing pin, shaft, spring, and aluminum shroud

Bolt knob prep

10-32 hardened steel stud installed

My sako extractor jig I made.

Phoenix 4 groove knob, not tapped and screwed on yet

Next will be a Sako style extractor, then blasting and Cerakote

Total price so far: $351

Hope you enjoy this project as it comes along.