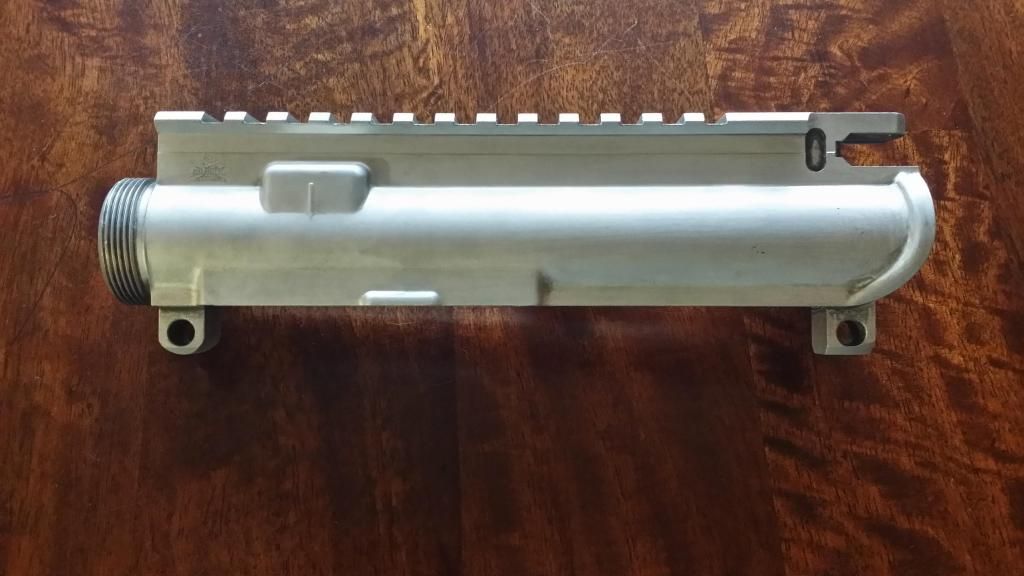

I wanted to paint an AR receiver set for my wife and decided to degrease it and remove any sealer by boiling them in water with a little Lemishine. This is what I ended up with.

The anodizing process consists of soaking the raw aluminum in an electrostatic-ally charged bath of sulfuric acid. This creates the anodized surface (aluminum oxide). It is VERY permanent. The natural color of anodizing is a gray to dark-gray color (as shown in pic). Dye is then added to the anodized surface make it look black (or any other color). After the dye, a sealer is applied to help hold the dye in the pores of the anodizing.

By boiling for 30 minutes with Lemishine I was able to removed the dye(and a little of the outer anodized surface) meaning the anodized surface left is now completely bare and ready to accept some paint. Both the dye and sealer are gone, and all without changing dimensional specs.

I did not know it would work this well so I wanted to pass it along for anyone that may want to paint a receiver. This may be well known but I just discovered it.

L

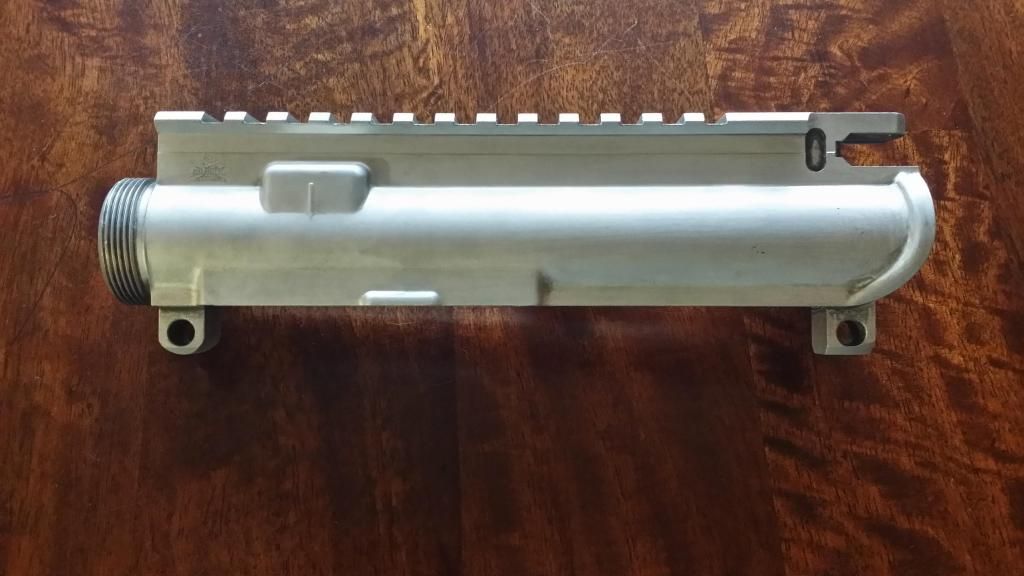

The anodizing process consists of soaking the raw aluminum in an electrostatic-ally charged bath of sulfuric acid. This creates the anodized surface (aluminum oxide). It is VERY permanent. The natural color of anodizing is a gray to dark-gray color (as shown in pic). Dye is then added to the anodized surface make it look black (or any other color). After the dye, a sealer is applied to help hold the dye in the pores of the anodizing.

By boiling for 30 minutes with Lemishine I was able to removed the dye(and a little of the outer anodized surface) meaning the anodized surface left is now completely bare and ready to accept some paint. Both the dye and sealer are gone, and all without changing dimensional specs.

I did not know it would work this well so I wanted to pass it along for anyone that may want to paint a receiver. This may be well known but I just discovered it.

L

Last edited: