Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What did you do in the reloading room today?

- Thread starter Kisssofdeath

- Start date

It's coming along boys.... I had major surgery a few weeks ago and was laid up for a month basically before that so that slowed things down quite a bit, and i did most of the work on the whole addition myself (though i did call in my guys to do a few things). With some luck, I will be done in a week. Gonna try to get the 4 Inline Fab flush mount plates routed out today and installed. I really struggled with doing this or using T slot tracks and I decided on these flush mount plates and the inline Fab work station bases. I will have 4 total and likely only 3 with a press on them most of the time. Any last words of advice before I do it?

Attachments

Last edited:

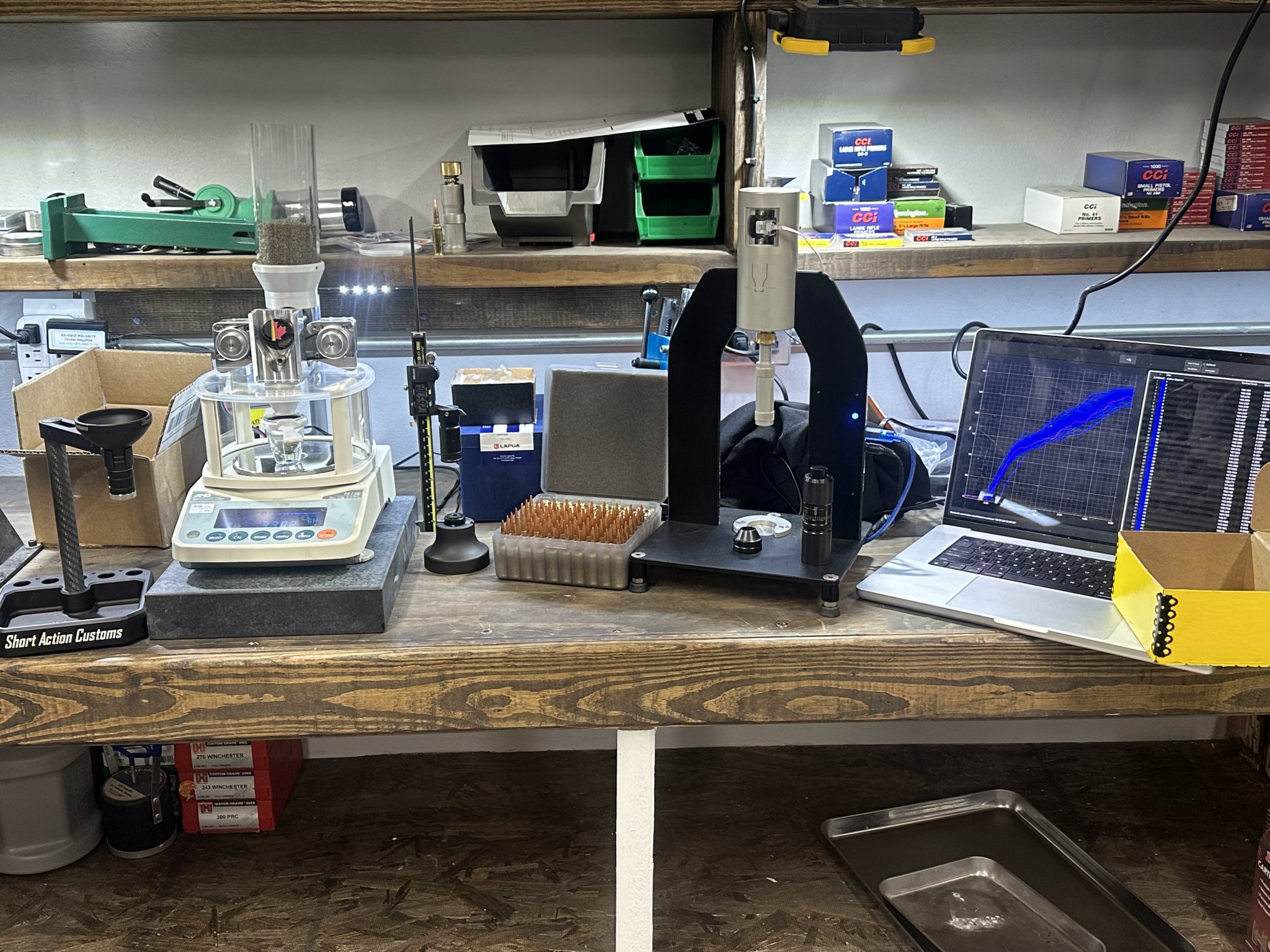

Some 6gt and 7prc. Still working out location of each piece of equipment for most efficient workflow on this bench.

That's kind of tough to figure out. I've been trying to do that too.Some 6gt and 7prc. Still working out location of each piece of equipment for most efficient workflow on this bench.

View attachment 8286618

I just finished relocating 7.6 lbs of WC872 from 1 container to 231 containers.

It’s only for the pics…they are a disaster 30 seconds after lolI'm not poor, and I'm reasonably organized. But this thread makes me feel like a homeless slob.

I was going to do a stainless topI just finished relocating 7.6 lbs of WC872 from 1 container to 231 containers.

View attachment 8298092

Do you have to worry about static?

I was going to do a stainless top

Do you have to worry about static?

No, I have not noticed any issues with static on SS top benches at home or at work.

Got the Inline Fab stuff mounted up and presses back set up. I have to wait until the floor is done in the old part (new playroom for kids) so my painter can come back and do touch up so I can't just set everything up yet but I'm trying to do what I can to limit how much there is to do after and get back in action. Slowly but surely.....

Attachments

Got the Inline Fab stuff mounted up and presses back set up. I have to wait until the floor is done in the old part (new playroom for kids) so my painter can come back and do touch up so I can't just set everything up yet but I'm trying to do what I can to limit how much there is to do after and get back in action. Slowly but surely.....

That looks really nice.

Thank you. It's been a lot of work but I'm happy with it. I just wish I could be using it by now. I have to pull tile up in the other room and put down a new floor and there's just not time before Christmas with the wife having surgery on the 20th. So, gonna have to wait until after new years to actually be done and get everything set up and back in action.That looks really nice.

Loaded some 6.5 Grendel. 7 yr old grandson helped. Brass was prepped and primed. He pushed the button on the auto trickler, put powder in case, case in shell holder, bullet in, and pulled press handle. He learned a lot! (E.g. Bullet vs cartridge) Then he wanted to see WW2 guns, and since they are in the back of the safe, I had to empty the safe to show him some. (plus pistols, revolvers, civil war rifle, antique lever action, etc) He wore me out! Doesn’t get any better than this!

Any of you guys tried one of these for your bench? I have plugs insideal of the cabinets under my bench and on the wall under. I planned and will still have a power strip in a few spots to run all power cords through the top at the back so I minimize the cords on the bench. I thought a few of these might be handy to have though to charge my phone or plug in the occasional item without having to route a wire or use a drop cord or a cord wrap around ect... I have some grommets as well as 4 of these coming to put 2 on the long part and one in the middle of each shorter part of my top, just wondering if anyone else has used them?

Nope. That's awesome!Loaded some 6.5 Grendel. 7 yr old grandson helped. Brass was prepped and primed. He pushed the button on the auto trickler, put powder in case, case in shell holder, bullet in, and pulled press handle. He learned a lot! (E.g. Bullet vs cartridge) Then he wanted to see WW2 guns, and since they are in the back of the safe, I had to empty the safe to show him some. (plus pistols, revolvers, civil war rifle, antique lever action, etc) He wore me out! Doesn’t get any better than this!

Got everything set up and the first 150 of the 2025 shooting season 308 bolt gun loads done. Hoping to have it wrapped up before the Fat Man makes his rounds.

Skipping 2024?Got everything set up and the first 150 of the 2025 shooting season 308 bolt gun loads done. Hoping to have it wrapped up before the Fat Man makes his rounds.

I wondered about that too... I figured I was missing something and would wait for someone else to clarify this, so thanks.Skipping 2024?

Is there anything special that you do to keep em from cold welding or sticking or whatever over that long of a period of time?2024 was loaded in 2022 grasshopper.

My method is not to worry about cold welding and a lot of other things that are endless arguments here on the interwebs. I keep my reloading tools and techniques as KISS as possible to achieve my needs and to get back behind the gun as quickly as possible.Is there anything special that you do to keep em from cold welding or sticking or whatever over that long of a period of time?

Is there anything special that you do to keep em from cold welding or sticking or whatever over that long of a period of time?

This is something we consider since we make ammo for customers and never now how long it will sit on their shelf. Every time we've decided to test, something happens and we just don't get to it (ammo needs to sit a while and be checked months/years later). It's annoying because there seems to be no consensus and valid examples for both sides of the argument.

To be safe, we use stuff like graphite suspended in alcohol since it's easy to coat the insides of the necks. The downside.....it lubricates so well, that you need to increase your interference fit/inside diameter of the necks so bullets won't slip under recoil and such.

Yeah I never have done anything like that when putting up ammo but I have some I've been waiting to test and see if it makes a noticeable difference for it to sit for a year or more.This is something we consider since we make ammo for customers and never now how long it will sit on their shelf. Every time we've decided to test, something happens and we just don't get to it (ammo needs to sit a while and be checked months/years later). It's annoying because there seems to be no consensus and valid examples for both sides of the argument.

To be safe, we use stuff like graphite suspended in alcohol since it's easy to coat the insides of the necks. The downside.....it lubricates so well, that you need to increase your interference fit/inside diameter of the necks so bullets won't slip under recoil and such.

Knocked out 400 rounds this morning. 62gr pulled bullets from AR with old stock wc844. Probably get the other few hundred done tomorrow. Really wish I had access to an X10 or a dillon 1100 because the three step process to reload 223 is getting old.

Well said , I am shooting loads from 25 years ago with no problems . Some folks arguing/inventing cold weld, etc . have not been alive that long , and sure as hell have not been in business that long so Their claims are null and void .My method is not to worry about cold welding and a lot of other things that are endless arguments here on the interwebs. I keep my reloading tools and techniques as KISS as possible to achieve my needs and to get back behind the gun as quickly as possible.

So you are shooting rounds that you yourself loaded 25 years ago? Do you know what the ES was then vs now or ever checked it in any way? I haven't really worried about it but everyone seems to think it's a big deal so I've got some 223 loads and 6.5cm loads that I put up that I have really good numbers on and am going to see what the fuss is about.Well said , I am shooting loads from 25 years ago with no problems . Some folks arguing/inventing cold weld, etc . have not been alive that long , and sure as hell have not been in business that long so Their claims are null and void .

I received my Lee Precision neck sizing die so I can tighten the neck tension on 367 primed .223 Rem cases that I had to break down. Remove the deprimer pin and I'm off.

Also got the 6.5 PRC neck sizing die I’ve been waiting for.

P

Also got the 6.5 PRC neck sizing die I’ve been waiting for.

P

Yes, rounds I loaded at least 25 years ago . No Idea ES then or now . I do know they group the same from my records . Some rifles have had the same scope on the whole time and POI changes very little . That shift could be as simple s the weather, I shoot from a high of near 100 degrees and on occasion go down to 20 below zero or so . I have tried moly,mica,graphite, etc. over the years and have not seen a measurable difference . Just my experience .So you are shooting rounds that you yourself loaded 25 years ago? Do you know what the ES was then vs now or ever checked it in any way? I haven't really worried about it but everyone seems to think it's a big deal so I've got some 223 loads and 6.5cm loads that I put up that I have really good numbers on and am going to see what the fuss is about.

David Tubb claims he loads his ammo long and when he seats them months later he can feel/hear the cold weld breaking.

Though he might not have been shooting long enough to be valid according to some.

I have no idea if it happens. But there are respectable people on both sides of the debate.

Though he might not have been shooting long enough to be valid according to some.

I have no idea if it happens. But there are respectable people on both sides of the debate.

I am pretty sure that's true. I've done it. I loaded em long and put them up and then did final seating depth when I was going to shoot and I could always feel a little brake sort of when seating that isn't normally there. I don't even think that's in question is it? What is in question, is 1- does that matter on target. 2- is it a so called "cold weld" or just two metals sticking together for whatever reason. Perhaps a distinction without a difference there.David Tubb claims he loads his ammo long and when he seats them months later he can feel/hear the cold weld breaking.

Though he might not have been shooting long enough to be valid according to some.

I have no idea if it happens. But there are respectable people on both sides of the debate.

I am pretty sure that's true. I've done it. I loaded em long and put them up and then did final seating depth when I was going to shoot and I could always feel a little brake sort of when seating that isn't normally there. I don't even think that's in question is it? What is in question, is 1- does that matter on target. 2- is it a so called "cold weld" or just two metals sticking together for whatever reason. Perhaps a distinction without a difference there.

If Tubb didn't think it matters on paper, then no reason to seat long for that specific reason. Though he could just to it for an overabundance of caution.

It likely depends on what kind of shooting and/or distance you are doing. Since you can't control if all of them stick or stick the same amount, that will theoretically cause larger velocity SDs. Shortrange BR probably doesn't care as they aren't worried about loading to the kernel for small SDs. Longrange BR on the other hand might care because you really need consistent velocities to win.

Yeah, that's why I did the rounds to test so I can see what kind of ES I get compared to my known ES over 30 rounds.If Tubb didn't think it matters on paper, then no reason to seat long for that specific reason. Though he could just to it for an overabundance of caution.

It likely depends on what kind of shooting and/or distance you are doing. Since you can't control if all of them stick or stick the same amount, that will theoretically cause larger velocity SDs. Shortrange BR probably doesn't care as they aren't worried about loading to the kernel for small SDs. Longrange BR on the other hand might care because you really need consistent velocities to win.

Finally started setting up an old hand me down Dillon 550 that I got for free last summer.

Will probably need to buy a few parts from Dillon to get it running.

Also got a case feeder with it but I pulled it off for now. I'll deal with it later. Even w/o the feeder it will be faster than the rockchucker that I've been loading four uspsa seasons with.

Will probably need to buy a few parts from Dillon to get it running.

Also got a case feeder with it but I pulled it off for now. I'll deal with it later. Even w/o the feeder it will be faster than the rockchucker that I've been loading four uspsa seasons with.

Uspsa..on a rockFinally started setting up an old hand me down Dillon 550 that I got for free last summer.

Will probably need to buy a few parts from Dillon to get it running.

Also got a case feeder with it but I pulled it off for now. I'll deal with it later. Even w/o the feeder it will be faster than the rockchucker that I've been loading four uspsa seasons with.

You prob have a forearm like Popeye lol

Finally started setting up an old hand me down Dillon 550 that I got for free last summer.

Will probably need to buy a few parts from Dillon to get it running.

Also got a case feeder with it but I pulled it off for now. I'll deal with it later. Even w/o the feeder it will be faster than the rockchucker that I've been loading four uspsa seasons with.

JFC man.....uspsa ammo on a chuck?

Ask Santa for Mark 7 this year. Goddamn

I guess you could say "I did it" but I got 300 some odd cases decapped and annealed. I did the annealing with my AMP and Amp-Mate. Btw- if anyone is on the fence in getting an AMP and Mate, just do it. I mean, the difference is just insane in what you get and the tiny amount of effort it takes to do it.

I guess you could say "I did it" but I got 300 some odd cases decapped and annealed. I did the annealing with my AMP and Amp-Mate. Btw- if anyone is on the fence in getting an AMP and Mate, just do it. I mean, the difference is just insane in what you get and the tiny amount of effort it takes to do it.

We have this setup as well and it's awesome.

The amp press' auto-run option is also very handy (unless you seat on a progressive already).

I pretty much use my turret for everything accept decapping(i use MEC for that ) and .223 progressive. I do my precision 223 on my turret press too but I'm trying to transition to doing precision 223 on the 550C also.We have this setup as well and it's awesome.

The amp press' auto-run option is also very handy (unless you seat on a progressive already).

The amp press set up sounds cool but I didn't see anything about automating it?

I pretty much use my turret for everything accept decapping(i use MEC for that ) and .223 progressive. I do my precision 223 on my turret press too but I'm trying to transition to doing precision 223 on the 550C also.

The amp press set up sounds cool but I didn't see anything about automating it?

It has an auto-run function where it will actuate after sensing a weight change. I.E. you put the die on the load cell, and a second or so later, without pushing a button or anything else, it actuates and does its thing.

When I'm seating, I pick up a piece of prepped brass in left hand, prime on CPS, dump powder, put bullet in neck, put in inline die and slide it on the load cell. Then I start with the next piece of brass while the AMP is seating on its own. I replace the loaded round with the next one and keep going.

So. I pick up a piece of brass with my left hand and it doesn't leave my hand until the press is seating.

Might sound a little trivial, but when you're loading a ton of ammo, it's really nice to not need to press another button or something. And you still get your graph.

I had to decap some cci400s I made the mistake of using in my 6arc. And I found a box of primed 300wm brass I hadn't annealed. So I decided might as well since I just ran the rest of the Winchester 300wm brass. So I invented a new primer catcher for my rockchucker. I was going to throw it away when I was done but who likes 20 or 30 percent of decapped primers on the floor. Now I can load the higher charge weights of mp501 again that were making pin holes in the center of the cci400s.

Too bad you spent your money on such a defective pile of crap.Unpacked a powder thrower.....

View attachment 8326687

Tell you what, I’ll do you big favor and take it off your hands so it doesn’t inconvenience you if you just send it to me.

LOL….

#jealous….

Finally started setting up an old hand me down Dillon 550 that I got for free last summer.

Will probably need to buy a few parts from Dillon to get it running.

Also got a case feeder with it but I pulled it off for now. I'll deal with it later. Even w/o the feeder it will be faster than the rockchucker that I've been loading four uspsa seasons with.

Wait wut?

You’re loading volume pistol ammo on a Rock Chucker?

Why do you hate yourself so much? Have you also been considering self harm?

Interestingly enough I'm switching to primarily factory ammo. The main problem is brass sorting.Wait wut?

You’re loading volume pistol ammo on a Rock Chucker?

Why do you hate yourself so much? Have you also been considering self harm?

9 mm CBC brass is absolutely atrocious and I will not deal with it. I need to find someone to do a headstamp sort or I'm done for good.

Made M class in carry optics that way.JFC man.....uspsa ammo on a chuck?

Ask Santa for Mark 7 this year. Goddamn

People think that ammo volume is where it's at but it aint.

That's from something elseYou prob have a forearm like Popeye lol

Interestingly enough I'm switching to primarily factory ammo. The main problem is brass sorting.

9 mm CBC brass is absolutely atrocious and I will not deal with it. I need to find someone to do a headstamp sort or I'm done for good.

You love CBC brass and you just won’t admit it.

There’s nothing better than primers that are glued in and refuse to come out with a normal stroke of the press. It’s extra fun to have this happen when using a progressive press with automatic indexing.