Here are a couple of my boxes. The top one is mahogany. It came out nice, but I’m not happy with the finish. I should have tested it on a trial piece. It’s too opaque and the beautiful grain on the top board got lost. Won’t do that again. Did the light colored box a few years back. I think I've seen someone else post one on here. They put the build in a magazine and I’m sure a bunch of folks made them, but it was a fun little project.

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Maggie’s The Wood Shop

- Thread starter TxWelder35

- Start date

I have the Openbuilds 1500 Lead machine and use Vectric VCarve Pro software. It took some work to get it dialed in and learn the software but I think it’s working pretty well now.Very nice! What CNC machine did you use? I’ve been thinking about getting one, but have no experience.

Do yourself a favor and use a spoil board behind it if you’re using your table saw for box joints. That’ll just about eliminate tear out.Those finger joints look good. Getting ready to make a box for my son out of curly maple. Using finger joints for corners and I’m praying that it doesn’t blow out. Should have it done by this weekend. We have some very talented people on this forum.

Wow, that bottom one is my original design. I'm guessing you might have ran onto it in Fine Woodworking? Nicely done!Here are a couple of my boxes. The top one is mahogany. It came out nice, but I’m not happy with the finish. I should have tested it on a trial piece. It’s too opaque and the beautiful grain on the top board got lost. Won’t do that again. Did the light colored box a few years back. I think I've seen someone else post one on here. They put the build in a magazine and I’m sure a bunch of folks made them, but it was a fun little project. View attachment 8049284View attachment 8049285

What finish did you use on the top one that disappointed you?Here are a couple of my boxes. The top one is mahogany. It came out nice, but I’m not happy with the finish. I should have tested it on a trial piece. It’s too opaque and the beautiful grain on the top board got lost. Won’t do that again. Did the light colored box a few years back. I think I've seen someone else post one on here. They put the build in a magazine and I’m sure a bunch of folks made them, but it was a fun little project. View attachment 8049284View attachment 8049285

Thank you!!That turned out really nice!

They are two piece and feel mainly small in the back but a bit on the sides too I'll try to post a pic when I can figure out how to download it from my phone..Do you have one or two piece grips on it right now?

Are the grips too small in the back, the front, or all around?

Most single action grip panels are between .4-.6 at the thickest part. .4 would be small for sure. Most people are happy with .5 thickness in the panels, but if you have large hands then .6 might be where you need to be.They are two piece and feel mainly small in the back but a bit on the sides too I'll try to post a pic when I can figure out how to download it from my phone..

How many Flips?Aqua Faux-tis achieved!!

View attachment 8049191

2 coats of a dark water based stain/dye followed by 4 coats of the reddish/brown water based stain/dye.

Really easy process and being water based dries really fast in between coats. I can modify from here if needed with more brown or red.

You could make this with an alcohol base and not have any grain rise, but the evaporation rate of alcohol is not what I want. The dark base has to be able to soak in.

I’ll share this groundbreaking recipe for $14,999.00

If it blows out, bondo and paint will fix it!Those finger joints look good. Getting ready to make a box for my son out of curly maple. Using finger joints for corners and I’m praying that it doesn’t blow out. Should have it done by this weekend. We have some very talented people on this forum.

1 flip for the recipe.How many Flips?

Friend of mind carved this out of a 16” butt cut.. he’s planning on a stand with a pcs of laurel holding it in a flying position.. I thought it turned out really nice..

Attachments

So if the one piece grip would cover the backstrap and give me a bit more length of pull that's what I really need.Most single action grip panels are between .4-.6 at the thickest part. .4 would be small for sure. Most people are happy with .5 thickness in the panels, but if you have large hands then .6 might be where you need to be.

I’d fuck it.

@Bigfatcock , sorry for the delay. I used min-wax poly stain. It has the stain and polyurethane in one product. I had used the dark “Bombay” color on things in the house and it came out great, so I thought a lighter color would work for the mahogany. The stain was just too thick colored for the grain to show, and there is spectacular grain on the lid. My mistake, but I learned from it. My wife loves the box, so that’s what matters.

Thank you! I think it still looks really good!@Bigfatcock , sorry for the delay. I used min-wax poly stain. It has the stain and polyurethane in one product. I had used the dark “Bombay” color on things in the house and it came out great, so I thought a lighter color would work for the mahogany. The stain was just too thick colored for the grain to show, and there is spectacular grain on the lid. My mistake, but I learned from it. My wife loves the box, so that’s what matters.

If I’m working with really nice grain, I’ll usually stain with a water or alcohol based dye if I have to stain. Doesn’t muddy things like oil based stains can.

I might also opt for a water based polyurethane since it is clear unlike oil based polyurethane.

What do you use to cut the tails?

Beautiful. Did you make the handle for the saw also?I use 1:6 for all dovetails.

View attachment 8060348

I bought the OpenBuilds 1515 Lead machine a couple years ago. You have to assemble it yourself which allows you to learn every inch of the machine and also allows you to get it perfectly square. It took me quite a while and many jobs to get it dialed in but at this point, I’m happy with my decision. As far as customer support, I had an issue with one of the electronic parts, and they sent me a new part, no questions asked, very quickly. There’s also a big forum on the site with plenty of people willing to help if you have a question. I have no affiliation and spent my own money for all of it. I also purchased the table for it from Openbuilds. I use Vectric VCarve pro but I’ve been wanting to upgrade to Vectric Aspire which is an additional cost. I probably have around 5 grand in my setup, but you can certainly get smaller machines for less. Feel free to give me a shout if you have any other questions, I did a ton of research and picked the route that I thought would be best for me.Has any used or have any experience or suggestions on home CNC machines? Ive started looking at them and know that the most marketed aren't always the best.

I did not. It came on the saw.Beautiful. Did you make the handle for the saw also?

Step 2 in a multiple step finishing process.

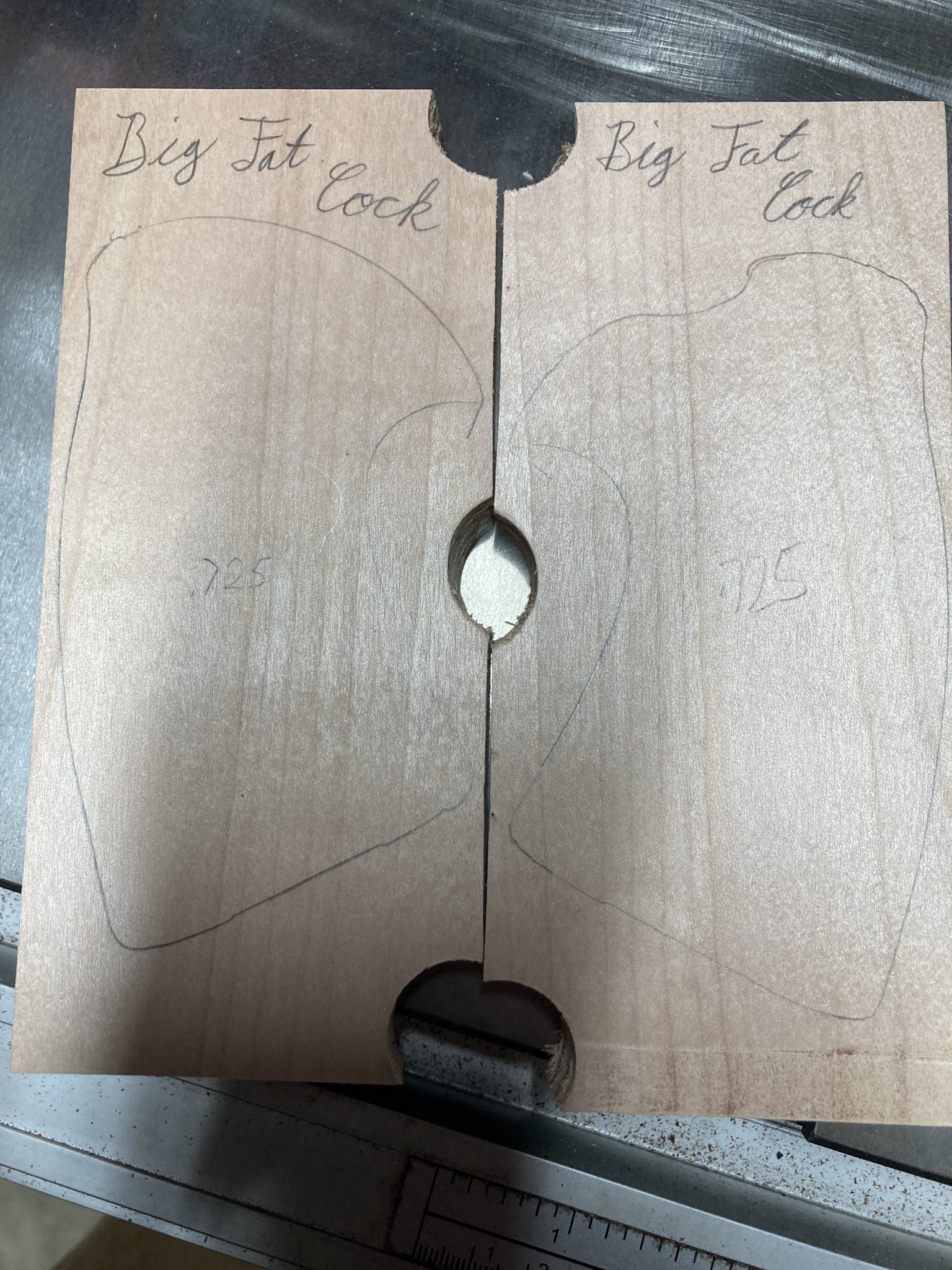

Starting on a new project:

Sort of the right shape:

This is just scrap maple from an old set of a vice jaws. This is a sacrificial test set. A lot of interesting details and nuance to get right in this set.

Sort of the right shape:

This is just scrap maple from an old set of a vice jaws. This is a sacrificial test set. A lot of interesting details and nuance to get right in this set.

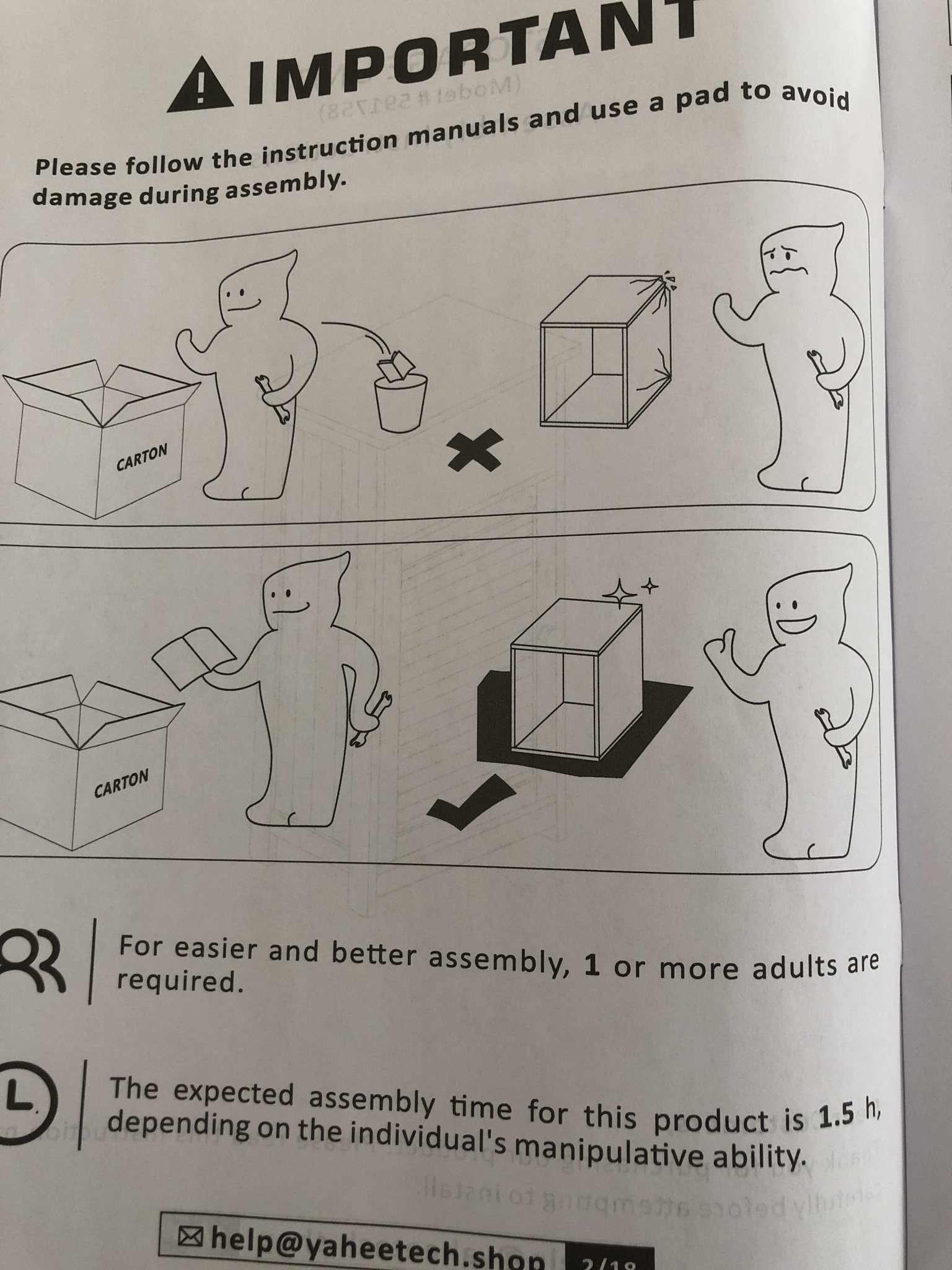

Does this count…..Made by Yaheetech!

I won’t to hang out with “trashed directions guy”.

What’s with these Chinamen calling me Casper?

I won’t to hang out with “trashed directions guy”.

What’s with these Chinamen calling me Casper?

Does this count…..Made by Yaheetech!

View attachment 8088835

View attachment 8088834

I won’t to hang out with “trashed directions guy”.

View attachment 8088836

What’s with these Chinamen calling me Casper?

Seems legit

Would you prefer “Spook”?What’s with these Chinamen calling me Casper?

Does anyone know the proper tourque value for setting a screw in cardboard?

Does anyone know the proper tourque value for setting a screw in cardboard?

300 in lbs

No. I always fuck up at least one on a project like thatDoes anyone know the proper tourque value for setting a screw in cardboard?

Cocksuckers didnt clearance the hinges enough to allow the door to full swing.

Sweet.

My hinge fix looks a little fucked….

But it allows the door to swing 180 degrees.

If I left it at 90 the kids would force it open to 180 ripping the door off.

This fine piece of dung is for their head.

My hinge fix looks a little fucked….

But it allows the door to swing 180 degrees.

If I left it at 90 the kids would force it open to 180 ripping the door off.

This fine piece of dung is for their head.

Got some extra hardware.

Might pay the twenty bucks and try to sell it in the PX.

Might pay the twenty bucks and try to sell it in the PX.

Sweet.

View attachment 8088888

My hinge fix looks a little fucked….

View attachment 8088891

But it allows the door to swing 180 degrees.

View attachment 8088892

If I left it at 90 the kids would force it open to 180 ripping the door off.

This fine piece of dung is for their head.

Hoo suk cok thanks you for your contribution.

If they build fighter aircraft like furniture……Hoo suk cok thanks you for your contribution.

I'm in my shop now. This is my latest project. Its a retirement gift for a local Police Chief. Dept coins will go in the circles.

Wade2Big supports your efforts.View attachment 8088904

I'm in my shop now. This is my latest project. Its a retirement gift for a local Police Chief. Dept coins will go in the circles.

Step 875,432 of the multi step finish process. The goal here is to get the color and depth of Aqua Fortis Reagent without having to use actual Aqua Fortis Reagent. The heat required to blush the nitric acid would ruin any glue joints.

I achieve this color using two different dyes made up of two different dyes each.

I achieve this color using two different dyes made up of two different dyes each.

Sum Ting Wong?Hoo suk cok thanks you for your contribution.

Mrs Pmclaine does not like that in order to do this…..

You have to accept this..

Mrs Pmclaine is going to find out.

You have to accept this..

Mrs Pmclaine is going to find out.

Mrs Pmclaine does not like that in order to do this…..

View attachment 8089514

You have to accept this..

View attachment 8089513

Mrs Pmclaine is going to find out.

Let her know that I would have charged $60 to make that modification. You saved her $60 which should immediately be rolled over to the liquor fund.

I guess 90 degrees will be okay if careful….Its a hard stop where the corner of the door meets the cabinet. No way my kids will allow physics stop them from stressing those 1/4” screws in the pressed shitium boards. Not even the arsenic based glues they use in that stuff will prevent failure.

Maybe I just overthink stuff.

I picture stressed hinges in cardboard. Once pulled free they will never be repaired.

This is the last time I touch this piece of shitanium.

If I cared I’d go buy a deeper hinge.

Maybe I just overthink stuff.

I picture stressed hinges in cardboard. Once pulled free they will never be repaired.

This is the last time I touch this piece of shitanium.

If I cared I’d go buy a deeper hinge.

Last edited:

Gonna do something useful….

Running ultra juicy patches of Hoppes down the barrel of the new gun soaking out some copper and carbon.

Running ultra juicy patches of Hoppes down the barrel of the new gun soaking out some copper and carbon.

More Aqua Faux-tis.

The base coat dye is:

6 oz distilled water

61 drops of Trans Tint dark walnut

6 drops of Trans Tint orange

The top coat dye is:

1 quart distilled water

1/2 oz Transfast Antique Cherry Brown powder

36 drops Trans Tint dark walnut

The base coat dye is:

6 oz distilled water

61 drops of Trans Tint dark walnut

6 drops of Trans Tint orange

The top coat dye is:

1 quart distilled water

1/2 oz Transfast Antique Cherry Brown powder

36 drops Trans Tint dark walnut

Does this count…..Made by Yaheetech!

View attachment 8088835

View attachment 8088834

I won’t to hang out with “trashed directions guy”.

View attachment 8088836

What’s with these Chinamen calling me Casper?

Looks more like a happy little KKK guy.

My current project is a rustic alder mantel along with some crown and trim, it started as a straight beam of alder and then I pulled out some of the knots/colored them in to look like "old" wood and roughed it up a little bit:

Last edited:

Similar threads

Reloading Equipment

Henderson Gen.2 Trimmer W/Motor

- Replies

- 9

- Views

- 611

Precision Rifle Gear

Can you use a Badger Ordnance Diving Board w/ Leupold MK4 rings?

- Replies

- 0

- Views

- 121