If I could shoot an inch at 300 yards I’d be more than pleased. You are correct, I don’t need the best for my application. It will strictly be used for hunting and paper punching in the back yard.It's probably as good as any other cartridge.

To answer your question about "the best" prefit I'm going to assume you want a shouldered prefit. The best shouldered prefit in a hunting rifle contour is probably a Proof. I think PVA might make a button rifled shouldered Tikka prefit and if it actually gets delivered it's probably pretty decent. My Tikka barrels are from McGowen and Carbon Six. They make shouldered prefits for Tikka's. You can customize the contour, twist rate, muzzle treatment, cerakote, etc. I don't think anyone would argue that their button rifle chromoly or steel barrels are "the best" but mine shoot exceptionally well. Talking sub 1 inch groups at 300 yards. For hunting rifle that's far exceeding what's required. In fact I would question whether you really need "the best" for a lightweight hunting rifle. You probably won't be able to exploit the accuracy potential of "the best" barrel in a lightweight hunting rifle shooting factory ammo.

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

He would have to get a new bolt or open up the bolt face. It's doable, I did it, but all things considered It may not be worth the effort or expense given the margin of difference between a 280 AI and a 7 saum.

That's true, but it's an excuse to buy another rifle.

What barrel length did you go with? I’m hoping to keep it 22” or shorter.

I went with 24, it will be used for hunting and some paper punching at long range matches. Since most of my other rifles are 26 or longer it seems short.

Me likey.

What are the barrel specs? Total weight?

That's a Rock Creek button blank 1:8 TW done by PVA in six and a half bore 26" proof competition contour I bought on here from @Estes640 . Did an OD spray job and a 2 port 419 brake. Think its around 18lbs when weighted out.Me likey.

What are the barrel specs? Total weight?

Last edited:

Which bipod is that?upgraded the glass and tripod, even happier with it now

Thunder BeastWhich bipod is that?

I bought a CTR 6.5cm off the GB back in July. Last week I mounted an Athlon Helos 2-12x42, and finally got a chance to shoot it with a 140gr NBT hunting load. I got a quick zero, then confirmed dope out to 500. It makes for an awesome knock-around package!

Got my T3x out to the indoor range today

I discovered that this is NOT the rifle to zero when you have a headache

M

I discovered that this is NOT the rifle to zero when you have a headache

M

All boresighted, hopefully getting out to zero this week

Where'd you get the scope wrap?All boresighted, hopefully getting out to zero this week

Here ya go homieWhere'd you get the scope wrap?

https://www.gearaid.com/products/camouflage-gun-wrap-camo-form?variant=28044139793

What happened? Did you try beretta/warranty? LRI bolts look v. nice, but never used them.Anyone here have any experience with the LRI bolt? Would you recommend? Have to replace mine

Take one of these and call me in the morning...Got my T3x out to the indoor range today

I discovered that this is NOT the rifle to zero when you have a headache

M

Looks like they repurposed flex wrap for wrapping bandages to wrapping scopes, etc. Genius!

That doesn't do anything for the recoil. That bounces my brain of the skull. When your head hurts, recoil makes it hurt moreTake one of these and call me in the morning...View attachment 7955780

M

Doesn't help as much as a brake but it does reduce recoil some.That doesn't do anything for the recoil. That bounces my brain of the skull. When your head hurts, recoil makes it hurt more

M

Bought a t3x lite for my first rifle. I bought this scope base: https://www.leupold.com/backcountry-cross-slot-tikka-t3-t3x-1-pc-20-moa-matte

currently, the screws are threading a few threads into the action to the point that the bolt wont go in. have I done something wrong?

Edit: after reading a bit more, I guess I just need to take a file to the screws to shorten them up! I didnt know that this was common. Someone call me out if I'm about to make a mistake

currently, the screws are threading a few threads into the action to the point that the bolt wont go in. have I done something wrong?

Edit: after reading a bit more, I guess I just need to take a file to the screws to shorten them up! I didnt know that this was common. Someone call me out if I'm about to make a mistake

Last edited:

Looks like a susceptible issue if the bolt is open and it falls on the knob based on the other thread. Talking to LRI their dovetail section is reinforced for this specific issue.What happened? Did you try beretta/warranty? LRI bolts look v. nice, but never used them.

My range requires the bolt to be opened when it's not fired and I don't know how it fell off the table but it did.

Does anyone here have the tools to remove and install a prefit shouldered barrel? I’m going to order the 280ai barrel for my t3 and would rather rent the tools if anyone does that or knows some place that will.

This is a request to KRG!!! Would you guys sell an X-ray for CTR mags please? It’d just be a matter of putting the CTR Bravo forend in the box with the X-ray buttstock right @Massoud?

What’s the weight on that?

SAC built 284Win

Tikka long action

Ouch !!!My range requires the bolt to be opened when it's not fired and I don't know how it fell off the table but it did.

Glad to hear I'm not the only one doing this, I managed to snap it off by hand on my bolt. First round jammed on the feed ramp, I gave it a tap with my hand thinking it was just tight coming out of the magazine and I guess the rest is history. Thankfully it's all fixed up now, a friend with a welder got it looking like new for me.Anyone here have any experience with the LRI bolt? Would you recommend? Have to replace mine

Heck of a "tap" HulkGlad to hear I'm not the only one doing this, I managed to snap it off by hand on my bolt. First round jammed on the feed ramp, I gave it a tap with my hand thinking it was just tight coming out of the magazine and I guess the rest is history. Thankfully it's all fixed up now, a friend with a welder got it looking like new for me.

View attachment 7957214

A Tikka T3x from our customer, with our new MT30 stock

Can you send/post a link to this stock?

I’ll bet some of the screws are longer (they go in the back) than the others to make the 20 MOA rail mount flat.

Bought a t3x lite for my first rifle. I bought this scope base: https://www.leupold.com/backcountry-cross-slot-tikka-t3-t3x-1-pc-20-moa-matte

currently, the screws are threading a few threads into the action to the point that the bolt wont go in. have I done something wrong?

Edit: after reading a bit more, I guess I just need to take a file to the screws to shorten them up! I didnt know that this was common. Someone call me out if I'm about to make a mistake

Is the grip and stock comb symmetrical for left hand shooters on your MT30 stock? Also confused on what option to choose on your website for a picatiny rail for the bipod, and what barrel channel option for a proof carbon barrel. Looks like another great option for a light hunter stock at 21 ounces. What is the price in US dollars?

In order not to violate the forum rules I'll send you a PM with a link, if it's OKCan you send/post a link to this stock?

The grip will be shifted a bit for best ergonomics, they won't be symmetrical. We have the LH model, but still didn't launch it in manufacture. The rail or Harris stud - just make a note in the commentary field, Proof barrel will be also an option a bit later - we decided to go with factory options for EU market, but are finishing the model with possibility to use Proof Research Pre-fits and similar barrels.Is the grip and stock comb symmetrical for left hand shooters on your MT30 stock? Also confused on what option to choose on your website for a picatiny rail for the bipod, and what barrel channel option for a proof carbon barrel. Looks like another great option for a light hunter stock at 21 ounces. What is the price in US dollars?

As for price - PM will be sent to you not to break any forum rules.

And a small pic of the stock in action:

I've decided to make a separate thread about our stock, you can find it here

Last edited:

You're a commercial supporter. You can't post a link to your own site?In order not to violate the forum rules I'll send you a PM with a link, if it's OK

The grip and the comb will be shifted a bit for best ergonomics, they won't be symmetrical. We have the LH model, but still didn't launch it in manufacture. The rail or Harris stud - just make a note in the commentary field, Proof barrel will be also an option a bit later - we decided to go with factory options for EU market, but are finishing the model with possibility to use Proof Research Pre-fits and similar barrels.

As for price - PM will be sent to you not to break any forum rules.

And a small pic of the stock in action:

View attachment 7958604

I've decided to make a separate thread about our stock, you can find it here

You're a commercial supporter. You can't post a link to your own site?

Well...guess we might give it a try.

Here is a link to our web site

And here is a link to a special promotion for forum users

Literally doing this to my CTR right now. Putting the folding TRG stock on my build. Gonna be Amazing!This is a request to KRG!!! Would you guys sell an X-ray for CTR mags please? It’d just be a matter of putting the CTR Bravo forend in the box with the X-ray buttstock right @Massoud?

Attachments

People who want´s to have a 2-stage trigger to Tikka, i am taking a project as soon as i get my 2 triggers from Sako.

Ordered 2 new TRG triggers from the factory.

I am working on a gun store, so i can buy ALL Beretta consern items -30% off on our intak price, so it was a bargain, could not resist my self on that price, and ordered 2 units.

I tested the TRG trigger that is early 2013 model, safety notch is small plastic plate on front of the trigger.

It does fit and work, but the trigger shoe needs to be shorten a bit, it will touch the trigger guar, no need to do a little modification.

I have 3 rifles, one does have KRG Midas, that i love, that wont go away, but TAC A1 trigger i will sell, all ready sold the Timney.

I bet i can ask the TAC A1 unit more than TRG, because these are not for sale, factory wont do sell these at all, but TRG trigger you can buy.

Basically TAC A1 trigger is not a 2-stage trigger, the first stage has been build with a spring load, but it work and feel like 2-stage, so what the hell.

But TRG trigger is a king of all triggers that can be put to Tikka.

Ordered 2 new TRG triggers from the factory.

I am working on a gun store, so i can buy ALL Beretta consern items -30% off on our intak price, so it was a bargain, could not resist my self on that price, and ordered 2 units.

I tested the TRG trigger that is early 2013 model, safety notch is small plastic plate on front of the trigger.

It does fit and work, but the trigger shoe needs to be shorten a bit, it will touch the trigger guar, no need to do a little modification.

I have 3 rifles, one does have KRG Midas, that i love, that wont go away, but TAC A1 trigger i will sell, all ready sold the Timney.

I bet i can ask the TAC A1 unit more than TRG, because these are not for sale, factory wont do sell these at all, but TRG trigger you can buy.

Basically TAC A1 trigger is not a 2-stage trigger, the first stage has been build with a spring load, but it work and feel like 2-stage, so what the hell.

But TRG trigger is a king of all triggers that can be put to Tikka.

Is the Trg trigger available lefty?People who want´s to have a 2-stage trigger to Tikka, i am taking a project as soon as i get my 2 triggers from Sako.

Ordered 2 new TRG triggers from the factory.

I am working on a gun store, so i can buy ALL Beretta consern items -30% off on our intak price, so it was a bargain, could not resist my self on that price, and ordered 2 units.

I tested the TRG trigger that is early 2013 model, safety notch is small plastic plate on front of the trigger.

It does fit and work, but the trigger shoe needs to be shorten a bit, it will touch the trigger guar, no need to do a little modification.

I have 3 rifles, one does have KRG Midas, that i love, that wont go away, but TAC A1 trigger i will sell, all ready sold the Timney.

I bet i can ask the TAC A1 unit more than TRG, because these are not for sale, factory wont do sell these at all, but TRG trigger you can buy.

Basically TAC A1 trigger is not a 2-stage trigger, the first stage has been build with a spring load, but it work and feel like 2-stage, so what the hell.

But TRG trigger is a king of all triggers that can be put to Tikka.

Safey is on front of the trigger.Is the Trg trigger available lefty?

I might need to make those holes to my Whiskey trigger guard too, but it is worth it.

KRG offered a short period time the Midas with a TRG styler safety.

I am not sure, does the SOTIC comes with this type of safety on a rifle, like this picture show.

Would be nice to test one of these rifles.

Keep us updated. I've been considering buying a current midas and switching the safety lever from the factory single stage. If I do that it will void the midas warranty though.Safey is on front of the trigger.

I might need to make those holes to my Whiskey trigger guard too, but it is worth it.

KRG offered a short period time the Midas with a TRG styler safety.

I am not sure, does the SOTIC comes with this type of safety on a rifle, like this picture show.

Would be nice to test one of these rifles.

KRG Midas trigger is awesome, but cost 550€ in Finland.

I would get those to my rifles, but i can get the TRG quarter of that price.

I would get those to my rifles, but i can get the TRG quarter of that price.

KRG folding TRG stock installed. Went from 12.6 with empty mag to 13.4

Sweet looking rig.

Check out the overmolded cheek rest from KRG, i bet you love it

My first T3X CTR .260Rem is having a new barrel from US.

Krieger SS barrel is coming on this rifle.

M24 contour, and the blank it 28" long.

I thought that i leave is as long it can be, will see what kind of speed monster it will be

Factory SS 24" Tikka barrel with 123 Scenar goes close to 3000 fps.

I bet the Krieger will be with 27" barrel 3200fps.

A dollar question, name the scope

Krieger SS barrel is coming on this rifle.

M24 contour, and the blank it 28" long.

I thought that i leave is as long it can be, will see what kind of speed monster it will be

Factory SS 24" Tikka barrel with 123 Scenar goes close to 3000 fps.

I bet the Krieger will be with 27" barrel 3200fps.

A dollar question, name the scope

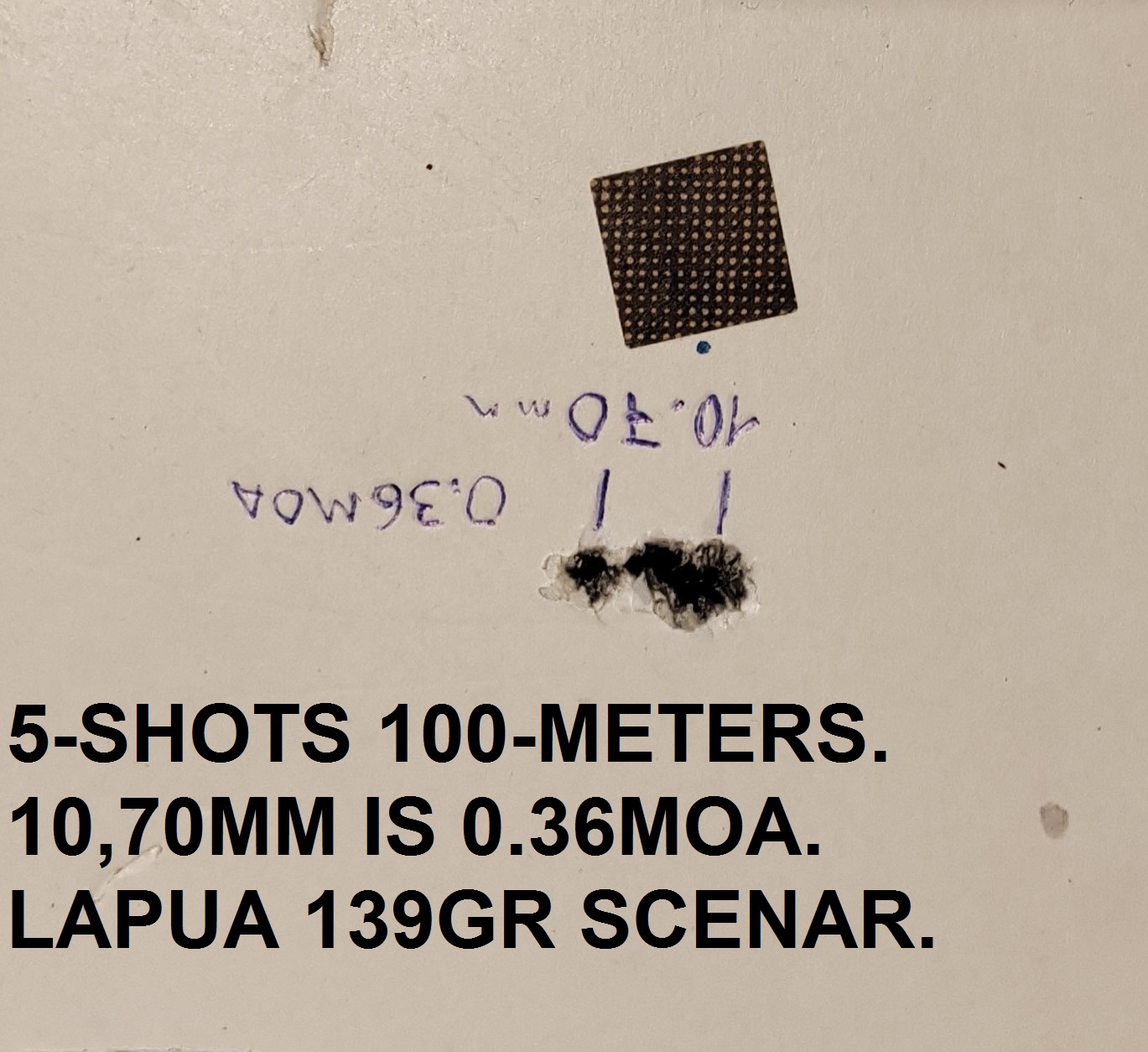

This CTR just keep surprizing me

Gunsmith shorten the barrel about 1/2" and made new threads.

139gr Scenar 0.36MOA 5-shots.

These were this day 20-25th shots, so the barrel was not cold.

Also with out a suppressor cover, so there was a bit of mirage from the can.

This rifle has been shot about 6000 rounds.

Could you do it with 6.5CM?

Gunsmith shorten the barrel about 1/2" and made new threads.

139gr Scenar 0.36MOA 5-shots.

These were this day 20-25th shots, so the barrel was not cold.

Also with out a suppressor cover, so there was a bit of mirage from the can.

This rifle has been shot about 6000 rounds.

Could you do it with 6.5CM?

Similar threads

- Replies

- 7

- Views

- 491

- Replies

- 22

- Views

- 2K