I bought an openbuilds machine a few years ago and use Vectric software for the designing. My machine required assembly which saved some money and taught me everything about the machine. It uses a Dewalt 611 router. I have the 1500x1500 machine because I wanted to have the larger bed for whatever I might want to work with, but a smaller bench top machine would be easy and cheap for doing grips and smaller stuff for sure. There are certainly nicer machines than mine out there, just depends on your budget I suppose. Mine is quite capable of doing some nice 3D stuff. (Technically 2.5D)

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Maggie’s The Wood Shop

- Thread starter TxWelder35

- Start date

Very nice!I bought an openbuilds machine a few years ago and use Vectric software for the designing. My machine required assembly which saved some money and taught me everything about the machine. It uses a Dewalt 611 router. I have the 1500x1500 machine because I wanted to have the larger bed for whatever I might want to work with, but a smaller bench top machine would be easy and cheap for doing grips and smaller stuff for sure. There are certainly nicer machines than mine out there, just depends on your budget I suppose. Mine is quite capable of doing some nice 3D stuff. (Technically 2.5D)View attachment 8175651View attachment 8175652View attachment 8175653View attachment 8175654View attachment 8175655

Yeah, I’m definitely looking to the smaller side of machines and mainly for knocking out about 75%-90% of the shaping and contouring. Honestly doesn’t take too long to do by hand, but the CNC looks very useful. I figure for 1911 grips it can do 100% of the work aside from finishing.

The revolver grips will likely still require hand fitting for that final 10%, which is where the majority of time is spent!

Maybe one of you know a source….

I believe the size is 44-7/8….

I’m looking for wood type bandsaw blades for the “porta-band” type saws. My google-foo has let me down.

It’s my intention to put a spare Milwaukee corded saw into one of the stands made by Swag.

I believe the size is 44-7/8….

I’m looking for wood type bandsaw blades for the “porta-band” type saws. My google-foo has let me down.

It’s my intention to put a spare Milwaukee corded saw into one of the stands made by Swag.

Rockler sells custom length bandsaw blades.

Most blade sellers will weld to custom length.

Most blade sellers will weld to custom length.

Last edited:

Home Depot has a couple optionsMaybe one of you know a source….

I believe the size is 44-7/8….

I’m looking for wood type bandsaw blades for the “porta-band” type saws. My google-foo has let me down.

It’s my intention to put a spare Milwaukee corded saw into one of the stands made by Swag.

Milwaukee - Band Saw Blade - Saw Blades - The Home Depot

Get free shipping on qualified Milwaukee Band Saw Blade products or Buy Online Pick Up in Store today in the Tools Department.

www.homedepot.com

Highland Hardware is a good source for blades.Maybe one of you know a source….

I believe the size is 44-7/8….

I’m looking for wood type bandsaw blades for the “porta-band” type saws. My google-foo has let me down.

It’s my intention to put a spare Milwaukee corded saw into one of the stands made by Swag.

Check out Hastings Saw Blades. I buy my vertical and horizontal band saw blades from them.Highland Hardware is a good source for blades.

Never located a dedicated wood blade for the porta-band but did get a couple 8/11 tooth that’ll do for now.

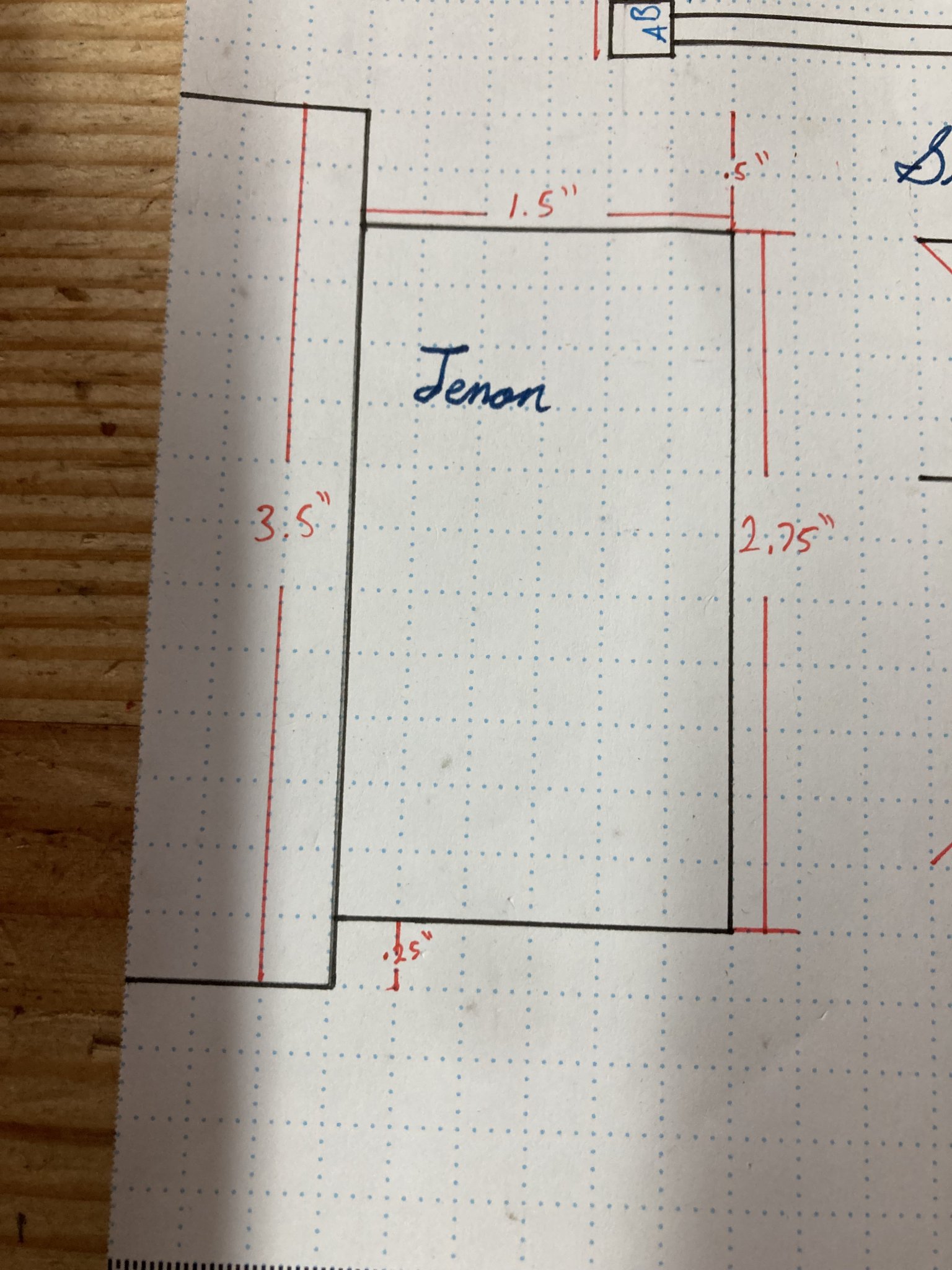

Made a simple tenon jig today for my little shit box DeWalt table saw. For a entry level jobsite type saw it is surprisingly accurate.

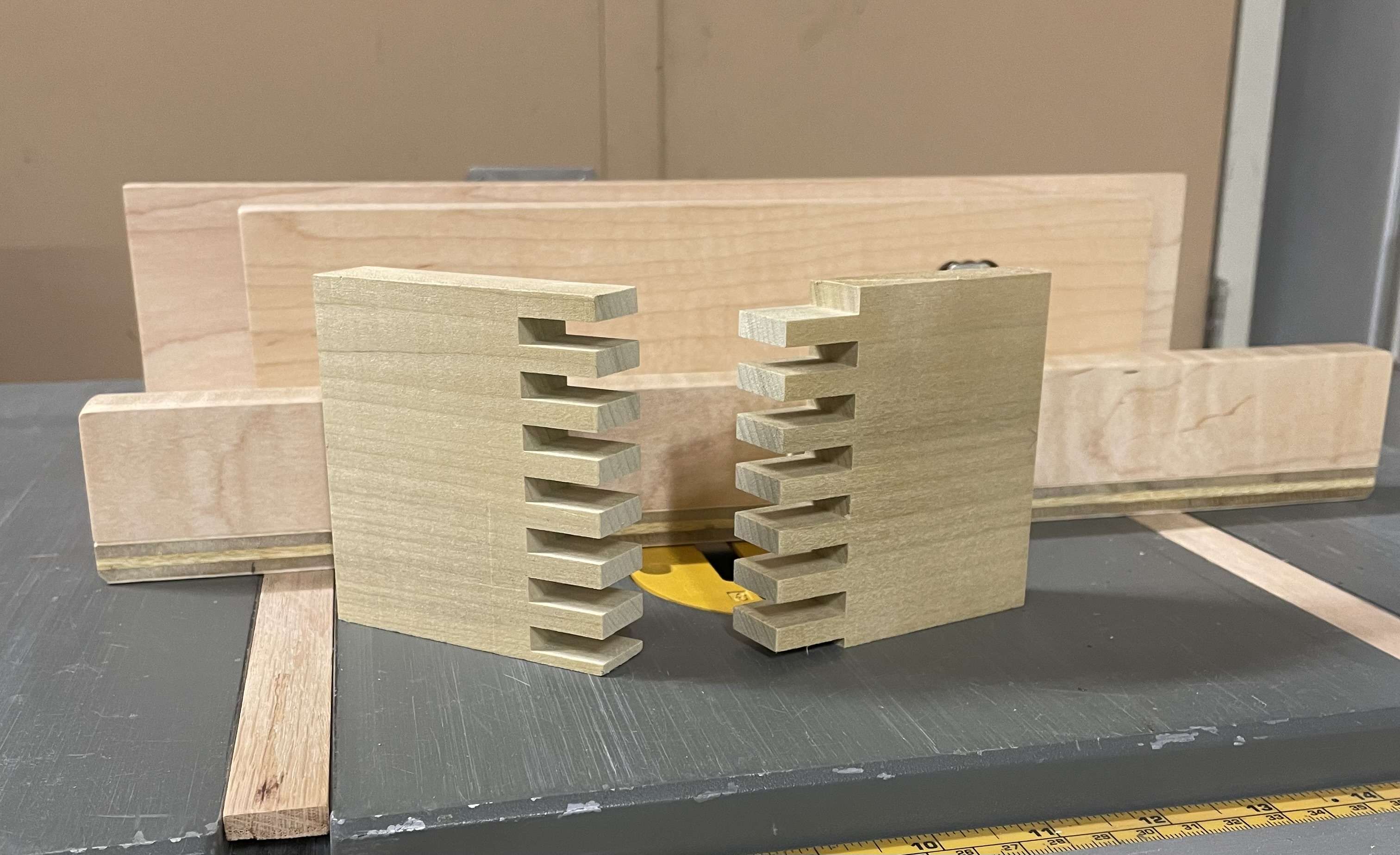

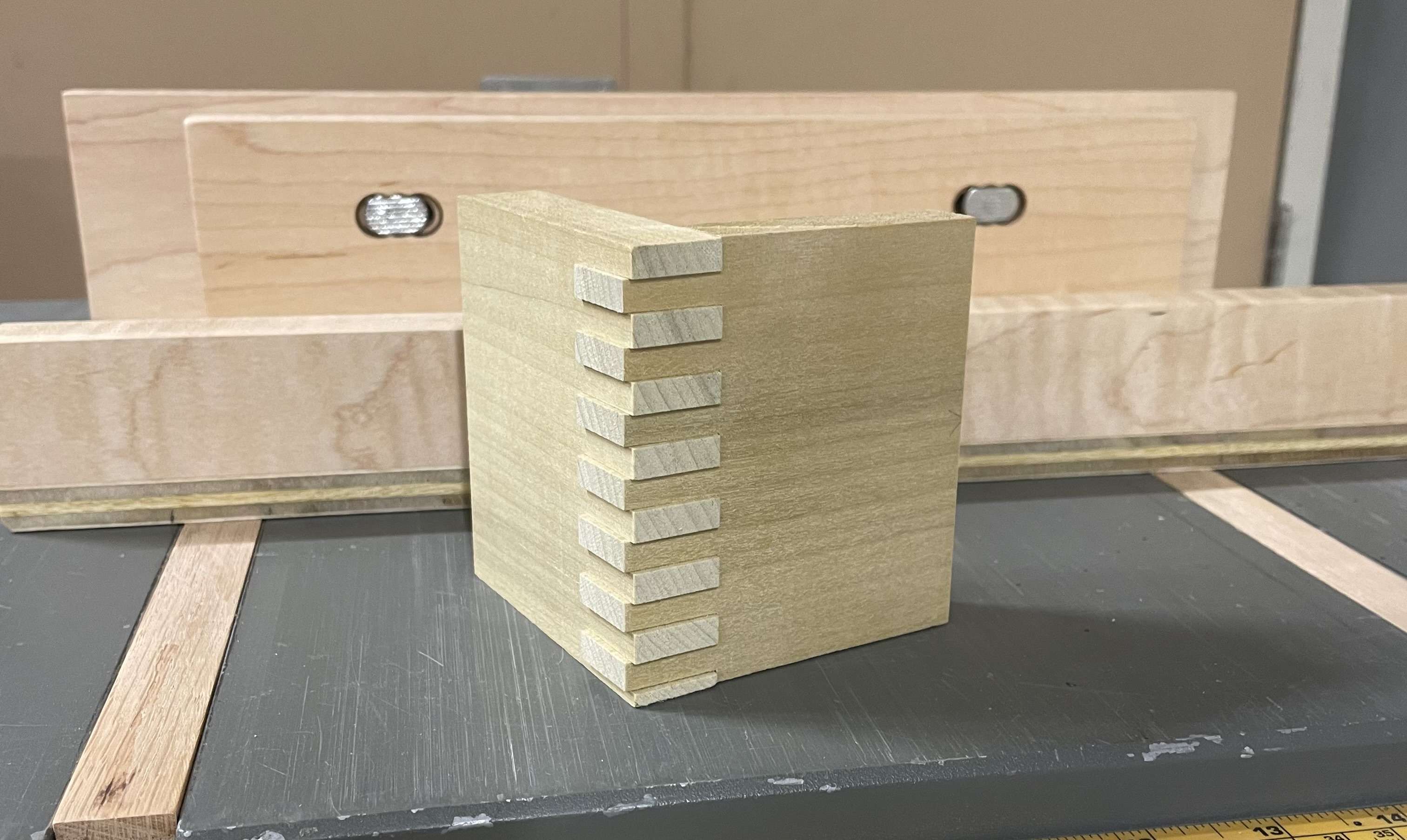

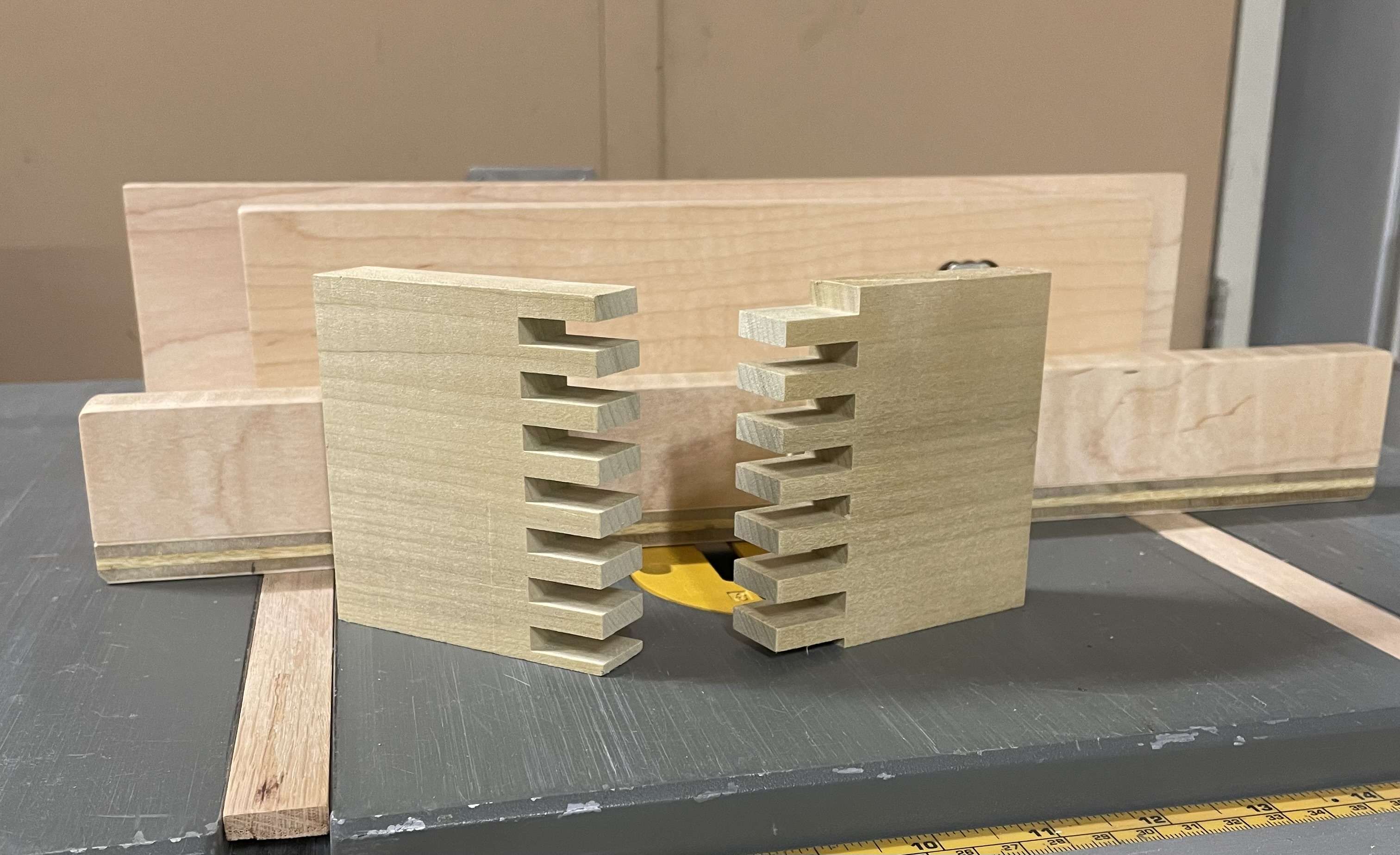

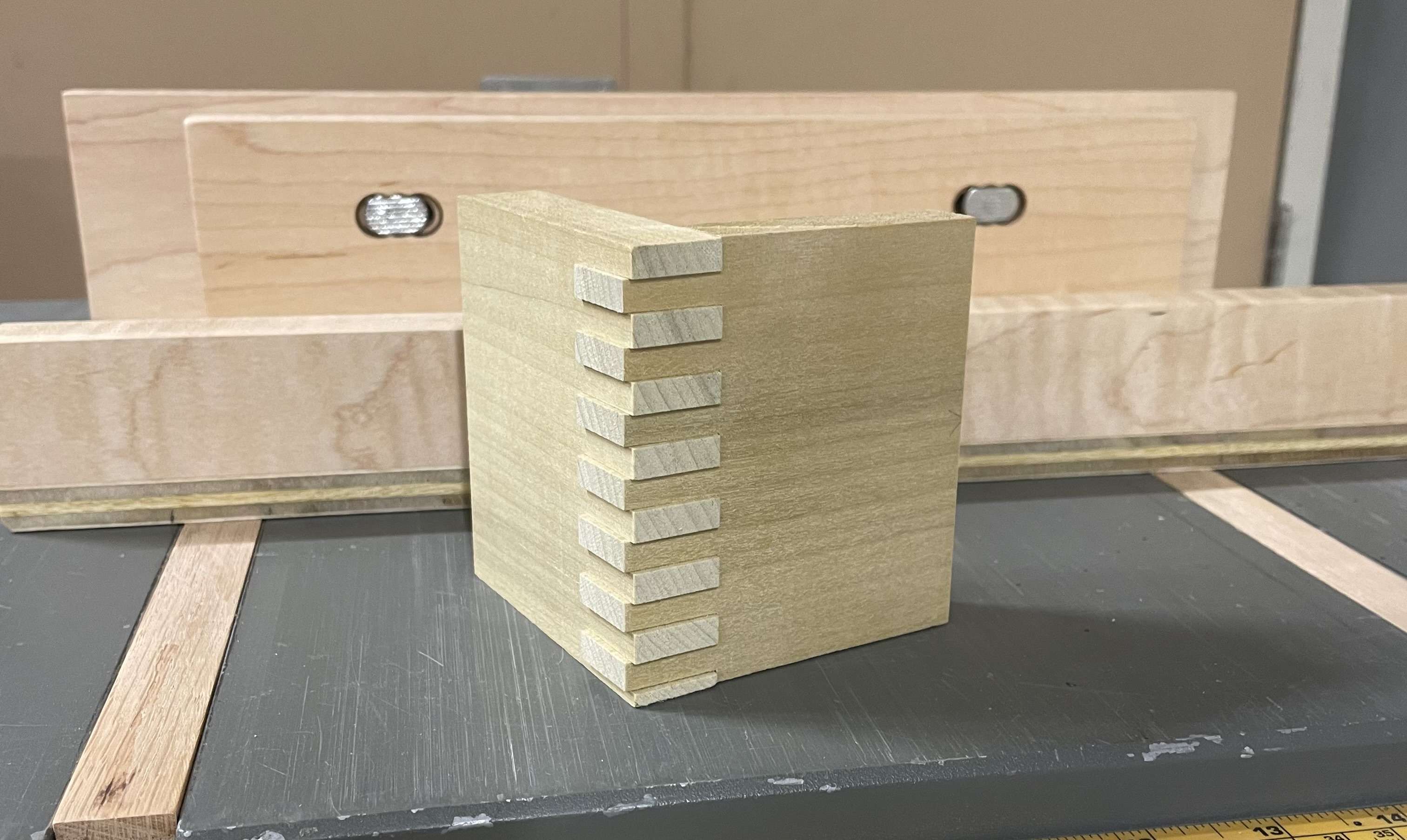

Made another fixture for the table saw. Have been wanting to step up my joinery game a little so a box joint jig was in order….

The piece with the locating pin can be changed out for different size slots. Will eventually make a 1/8”, 3/8” and a 1/2”.

The piece with the locating pin can be changed out for different size slots. Will eventually make a 1/8”, 3/8” and a 1/2”.

I have the Dewalt DW745. It has the short arbor that prohibits a traditional dado blade set.

I‘m using the same Freud box joint blade set you have.

I won’t be able to do dados over 3/8” until I upgrade to a better saw and dedicated dado blade. When that happens I’ll re do the slot runners.

I‘m using the same Freud box joint blade set you have.

I won’t be able to do dados over 3/8” until I upgrade to a better saw and dedicated dado blade. When that happens I’ll re do the slot runners.

Thanks for the info. Your jig looks nice. I made a much more rudimentary version but it’s doing it’s job for now.

Decided to upgrade my old Delta wet wheel grinder now that I have a lathe. Made a shop made base so I could mount a Wolverine jig with the new slow speed grinder and CBN wheels.

Have the same setup on my grinder and great for sharpening turning tools.View attachment 8216007

Decided to upgrade my old Delta wet wheel grinder now that I have a lathe. Made a shop made base so I could mount a Wolverine jig with the new slow speed grinder and CBN wheels.

Decided to upgrade my old Delta wet wheel grinder……./………and CBN wheels.

I have one of the wet wheel Deltas here, haven’t used it in years. Switched to flat diamond plates for sharpening my chisels.

How well do the wheels hold up on that grinder? A diamond wheel on the Delta would be the cats azz.

The CBN wheels will outlast me and never need truing.I have one of the wet wheel Deltas here, haven’t used it in years. Switched to flat diamond plates for sharpening my chisels.

How well do the wheels hold up on that grinder? A diamond wheel on the Delta would be the cats azz.

Picked this up a few weeks ago at an auction. For me this is a huge upgrade. I’m pretty much at the beginning of my woodworking hobby. Been using a small contractor sized saw for years. Haven’t used it yet. Been getting it set up. Blade, fence adjustment etc. Comments, advice would be appreciated

It's a nice looking saw, I bet you're going to love itPicked this up a few weeks ago at an auction. For me this is a huge upgrade. I’m pretty much at the beginning of my woodworking hobby. Been using a small contractor sized saw for years. Haven’t used it yet. Been getting it set up. Blade, fence adjustment etc. Comments, advice would be appreciated

View attachment 8217683View attachment 8217684

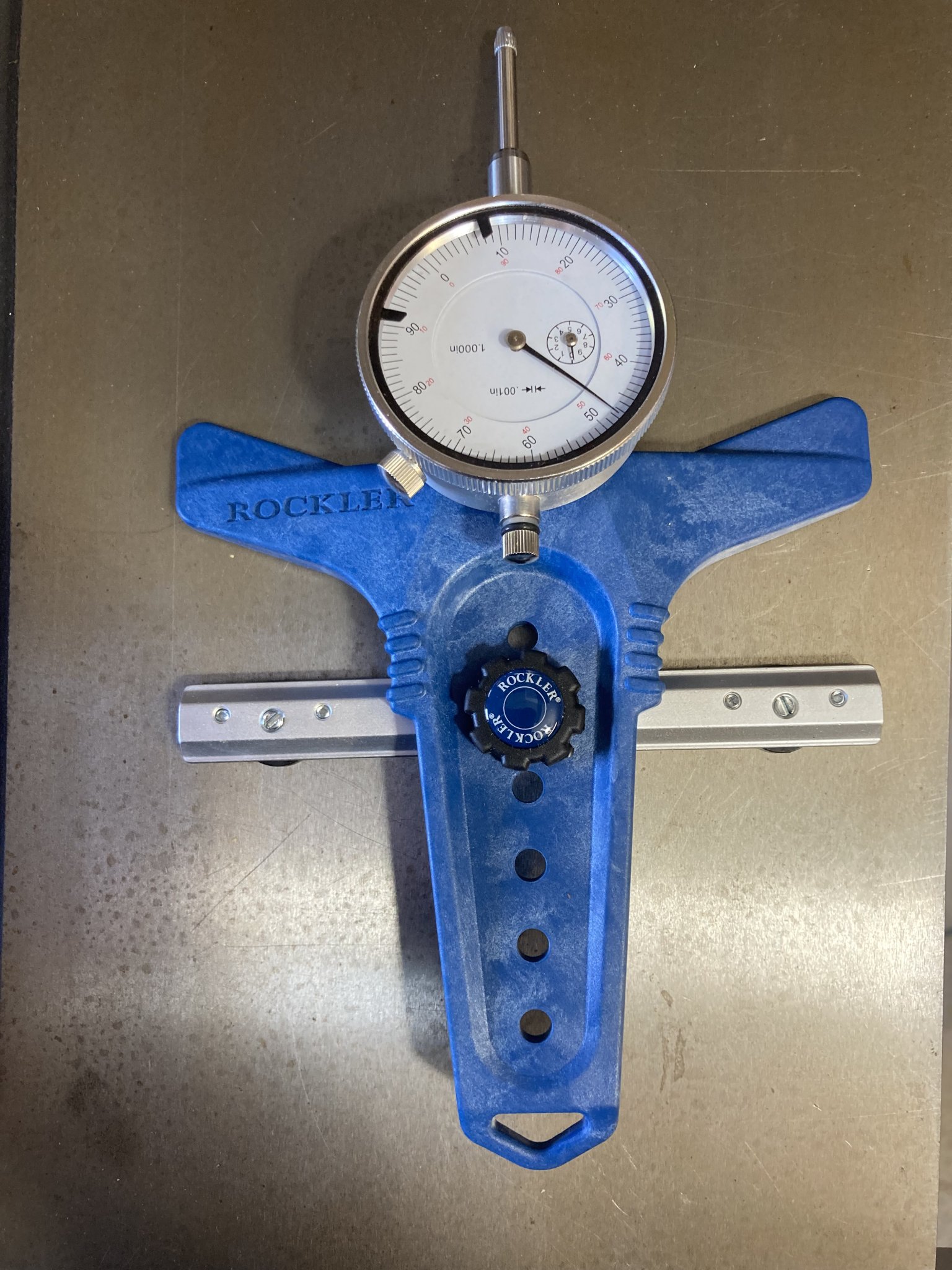

I bought this. Got the blade down to .002

I've got one, good saw, not a great saw.........buy a better blade than what came on it ,Picked this up a few weeks ago at an auction. For me this is a huge upgrade. I’m pretty much at the beginning of my woodworking hobby. Been using a small contractor sized saw for years. Haven’t used it yet. Been getting it set up. Blade, fence adjustment etc. Comments, advice would be appreciated

View attachment 8217683View attachment 8217684

don't remember what it was, and not going to go look, but a higher tooth per inch will give you a much smoother cut.

I made up a tool to verify square. Too cheap to buy one as I already had the Starrett dial.

I made up a tool to verify square. Too cheap to buy one as I already had the Starrett dial.

Freud thin kerf. Helps with a lower horsepower saw.Any recommendations on blade brands?

Freud, Diablo (made by Freud) and CMT are what I use the most. I’m sure there are other great blades out there.

The 60 tooth Diablo Fine Finish blade makes a very smooth cut in oak or maple. I don’t use it for general cutting though, I’ll grab a standard ripping blade for rougher work.

![ImSv0r.jpg[img]](https://imagizer.imageshack.com/img923/7040/ImSv0r.jpg[img])

The 60 tooth Diablo Fine Finish blade makes a very smooth cut in oak or maple. I don’t use it for general cutting though, I’ll grab a standard ripping blade for rougher work.

![ImSv0r.jpg[img]](https://imagizer.imageshack.com/img923/7040/ImSv0r.jpg[img])

Forrest Woodworker II is another really good thin kerf blade. Very high quality carbide and they are sharpened to a high standard

I think you will like your saw. I have an older rigid full size, and it works pretty good. It’s not the best by far, but it’s good enough for most people. Looks like you are off to a good start. I haven’t been doing woodwork because I’m still moving into my new shop. I had no idea that it would take this long. Stupid job is getting in the way of my life!

Posted in the firewood thread, but forgot about this one..

Few white oaks for the mill!

Few white oaks for the mill!

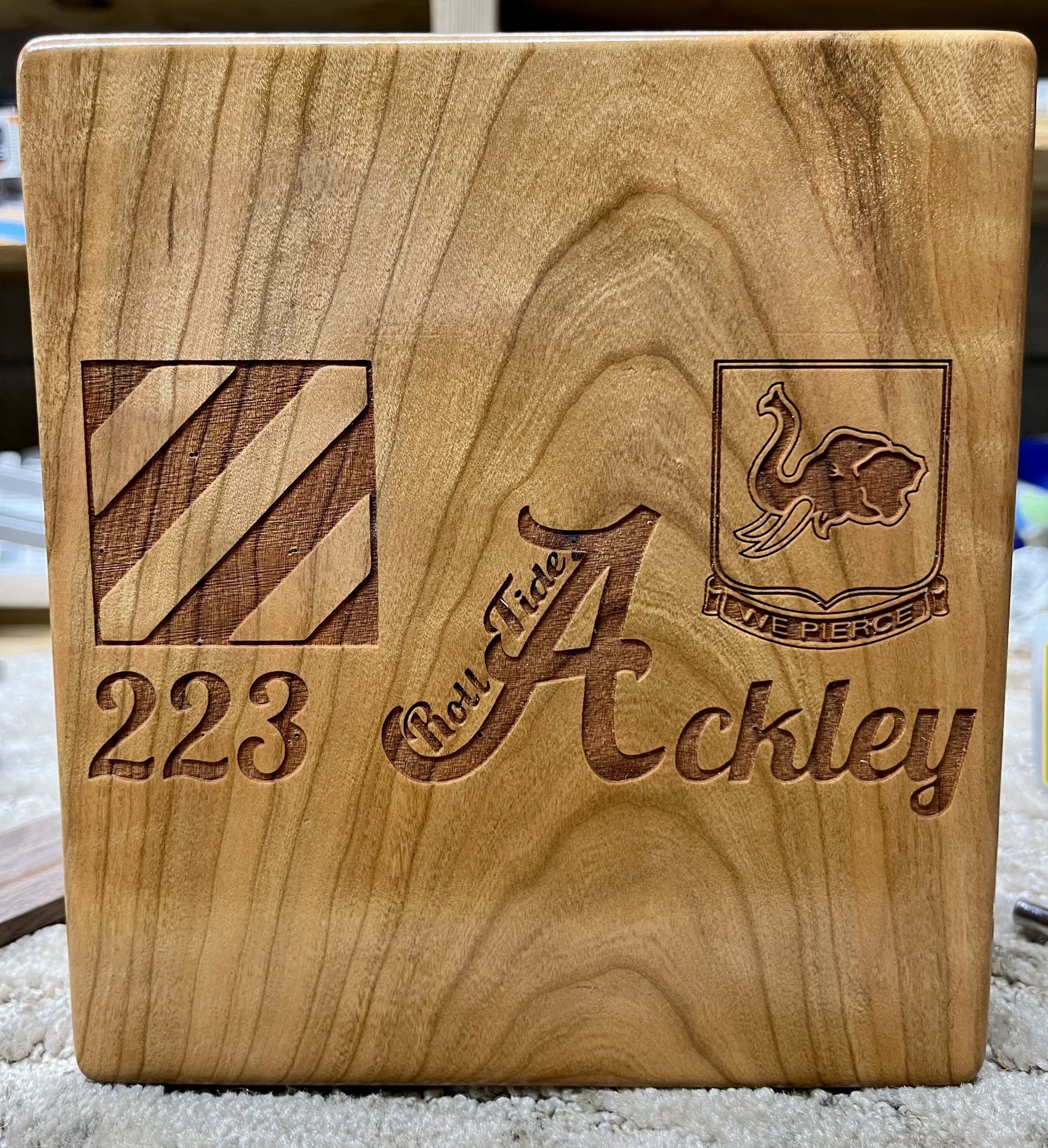

I make these custom ammo boxes. Give me a PM if you’re interested. Walnut or Cherry wood , laser engraved .

Going to be a chopping fool! Actually a paring fool since I’ll remove the majority of the waste with an auger in the brace.

Chopping some shit. Damn, why can’t the whole world use the imperial system? Measure in inches, chop using MM chisels.

Honestly, I should have based the mortise off of chisel width, but I want 1” thick tenons!

Honestly, I should have based the mortise off of chisel width, but I want 1” thick tenons!

But that Japanese steel makes it worth it….Chopping some shit. Damn, why can’t the whole world use the imperial system? Measure in inches, chop using MM chisels.

Honestly, I should have based the mortise off of chisel width, but I want 1” thick tenons!

View attachment 8245964

It really does. I use the Japanese chisels when working mortises in soft woods.But that Japanese steel makes it worth it….

Not really woodworking since I’ll be using MDF, but will be making a new key bed for this piano. The leg pulled through the original key bed. This is why you use furniture dollies to move pianos around a building , and not the wheels on the piano.

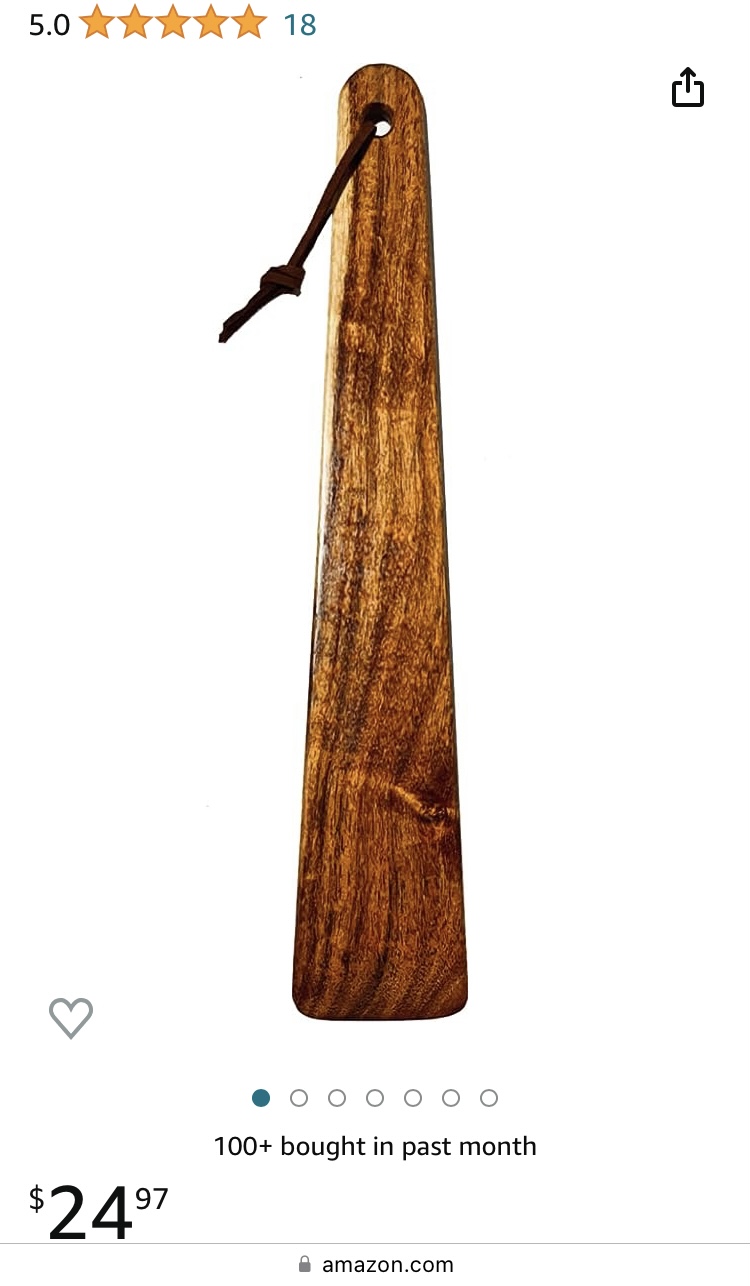

Damn, I’ve been doing it wrong all along. Found these on Amazon. A flat piece of wood with some food safe finish on it for $24. Over 100 sold in the last month. Now that’s easy money!

So a fun little woodworking project today... I'll finish it up tomorrow with the metal work and stain, etc.

This is a cigar cutter in the form of a French Revolution Guillotine! All made out of oak with the blade made of spring steel weighted with .175" thick copper plates/guides. Stands about 24" tall including the keystone at the top. Pretty sure it would lop a finger off without too much trouble!

3/4" oak plank sliced into beams. Sort of like a Lincoln Logs project!

Blade is flat spring steel bolted to copper weights/guides. It weighs enough that it comes down with a 'thunk!'

Cheated and did most of the woodwork on a milling machine. But, hey, whatever works! Bolted and glued the beams together. Those are 8BA steel bolts.

This is sort of inspiring me to pursue my dreams of building a real one. It's not that daunting a project, in reality. Though the joining would be some serious work with a chainsaw and chisels. But I think every neighborhood needs one these days...

Well, I'll finish it up tomorrow and post 'After' pix. Hopefully while enjoying a nice cleved-stogie!

Sirhr

This is a cigar cutter in the form of a French Revolution Guillotine! All made out of oak with the blade made of spring steel weighted with .175" thick copper plates/guides. Stands about 24" tall including the keystone at the top. Pretty sure it would lop a finger off without too much trouble!

3/4" oak plank sliced into beams. Sort of like a Lincoln Logs project!

Blade is flat spring steel bolted to copper weights/guides. It weighs enough that it comes down with a 'thunk!'

Cheated and did most of the woodwork on a milling machine. But, hey, whatever works! Bolted and glued the beams together. Those are 8BA steel bolts.

This is sort of inspiring me to pursue my dreams of building a real one. It's not that daunting a project, in reality. Though the joining would be some serious work with a chainsaw and chisels. But I think every neighborhood needs one these days...

Well, I'll finish it up tomorrow and post 'After' pix. Hopefully while enjoying a nice cleved-stogie!

Sirhr

I want one!So a fun little woodworking project today... I'll finish it up tomorrow with the metal work and stain, etc.

This is a cigar cutter in the form of a French Revolution Guillotine! All made out of oak with the blade made of spring steel weighted with .175" thick copper plates/guides. Stands about 24" tall including the keystone at the top. Pretty sure it would lop a finger off without too much trouble!

View attachment 8259337

3/4" oak plank sliced into beams. Sort of like a Lincoln Logs project!

View attachment 8259338

Blade is flat spring steel bolted to copper weights/guides. It weighs enough that it comes down with a 'thunk!'

View attachment 8259340

Cheated and did most of the woodwork on a milling machine. But, hey, whatever works! Bolted and glued the beams together. Those are 8BA steel bolts.

This is sort of inspiring me to pursue my dreams of building a real one. It's not that daunting a project, in reality. Though the joining would be some serious work with a chainsaw and chisels. But I think every neighborhood needs one these days...

Well, I'll finish it up tomorrow and post 'After' pix. Hopefully while enjoying a nice cleved-stogie!

Sirhr

I want one!

I loosely followed these plans. Like, for the basic shape. Is pretty much all.

Mini Guillotine

Mini Guillotine: What Halloween décor isn’t complete without a Guillotine? This 1/6 scale version could make a nice centerpiece to your decorations. Just like the Addams family! I couldn’t find free directions online so I did my best job of reverse engineering and …

This what what inspired me. But no way was I going to pay that kind of coin for something I can have fun making! I did a lot more complex joinery than the one in the 'plans.' He was just banging a nail gun into everything. I used pegs, bolts and real joints. Just because.

Cigar Cutter Vintage Wooden guillotine cutter Guillotina SIGLO XVIII | eBay

This was tested and works. I will add a video to the ad soon. There is a plaque at the top, and ‘made in Spain’ stamped on the back. I will be adding more photos of the item as it will show detailed images of what is being sold.

www.ebay.com

Go for it! Let me know if you want detailed photos!

Cheers,

Sirhr

That’s going on the list for me. As soon as I clear out these furniture repairs and grip project I’m going to make one.I loosely followed these plans. Like, for the basic shape. Is pretty much all.

Mini Guillotine

Mini Guillotine: What Halloween décor isn’t complete without a Guillotine? This 1/6 scale version could make a nice centerpiece to your decorations. Just like the Addams family! I couldn’t find free directions online so I did my best job of reverse engineering and …www.instructables.com

This what what inspired me. But no way was I going to pay that kind of coin for something I can have fun making! I did a lot more complex joinery than the one in the 'plans.' He was just banging a nail gun into everything. I used pegs, bolts and real joints. Just because.

Cigar Cutter Vintage Wooden guillotine cutter Guillotina SIGLO XVIII | eBay

This was tested and works. I will add a video to the ad soon. There is a plaque at the top, and ‘made in Spain’ stamped on the back. I will be adding more photos of the item as it will show detailed images of what is being sold.www.ebay.com

Go for it! Let me know if you want detailed photos!

Cheers,

Sirhr

I put in a new floor in a friends auto shop...

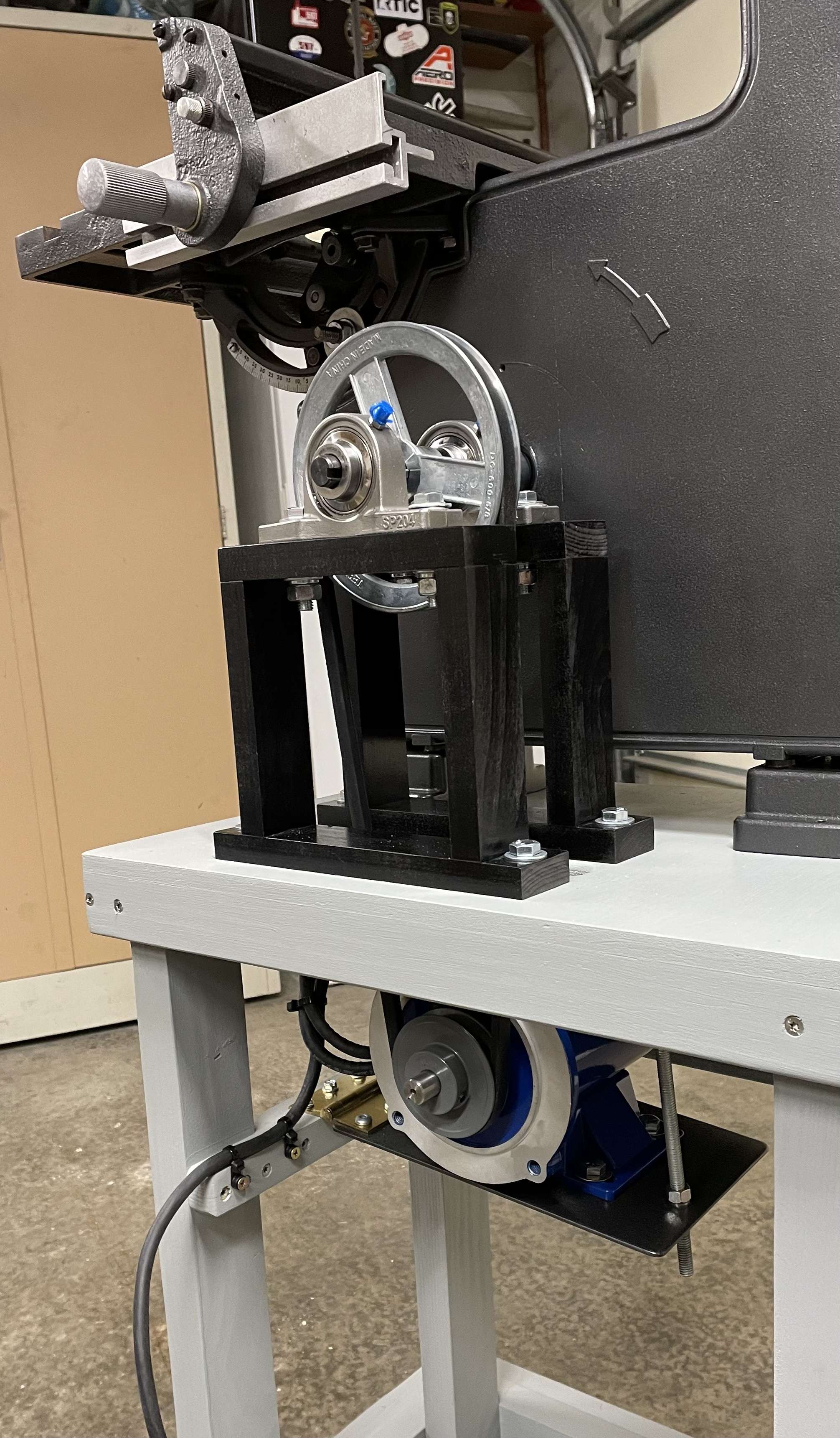

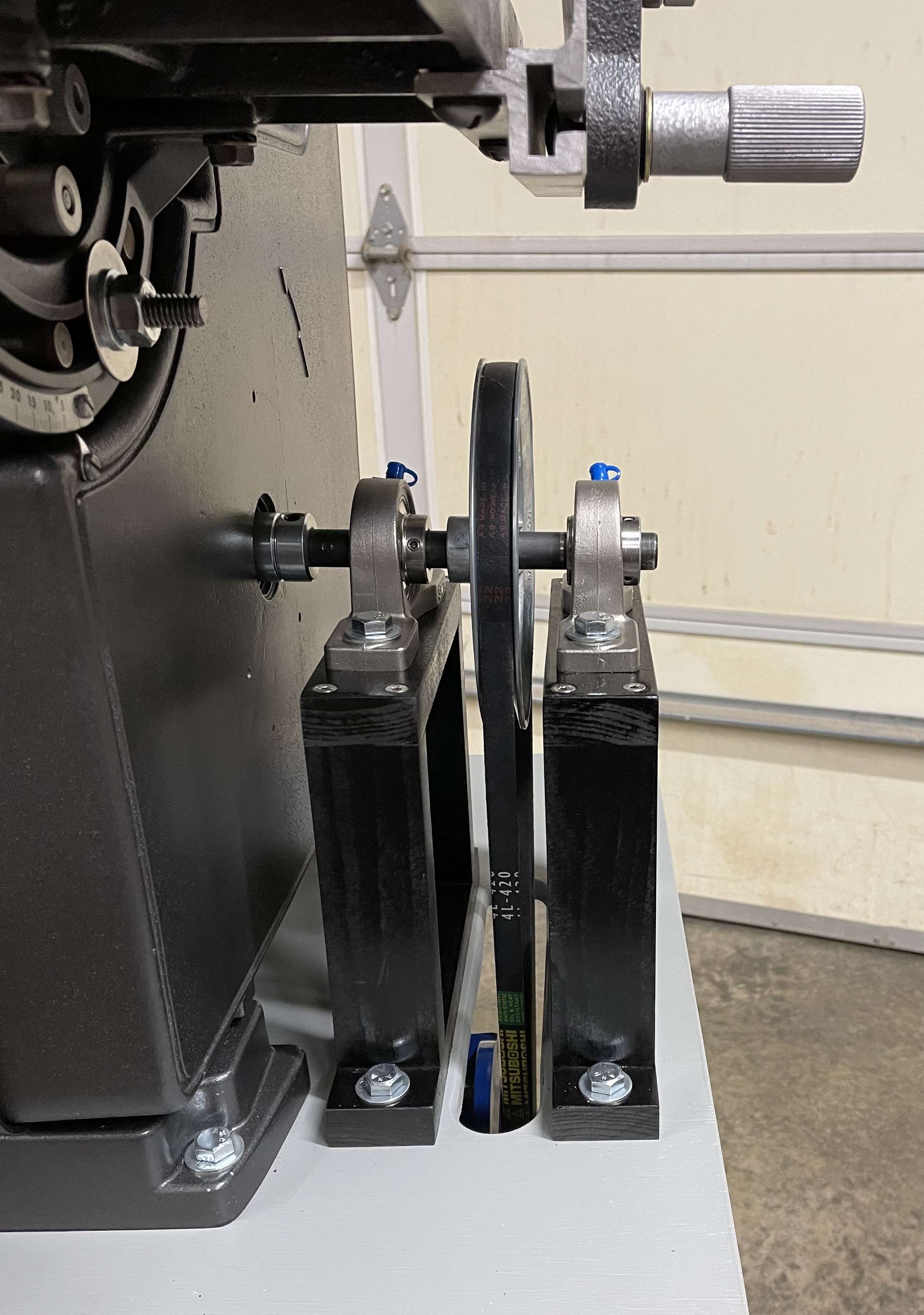

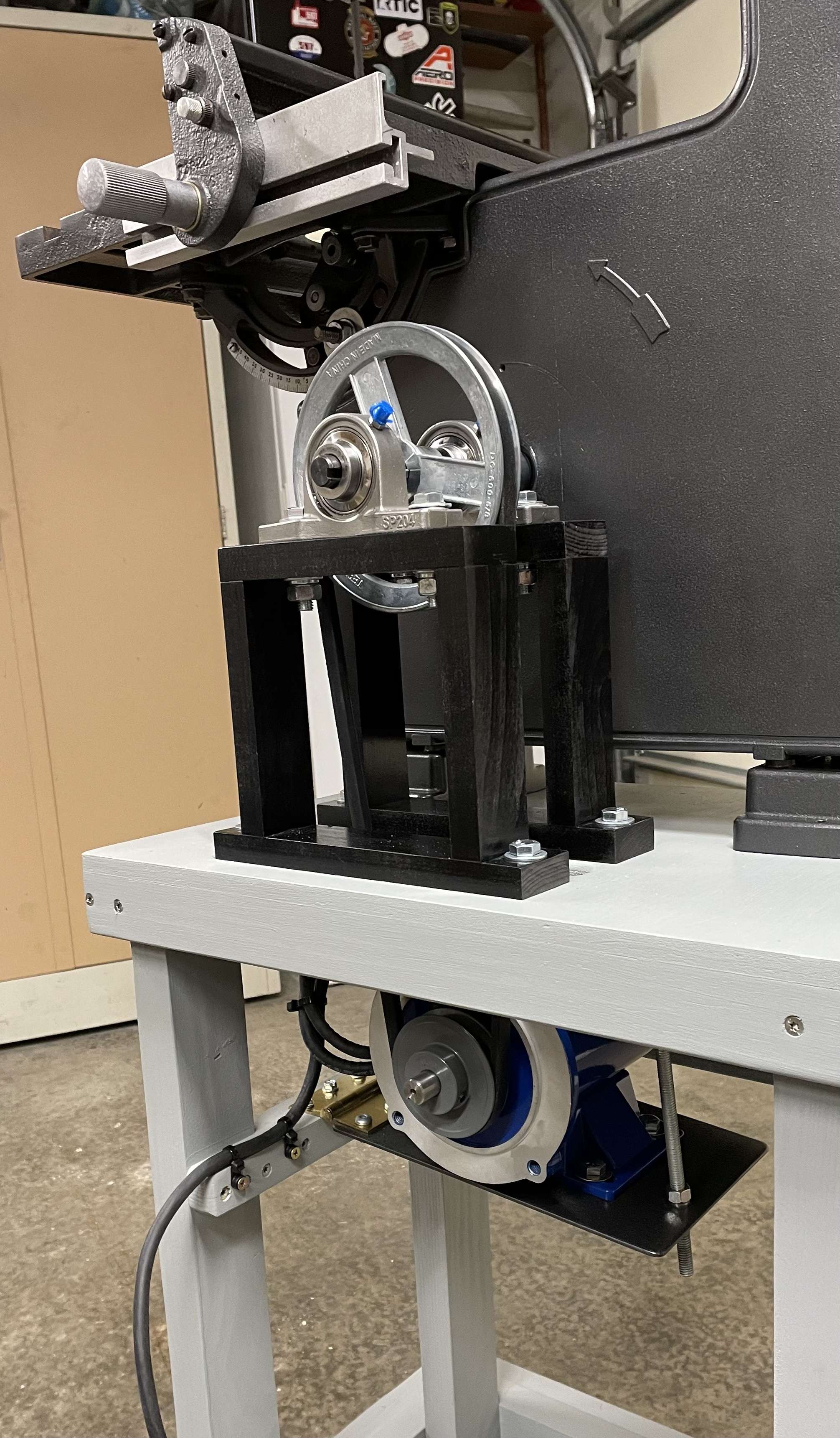

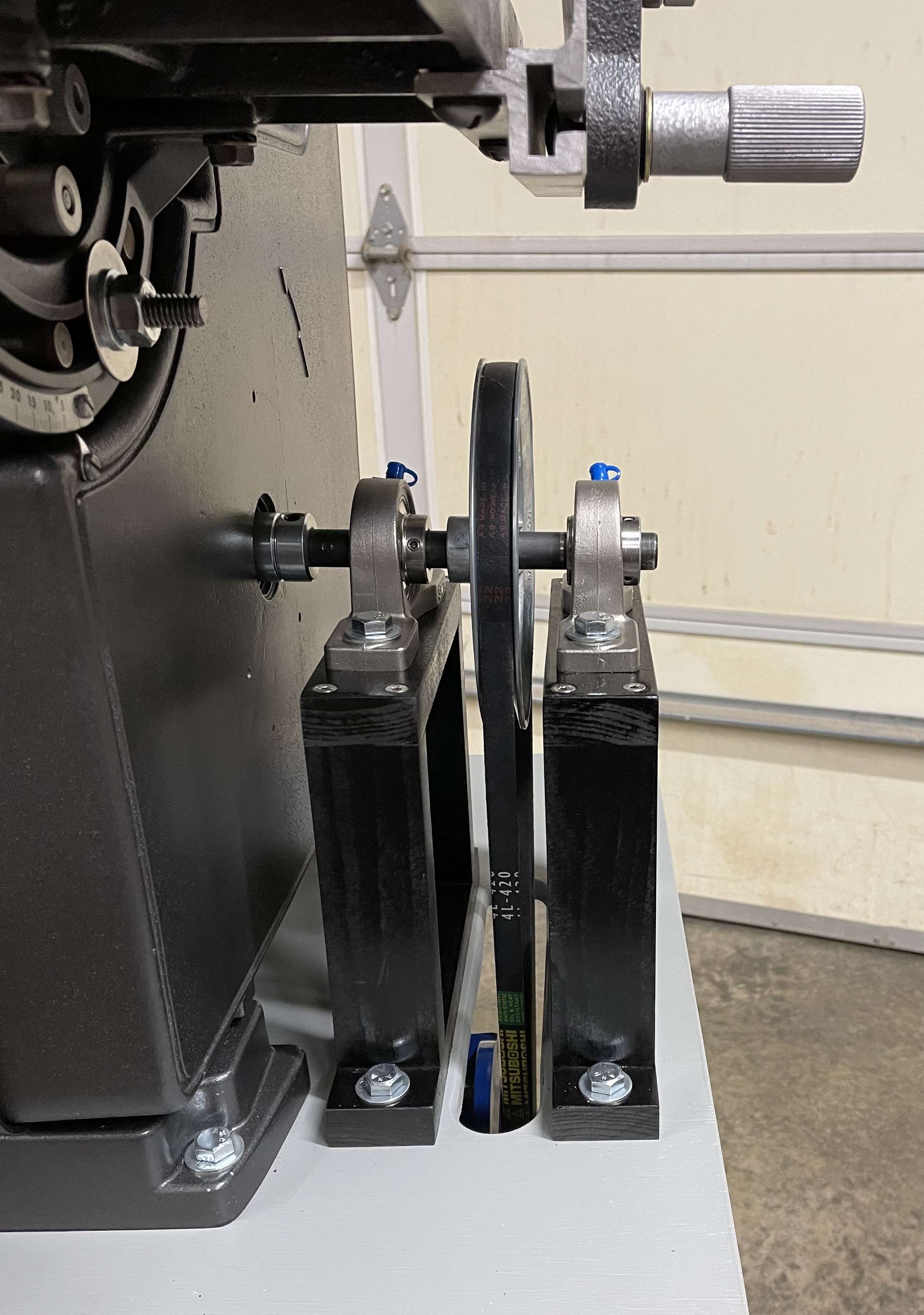

Just finished up a restoration on a 1974 vintage Craftsman 12” bandsaw. This was bought new by my grandfather. My dad had it for years before the bearings finally gave up the ghost.

I was able to locate all the correct bearings and a couple other small parts. A new cart was fabricated.

I added the pillow block bearings and extended shaft. In my opinion the original design was a weak point (though it lasted damn near 50yrs….. )

)

I went with a 90volt DC motor and a 120vac to 90vdc speed controller to give the saw more versatility…

I love projects like this, especially with the family history behind it…

I was able to locate all the correct bearings and a couple other small parts. A new cart was fabricated.

I added the pillow block bearings and extended shaft. In my opinion the original design was a weak point (though it lasted damn near 50yrs…..

I went with a 90volt DC motor and a 120vac to 90vdc speed controller to give the saw more versatility…

I love projects like this, especially with the family history behind it…

Last edited:

Got to move a couple of screws (the problem with not working off any real plans or blueprints... occasional oopsie. And clean up the stain and add the ropes. But it's done. Came out pretty cool!

Table with groove that lines up right with the head hole! Table is removable. I may or may not add some leather straps and buckles, just to make it creepy! I mean, why not? I have the footman loops and buckles in 1/6 scale. Hummmmm. I may have to do that!

Messed up on the engraving. I have to relocate three screw holes and it will be visible. 1789. La Republique. Seems fitting. Three new holes and my engraving will be properly revealed.

Pulley is ebony with machined brass yoke. Spins great. The rest of the bits are brass or German silver scrap. The whole thing was built from one 4' leftover piece of 3/4" oak. And scrap from other projects. The best kind of build! Just a weekend well spent in bad weather!

@Bigfatcock if you want detailed photos... let me know! I don't really have plans except the Interwebz 'plans' that I loosely followed. But really everything was just done ad hoc. The best way to build stuff! Just wing it!

Cheers,

Sirhr

Table with groove that lines up right with the head hole! Table is removable. I may or may not add some leather straps and buckles, just to make it creepy! I mean, why not? I have the footman loops and buckles in 1/6 scale. Hummmmm. I may have to do that!

Messed up on the engraving. I have to relocate three screw holes and it will be visible. 1789. La Republique. Seems fitting. Three new holes and my engraving will be properly revealed.

Pulley is ebony with machined brass yoke. Spins great. The rest of the bits are brass or German silver scrap. The whole thing was built from one 4' leftover piece of 3/4" oak. And scrap from other projects. The best kind of build! Just a weekend well spent in bad weather!

@Bigfatcock if you want detailed photos... let me know! I don't really have plans except the Interwebz 'plans' that I loosely followed. But really everything was just done ad hoc. The best way to build stuff! Just wing it!

Cheers,

Sirhr

Similar threads

Precision Rifle Gear

Can you use a Badger Ordnance Diving Board w/ Leupold MK4 rings?

- Replies

- 0

- Views

- 180