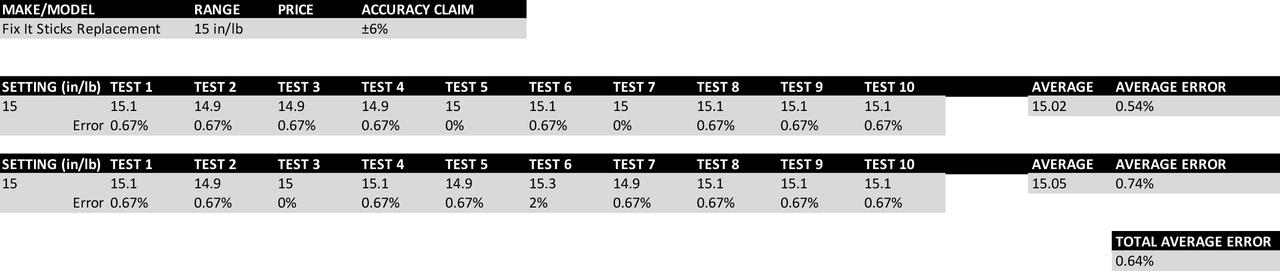

1. These error numbers look crazy high and these numbers are not in line with our tolerances.

2. Since introduction of BTD at the end of 2019 we've had no complaints about potential overtorquing.

3. The owner of this particular BTD is very welcome to contact me by PM and to send this BTD back to me, so I could find out what is going on...

Boris

Borka Tools

2. Since introduction of BTD at the end of 2019 we've had no complaints about potential overtorquing.

3. The owner of this particular BTD is very welcome to contact me by PM and to send this BTD back to me, so I could find out what is going on...

Boris

Borka Tools