Case overall length, as pointed out above, will always grow as the brass flows toward the case mouth (either from firing or re-sizing, especially full-length sizing -- the brass only has one direction to go/flow, and that's towards the case mouth).

Trimming the case back to minimum dimensions keeps the case within the boundaries of the chamber (the neck doesn't extend into the bore, "Pinching the bullet" and raising pressure).

Without an RCBS mic (as the OP pointed out) or some other device on your calipers (a Stoney Point or Hornday LNL, or some kind of comparator to consistently measure base-to-shoulder datum), how are you measuring?

Neck-sizing only/exclusively does not change the base-to-shoulder datum dimension or length, however the brass may eventually stick in the chamber and need an occasional full-length sizing to keep feeding and extraction easier. The frequency of how often you'll want to do it will vary by chamber pressure and brass hardness.

The first firing will determine the case's working length. If the brass had to stretch on the first shot the virgin brass will stretch-to-fit the chamber length. If it's a deep chamber then that's where first thinning will occur. Annealing will help with neck life later (as the neck is work-hardened), but may affect how much/far the the brass in the case walls and shoulder is worked on the fire-form.

The 142 SMK and the 140 A-Max are nominally the same length. The Sierra has a shorter bearing area and ogive. If seated to the same cartridge overall length as the A-Max it may touch the rifling leade sooner. In the OP's case, the bullet may jam into the lands sooner, spiking his pressure up a bit (in the Match King's favor it has a longer boat-tail which may also free up some case space. Add .1 grains more powder (as in his case) and pressures might (or might not) change (bullet seats earlier, plus more fuel).

Do you have a gage to check when your bullet ogives contact the leades, and then adjust from there for a touch fit, jam-fit, or free-jump?

Hodgdon's data states 41.5 to 44.5 of H4350, so your loads are well within min-max charges.

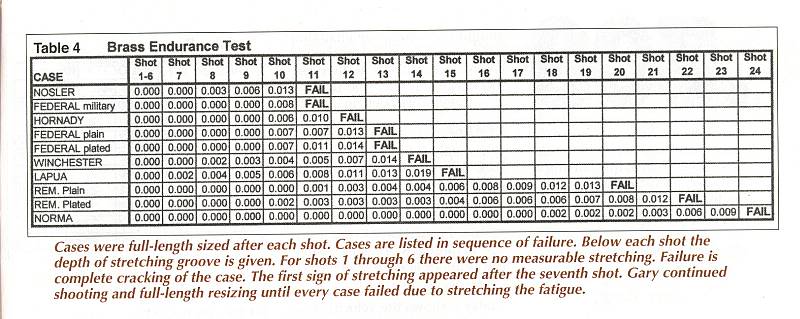

In the graphs I posted the case shoulders were DELIBERATELY pushed back .003-.005 to document case stretch to failure. Neck-sizing only (as benchresters do), or pushing back the shoulders .001-.002 with light-to-moderate charges should extend case life a bunch.