Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Stainless Steel Media Testimonials

- Thread starter Suasponte

- Start date

Re: Stainless Steel Media Testimonials

Working on 1,500 pieces of .308 right now. I need a bigger tumbler.

Working on 1,500 pieces of .308 right now. I need a bigger tumbler.

Re: Stainless Steel Media Testimonials

Has anyone used the stainless tumbling media for anything else gun related? I am wondering how it might work on a pistol barrel that is quite fouled and leaded...

Has anyone used the stainless tumbling media for anything else gun related? I am wondering how it might work on a pistol barrel that is quite fouled and leaded...

Re: Stainless Steel Media Testimonials

I went to Home Depot today looking for a piece of Lexan but the only ones I could find were .093" thick not the 1/8 or 3/16" (.125/.1875) described. Is that the one that was used?

I went to Home Depot today looking for a piece of Lexan but the only ones I could find were .093" thick not the 1/8 or 3/16" (.125/.1875) described. Is that the one that was used?

Re: Stainless Steel Media Testimonials

All my lids are either 1/8"thk or 3/16". My buddy worked at a sign shop and made me lids from drop materials.

If you have any local sign shops maybe you can get a piece big enough to cut your lid.

Terry

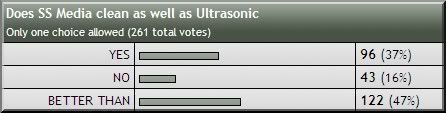

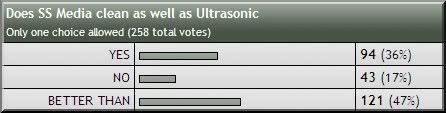

New poll results as of 3-21-2011 @ 5:30pm EST

All my lids are either 1/8"thk or 3/16". My buddy worked at a sign shop and made me lids from drop materials.

If you have any local sign shops maybe you can get a piece big enough to cut your lid.

Terry

New poll results as of 3-21-2011 @ 5:30pm EST

Re: Stainless Steel Media Testimonials

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: gunman_7</div><div class="ubbcode-body">Yep I have the rubber gasket on before the lid. I have noticed that when I put the rubber gasket on with the holes, that the holes don't line up well, in fact it creates like a wrinkle between the studs. But when I lightly push down with the cover on, it flattens it all out... I've run dozens of batches of .223 getting ready for P-Dog season and it happens each time. Leaks out from between the cover gasket seal and the rubber inner body liner. I suppose I could take picks on Monday but its pretty self explanatory... </div></div>

If you call Thumlers, they will probably replace your gasket for free. I called and talked to them about a problem and they were willing to take care of it.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: gunman_7</div><div class="ubbcode-body">Yep I have the rubber gasket on before the lid. I have noticed that when I put the rubber gasket on with the holes, that the holes don't line up well, in fact it creates like a wrinkle between the studs. But when I lightly push down with the cover on, it flattens it all out... I've run dozens of batches of .223 getting ready for P-Dog season and it happens each time. Leaks out from between the cover gasket seal and the rubber inner body liner. I suppose I could take picks on Monday but its pretty self explanatory... </div></div>

If you call Thumlers, they will probably replace your gasket for free. I called and talked to them about a problem and they were willing to take care of it.

Re: Stainless Steel Media Testimonials

Ditto! Call the people at Thumlers and they will take care of you!

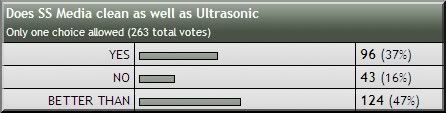

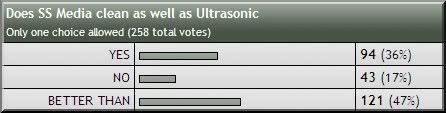

New poll results as of 3/23/2011 at 9:30pm EST

Terry

Good started tumbler on Ebay >> Thumlers Model "B"

For anyone looking to get started.

Ditto! Call the people at Thumlers and they will take care of you!

New poll results as of 3/23/2011 at 9:30pm EST

Terry

Good started tumbler on Ebay >> Thumlers Model "B"

For anyone looking to get started.

Re: Stainless Steel Media Testimonials

suasponte:

PM sent regarding SS media contact - thanks.

Figures - bought all the gee-whiz crap to ultrasonic clean last week and that ended up being about an $80 investment down the drain. Quickly lost interest after countless cycles and changing the solutions, etc. only to have to manually swab out excess carbon. Luckily I went with the cheaper Harbor Freight model cleaner. Seems like this is a no-fail solution.

suasponte:

PM sent regarding SS media contact - thanks.

Figures - bought all the gee-whiz crap to ultrasonic clean last week and that ended up being about an $80 investment down the drain. Quickly lost interest after countless cycles and changing the solutions, etc. only to have to manually swab out excess carbon. Luckily I went with the cheaper Harbor Freight model cleaner. Seems like this is a no-fail solution.

Re: Stainless Steel Media Testimonials

CardiacKid:

Pm sent!

I beleive once you crack the lid on your fisrt batch of brass you will become another convert.

Terry

CardiacKid:

Pm sent!

I beleive once you crack the lid on your fisrt batch of brass you will become another convert.

Terry

Re: Stainless Steel Media Testimonials

Terry I should have a tumbler coming in over the next month.

Will be in contact re: some media

Terry I should have a tumbler coming in over the next month.

Will be in contact re: some media

Re: Stainless Steel Media Testimonials

okay here we go...

I drank the Kool-Aid! and it is good! Love the results and not cleaning primer pockets!

Still have some kinks to work out like correct solution, and techniques.

So on that note can we get a sticky done with the recipes that others use?

I don't need the Lemishine stuff as our water is softened.

Also it would be good to post drying methods. maybe someone will come up with the uber efficient method...

T

okay here we go...

I drank the Kool-Aid! and it is good! Love the results and not cleaning primer pockets!

Still have some kinks to work out like correct solution, and techniques.

So on that note can we get a sticky done with the recipes that others use?

I don't need the Lemishine stuff as our water is softened.

Also it would be good to post drying methods. maybe someone will come up with the uber efficient method...

T

Re: Stainless Steel Media Testimonials

You think you don't need the Lemishine, But wait unitl you add it and see the differecne. Soft water or not it makes a difference!

1oz of Ivory soap, and a 9mm case of Lemishine!

Drying the are many methods posted.

1) Alcahol dip

2) Drying boxes

3) food dehydrators.

Zip thru all the pages, there is lots of good info to be had.

Terry

You think you don't need the Lemishine, But wait unitl you add it and see the differecne. Soft water or not it makes a difference!

1oz of Ivory soap, and a 9mm case of Lemishine!

Drying the are many methods posted.

1) Alcahol dip

2) Drying boxes

3) food dehydrators.

Zip thru all the pages, there is lots of good info to be had.

Terry

Re: Stainless Steel Media Testimonials

so how about some auto dishwasher soap?

ahhh see the food dehydrator excellent will try that one.

T

so how about some auto dishwasher soap?

ahhh see the food dehydrator excellent will try that one.

T

Re: Stainless Steel Media Testimonials

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: palmik</div><div class="ubbcode-body">No one wants to try the liquid laundry detergent huh? I have been using a 1/4 cup of wisk and it seems to work better than the dish stuff. </div></div>

Laundry Detergent recommendation! Have had some good reports.

I Still use the tried and true Ivory Soap (1oz, and a 9mm case of Lemishine)

Terry

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: palmik</div><div class="ubbcode-body">No one wants to try the liquid laundry detergent huh? I have been using a 1/4 cup of wisk and it seems to work better than the dish stuff. </div></div>

Laundry Detergent recommendation! Have had some good reports.

I Still use the tried and true Ivory Soap (1oz, and a 9mm case of Lemishine)

Terry

Re: Stainless Steel Media Testimonials

Went up to WalMart the other day to pick up Lemi-Shine and Ivory soap in prep for the arrival of my tumbler and ss media from Terry and had an odd thought - may have already been asked before, but I don't recall seeing it anywhere.

Has anyone tried adding the "spotless" additives to their solution? These are the additional little liquids right next to the dishwash soaps that are supposed to keep stuff in the dishwasher from getting water spots. Anyone ever try it in the media as well? Figure it may help in the rinse/dry process but haven't been able to check myself.

Went up to WalMart the other day to pick up Lemi-Shine and Ivory soap in prep for the arrival of my tumbler and ss media from Terry and had an odd thought - may have already been asked before, but I don't recall seeing it anywhere.

Has anyone tried adding the "spotless" additives to their solution? These are the additional little liquids right next to the dishwash soaps that are supposed to keep stuff in the dishwasher from getting water spots. Anyone ever try it in the media as well? Figure it may help in the rinse/dry process but haven't been able to check myself.

Re: Stainless Steel Media Testimonials

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: suasponte</div><div class="ubbcode-body">Wife picked up a bunch of this with coupons for a few cents.

Figured I would try it out on this range pick up! Used Ivory soap and a squirt of this! I'll check it a t 3hr's.

Terry

Looks like a thumbs down! Compared to Lemi Shine save your money! Maybe the wife can get clean dishes with it, but as for brass its a no go!

</div></div>

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: suasponte</div><div class="ubbcode-body">Wife picked up a bunch of this with coupons for a few cents.

Figured I would try it out on this range pick up! Used Ivory soap and a squirt of this! I'll check it a t 3hr's.

Terry

Looks like a thumbs down! Compared to Lemi Shine save your money! Maybe the wife can get clean dishes with it, but as for brass its a no go!

</div></div>

Re: Stainless Steel Media Testimonials

Please PM me the source for the magnetic stainless media as well please.

Couple of quick questions too:

-Any issues with leaving the SSM in water after cleaning? I was thinking I would simply rinse the media well after using it and then skip the drying part. Just leave it in a container with water completely submerged for storage.

-I've read this entire thread and after looking at the cleaned brass photos, I can't tell if the cases are a high mirror finish (almost a polished look) or are clean but display more of a matte look.

-Have we confirmed that Dawn or Ivory is the better soap option? Seems that its a toss up but would love a more direct comparison.

-I'm concerned about accidentally leaving SSM in a case while reloading. What check measures are you using to ensure that none is left in the case? Does this include laying the brass out and simply waving a magnet over the cases to see if anything attracts? Would this method even work?

-Any issues with 243 Win brass? With the small mouth, does this allow for the SSM to get into the inside and clean effectively?

Please PM me the source for the magnetic stainless media as well please.

Couple of quick questions too:

-Any issues with leaving the SSM in water after cleaning? I was thinking I would simply rinse the media well after using it and then skip the drying part. Just leave it in a container with water completely submerged for storage.

-I've read this entire thread and after looking at the cleaned brass photos, I can't tell if the cases are a high mirror finish (almost a polished look) or are clean but display more of a matte look.

-Have we confirmed that Dawn or Ivory is the better soap option? Seems that its a toss up but would love a more direct comparison.

-I'm concerned about accidentally leaving SSM in a case while reloading. What check measures are you using to ensure that none is left in the case? Does this include laying the brass out and simply waving a magnet over the cases to see if anything attracts? Would this method even work?

-Any issues with 243 Win brass? With the small mouth, does this allow for the SSM to get into the inside and clean effectively?

Re: Stainless Steel Media Testimonials

I've had my Thumlers Tumbler for a long time--prolly 5-6 years at least. I orderd it with a 'spare' rubber liner, that had a lip on it. Turns out the one that came in the tumbler was different, it did NOT have a 'lip' on it at all, my tumbler leaked like crazy with that liner. Put the other one in there and oila', no more leaky. Check with Thumlers as others suggested, and make sure you have the right liner.

I've had my Thumlers Tumbler for a long time--prolly 5-6 years at least. I orderd it with a 'spare' rubber liner, that had a lip on it. Turns out the one that came in the tumbler was different, it did NOT have a 'lip' on it at all, my tumbler leaked like crazy with that liner. Put the other one in there and oila', no more leaky. Check with Thumlers as others suggested, and make sure you have the right liner.

Re: Stainless Steel Media Testimonials

Mattmcg

Pm sent for Mark's contact info

I would say leaving the media submerged would not harm it. Mine has been constantly wet for well over 4-5 years.

Tumbling 3-4 hours gets them very clean.

Ivory soap is my choice.

I visually inspect all my rounds when loading and have not had any issues.

The only brass that is temperament is 22 hornet. However, it still cleans them very well. I have had no problems with 243's.

Terry

Mattmcg

Pm sent for Mark's contact info

I would say leaving the media submerged would not harm it. Mine has been constantly wet for well over 4-5 years.

Tumbling 3-4 hours gets them very clean.

Ivory soap is my choice.

I visually inspect all my rounds when loading and have not had any issues.

The only brass that is temperament is 22 hornet. However, it still cleans them very well. I have had no problems with 243's.

Terry

Re: Stainless Steel Media Testimonials

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: mattmcg</div><div class="ubbcode-body">Please PM me the source for the magnetic stainless media as well please.

Couple of quick questions too:

-Any issues with leaving the SSM in water after cleaning? I was thinking I would simply rinse the media well after using it and then skip the drying part. Just leave it in a container with water completely submerged for storage.

<span style="color: #000099">No problem so far. I just rinse it good and leave it in the tumbler. </span>

-I've read this entire thread and after looking at the cleaned brass photos, I can't tell if the cases are a high mirror finish (almost a polished look) or are clean but display more of a matte look.

<span style="color: #000099">Polished like new.</span>

-Have we confirmed that Dawn or Ivory is the better soap option? Seems that its a toss up but would love a more direct comparison.

<span style="color: #000099">Only used dawn so far.</span>

-I'm concerned about accidentally leaving SSM in a case while reloading. What check measures are you using to ensure that none is left in the case? Does this include laying the brass out and simply waving a magnet over the cases to see if anything attracts? Would this method even work?

<span style="color: #000099">My method: I use a Frakford Arsenal media seperator with the bucket full of water. That gets it all out but I still go further. I dump the cases in a towel and shake them around to get the rest of the water out/off. I have checked several batches after that process and found no media except one piece stuck in the mouth of a 6.5 case.</span>

-Any issues with 243 Win brass? With the small mouth, does this allow for the SSM to get into the inside and clean effectively?

<span style="color: #000099">I haven't done any 243 brass.</span>

</div></div>

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: mattmcg</div><div class="ubbcode-body">Please PM me the source for the magnetic stainless media as well please.

Couple of quick questions too:

-Any issues with leaving the SSM in water after cleaning? I was thinking I would simply rinse the media well after using it and then skip the drying part. Just leave it in a container with water completely submerged for storage.

<span style="color: #000099">No problem so far. I just rinse it good and leave it in the tumbler. </span>

-I've read this entire thread and after looking at the cleaned brass photos, I can't tell if the cases are a high mirror finish (almost a polished look) or are clean but display more of a matte look.

<span style="color: #000099">Polished like new.</span>

-Have we confirmed that Dawn or Ivory is the better soap option? Seems that its a toss up but would love a more direct comparison.

<span style="color: #000099">Only used dawn so far.</span>

-I'm concerned about accidentally leaving SSM in a case while reloading. What check measures are you using to ensure that none is left in the case? Does this include laying the brass out and simply waving a magnet over the cases to see if anything attracts? Would this method even work?

<span style="color: #000099">My method: I use a Frakford Arsenal media seperator with the bucket full of water. That gets it all out but I still go further. I dump the cases in a towel and shake them around to get the rest of the water out/off. I have checked several batches after that process and found no media except one piece stuck in the mouth of a 6.5 case.</span>

-Any issues with 243 Win brass? With the small mouth, does this allow for the SSM to get into the inside and clean effectively?

<span style="color: #000099">I haven't done any 243 brass.</span>

</div></div>

Re: Stainless Steel Media Testimonials

OK I have been using the SS with the Thumlers, all I can say is it works like nothing else I have ever seen. I shoot Hipower and I am occasionally asked if I use new brass every time I shoot. I told one fella what I use to clean my brass, He said that I am going to get hurt as the stainless Steel will work harden my brass and that I better be careful. I tried to explain how it works and that it DOES NOT WORK HARDEN BRASS ! But he would not listen, Oh well. It works and I will not be using corn cob or walnut media any time soon. I use Dawn and Lemishine, After I separate the brass I use the lemishine Rinse, It stops the brass from getting tarnished. I then dry the brass with a towel then lay it out (new Towel) and let a small fan blow on it for a little while.2-3hrs.? Done. load, shoot, repeat.Easy.

OK I have been using the SS with the Thumlers, all I can say is it works like nothing else I have ever seen. I shoot Hipower and I am occasionally asked if I use new brass every time I shoot. I told one fella what I use to clean my brass, He said that I am going to get hurt as the stainless Steel will work harden my brass and that I better be careful. I tried to explain how it works and that it DOES NOT WORK HARDEN BRASS ! But he would not listen, Oh well. It works and I will not be using corn cob or walnut media any time soon. I use Dawn and Lemishine, After I separate the brass I use the lemishine Rinse, It stops the brass from getting tarnished. I then dry the brass with a towel then lay it out (new Towel) and let a small fan blow on it for a little while.2-3hrs.? Done. load, shoot, repeat.Easy.

Re: Stainless Steel Media Testimonials

Pretty Brass. How's it show on the target? Looks like a lot of work and extra time (drying off brass).

Personally, I'd be willing to bet that it doesn't make a dime's bit of difference on the target. Sure is pretty, though.

Doubt it will make your dies last a bit longer. Tumbled brass is plenty clean for a die.

Pretty Brass. How's it show on the target? Looks like a lot of work and extra time (drying off brass).

Personally, I'd be willing to bet that it doesn't make a dime's bit of difference on the target. Sure is pretty, though.

Doubt it will make your dies last a bit longer. Tumbled brass is plenty clean for a die.

Re: Stainless Steel Media Testimonials

Received my media today from the source - Thanks again Terry. I'm like a kid in a candy store waiting for the first batch of .308 to finish up. Went with the usual .40S&W of Lemishine, a squirt of Ivory and just under a gallon of water. Didn't take photos of this first batch, as all of the brass I have had been previously tumbled in a vibratory - just going for insides and primer pockets on this one. I'll be TDY for a couple of weeks before I get to go back up to the range, but I'll try to find the nastiest range brass I can when I get back to do an additional photo comparison.

Found a Thumler's Model B on eBay although it turned out to be the low speed/1550rpm motor. Shouldn't matter that much as I usually tumble over night or while at work. It beats the heck out of turning on the ultrasonic every 8 minutes, not to mention the rotary is much quieter than my Smart Reloader tumbler is. I'll probably have the Harbor Freight 2.5L w/ heat US cleaner up for sale on craigslist tonight if my results are even close to the ones shown.

Received my media today from the source - Thanks again Terry. I'm like a kid in a candy store waiting for the first batch of .308 to finish up. Went with the usual .40S&W of Lemishine, a squirt of Ivory and just under a gallon of water. Didn't take photos of this first batch, as all of the brass I have had been previously tumbled in a vibratory - just going for insides and primer pockets on this one. I'll be TDY for a couple of weeks before I get to go back up to the range, but I'll try to find the nastiest range brass I can when I get back to do an additional photo comparison.

Found a Thumler's Model B on eBay although it turned out to be the low speed/1550rpm motor. Shouldn't matter that much as I usually tumble over night or while at work. It beats the heck out of turning on the ultrasonic every 8 minutes, not to mention the rotary is much quieter than my Smart Reloader tumbler is. I'll probably have the Harbor Freight 2.5L w/ heat US cleaner up for sale on craigslist tonight if my results are even close to the ones shown.

Re: Stainless Steel Media Testimonials

I've been using the SSM for a couple months now... My thoughts:

1. It does a beautiful job. I've done 308, 338LM, 45ACP, 30-06, and probably some others and it always comes out beautiful

2. It's a painful process. I reload in my garage, and I don't have a water source in there, so my "circular" pattern of use includes dumping some of the water from my RCBS seperator into the tumbler, decanting the rest, dumping media into the tumbler, dumping cases in, 2 or 3 shots of AJAX dish detergent and a 40 caseful of lemishine. Install 6 washers, install 6 wingnuts. It seems to take at LEAST 5 or 6 hours (yes, I have a high speed Model B). Remove 6 wingnuts, remove 6 washers, carefully open lid and wipe any media clinging to the gasket back into the tumbler. Carefully wipe media off the top of the tumbler liner, and back into the tumbler. Dump tumbler into a 2 gallon bucket, and carry that to the bathroom. Decant dirty water out of the bucket into the bathtub. Refill bucket, rake my hands around through the brass/media to rinse. Decant, fill, rake, decant, fill, rake....continue until water is clear and clean. Carry it back out to the garage. Dump bucket of water/brass/media into the seperator. Close lid, crank seperator for a minute, reversing directions every ten seconds. Open seperator, pull out squirrel cage, decant water back into the tumbler drum. Now the squirrel cage isn't half in/half out of the water. crank seperator for another minute or two, reversing directions, and spinning fast sometimes to "fling" water out. Open seperator, dump brass out of squirrel cage into a towel. I fold the towel in half the long way, grasp the ends shut, and allow the brass to tumble from one end of the towel to the other. Occassionally I "drop" the towel to the ground (while still holding the ends) to allow the brass to scatter around in the towel again. Then lay the towel out and let the brass sit for a day or two. Several times now, after this "drying" procedure, I've put the cases into a ziplock bag after at least 2 days drying time, only to notice a day later there is condensation inside the bag - obviously I didn't "dry" enough.

3. Its really easy to spill the media, and EXCEEDINGLY difficult to pick it back up. I think I read something about magnetic media - wish mine was, but of course the tradeoff is corrosion. If its got enough iron in it to be magnetic, its got enough iron in it to rust, right??

I don't know if I'd buy it over again. It sure does a nice job, but its such a pain.

TO VALIDATE YOUR DRYING PROCEDURE: I **HIGHLY** recommend you try the ziplock bag technique. When you think you're dry, dump the brass into a ziplock bag, zip it shut and let it sit for a day or two. If you see no trace of condensation, you're good. If you do - better rethink your drying process. Misfires and hangfires are no fun at the range, or at a match.

I've been using the SSM for a couple months now... My thoughts:

1. It does a beautiful job. I've done 308, 338LM, 45ACP, 30-06, and probably some others and it always comes out beautiful

2. It's a painful process. I reload in my garage, and I don't have a water source in there, so my "circular" pattern of use includes dumping some of the water from my RCBS seperator into the tumbler, decanting the rest, dumping media into the tumbler, dumping cases in, 2 or 3 shots of AJAX dish detergent and a 40 caseful of lemishine. Install 6 washers, install 6 wingnuts. It seems to take at LEAST 5 or 6 hours (yes, I have a high speed Model B). Remove 6 wingnuts, remove 6 washers, carefully open lid and wipe any media clinging to the gasket back into the tumbler. Carefully wipe media off the top of the tumbler liner, and back into the tumbler. Dump tumbler into a 2 gallon bucket, and carry that to the bathroom. Decant dirty water out of the bucket into the bathtub. Refill bucket, rake my hands around through the brass/media to rinse. Decant, fill, rake, decant, fill, rake....continue until water is clear and clean. Carry it back out to the garage. Dump bucket of water/brass/media into the seperator. Close lid, crank seperator for a minute, reversing directions every ten seconds. Open seperator, pull out squirrel cage, decant water back into the tumbler drum. Now the squirrel cage isn't half in/half out of the water. crank seperator for another minute or two, reversing directions, and spinning fast sometimes to "fling" water out. Open seperator, dump brass out of squirrel cage into a towel. I fold the towel in half the long way, grasp the ends shut, and allow the brass to tumble from one end of the towel to the other. Occassionally I "drop" the towel to the ground (while still holding the ends) to allow the brass to scatter around in the towel again. Then lay the towel out and let the brass sit for a day or two. Several times now, after this "drying" procedure, I've put the cases into a ziplock bag after at least 2 days drying time, only to notice a day later there is condensation inside the bag - obviously I didn't "dry" enough.

3. Its really easy to spill the media, and EXCEEDINGLY difficult to pick it back up. I think I read something about magnetic media - wish mine was, but of course the tradeoff is corrosion. If its got enough iron in it to be magnetic, its got enough iron in it to rust, right??

I don't know if I'd buy it over again. It sure does a nice job, but its such a pain.

TO VALIDATE YOUR DRYING PROCEDURE: I **HIGHLY** recommend you try the ziplock bag technique. When you think you're dry, dump the brass into a ziplock bag, zip it shut and let it sit for a day or two. If you see no trace of condensation, you're good. If you do - better rethink your drying process. Misfires and hangfires are no fun at the range, or at a match.

Re: Stainless Steel Media Testimonials

Turbo54, the ss media from Terry's guy Mark is magnetic and it doesn't rust. It would be a real pain to use without being able to pick up the pieces with a magnet.

I'm not sure how many cases you are doing at once, but you might not be using enough soap if it's taking 6 hours in a highspeed tumbler.

Dryers are easy to make and several types are listed in this long thread that work well in cool/cold/ conditions including alcohol drying. When the weather gets warm, it really doesn't take more than putting the cases where the sun can shine on them for an hour or so.

I like the system for myself, but some situations are going to be less conducive for it too work well for others such as yourself, (i.e. water source not located where you tumble).

Turbo54, the ss media from Terry's guy Mark is magnetic and it doesn't rust. It would be a real pain to use without being able to pick up the pieces with a magnet.

I'm not sure how many cases you are doing at once, but you might not be using enough soap if it's taking 6 hours in a highspeed tumbler.

Dryers are easy to make and several types are listed in this long thread that work well in cool/cold/ conditions including alcohol drying. When the weather gets warm, it really doesn't take more than putting the cases where the sun can shine on them for an hour or so.

I like the system for myself, but some situations are going to be less conducive for it too work well for others such as yourself, (i.e. water source not located where you tumble).

Re: Stainless Steel Media Testimonials

Now that I've been using this for a couple months, I've gotten a feel for how to judge how much soap is needed based on quantity of cases, and how foul they are. I've gotten pretty good at this, and always have a nice head of lather when I open her up. I don't *think* soap is the issue.

Another thing: Anyone notice 7.62 NATO brass doesn't get "gold", its more of a dark brownish "bronze".... Even after LOTS of tumbling?

Now that I've been using this for a couple months, I've gotten a feel for how to judge how much soap is needed based on quantity of cases, and how foul they are. I've gotten pretty good at this, and always have a nice head of lather when I open her up. I don't *think* soap is the issue.

Another thing: Anyone notice 7.62 NATO brass doesn't get "gold", its more of a dark brownish "bronze".... Even after LOTS of tumbling?

Re: Stainless Steel Media Testimonials

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: turbo54</div><div class="ubbcode-body">Now that I've been using this for a couple months, I've gotten a feel for how to judge how much soap is needed based on quantity of cases, and how foul they are. I've gotten pretty good at this, and always have a nice head of lather when I open her up. I don't *think* soap is the issue.

Another thing: Anyone notice 7.62 NATO brass doesn't get "gold", its more of a dark brownish "bronze".... Even after LOTS of tumbling?</div></div> <div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: turbo54</div><div class="ubbcode-body">I've been using the SSM for a couple months now... My thoughts:

1. It does a beautiful job. I've done 308, 338LM, 45ACP, 30-06, and probably some others and it always comes out beautiful

2. It's a painful process. I reload in my garage, and I don't have a water source in there, so my "circular" pattern of use includes dumping some of the water from my RCBS seperator into the tumbler, decanting the rest, dumping media into the tumbler, dumping cases in, 2 or 3 shots of AJAX dish detergent and a 40 caseful of lemishine. Install 6 washers, install 6 wingnuts. It seems to take at LEAST 5 or 6 hours (yes, I have a high speed Model B). Remove 6 wingnuts, remove 6 washers, carefully open lid and wipe any media clinging to the gasket back into the tumbler. Carefully wipe media off the top of the tumbler liner, and back into the tumbler. Dump tumbler into a 2 gallon bucket, and carry that to the bathroom. Decant dirty water out of the bucket into the bathtub. Refill bucket, rake my hands around through the brass/media to rinse. Decant, fill, rake, decant, fill, rake....continue until water is clear and clean. Carry it back out to the garage. Dump bucket of water/brass/media into the seperator. Close lid, crank seperator for a minute, reversing directions every ten seconds. Open seperator, pull out squirrel cage, decant water back into the tumbler drum. Now the squirrel cage isn't half in/half out of the water. crank seperator for another minute or two, reversing directions, and spinning fast sometimes to "fling" water out. Open seperator, dump brass out of squirrel cage into a towel. I fold the towel in half the long way, grasp the ends shut, and allow the brass to tumble from one end of the towel to the other. Occassionally I "drop" the towel to the ground (while still holding the ends) to allow the brass to scatter around in the towel again. Then lay the towel out and let the brass sit for a day or two. Several times now, after this "drying" procedure, I've put the cases into a ziplock bag after at least 2 days drying time, only to notice a day later there is condensation inside the bag - obviously I didn't "dry" enough.

3. Its really easy to spill the media, and EXCEEDINGLY difficult to pick it back up. I think I read something about magnetic media - wish mine was, but of course the tradeoff is corrosion. If its got enough iron in it to be magnetic, its got enough iron in it to rust, right??

I don't know if I'd buy it over again. It sure does a nice job, but its such a pain.

TO VALIDATE YOUR DRYING PROCEDURE: I **HIGHLY** recommend you try the ziplock bag technique. When you think you're dry, dump the brass into a ziplock bag, zip it shut and let it sit for a day or two. If you see no trace of condensation, you're good. If you do - better rethink your drying process. Misfires and hangfires are no fun at the range, or at a match. </div></div>

Instead of SSM, which would you use instead?

Did the SSM get the primer pockets clean?

Slightly offtopic, but what kind of turbo 5.4 are you running? Ford modular?

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: turbo54</div><div class="ubbcode-body">Now that I've been using this for a couple months, I've gotten a feel for how to judge how much soap is needed based on quantity of cases, and how foul they are. I've gotten pretty good at this, and always have a nice head of lather when I open her up. I don't *think* soap is the issue.

Another thing: Anyone notice 7.62 NATO brass doesn't get "gold", its more of a dark brownish "bronze".... Even after LOTS of tumbling?</div></div> <div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: turbo54</div><div class="ubbcode-body">I've been using the SSM for a couple months now... My thoughts:

1. It does a beautiful job. I've done 308, 338LM, 45ACP, 30-06, and probably some others and it always comes out beautiful

2. It's a painful process. I reload in my garage, and I don't have a water source in there, so my "circular" pattern of use includes dumping some of the water from my RCBS seperator into the tumbler, decanting the rest, dumping media into the tumbler, dumping cases in, 2 or 3 shots of AJAX dish detergent and a 40 caseful of lemishine. Install 6 washers, install 6 wingnuts. It seems to take at LEAST 5 or 6 hours (yes, I have a high speed Model B). Remove 6 wingnuts, remove 6 washers, carefully open lid and wipe any media clinging to the gasket back into the tumbler. Carefully wipe media off the top of the tumbler liner, and back into the tumbler. Dump tumbler into a 2 gallon bucket, and carry that to the bathroom. Decant dirty water out of the bucket into the bathtub. Refill bucket, rake my hands around through the brass/media to rinse. Decant, fill, rake, decant, fill, rake....continue until water is clear and clean. Carry it back out to the garage. Dump bucket of water/brass/media into the seperator. Close lid, crank seperator for a minute, reversing directions every ten seconds. Open seperator, pull out squirrel cage, decant water back into the tumbler drum. Now the squirrel cage isn't half in/half out of the water. crank seperator for another minute or two, reversing directions, and spinning fast sometimes to "fling" water out. Open seperator, dump brass out of squirrel cage into a towel. I fold the towel in half the long way, grasp the ends shut, and allow the brass to tumble from one end of the towel to the other. Occassionally I "drop" the towel to the ground (while still holding the ends) to allow the brass to scatter around in the towel again. Then lay the towel out and let the brass sit for a day or two. Several times now, after this "drying" procedure, I've put the cases into a ziplock bag after at least 2 days drying time, only to notice a day later there is condensation inside the bag - obviously I didn't "dry" enough.

3. Its really easy to spill the media, and EXCEEDINGLY difficult to pick it back up. I think I read something about magnetic media - wish mine was, but of course the tradeoff is corrosion. If its got enough iron in it to be magnetic, its got enough iron in it to rust, right??

I don't know if I'd buy it over again. It sure does a nice job, but its such a pain.

TO VALIDATE YOUR DRYING PROCEDURE: I **HIGHLY** recommend you try the ziplock bag technique. When you think you're dry, dump the brass into a ziplock bag, zip it shut and let it sit for a day or two. If you see no trace of condensation, you're good. If you do - better rethink your drying process. Misfires and hangfires are no fun at the range, or at a match. </div></div>

Instead of SSM, which would you use instead?

Did the SSM get the primer pockets clean?

Slightly offtopic, but what kind of turbo 5.4 are you running? Ford modular?

Re: Stainless Steel Media Testimonials

turb054, I have the SS media that is magnetic and it has never rusted after much use and put away wet.

turb054, I have the SS media that is magnetic and it has never rusted after much use and put away wet.

Re: Stainless Steel Media Testimonials

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: deisel</div><div class="ubbcode-body">turb054, I have the SS media that is magnetic and it has never rusted after much use and put away wet. </div></div>

+1

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: deisel</div><div class="ubbcode-body">turb054, I have the SS media that is magnetic and it has never rusted after much use and put away wet. </div></div>

+1

Re: Stainless Steel Media Testimonials

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: turbo54</div><div class="ubbcode-body">I've been using the SSM for a couple months now... My thoughts:

1. It does a beautiful job. I've done 308, 338LM, 45ACP, 30-06, and probably some others and it always comes out beautiful

2. It's a painful process. I reload in my garage, and I don't have a water source in there, so my "circular" pattern of use includes dumping some of the water from my RCBS seperator into the tumbler, decanting the rest, dumping media into the tumbler, dumping cases in, 2 or 3 shots of AJAX dish detergent and a 40 caseful of lemishine. Install 6 washers, install 6 wingnuts. It seems to take at LEAST 5 or 6 hours (yes, I have a high speed Model B). Remove 6 wingnuts, remove 6 washers, carefully open lid and wipe any media clinging to the gasket back into the tumbler. Carefully wipe media off the top of the tumbler liner, and back into the tumbler. Dump tumbler into a 2 gallon bucket, and carry that to the bathroom. Decant dirty water out of the bucket into the bathtub. Refill bucket, rake my hands around through the brass/media to rinse. Decant, fill, rake, decant, fill, rake....continue until water is clear and clean. Carry it back out to the garage. Dump bucket of water/brass/media into the seperator. Close lid, crank seperator for a minute, reversing directions every ten seconds. Open seperator, pull out squirrel cage, decant water back into the tumbler drum. Now the squirrel cage isn't half in/half out of the water. crank seperator for another minute or two, reversing directions, and spinning fast sometimes to "fling" water out. Open seperator, dump brass out of squirrel cage into a towel. I fold the towel in half the long way, grasp the ends shut, and allow the brass to tumble from one end of the towel to the other. Occassionally I "drop" the towel to the ground (while still holding the ends) to allow the brass to scatter around in the towel again. Then lay the towel out and let the brass sit for a day or two. Several times now, after this "drying" procedure, I've put the cases into a ziplock bag after at least 2 days drying time, only to notice a day later there is condensation inside the bag - obviously I didn't "dry" enough.

3. Its really easy to spill the media, and EXCEEDINGLY difficult to pick it back up. I think I read something about magnetic media - wish mine was, but of course the tradeoff is corrosion. If its got enough iron in it to be magnetic, its got enough iron in it to rust, right??

I don't know if I'd buy it over again. It sure does a nice job, but its such a pain.

TO VALIDATE YOUR DRYING PROCEDURE: I **HIGHLY** recommend you try the ziplock bag technique. When you think you're dry, dump the brass into a ziplock bag, zip it shut and let it sit for a day or two. If you see no trace of condensation, you're good. If you do - better rethink your drying process. Misfires and hangfires are no fun at the range, or at a match. </div></div>

So how painful would it be if you didn't have heat?

I don't, so I wait till it was warm enough to spend time out there.

I cast 26 lbs of 45-70 330grn HP's about a month ago and it was a balmy -10C that's about 15 F for you guy's down South of me.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: turbo54</div><div class="ubbcode-body">I've been using the SSM for a couple months now... My thoughts:

1. It does a beautiful job. I've done 308, 338LM, 45ACP, 30-06, and probably some others and it always comes out beautiful

2. It's a painful process. I reload in my garage, and I don't have a water source in there, so my "circular" pattern of use includes dumping some of the water from my RCBS seperator into the tumbler, decanting the rest, dumping media into the tumbler, dumping cases in, 2 or 3 shots of AJAX dish detergent and a 40 caseful of lemishine. Install 6 washers, install 6 wingnuts. It seems to take at LEAST 5 or 6 hours (yes, I have a high speed Model B). Remove 6 wingnuts, remove 6 washers, carefully open lid and wipe any media clinging to the gasket back into the tumbler. Carefully wipe media off the top of the tumbler liner, and back into the tumbler. Dump tumbler into a 2 gallon bucket, and carry that to the bathroom. Decant dirty water out of the bucket into the bathtub. Refill bucket, rake my hands around through the brass/media to rinse. Decant, fill, rake, decant, fill, rake....continue until water is clear and clean. Carry it back out to the garage. Dump bucket of water/brass/media into the seperator. Close lid, crank seperator for a minute, reversing directions every ten seconds. Open seperator, pull out squirrel cage, decant water back into the tumbler drum. Now the squirrel cage isn't half in/half out of the water. crank seperator for another minute or two, reversing directions, and spinning fast sometimes to "fling" water out. Open seperator, dump brass out of squirrel cage into a towel. I fold the towel in half the long way, grasp the ends shut, and allow the brass to tumble from one end of the towel to the other. Occassionally I "drop" the towel to the ground (while still holding the ends) to allow the brass to scatter around in the towel again. Then lay the towel out and let the brass sit for a day or two. Several times now, after this "drying" procedure, I've put the cases into a ziplock bag after at least 2 days drying time, only to notice a day later there is condensation inside the bag - obviously I didn't "dry" enough.

3. Its really easy to spill the media, and EXCEEDINGLY difficult to pick it back up. I think I read something about magnetic media - wish mine was, but of course the tradeoff is corrosion. If its got enough iron in it to be magnetic, its got enough iron in it to rust, right??

I don't know if I'd buy it over again. It sure does a nice job, but its such a pain.

TO VALIDATE YOUR DRYING PROCEDURE: I **HIGHLY** recommend you try the ziplock bag technique. When you think you're dry, dump the brass into a ziplock bag, zip it shut and let it sit for a day or two. If you see no trace of condensation, you're good. If you do - better rethink your drying process. Misfires and hangfires are no fun at the range, or at a match. </div></div>

So how painful would it be if you didn't have heat?

I don't, so I wait till it was warm enough to spend time out there.

I cast 26 lbs of 45-70 330grn HP's about a month ago and it was a balmy -10C that's about 15 F for you guy's down South of me.

Re: Stainless Steel Media Testimonials

Poor mans drying source is a black towel laid out on the ground and let the sun work on brass while you are gone all day. In the winter time I have one of those nylon net type laundry bags I put the wet brass in and lay it over a heat register coming up through floor and next morning it is nice and dry.

Insofar as enough soap. The rule of thumb I wound up with is I feel the water between the fingers. If it does not feel slick when the lid is opened the soap for lack of a better term has gone dead. Before clamping lid down feel wet fingers and feel how slick it is. If it is not slick on opening the soap has broken down.

Just as soon as the soap breaks down the carbon starts to deposit back on the cases ! ! ! ! ! If your cases are not gold I suspect that is what has happened.

I live in a soft water area and use well water and the Limishine is the greatest addition to the process anyone has come up with. Whoever decided to give it a try and let us in on it deserves a big ATTABOY ! ! ! ! !

Who thought of that anyhow?

I tried the Orange Cleaner and it was a bomb ! ! ! ! I have also used Joy and Dawn. Both will work but Ivory is the prettiest of them all.

Gives the term White Lightning a new definition ! ! !

I have been using it several years and always put it up wet BUT CLEAN and it stays shiney even though I don't use it for maybe two weeks at a time and the water has dried up in tumbler.

At Wally World in kitchen section they sell a measuring glass (Anchor Hocking made) with all kinds of lines on it for CC, oz etc. costs a buck. I fill it with Ivory to the one ounce line and pour it on brass and then rinse it out with the hot water I am pouring in as the dish soap tends to cling to the container.

On particularly scuzzy brass loaded multiple times it may take several cleanings but it will come gold eventually when you get rid of the carbon.

Someone mentioned about cleaning other things. Well I had some sling swivels that had rusted and I tumbled them and the rust was gone. Next time I find rusted dies at flea market etc I will tumble them.

Poor mans drying source is a black towel laid out on the ground and let the sun work on brass while you are gone all day. In the winter time I have one of those nylon net type laundry bags I put the wet brass in and lay it over a heat register coming up through floor and next morning it is nice and dry.

Insofar as enough soap. The rule of thumb I wound up with is I feel the water between the fingers. If it does not feel slick when the lid is opened the soap for lack of a better term has gone dead. Before clamping lid down feel wet fingers and feel how slick it is. If it is not slick on opening the soap has broken down.

Just as soon as the soap breaks down the carbon starts to deposit back on the cases ! ! ! ! ! If your cases are not gold I suspect that is what has happened.

I live in a soft water area and use well water and the Limishine is the greatest addition to the process anyone has come up with. Whoever decided to give it a try and let us in on it deserves a big ATTABOY ! ! ! ! !

Who thought of that anyhow?

I tried the Orange Cleaner and it was a bomb ! ! ! ! I have also used Joy and Dawn. Both will work but Ivory is the prettiest of them all.

Gives the term White Lightning a new definition ! ! !

I have been using it several years and always put it up wet BUT CLEAN and it stays shiney even though I don't use it for maybe two weeks at a time and the water has dried up in tumbler.

At Wally World in kitchen section they sell a measuring glass (Anchor Hocking made) with all kinds of lines on it for CC, oz etc. costs a buck. I fill it with Ivory to the one ounce line and pour it on brass and then rinse it out with the hot water I am pouring in as the dish soap tends to cling to the container.

On particularly scuzzy brass loaded multiple times it may take several cleanings but it will come gold eventually when you get rid of the carbon.

Someone mentioned about cleaning other things. Well I had some sling swivels that had rusted and I tumbled them and the rust was gone. Next time I find rusted dies at flea market etc I will tumble them.

Re: Stainless Steel Media Testimonials

My mothers friend was fixing up a old home that had a whole bunch of brass hardware. Needless to say they was rather green and tarnished. She told my mother that she had be trying to polish them with brasso and a few others.

I should have taken photos but did not. Needless to say she was totally amazed when I gave them back. They looked like new!

Terry

My mothers friend was fixing up a old home that had a whole bunch of brass hardware. Needless to say they was rather green and tarnished. She told my mother that she had be trying to polish them with brasso and a few others.

I should have taken photos but did not. Needless to say she was totally amazed when I gave them back. They looked like new!

Terry

Re: Stainless Steel Media Testimonials

Yet another true believer now. I've been struggling with black powder cleanup in 45-70 and 45 colt.

Left to right is as fired, ceramic cleaned, and straight from the ss media.

as you can see, the ceramic media had a nasty habit of getting caught in the case.

This was after 3 hours only in the ss media.

I love this stuff!

For a dryer, I have an old food dehydrator that wasn't being used.

Yet another true believer now. I've been struggling with black powder cleanup in 45-70 and 45 colt.

Left to right is as fired, ceramic cleaned, and straight from the ss media.

as you can see, the ceramic media had a nasty habit of getting caught in the case.

This was after 3 hours only in the ss media.

I love this stuff!

For a dryer, I have an old food dehydrator that wasn't being used.

Re: Stainless Steel Media Testimonials

Best guess I processed 5-600 rounds of Rifle and twice that in pistol this weekend. The only thing I could wish for is a larger tumbler.

Hummer and Terry......

Thank you

Best guess I processed 5-600 rounds of Rifle and twice that in pistol this weekend. The only thing I could wish for is a larger tumbler.

Hummer and Terry......

Thank you

Re: Stainless Steel Media Testimonials

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: 9mmkungfu</div><div class="ubbcode-body">

Instead of SSM, which would you use instead?

Did the SSM get the primer pockets clean?

Slightly offtopic, but what kind of turbo 5.4 are you running? Ford modular? </div></div>

I don't know what else to use. I'm not *unhappy* with the SSM, it's just that for every Pro, there is a Con. Tumbling wet makes the whole thing a pain... A mini cement mixer that you didn't have to seal with a gasket and wing nuts would be more convenient for sure. A better way to rinse the media/brass slurry of crap and soap would be nice.

The SSM certainly gets the primer pockets 98% clean - much better than any another method I've used including corn, walnut and primer pocket cleaning tools.

I don't have a turbocharged 5.4 anymore - used to be into Ford Mod Motors - back before I went back to school for my Masters. The screen name/handle goes way back, and I've just stuck with it for continuity sake. You're the only person not from the corral that has recognized the "meaning" of turbo54.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: 9mmkungfu</div><div class="ubbcode-body">

Instead of SSM, which would you use instead?

Did the SSM get the primer pockets clean?

Slightly offtopic, but what kind of turbo 5.4 are you running? Ford modular? </div></div>

I don't know what else to use. I'm not *unhappy* with the SSM, it's just that for every Pro, there is a Con. Tumbling wet makes the whole thing a pain... A mini cement mixer that you didn't have to seal with a gasket and wing nuts would be more convenient for sure. A better way to rinse the media/brass slurry of crap and soap would be nice.

The SSM certainly gets the primer pockets 98% clean - much better than any another method I've used including corn, walnut and primer pocket cleaning tools.

I don't have a turbocharged 5.4 anymore - used to be into Ford Mod Motors - back before I went back to school for my Masters. The screen name/handle goes way back, and I've just stuck with it for continuity sake. You're the only person not from the corral that has recognized the "meaning" of turbo54.

Re: Stainless Steel Media Testimonials

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: mattmcg</div><div class="ubbcode-body">Are there any issues with the RCBS rotary tumbler? From the pics it seems like a possibility. What, if any, are the cons of this tumbler vs the Thumlers? </div></div>

I know of two guys using the SS media with the RCBS tumbler and they have no issues with it.

Terry

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: mattmcg</div><div class="ubbcode-body">Are there any issues with the RCBS rotary tumbler? From the pics it seems like a possibility. What, if any, are the cons of this tumbler vs the Thumlers? </div></div>

I know of two guys using the SS media with the RCBS tumbler and they have no issues with it.

Terry

Re: Stainless Steel Media Testimonials

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: suasponte</div><div class="ubbcode-body"><div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: mattmcg</div><div class="ubbcode-body">Are there any issues with the RCBS rotary tumbler? From the pics it seems like a possibility. What, if any, are the cons of this tumbler vs the Thumlers? </div></div>

I know of two guys using the SS media with the RCBS tumbler and they have no issues with it.

Terry </div></div>

Terry, were there any improvements that the Thumler provided over the RCBS? Since I'm starting from scratch, I'd love to know why I should go one way or the other for SSM.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: suasponte</div><div class="ubbcode-body"><div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: mattmcg</div><div class="ubbcode-body">Are there any issues with the RCBS rotary tumbler? From the pics it seems like a possibility. What, if any, are the cons of this tumbler vs the Thumlers? </div></div>

I know of two guys using the SS media with the RCBS tumbler and they have no issues with it.

Terry </div></div>

Terry, were there any improvements that the Thumler provided over the RCBS? Since I'm starting from scratch, I'd love to know why I should go one way or the other for SSM.

Re: Stainless Steel Media Testimonials

You will be able to put more cases/media in the Thumblers than the RCBS, the RCBS is angled and not level.

Just thinking, Harbor Freight has a $20 coupon on their site, and their small cement mixer is on sale for $149, sounds cheaper than a Thumblers,, if it will work.

You will be able to put more cases/media in the Thumblers than the RCBS, the RCBS is angled and not level.

Just thinking, Harbor Freight has a $20 coupon on their site, and their small cement mixer is on sale for $149, sounds cheaper than a Thumblers,, if it will work.

Re: Stainless Steel Media Testimonials

Just a cell pic, but managed to get 1,500 pieces of LC .308 done. (100 pieces at a time in Thumler) About 30 years of head stamps. Some of it was pretty bad. It all looks identical now.

Just a cell phone pic.

Now just to size, trim, prime, and hopefully one day shoot!

Just a cell pic, but managed to get 1,500 pieces of LC .308 done. (100 pieces at a time in Thumler) About 30 years of head stamps. Some of it was pretty bad. It all looks identical now.

Just a cell phone pic.

Now just to size, trim, prime, and hopefully one day shoot!

Similar threads

- Replies

- 2

- Views

- 503

- Replies

- 15

- Views

- 2K