Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

245 Berger eol

2.770” bto

215m

Virgin Peterson case

84gr Retumbo

2858fps

28” 1-8 bartlein

2.770” bto

215m

Virgin Peterson case

84gr Retumbo

2858fps

28” 1-8 bartlein

Last edited:

300 Norma Improved

Bartlein 30 1:9 twist

Peterson Brass

250 Atip

CCI 250

H1000

OAL 3.808

82 gr-2866

82.5 2878

83 2891

83.5 2910

84 2919

84.5 2939

85 2950

85.5 2994

86 2998 ejector marks

86.5 3013 ejector marks and stiff bolt.

I changed primers to Fed 215 and got clickers and it increased FPS. I think 3000 fps is the max ceiling for my gun and this powder/bullet combination.

84.5 gr 3004

85 3009

85.5 3050

Bartlein 30 1:9 twist

Peterson Brass

250 Atip

CCI 250

H1000

OAL 3.808

82 gr-2866

82.5 2878

83 2891

83.5 2910

84 2919

84.5 2939

85 2950

85.5 2994

86 2998 ejector marks

86.5 3013 ejector marks and stiff bolt.

I changed primers to Fed 215 and got clickers and it increased FPS. I think 3000 fps is the max ceiling for my gun and this powder/bullet combination.

84.5 gr 3004

85 3009

85.5 3050

I'd load up that 85 grain load with the cci250's and run that. 2950 for a 250 is nothing to scoff at.300 Norma Improved

Bartlein 30 1:9 twist

Peterson Brass

250 Atip

CCI 250

H1000

OAL 3.808

82 gr-2866

82.5 2878

83 2891

83.5 2910

84 2919

84.5 2939

85 2950

85.5 2994

86 2998 ejector marks

86.5 3013 ejector marks and stiff bolt.

I changed primers to Fed 215 and got clickers and it increased FPS. I think 3000 fps is the max ceiling for my gun and this powder/bullet combination.

84.5 gr 3004

85 3009

85.5 3050

Go into Options> Loadable Table Settings> Set Loadable Table Step width> User defined>In weight increments. Then you set up in .3 .5 or a grain or what have you. Most of us load into the tenth...View attachment 8085996

I just played around with what mass bullet would work (fill % > 90) with RL26 in .300NM and the best result was 155gr. So yeah, not a great option.

Running 250 atips with 88.7grs of N568 in Lapua brass I occasionally get a case that is hard to extract. Pressure wise I think I am okay, bolt lift is fine, it's just an issue pulling the bolt rearward sometimes.

When this happened with my 300PRC I swapped to redding type S sizing die to get the case web resized a bit smaller. Well on my 300NM I'm also using a redding type S die given I thought that would be my best chance of preventing this issue.

Curious if the group has any other ideas on how to clean up sticky bolt pull? Is this actually a sign of pressure that I'm missing? Is there a smaller base sizing die on the market I can use to get the web down smaller?

When this happened with my 300PRC I swapped to redding type S sizing die to get the case web resized a bit smaller. Well on my 300NM I'm also using a redding type S die given I thought that would be my best chance of preventing this issue.

Curious if the group has any other ideas on how to clean up sticky bolt pull? Is this actually a sign of pressure that I'm missing? Is there a smaller base sizing die on the market I can use to get the web down smaller?

What's the measurement of the base of the fired brass before and after sizing?Running 250 atips with 88.7grs of N568 in Lapua brass I occasionally get a case that is hard to extract. Pressure wise I think I am okay, bolt lift is fine, it's just an issue pulling the bolt rearward sometimes.

When this happened with my 300PRC I swapped to redding type S sizing die to get the case web resized a bit smaller. Well on my 300NM I'm also using a redding type S die given I thought that would be my best chance of preventing this issue.

Curious if the group has any other ideas on how to clean up sticky bolt pull? Is this actually a sign of pressure that I'm missing? Is there a smaller base sizing die on the market I can use to get the web down smaller?

What's the measurement of the base of the fired brass before and after sizing?

Had a chance to take some measurements tonight. For reference this lapua brass with 3 firings, loading up my 4th now.

Measurements:

- fired case .5845"

- reized cases .5835-.5840

- virgin case- .5775"

Here's a pic for reference. I'm taking my measurement roughly .2-.25" up (red arrow) from the bottom of the case, in the area that the die just barely touches. If it matters I'm targeting .002" shoulder bump. Also the resized cases run fine through my rifle with out firing.

Attachments

So you're measurements are pretty much in line with what mine are with the exception of the virgin brass. My virgin is usually around .579-580 and if yours are .5775 you may be over pressure. I also see die marks on the brass, are you having any trouble sizing? And what is the case growth looking like?Had a chance to take some measurements tonight. For reference this lapua brass with 3 firings, loading up my 4th now.

Measurements:

- fired case .5845"

- reized cases .5835-.5840

- virgin case- .5775"

Here's a pic for reference. I'm taking my measurement roughly .2-.25" up (red arrow) from the bottom of the case, in the area that the die just barely touches. If it matters I'm targeting .002" shoulder bump. Also the resized cases run fine through my rifle with out firing.

So you're measurements are pretty much in line with what mine are with the exception of the virgin brass. My virgin is usually around .579-580 and if yours are .5775 you may be over pressure. I also see die marks on the brass, are you having any trouble sizing? And what is the case growth looking like?

Yes over pressure is something I'm wondering about myself.... I've actually loaded up 10 lighter charge rounds to try out in hopes that makes a difference. Yes the case has die marks after sizing but I don't have any trouble running them through the resizing die.

What do you mean by case growth? I'll have to take some measurements to determine this as I'm not familiar with the term.

Thanks

Are you having to trim your brass?Yes over pressure is something I'm wondering about myself.... I've actually loaded up 10 lighter charge rounds to try out in hopes that makes a difference. Yes the case has die marks after sizing but I don't have any trouble running them through the resizing die.

What do you mean by case growth? I'll have to take some measurements to determine this as I'm not familiar with the term.

Thanks

I think the brass is so tough that you don't get the usual pressure signs. I've been doing load development with the 250 gr. Atip and as soon as I get close to 3000 fps I get clickers even though I'm full length resizing. The primers are not overly flattened and only a very faint ejector mark. If I drop down to 2950 or below all is good.Running 250 atips with 88.7grs of N568 in Lapua brass I occasionally get a case that is hard to extract. Pressure wise I think I am okay, bolt lift is fine, it's just an issue pulling the bolt rearward sometimes.

When this happened with my 300PRC I swapped to redding type S sizing die to get the case web resized a bit smaller. Well on my 300NM I'm also using a redding type S die given I thought that would be my best chance of preventing this issue.

Curious if the group has any other ideas on how to clean up sticky bolt pull? Is this actually a sign of pressure that I'm missing? Is there a smaller base sizing die on the market I can use to get the web down smaller?

I think the brass is so tough that you don't get the usual pressure signs. I've been doing load development with the 250 gr. Atip and as soon as I get close to 3000 fps I get clickers even though I'm full length resizing. The primers are not overly flattened and only a very faint ejector mark. If I drop down to 2950 or below all is good.

It depends on the powder. I ran the 250's out of a 26" barrel at 3025 fps with N570 and had no visible signs of pressure.

Ah yes..... My trim length is 2.485". After firing and resizing, it seems like the cases have grown to 2.488-2.490".Are you having to trim your brass?

With regards to the other couple comments regarding pressure and tough brass I'm primarily using velocity and bolt lift to determine pressure. My bolt lift is fine, nothing stiff that I've noticed and from what I can tell low 2900s is not unreasonable velocity for a 250 out of a 29" barrel. Primers are fine, not flattened and I don't see any kind of ejector marks on the brass.

Hoping to test the pressure theory at the range tomorrow. I've got 10 rounds loaded up with a slightly lower powder charge so we'll see what happens.

Edit: I'm running a 26" barrel

Last edited:

That case growth is .004-005" more on average than I'm seeing.Ah yes..... My trim length is 2.485". After firing and resizing, it seems like the cases have grown to 2.488-2.490".

With regards to the other couple comments regarding pressure and tough brass I'm primarily using velocity and bolt lift to determine pressure. My bolt lift is fine, nothing stiff that I've noticed and from what I can tell low 2900s is not unreasonable velocity for a 250 out of a 29" barrel. Primers are fine, not flattened and I don't see any kind of ejector marks on the brass.

Hoping to test the pressure theory at the range tomorrow. I've got 10 rounds loaded up with a slightly lower powder charge so we'll see what happens.

Let me know how the test goes and re-measure eveything with that brass tomorrow.

Loaded up some 250 A-Tips with RL50 from 86gr to 92gr in 0.3 gr increments. Started to feel some crunching at 91.1gr, but very little resistance, at 92gr I had to adjust my seating micrometer 2 thousandths.

AI AXSR 27" 1:8" and 338 Ultra SR

Trim Length 2.489

Case volume (fired case, filled to brim): 103.84 gr

BTO: 2.8450"

OAL: 3.6980"

CCI 250

53* F, 21% RH, 28.04 inHg

No pressure signs at 92 gr, Id like to see how much more velocity I can get out of it, but my goal was 2800 fps, and I get that at a pretty low pressure. Whereas, the Berger Ammunition 300 NM 230 Hybrids is 2883fps 19.4 SD (54 rounds fired over the chrono), and I get some minor ejector swipe and flattened primers.

AI AXSR 27" 1:8" and 338 Ultra SR

Trim Length 2.489

Case volume (fired case, filled to brim): 103.84 gr

BTO: 2.8450"

OAL: 3.6980"

CCI 250

53* F, 21% RH, 28.04 inHg

No pressure signs at 92 gr, Id like to see how much more velocity I can get out of it, but my goal was 2800 fps, and I get that at a pretty low pressure. Whereas, the Berger Ammunition 300 NM 230 Hybrids is 2883fps 19.4 SD (54 rounds fired over the chrono), and I get some minor ejector swipe and flattened primers.

85.7 | 86 | 86.3 | 86.6 | 86.9 | 87.2 | 87.5 | 87.8 | 88.1 | 88.4 | 88.7 | 89 | 89.3 | 89.6 | 89.9 | 90.2 | 90.5 | 90.8 | 91.1 | 91.4 | 91.7 | 92 |

2641 | 2707 | 2642 | 2721 | 2704 | 2705 | N/A | 2730 | 2719 | 2742 | 2732 | 2748 | 2751 | 2786 | 2812 | 2818 | 2788 | 2828 | 2823 | 2854 | 2847 | 2844 |

Not bad velocity, RL50 won't compete with n570 but it seems viable. I'm interested in trying some again and seeing how ES/SD's are with some slightly crunch loads.Loaded up some 250 A-Tips with RL50 from 86gr to 92gr in 0.3 gr increments. Started to feel some crunching at 91.1gr, but very little resistance, at 92gr I had to adjust my seating micrometer 2 thousandths.

AI AXSR 27" 1:8" and 338 Ultra SR

Trim Length 2.489

Case volume (fired case, filled to brim): 103.84 gr

BTO: 2.8450"

OAL: 3.6980"

CCI 250

53* F, 21% RH, 28.04 inHg

No pressure signs at 92 gr, Id like to see how much more velocity I can get out of it, but my goal was 2800 fps, and I get that at a pretty low pressure. Whereas, the Berger Ammunition 300 NM 230 Hybrids is 2883fps 19.4 SD (54 rounds fired over the chrono), and I get some minor ejector swipe and flattened primers.

N/A

I wish I could find some n570 to try but all I have is H1000.It depends on the powder. I ran the 250's out of a 26" barrel at 3025 fps with N570 and had no visible signs of pressure.

N570 is definitely hard to get, but honestly not as hard as H1000 over the past couple of years. Yes, I know that doesn't help you right now, but my point is that if you keep an eye out, you'll find N570 before any more H1000 most likely. I've been using the notifications at Midsouth, Midway (not best prices), Natchez, and Bullet Central with good results (usually get 8lbs every six months or so).

Lack of components is getting old. I made a comment in the "powder in stock thread" about a year and half ago indicating we were years away from seeing regular components back on the shelves and remember one response acting like I was trying to stir up a doom and gloom response from everyone. Well last time I checked which is pretty often, I still can't buy a majority of the components I need. I was lucky to be thinking ahead when I got the N570 before it disappeared.

I see H1000 for sale way more often than N570. I finally found some N570 after 8 months of trying. I use shootingbot alerts and you have to be really fast. Also been trying to get 245gr EOL for the longest.

My biggest problem is I can't ship primers or powder to Alaska.N570 is definitely hard to get, but honestly not as hard as H1000 over the past couple of years. Yes, I know that doesn't help you right now, but my point is that if you keep an eye out, you'll find N570 before any more H1000 most likely. I've been using the notifications at Midsouth, Midway (not best prices), Natchez, and Bullet Central with good results (usually get 8lbs every six months or so).

Does H50BMG work for 250 atips?Well that's sucktacular.

Thanks, that’s reloader 50 from alliant was looking to see if there was difference with Hodgon h50bmg. @Kopfjager1 thanks for the max. That’s too slow.

Where are you in Alaska... I am in SE and ship to my cousins in Washington then run down shoot a match and drop it at AML and ship ot home.My biggest problem is I can't ship primers or powder to Alaska.

I shipped 90lbs home a few weeks ago. A bit went to some friends, but the rest went into my hoarding, Plenty of us have powder and primers for days, we just have a way figured out on how to ship it.

I'm up in Kenai. I found a freight forwarder that will ship it but I need to find a few friends that will go in on a pallets worth of shipping. Nice stash by the way!Where are you in Alaska... I am in SE and ship to my cousins in Washington then run down shoot a match and drop it at AML and ship ot home.

I shipped 90lbs home a few weeks ago. A bit went to some friends, but the rest went into my hoarding, Plenty of us have powder and primers for days, we just have a way figured out on how to ship it. View attachment 8097011View attachment 8097012

I believe my buddy Paul might be the terminal manager of Carlile up there in Kenai. If you had someone in Washington you could send powder to when you find it, you could do what I do and it would be super easy to send larger amounts.I'm up in Kenai. I found a freight forwarder that will ship it but I need to find a few friends that will go in on a pallets worth of shipping. Nice stash by the way!

Primers are around, with small being super plentiful in Washington, bit large were allot harder to find a few weeks back. This pic was almost all small primers, after a week of being on the shelf.

If there is anything I can do to help you all get a larger order together don't be afraid to ask.

Been looking over this thread like crazy and haven't been able to find:

225gr ELD-M

N570

30" 1:8 Bart

AXMC

any one have some good date?

thanks

225gr ELD-M

N570

30" 1:8 Bart

AXMC

any one have some good date?

thanks

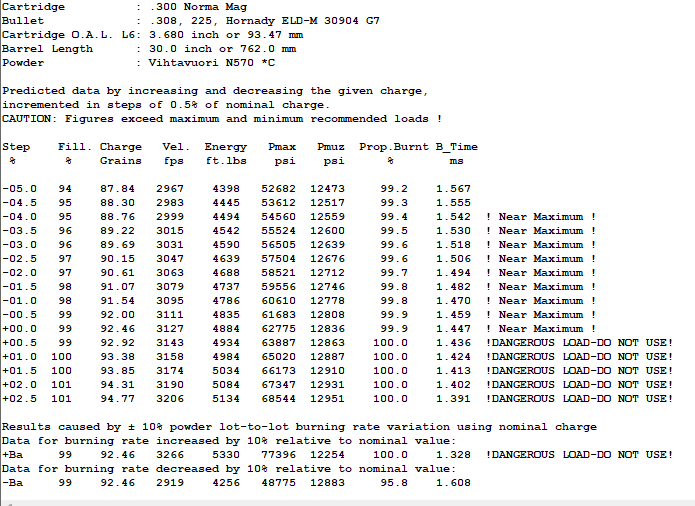

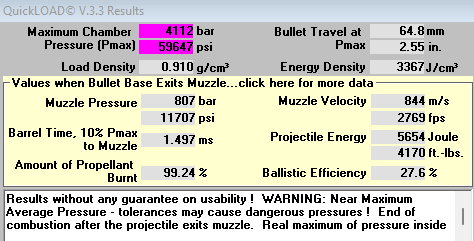

I've never used that particular bullet, but here's what QL predicts with the combo in question

Damn that's a sight for sore eyes. Unfortunately many of my shooting buddies are passing away and leaving behind all of their supplies and guns. So I'm sitting fat on everything but magnum powders. But thanks for the offer and I think I know Paul from when I was in the fish business.I believe my buddy Paul might be the terminal manager of Carlile up there in Kenai. If you had someone in Washington you could send powder to when you find it, you could do what I do and it would be super easy to send larger amounts.

Primers are around, with small being super plentiful in Washington, bit large were allot harder to find a few weeks back. This pic was almost all small primers, after a week of being on the shelf.

View attachment 8097033

If there is anything I can do to help you all get a larger order together don't be afraid to ask.

Didn't see any ADG brass datapoints, here is one:

Berger 220 LRHT

ADG Brass

CCI 250

88.0 N570

3.620" COAL

3095 AVG out of 30" barrel

No pressure signs all the way up to 90gr. Liked 88 @ .040 jump the best.

Berger 220 LRHT

ADG Brass

CCI 250

88.0 N570

3.620" COAL

3095 AVG out of 30" barrel

No pressure signs all the way up to 90gr. Liked 88 @ .040 jump the best.

300 NMI

Peterson brass

Fed215

H869

A tip 250

OAL 3.810

30 inch Bartlein 5r 1:9 twist

94.5 2803

95. 2816

95.5 2841

96. 2834

96.5 2859

97. 2856

97.5 2875

98. 2891

98.5 2889

99. 2943

99.5 2981

100. 3000

100.5 2994

101. 3019

Still no pressure signs. I’m going to try a couple more grains but cut it back to .3 jumps.

Peterson brass

Fed215

H869

A tip 250

OAL 3.810

30 inch Bartlein 5r 1:9 twist

94.5 2803

95. 2816

95.5 2841

96. 2834

96.5 2859

97. 2856

97.5 2875

98. 2891

98.5 2889

99. 2943

99.5 2981

100. 3000

100.5 2994

101. 3019

Still no pressure signs. I’m going to try a couple more grains but cut it back to .3 jumps.

Attachments

Having a brass issue that has me somewhat stumped. Lapua brass, I take my initial measurement (SAC comparator tool) with a fired case zeroed out the calipers and try to bump the shoulder back only .001 and the case would be really hard to close and open. But if I bump it back .002 it gets better and .003 it closes and opens no problem. I have never had this issue before with any other cartridge that I load for. One thing I didnt check was a fired case unsized but on extraction has been pretty easy after I got the freebore issue resolved. What do you guys normally bump back to? I also let it sit in the die for a little bit while I lube up the next case, so maybe 3-4 seconds of dwell time in the die to allow for some set back.

I’ve been bumping it back .003 or I get the same problem. I don’t know if it’s because of the high velocity or the stiff brass.Having a brass issue that has me somewhat stumped. Lapua brass, I take my initial measurement (SAC comparator tool) with a fired case zeroed out the calipers and try to bump the shoulder back only .001 and the case would be really hard to close and open. But if I bump it back .002 it gets better and .003 it closes and opens no problem. I have never had this issue before with any other cartridge that I load for. One thing I didnt check was a fired case unsized but on extraction has been pretty easy after I got the freebore issue resolved. What do you guys normally bump back to? I also let it sit in the die for a little bit while I lube up the next case, so maybe 3-4 seconds of dwell time in the die to allow for some set back.

I keep reading N570 is an absolute barrel burner. Anyone have good luck with N170 or RL 26 pushing the 245 berger or 250 ATIPs?

It can be a barrel burner if you push it hard and shoot fairly rapid strings. It's a double-based powder so it generates quite a bit of heat and therefore more pressure and velocity (thanks nitroglycerine!). N170 lacks that added nitro, so it won't generate anywhere near as much heat, but then you'll also get reduced pressure and velocity.

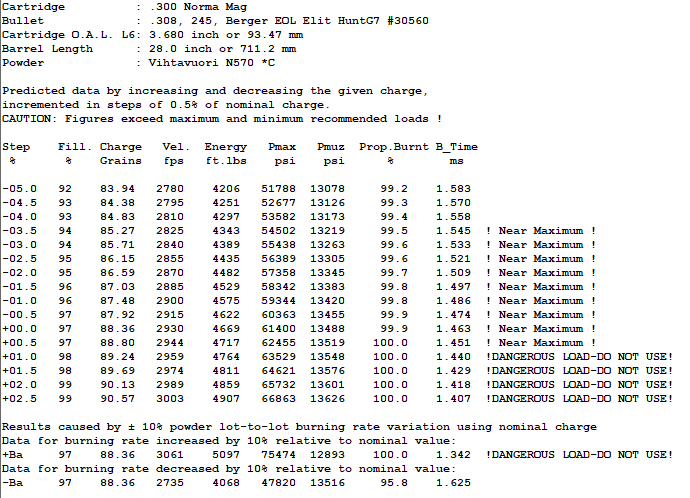

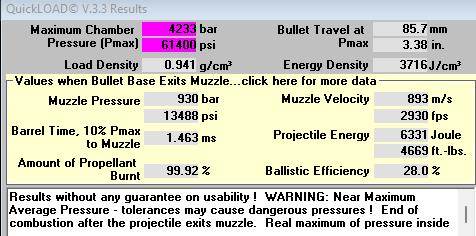

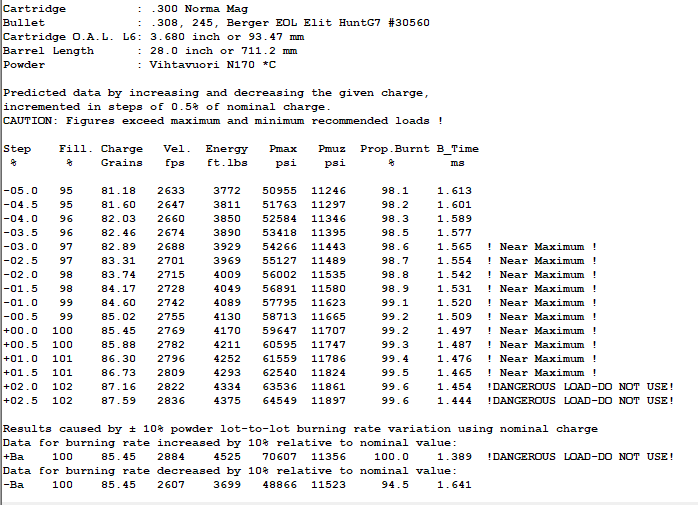

Here are some velocity comparisons:

N570

N170

So right off the bat, you're pretty much losing at least 100fps by switching to N170, but look at the reduced pressure. It's not a huge difference, but you could argue that if you run N170 you'll likely get less throat erosion, at the cost of velocity. But you could also just shoot N570 in a milder load and avoid rapid strings and probably get less throat erosion as well.

The problem is that N570 is almost the perfect powder for most 200gr+ bullets in .300NM - it's just so well optimized. And if your priority is long range performance then you need to think of barrels as consumables. If you're hunting, you have quite a bit more flexibility and should probably run N170 anyway.

Here are some velocity comparisons:

N570

N170

So right off the bat, you're pretty much losing at least 100fps by switching to N170, but look at the reduced pressure. It's not a huge difference, but you could argue that if you run N170 you'll likely get less throat erosion, at the cost of velocity. But you could also just shoot N570 in a milder load and avoid rapid strings and probably get less throat erosion as well.

The problem is that N570 is almost the perfect powder for most 200gr+ bullets in .300NM - it's just so well optimized. And if your priority is long range performance then you need to think of barrels as consumables. If you're hunting, you have quite a bit more flexibility and should probably run N170 anyway.

@schmi015 just in case...

I run HBMG50 behind the 250 atips. My sd is 10 on 5 shot string, MV is 2820 fps with 87 grains. Get pressure signs with anything over 88.5 grains. Using a magnetospeed. Am jumping .020" out of a 29.5" barrel.

Does H50BMG work for 250 atips?

yep, this is what im shooting... I have a 30" 1:8 barrel, using 88.5gr of N570 and 225ELDM. im getting 3140 fps. this is an amazing 1 mile load. ive had consistent hits at 2200m. I do notice that N570 is very very dirty.Been looking over this thread like crazy and haven't been able to find:

225gr ELD-M

N570

30" 1:8 Bart

AXMC

any one have some good date?

thanks

I have shot this combo with H1000, and don't love it. im going to explore with Retumbo soon to see if I can get N570 performance without the N570 grime and dirt!

I would say that I run this load quite hard. don't have serious barrel erosion signs, and im 600 rounds down the pipe now.

I came here to ask if anybody has some good experience or reviews with 230gr Sierra Matchking's in the 300NM? application is long range??

they seem to have a 0.800 BC (G1) which is quite nice, and im currently fighting an availability issue with the components I like using. looking for alternatives.

they seem to have a 0.800 BC (G1) which is quite nice, and im currently fighting an availability issue with the components I like using. looking for alternatives.

Followingyep, this is what im shooting... I have a 30" 1:8 barrel, using 88.5gr of N570 and 225ELDM. im getting 3140 fps. this is an amazing 1 mile load. ive had consistent hits at 2200m. I do notice that N570 is very very dirty.

I have shot this combo with H1000, and don't love it. im going to explore with Retumbo soon to see if I can get N570 performance without the N570 grime and dirt!

I would say that I run this load quite hard. don't have serious barrel erosion signs, and im 600 rounds down the pipe now.

Similar threads

- Replies

- 9

- Views

- 426

- Replies

- 23

- Views

- 1K

- Replies

- 14

- Views

- 986