I going to throw it back to what @rustyinbend was mentionoing way back in post #55 about feel while seating bullets, and chime in that I'll cosign those who put in the extra work to lube necks before seating bullets (I just had to find a way that was fast, easy, and low drama enough for me to actually employ and stick to)...

I think when it comes to seating bullets, size does matter. I've been seating bullets on my cheap ass little fucker Lyman press for 3+ years now and I still dig it. It's still the only press I use for all of my precision rifle ammo and I think a lot of that has to do with its small size. The feel it provides is unmatched by larger presses.

Even when FL sizing cases, where obviously a larger press with more leverage would make things easier, it turns out, if cases are lubed properly, the little fucker provides plenty of leverage. But, unlike a big press, I still can feel if something is fucked up or not right immediately (and usually stop before it's too late).

Anyways, for seating bullets, the little press allows me to literally feel whether the batch of rounds I'm loading is going to be good or not. I know whether I'm in single-digit SD territory by muscle memory at this point.

Now, at my club, there's an RCBS Rockchucker for guys to use, and I've used it exactly one time to seat some bullets while doing some load development on a new barrel... it sucked donkey balls, never again, zero* feel. If that's all you know, you're missing out and I kind of feel bad for you lol.

*Speaking of "zero", maybe not a bad time to mention that I'm not using the little Lyman because I'm poor lol. I could buy ~10 A419 Zero presses today if I wanted or needed to before my wife noticed and gave me shit about it lol... money spent is not the point, more funds doesn't necessarily equal better ammo in this reloading game.

But, IMHO, if you've got ~$100 bucks or so (I know a lot of us guys can't go outside without it costing that much), take a hard look at picking up a little press for just seating bullets (or maybe everything), there are a couple of others besides the Lyman too if you don't like Tennessee orange, hear me now, believe me later.

Also, once you have a really good feel while seating bullets, even slight variations in seating pressure become super annoying.

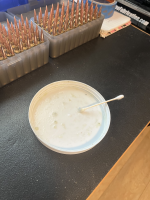

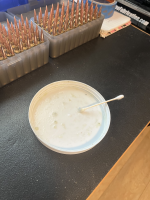

After trying a bunch of different shit to lube necks, almost all of which were annoying and slow, some somewhat sketchy/messy (moly, graphite dust, etc), I arrived at this:

Same shit many of you and I use to lube our cases for sizing: lanolin & IPA ...and a q-tip.

I get the q-tip saturated with lube, and then, with a steady hand, I do a quick swirl in each neck while they're in the loading block (taking care to not insert the q-tip deep enough to touch/disturb the powder). The trick is: I'm not trying to apply much lube, the cotton from the q-tip does all the work. Takes ~20 seconds to do 100 cases.

After, seating bullets is smooooooooth.

The alcohol evaporates, and the friction fit of the brass overcomes whatever lube left behind if it wasn't smeared out of the way while the bullet slid into place (no need to worry about bullets shifting or moving after), nice. ;-)

Anyways, worth a try, I do it every single batch now because I've seen the results downrange and I feel like I'd be leaving something on the table if I skipped it now.

As always, YMMV.

I think when it comes to seating bullets, size does matter. I've been seating bullets on my cheap ass little fucker Lyman press for 3+ years now and I still dig it. It's still the only press I use for all of my precision rifle ammo and I think a lot of that has to do with its small size. The feel it provides is unmatched by larger presses.

Even when FL sizing cases, where obviously a larger press with more leverage would make things easier, it turns out, if cases are lubed properly, the little fucker provides plenty of leverage. But, unlike a big press, I still can feel if something is fucked up or not right immediately (and usually stop before it's too late).

Anyways, for seating bullets, the little press allows me to literally feel whether the batch of rounds I'm loading is going to be good or not. I know whether I'm in single-digit SD territory by muscle memory at this point.

Now, at my club, there's an RCBS Rockchucker for guys to use, and I've used it exactly one time to seat some bullets while doing some load development on a new barrel... it sucked donkey balls, never again, zero* feel. If that's all you know, you're missing out and I kind of feel bad for you lol.

*Speaking of "zero", maybe not a bad time to mention that I'm not using the little Lyman because I'm poor lol. I could buy ~10 A419 Zero presses today if I wanted or needed to before my wife noticed and gave me shit about it lol... money spent is not the point, more funds doesn't necessarily equal better ammo in this reloading game.

But, IMHO, if you've got ~$100 bucks or so (I know a lot of us guys can't go outside without it costing that much), take a hard look at picking up a little press for just seating bullets (or maybe everything), there are a couple of others besides the Lyman too if you don't like Tennessee orange, hear me now, believe me later.

Also, once you have a really good feel while seating bullets, even slight variations in seating pressure become super annoying.

After trying a bunch of different shit to lube necks, almost all of which were annoying and slow, some somewhat sketchy/messy (moly, graphite dust, etc), I arrived at this:

Same shit many of you and I use to lube our cases for sizing: lanolin & IPA ...and a q-tip.

I get the q-tip saturated with lube, and then, with a steady hand, I do a quick swirl in each neck while they're in the loading block (taking care to not insert the q-tip deep enough to touch/disturb the powder). The trick is: I'm not trying to apply much lube, the cotton from the q-tip does all the work. Takes ~20 seconds to do 100 cases.

After, seating bullets is smooooooooth.

The alcohol evaporates, and the friction fit of the brass overcomes whatever lube left behind if it wasn't smeared out of the way while the bullet slid into place (no need to worry about bullets shifting or moving after), nice. ;-)

Anyways, worth a try, I do it every single batch now because I've seen the results downrange and I feel like I'd be leaving something on the table if I skipped it now.

As always, YMMV.

Last edited: