Actually I think it was 3/4.That’s with 1/2” right?

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

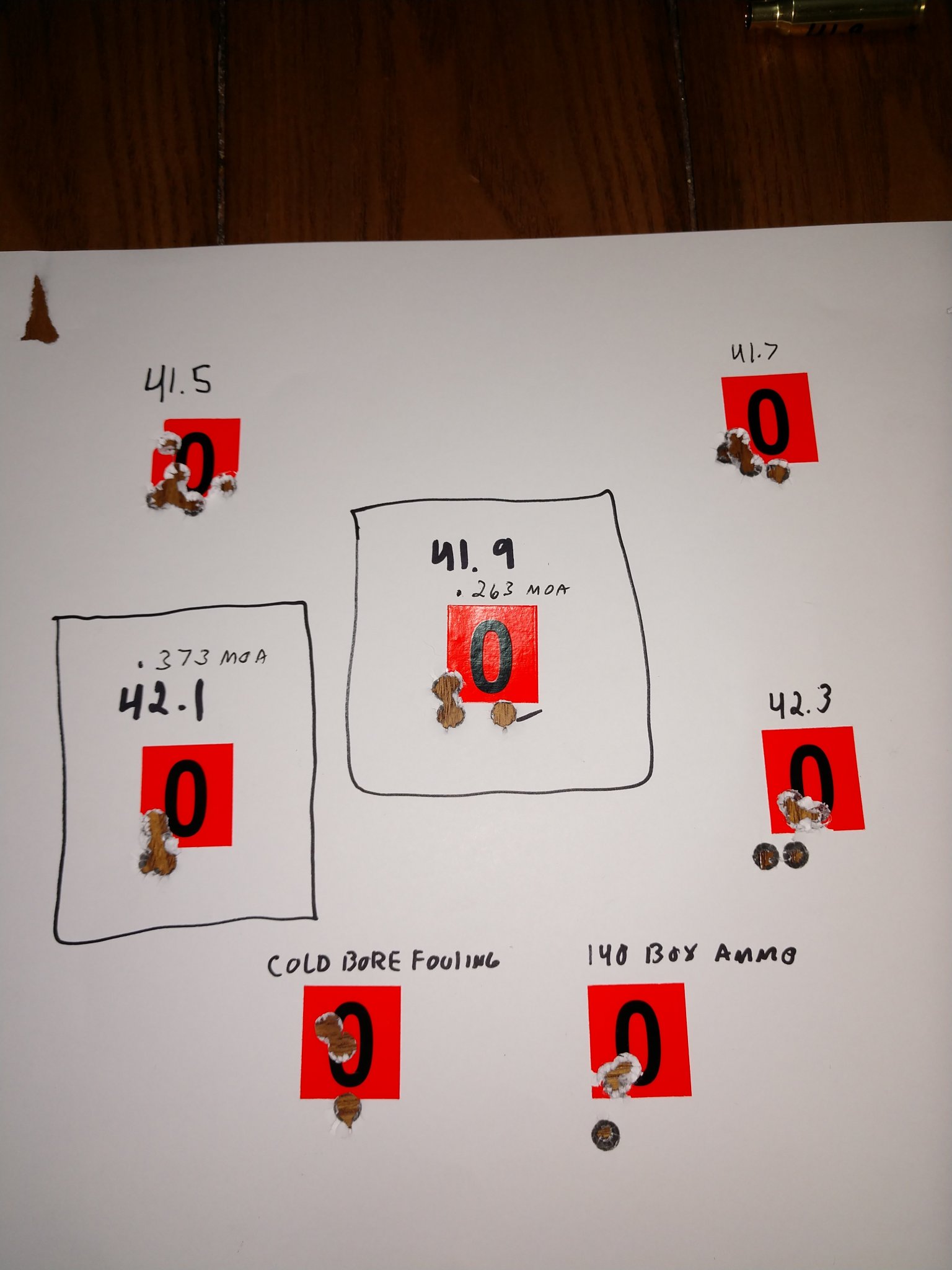

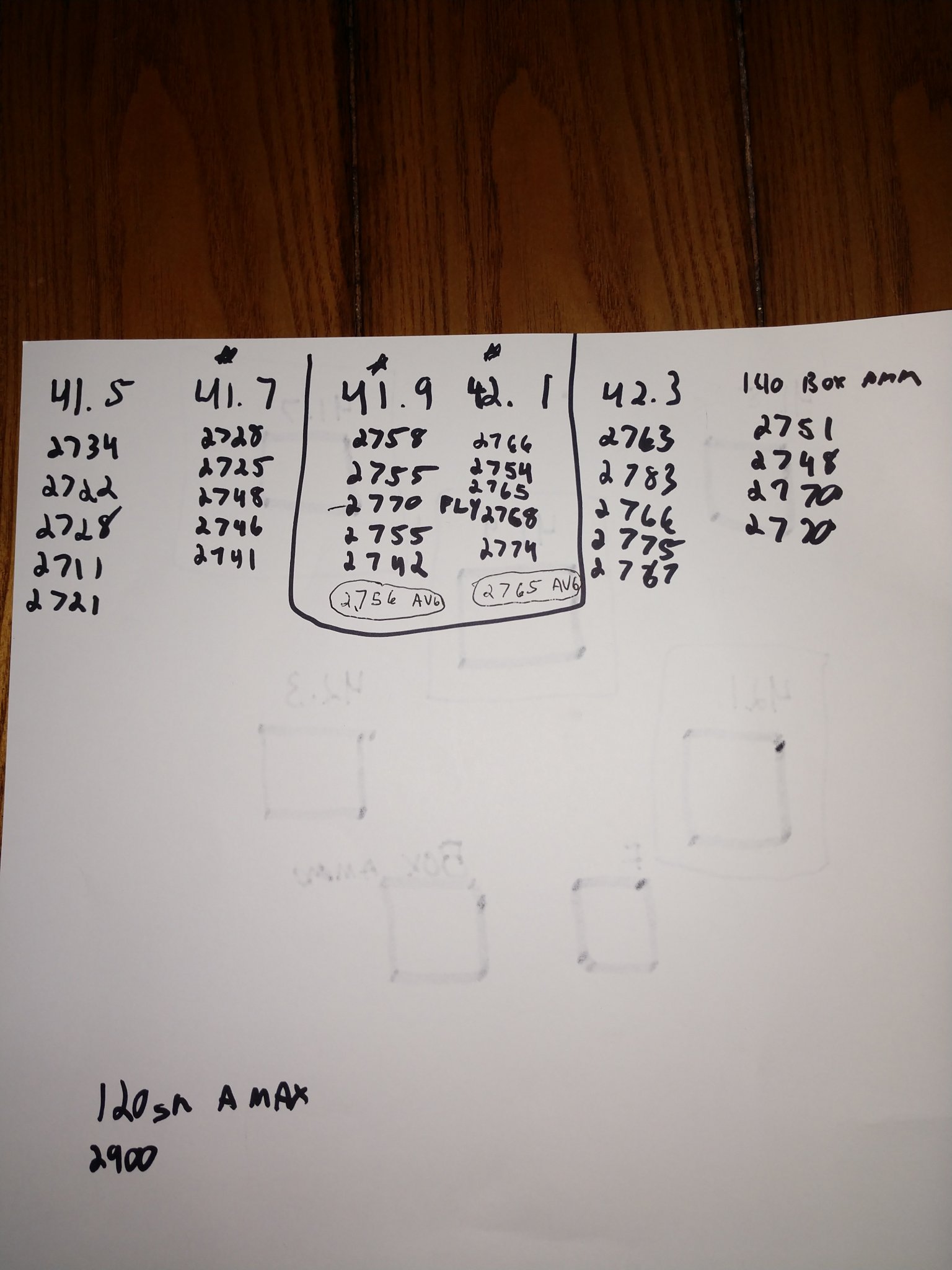

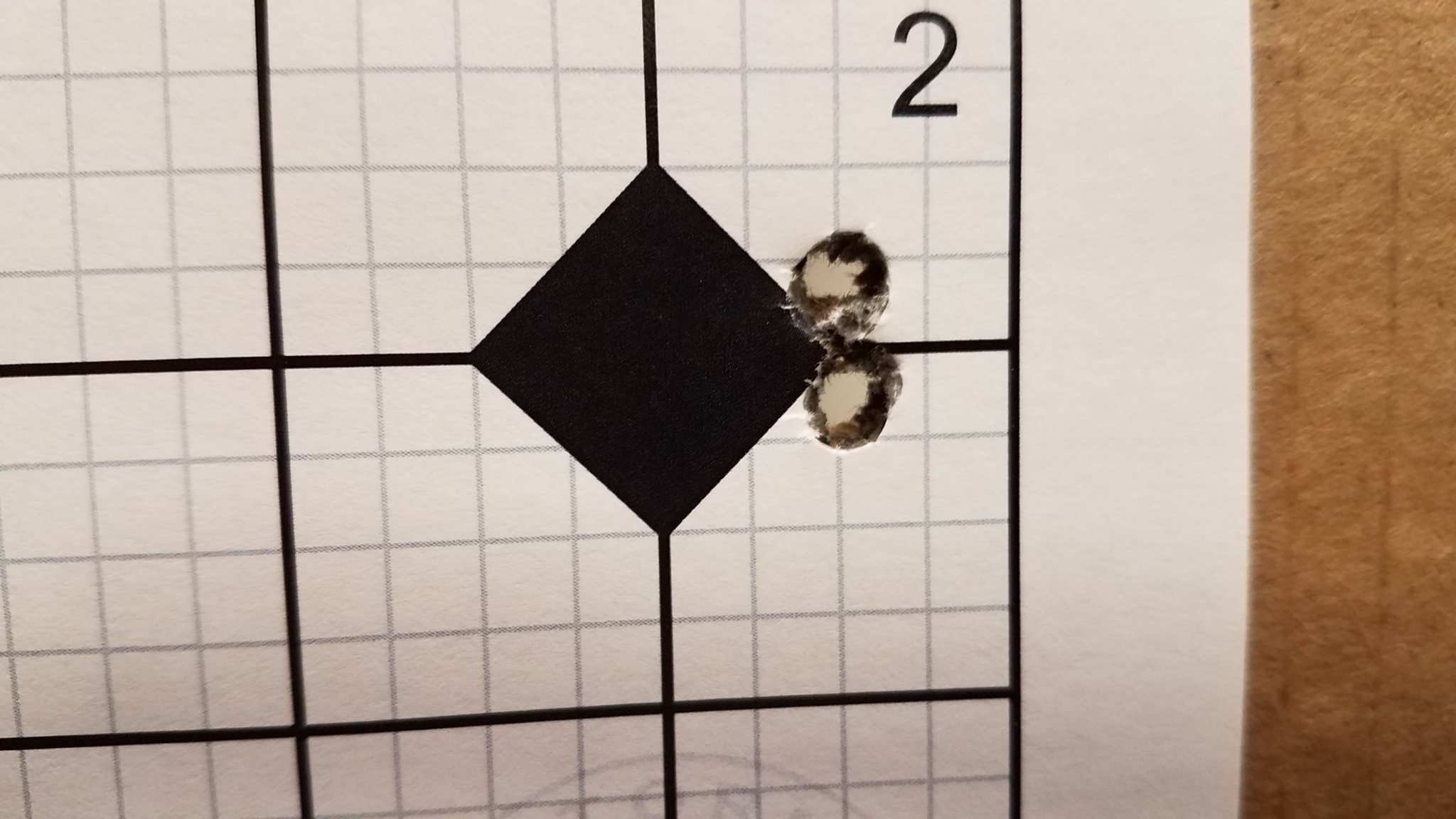

Finished up load development narrowed it down to two loads 41.9 and 42.1 H4350. Tell me what you all think.

I have no idea what happened on my third shot of 41.9 I must have bumped the table and accidentally dropped a few extra kernels of powder in, because when that shot broke I actually felt the difference in the recoil.

I also noticed a bit of a difference from my last test, the first round of handloads I only neck sized the once fired brass and had quite a few that the bolt wouldn't close on. This time I full length sized my brass and had zero issues, but it did change my groups a bit. Those groups should tighten up even more once I get some AR mags that allow for a longer COAL, going to try some LaRue or KAC mags I believe those are the two that allow for the longest COAL

But all in all not too shabby for a bone stock RPR.

I have no idea what happened on my third shot of 41.9 I must have bumped the table and accidentally dropped a few extra kernels of powder in, because when that shot broke I actually felt the difference in the recoil.

I also noticed a bit of a difference from my last test, the first round of handloads I only neck sized the once fired brass and had quite a few that the bolt wouldn't close on. This time I full length sized my brass and had zero issues, but it did change my groups a bit. Those groups should tighten up even more once I get some AR mags that allow for a longer COAL, going to try some LaRue or KAC mags I believe those are the two that allow for the longest COAL

But all in all not too shabby for a bone stock RPR.

Last edited:

I also noticed a bit of a difference from my last test, the first round of handloads I only neck sized the once fired brass and had quite a few that the bolt wouldn't close on. This time I full length sized my brass and had zero issues, but it did change my groups a bit.

Yeah, it's really not so unusual that neck sizing will result in too tight a fit for some or all fired rounds. This is why when I neck size, I always bump the shoulder back to be sure to have enough and consistent head space. I find for my RPR .308, I get better results from neck sized cartridges than full length sized (even when adjusting for the difference in case volume). I suspect that may be because there seems to be some looseness built into the RPR SAAMI spec chamber that effects the over all concentricity on a chambered cartridge. I also bump the should back for consistency to get consistent trim length from my Giraud Tri Way Trimmer where the shoulder is what gauges the depth of the cut.

And, no surprise here that FL sizing gave you no feeding problems since that operation bumps the necks back . . . and, that your groups changed a bit since FL sizing reduces case volume, thereby increasing pressure and velocity.

But all in all not too shabby for a bone stock RPR.

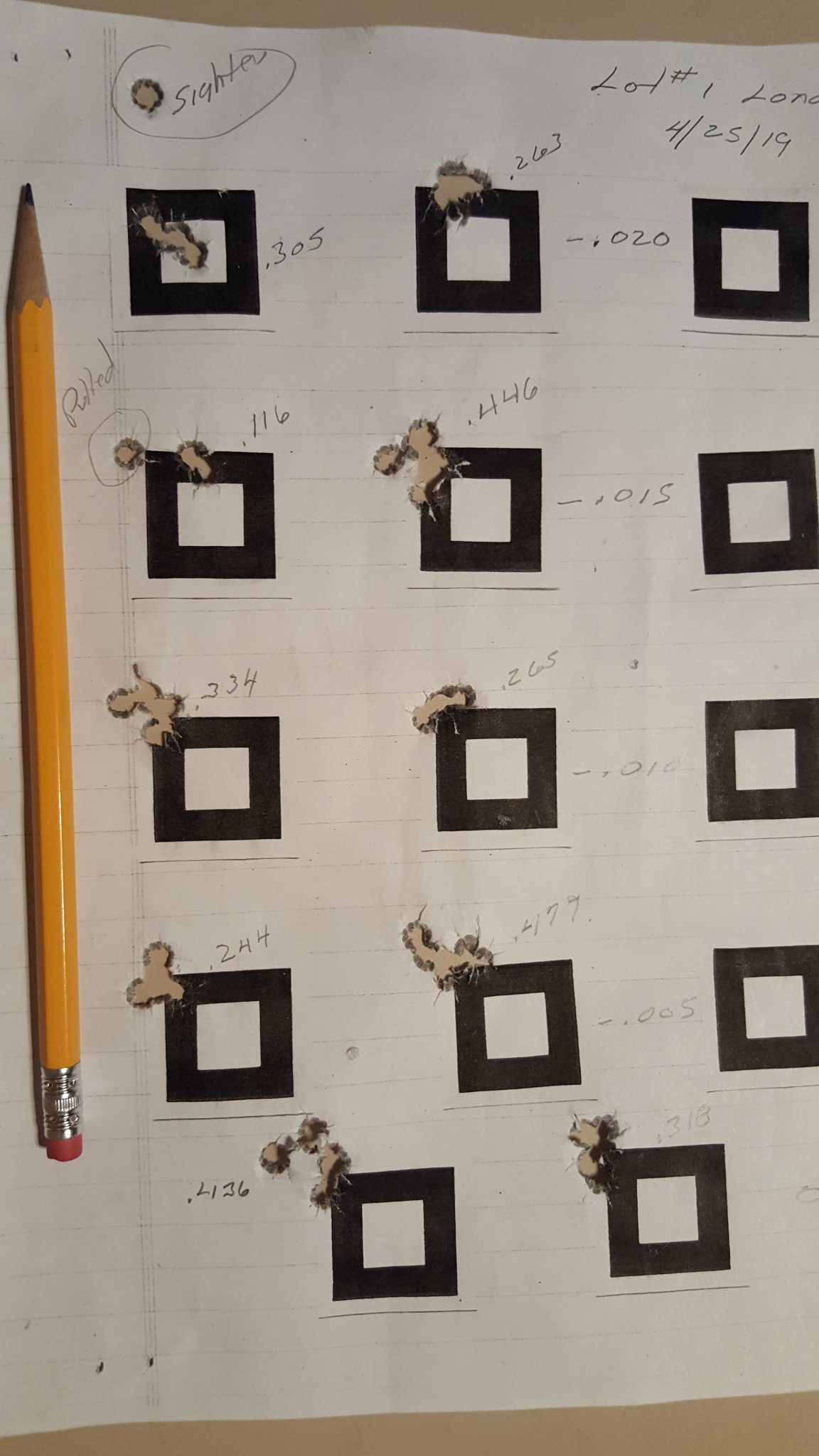

My load testing is about complete. Settled on Hornady ELD 140gr match, 42.0 gr H 4350 and hornady brass.

My last test was setting distance off the lands. Tested .020", .015", .010", .005", and JT.

The test was all 5 shot groups. Two groups at each jump measurement.

Being pleased with the results the next step is increasing the range out from 100 yds. Start with 200 yds and go from there.

My last test was setting distance off the lands. Tested .020", .015", .010", .005", and JT.

The test was all 5 shot groups. Two groups at each jump measurement.

Being pleased with the results the next step is increasing the range out from 100 yds. Start with 200 yds and go from there.

Last edited:

What the heck is that? Mistyped 4350?H 4395

My load testing is about complete. Settled on Hornady ELD 140gr match, 42.0 gr H 4350 and hornady brass.

My last test was setting distance off the lands. Tested .020", .015", .010", .005", and JT.

The test was all 5 shot groups. Two groups at each jump measurement.

Being pleased with the results the next step is increasing the range out from 100 yds. Start with 200 yds and go from there.

View attachment 7067835

Nice Shooting ?

What mag did you use for the seating test or are you single loading them?

It's been quite a while since I read (somewhere around here) that one could make those mags work by filing/grinding of a piece of the mag at the back that keeps the bolt from moving forward when empty. I didn't do this myself as I simply bought a single stack MP mag that allowed the bolt to close when empty.

I ground the corner of all my pmag bolt stops with a dremel. You can close the bolt easy on empty, but the problem with single feeding is that it still doesn’t load the round at the correct angle. It’s either much to high or you have to keep the mag lower in the well about just before it clips in. I use the bob sled but I’ve always heard the PVC trick works very well too

I single load. Made a pvc pipe piece that loads in the mag . Kind of like a half pipe. Works well.

It just occurred to me that my load may not fit in a mag. Never checked it.

All my range shooting is single load.

It just occurred to me that my load may not fit in a mag. Never checked it.

All my range shooting is single load.

Is the 6.5 PRC and 300 PRC RPR’s new or am I just a day late and a dollar short?

Is the 6.5 PRC and 300 PRC RPR’s new or am I just a day late and a dollar short?

Nope Brand New, good update.

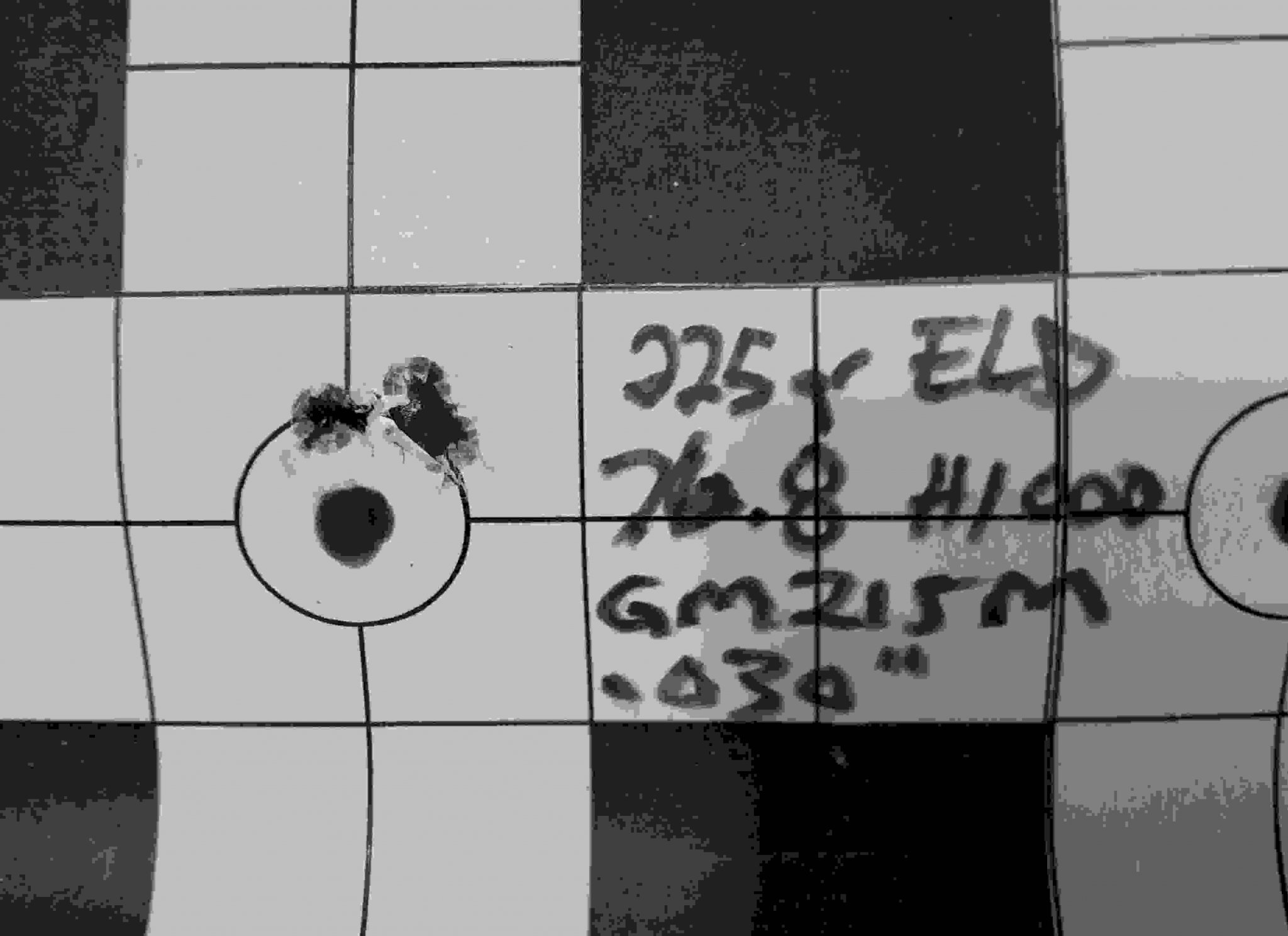

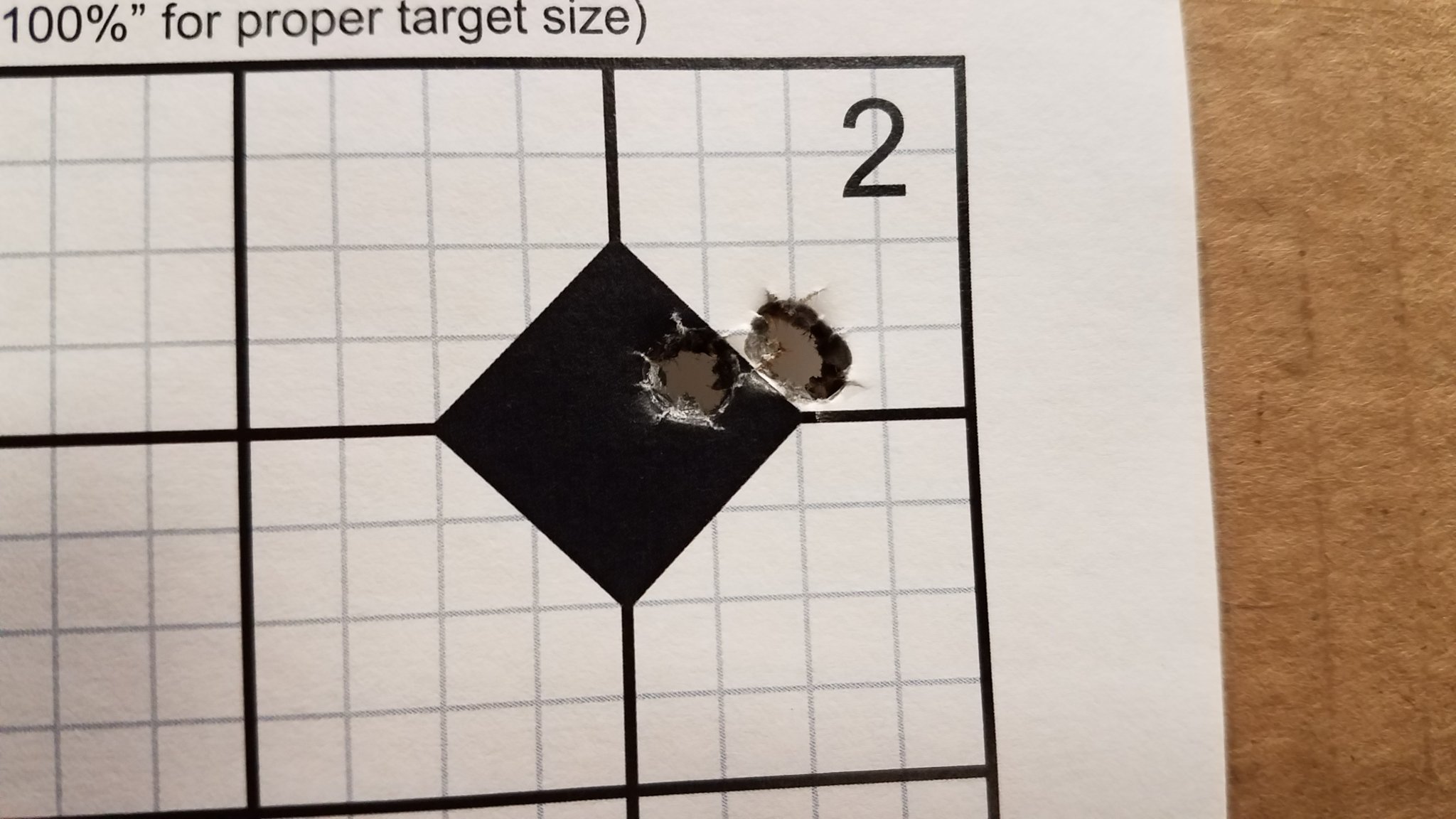

RPR 300 Win Mag

5x25 vortex PST gen2

225gr Hornady ELD M

76.8gr H1000

Win brass

GM215M primer

.030" off the lands (3.616" coal, 2.844" cbto)

The 225gr version of the .30 Cal ELD M bullet has a secant ogive so I had to experiment with seating depth to get better groups.

2888fps Ave (Prochrono @15')

13fps ES

5fps SD

5x25 vortex PST gen2

225gr Hornady ELD M

76.8gr H1000

Win brass

GM215M primer

.030" off the lands (3.616" coal, 2.844" cbto)

The 225gr version of the .30 Cal ELD M bullet has a secant ogive so I had to experiment with seating depth to get better groups.

2888fps Ave (Prochrono @15')

13fps ES

5fps SD

Last edited:

I got this email today and this is another option besides the Bob Sled or doing it yourself: https://mkmachining.com/product/aics-sa-single-shot-sled/?mc_cid=5ee8c2249a&mc_eid=0525b62772My friend wants to use his RPR in F Class competition, and the rule is that you can only load one round at a time and not from a magazine. He says the bolt on his RPR locks back when the mag is empty. Is there a way to make the RPR work for F Class?

Has anyone checked out Hornady's new A-Tip bullets?

Obviously, they're not for everyone, being that they're quite pricey (about double the cost of a typical match bullet). From listening to their video about this new A-Tip, it sounds like they really raised the bar for competitive shooters. see: https://www.hornady.com/bullets/a-tip-match#!/

Interestingly, RPR's are mentioned where the bullets will work particularly well with the twist rates the Ruger puts into them. Unfortunately for me, they don't make anything for .308's (currently, anyway). But if you're competitive and shooting 6's, 6.5's or 300's, it appears they've got a winner for you.

Guess I should have converted to a 6.5 when I swapped out my barrel???

Obviously, they're not for everyone, being that they're quite pricey (about double the cost of a typical match bullet). From listening to their video about this new A-Tip, it sounds like they really raised the bar for competitive shooters. see: https://www.hornady.com/bullets/a-tip-match#!/

Interestingly, RPR's are mentioned where the bullets will work particularly well with the twist rates the Ruger puts into them. Unfortunately for me, they don't make anything for .308's (currently, anyway). But if you're competitive and shooting 6's, 6.5's or 300's, it appears they've got a winner for you.

Guess I should have converted to a 6.5 when I swapped out my barrel???

Working on load development with this at 100 yds is proving to be a challenge. Theres almost not enough variation to say one group stands away from another. Testing varying seating depths all day. Best groups of the day....

All 5 shot groups with either 115DTAC or 105 Nosler RDF'S. Both seemed to perform about the same.

All 5 shot groups with either 115DTAC or 105 Nosler RDF'S. Both seemed to perform about the same.

^ Pretty nice. That’s just how development is I guess. One head scratch after another. I have a few different loads that work best in my rifle given different weather, distance etc. But I probably went through half a dozen before I found one that performs great in pretty much any scenario

I just purchased a second generation RPR .308 with the M-Lok Handguard. Has anyone else's M-Lok had very sharp burrs around all the cutouts in the handguard? Mine cut my hand and is literally razor sharp in 20 different locations. It's like the hand guard wasn't finished being machined.

Ruger Precision Rifle Discussion thread

^ Wasn’t deburred after being machined. Might be the first I’ve heard of that. Ruger will take care of you

My friend and I shared his rpr at a match this weekend. It was our first time using the RPR in match conditions where you have to advance and lock down the bolt only after getting your crosshairs on the target. We both noticed that locking down the bolt threw us off target. I know I actually lost the target several times and had to find it again. We had already cycled the bolt a thousand times which did smooth out the advance of the bolt, but did not seem loosen up the bolt rotation at all. Is this issue something that we just have to live with or is there anything to be done? I have a rifle on order that has a surgeon action. Should I expect the same issue with that one?

No problem with managing recoil with the 6.5 creedmoor. Very mild.

[/QUOTEI

I would agree, my son generally shoots the Ruger PR, which he has done since he was age 14.

I'm sure your surgeon will be night and day difference regarding bolt lock/bolt lift.My friend and I shared his rpr at a match this weekend. It was our first time using the RPR in match conditions where you have to advance and lock down the bolt only after getting your crosshairs on the target. We both noticed that locking down the bolt threw us off target. I know I actually lost the target several times and had to find it again. We had already cycled the bolt a thousand times which did smooth out the advance of the bolt, but did not seem loosen up the bolt rotation at all. Is this issue something that we just have to live with or is there anything to be done? I have a rifle on order that has a surgeon action. Should I expect the same issue with that one?

The rpr is very stiff , it's just something I've gotten used to.

Build a solid firing position, I kind of lean in when I'm loading my bipod and my sight picture doesn't move.

Just had to learn how to deal with it.

Then I shot my buddy's tikka, I almost ripped the bolt handle off.... lol..

The bolt on my gen 1 .308 isn’t stiff at all but still after 3500 rounds has a little of the zipper effect. After this season I’ll send the bolt off to LRI to have it cerakoted. I already had them do the shroud. I don’t really care and it doesn’t bother me or effect me at all. It’s just one of those things where, I know it’s there.

Would cerakoting the bolt smooth out the bolt lock and lift?

Possibly. Cerakote works as basically a solid lubricant as well as a protective finish. I’m just not sure how much space you’d have to work with between those surfaces

I have been toying with trying a rifle in 300prc, excited to see how the new prc rifles shoot. Likely they will be like all the other RPRs and shoot great. Glad to see someone paying attention to the details as well like the Arca Swiss rail integrated in the hand guard.

I just put an A2 flash hider onThe 223 gen 2s that I bought came with thread protectors in the box. I replaced the brakes with those thread protectors. If you bought it new I think it was supposed to be in the box.

The manual calls it a muzzle cap. On the shopruger.com site they are called thread protectors. The spec sheet for the current 6mm Creedmoor RPR says it is a 5/8-24 thread.

The factory keymod isnt really that bad. I have a Seekins SP3R handguard with MLOK but I wouldnt have minded keeping the keymod. It works just as well.

Use will loosen up any weapon with the current tight tolerances. DIY gunsmith work can be ugly unless you are extremely familiar with weapon.

Anyone ever run some 'large' 308's and have the cases possibly deform? My Gen2 has about 300 rounds of Herters 180gr soft point (Yeah yeah, I was looking for ANYTHING under 60 cents a round locally to get some range time with this.) I kept all the cases thinking I was going to use them to reload but have run into something that's got me a bit concerned now. The primers on all of them are about .20~.3mm sticking out of the case after firing. Stupidly I don't have a single round of this stuff unfired to even look at. I shot it all, mostly at 500 and been quite happy with it. The stuff was like shooting a schoolbus out of the barrel. But it worked to get trigger time.

It wasn't until the 75th page that I started thinking about headspace. It was a long thick bullet for sure. The second issue is the head of most all of the rounds (maybe 1 in 30 are good) are swollen too much to get into my shell holder for reloading. I shot all 300 rounds before noticing any of this. I'm thinking the ones that are still really close to spec are the ones i let sit in the chamber to cool before ejecting them.

I have some 168gr smk's by Magtech that I'm going to just chamber and take a look at the round here in a few min. but Here's some pics of what I've got going on

It wasn't until the 75th page that I started thinking about headspace. It was a long thick bullet for sure. The second issue is the head of most all of the rounds (maybe 1 in 30 are good) are swollen too much to get into my shell holder for reloading. I shot all 300 rounds before noticing any of this. I'm thinking the ones that are still really close to spec are the ones i let sit in the chamber to cool before ejecting them.

I have some 168gr smk's by Magtech that I'm going to just chamber and take a look at the round here in a few min. but Here's some pics of what I've got going on

Attachments

Az Erik, have no idea if this is directly related and can not confirm since brass has since been tossed but a reloading buddy had similar issues with his small trial batch of .243 HRTRS fired brass from his bolt gun.

His once fired brass was difficult to reload due to thick rims not fitting well into shell holders and was consistently more difficult to extract than other ammo he test fired. He reloaded some cartridges a second time with continued dimensional issues before deciding to toss them since he only had a total of 20 cases of the Herters headstamp.

He had no chambering/extraction issues whatsoever with multiple other brands of ammunition he tried in the rifle.

His once fired brass was difficult to reload due to thick rims not fitting well into shell holders and was consistently more difficult to extract than other ammo he test fired. He reloaded some cartridges a second time with continued dimensional issues before deciding to toss them since he only had a total of 20 cases of the Herters headstamp.

He had no chambering/extraction issues whatsoever with multiple other brands of ammunition he tried in the rifle.

Interestingly when I loaded up and cycled these CBC Magtech they go in and out quite a bit easier. I thought it was all my PMAG's causing the chambering drag, but I watch these pop right up where was the others were sliding into the chamber with what I woudn't call zero force. I now have the Magpul ACIS 5 round mag as well, which feels quite a bit nicer than the PMAG

I shoot 190 SMK’s and haven’t had any problem. I use Nosler Custom brass though. It’s thinner and a little softer but has produced the best results with this load

What kind of wrench are you guys using to remove your factory muzzle break? All my wrenches are either too wide to fit on the nut, or not big enough.

Crescent wrench + philipshead screwdriver

RPR3 did OK at first match night. I know its's only 250yds but that's what we got around here. Going to be looking to take a trip to another longer range sooner than later. Anyhow, took 3rd out of the group, 2 points out of 2nd and 3 points out of first. One of my better targets...

What kind of wrench are you guys using to remove your factory muzzle break? All my wrenches are either too wide to fit on the nut, or not big enough.

Put some tape around the nut to minimize marring.Crescent wrench + philipshead screwdriver

Just got my RPR project done. 6 creed proof CF barrel, seekins rail, seekins stock, timney, stripper camo, and did bolt in Cerakote elite which did smooth it up. Was a fun project now moving on lol. The strippers can keep u distracted in between strings!

Might be the nicest example I've seen yet. Well done.Just got my RPR project done. 6 creed proof CF barrel, seekins rail, seekins stock, timney, stripper camo, and did bolt in Cerakote elite which did smooth it up. Was a fun project now moving on lol. The strippers can keep u distracted in between strings!

View attachment 7074902View attachment 7074903View attachment 7074904

I need some of you super smart dudes to help me with a problem. Recently I purchased a RPR in .338 Lapua. When I opened the box I noticed that Ruger had shipped it with two 300 Win mags, this problem has since been rectified. So while waiting for the new magazines to ship I put the rifle together and wanted to ensure that the bolt would lock up so I hand fed a American Eagle 250 grain soft point round. it seemed to lock up fine. after I tried it a couple of times I ejected the bullet but suddenly my bolt became extremely hard to close. Ive tried to trouble shoot the problem to no avail. It ran smooth prior to and during my bullet test. Im not sure what happened but would greatly appreciate any advice you all have. I'm hoping it is something simple, I dont really want to ship a rifle back without shooting one round.

I have been toying with trying a rifle in 300prc, excited to see how the new prc rifles shoot. Likely they will be like all the other RPRs and shoot great. Glad to see someone paying attention to the details as well like the Arca Swiss rail integrated in the hand guard.

For an rpr that already has a long magazine, the real benefit I see with the prc over the win mag is the chamber in the production barrel. The prc has a tighter freebore diameter than the win mag since Ruger used a saami spec chamber in the win mag vs. a more appropriate, match chamber with a .3085" vs. .315" freebore diameter. This means the prc production barrel will likely be more accurate out of the box. At some point I'll likely replace the mediocre stock win mag barrel with a true match grade aftermarket offering.

I need some of you super smart dudes to help me with a problem. Recently I purchased a RPR in .338 Lapua. When I opened the box I noticed that Ruger had shipped it with two 300 Win mags, this problem has since been rectified. So while waiting for the new magazines to ship I put the rifle together and wanted to ensure that the bolt would lock up so I hand fed a American Eagle 250 grain soft point round. it seemed to lock up fine. after I tried it a couple of times I ejected the bullet but suddenly my bolt became extremely hard to close. Ive tried to trouble shoot the problem to no avail. It ran smooth prior to and during my bullet test. Im not sure what happened but would greatly appreciate any advice you all have. I'm hoping it is something simple, I dont really want to ship a rifle back without shooting one round.

What’s the bullet/brass look like?

I need some of you super smart dudes to help me with a problem. Recently I purchased a RPR in .338 Lapua. When I opened the box I noticed that Ruger had shipped it with two 300 Win mags, this problem has since been rectified. So while waiting for the new magazines to ship I put the rifle together and wanted to ensure that the bolt would lock up so I hand fed a American Eagle 250 grain soft point round. it seemed to lock up fine. after I tried it a couple of times I ejected the bullet but suddenly my bolt became extremely hard to close. Ive tried to trouble shoot the problem to no avail. It ran smooth prior to and during my bullet test. Im not sure what happened but would greatly appreciate any advice you all have. I'm hoping it is something simple, I dont really want to ship a rifle back without shooting one round.

You might have shave a small sliver of lead off of the bullet and it in the area where the lugs lock up. You could pull the trigger housing and bend a Q Tip at a 90 degree angle and fish it out. Maybe flush the area with contact cleaner and wash it out??

So I’m thinking about getting an RPR. In .308 what kind of shot groups are you guys getting?

So I’m thinking about getting an RPR. In .308 what kind of shot groups are you guys getting?

When I got Gen2 a little over 2 years ago I was getting 3/4 MOA out of the box using FGMM 168's & 175's. Started precision hand loading and was able to get that down to just under 1/2 MOA with 168 and 175 SMK's. With a high end barrel, I got it down to 1/3 MOA or slightly little better.

PS: I feel the rifle/I could have done a little better having had better glass than the Vortex Viper. It's not the best by any means, but it's better than most, IMHO.

Last edited:

Has anyone else managed to break their aluminum bolt shroud? On mine, the tabs that lock it onto the bolt sheared and it won’t stay on anymore. I was already thinking about replacing it with a Ti shroud from Anarchy Outdoors. This makes that d3cision easier.

Pro tip- The rifle will function without the shroud- or if the shroud falls off and is rattling around in the receiver extension. BUT, the cocking piece can rotate out of alignment with the bolt open. If this happens, you cannot close the bolt, as it runs in a channel cut in the bottom of the receiver. And, because you cannot close the bolt, you cannot fold the butt stock to remove the bolt. Your remedy is to remove the receiver extension and then rotate the cocking piece back into proper alignment. This allows you to close the bolt so that you can fold the butt stock. Now, do this between stages at a match. Thankfully, I had just put together a travel repair kit- including an armorer’s wrench- the week prior.

Pro tip- The rifle will function without the shroud- or if the shroud falls off and is rattling around in the receiver extension. BUT, the cocking piece can rotate out of alignment with the bolt open. If this happens, you cannot close the bolt, as it runs in a channel cut in the bottom of the receiver. And, because you cannot close the bolt, you cannot fold the butt stock to remove the bolt. Your remedy is to remove the receiver extension and then rotate the cocking piece back into proper alignment. This allows you to close the bolt so that you can fold the butt stock. Now, do this between stages at a match. Thankfully, I had just put together a travel repair kit- including an armorer’s wrench- the week prior.

Have any of you 6.5 RPR guys made a 1 mile shot with the factory barrel and factory ammo?

Furthest that I took mine was 1305, but no issues. One mile may be pushing it as running my ELDs at 2850, i'm down to around 900fps by 1760.

Have any of you 6.5 RPR guys made a 1 mile shot with the factory barrel and factory ammo?

Target size makes all the difference...

Not sure if this has been talked about but I have been thinking about rebarreling my RPR Gen 2 to 6.5 PRC once this 6 Creed is shot out. Is there enough material on the bolt face to open it up to a magnum diameter? Anyone know if the PRC bolt will fit in a standard RPR? I don't see why it wouldn't. Just starting to think before I shoot out this barrel and need something right away.

Similar threads

- Replies

- 0

- Views

- 202

- Replies

- 13

- Views

- 679

- Replies

- 3

- Views

- 420

- Replies

- 17

- Views

- 1K