Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Ingenuity Powder System

- Thread starter Jsstalli

- Start date

Are you kidding....they bought JAE and then sat on it for...what, maybe 4-5 years before they released their version and by that time the design was OBE.Part of me wishes a company like MDT would buy the design. Not only would they get this done, but do what is right for the original inventor.

There seem to be more agile manf than MDT...and don't get me wrong, I buy product from them. But they sure don't seem fast on the draw.

OBE?Are you kidding....they bought JAE and then sat on it for...what, maybe 4-5 years before they released their version and by that time the design was OBE.

There seem to be more agile manf than MDT...and don't get me wrong, I buy product from them. But they sure don't seem fast on the draw.

I have the privilege of shooting with MDT folks who are very close to the product development process, and all I'll say is that there are almost always more considerations to balance than are evident to the consumer.Are you kidding....they bought JAE and then sat on it for...what, maybe 4-5 years before they released their version and by that time the design was OBE.

There seem to be more agile manf than MDT...and don't get me wrong, I buy product from them. But they sure don't seem fast on the draw.

And yeah in general (my opinions now), big business decisions take time because of the financial risks involved. I get exasperated in my own line of work with that at times, but the implications of a poor choice are big enough that it behooves us to choose slowly and wisely.

Ckyepod, the new carbon fiber bipods, Send-it levels and there are a few others I think I'm missing. Of all of those they increased production once acquired. I'm not too positive production of this IP unit will increase cadence once this first 1,000 or so units goes out given the current history.Are you kidding....they bought JAE and then sat on it for...what, maybe 4-5 years before they released their version and by that time the design was OBE.

There seem to be more agile manf than MDT...and don't get me wrong, I buy product from them. But they sure don't seem fast on the draw.

If I was going to think of a business that could actually make this product happen, it's would be Area419. They already do reloading equipment.

Only issue comes down to capital and capacity. They already run machines 24/7. Where would something like this fit in. If there is assembly, can the current employees handle the increased assembly demand, would they have to hire more people?

In another related product, the printed precision trickler could probably be handled by MKM. Who also sells some reloading gear. At least that product exists, the only thing that seems to hold him up is the PCB.

Like Area419, do they also have the capital and capacity.

Business exist where these products align. Just don't see this sort of thing happening. Unless maybe it was a joint venture.

Only issue comes down to capital and capacity. They already run machines 24/7. Where would something like this fit in. If there is assembly, can the current employees handle the increased assembly demand, would they have to hire more people?

In another related product, the printed precision trickler could probably be handled by MKM. Who also sells some reloading gear. At least that product exists, the only thing that seems to hold him up is the PCB.

Like Area419, do they also have the capital and capacity.

Business exist where these products align. Just don't see this sort of thing happening. Unless maybe it was a joint venture.

Last edited:

Yay and nay. My choice on MDT was simply because they already do all the portions of manufacturing to get this accomplished.If I was going to think of a business that could actually make this product happen, it's would be Area419. They already do reloading equipment.

Only issue comes down to capital and capacity. They already runs machines 24/7. Where would something like this fit in. If there is assembly, can the current employees handle the increased assembly demand, would they have to hire more people?

In another related product, the printed precision trickler could probably be handled by MKM. Who also sells some reloading gear. At least that product exists, the only thing that seems to hold him up is the PCB.

Like Area419, do they also have the capital and capacity.

Business exist where these products align. Just don't see this sort of thing happening. Unless maybe it was a joint venture.

- machining

- electronics

- injection molding

They don’t have a reloading line, but could change.

Per Paul the issue in releasing the product, as of mid June, was 3 parts needed to machine. PCBs didn’t seem to be an issue.

Thanks. I’ll try that instead of contacting him directly through emails.

If you get a call from a number you don’t notice he will normally hang up and call back immediately and keep it up until you answerThanks. I’ll try that instead of contacting him directly through emails.

Ha! He did that to me, then sent a text saying, "Ingenuity Precision is trying to call you." I back-dialed the number and he answered, "Oh, now you know who it is." Funny! But yeah, that was nearly two years ago and it isn't funny anymore.If you get a call from a number you don’t notice he will normally hang up and call back immediately and keep it up until you answer

I assume people will receive notice to pay for their no-cost preorder first, no???

If they are still alive……..

Care to share if it was a delay in machining or an issue machining to the spec he wanted?Yay and nay. My choice on MDT was simply because they already do all the portions of manufacturing to get this accomplished.

- machining

- electronics

- injection molding

They don’t have a reloading line, but could change.

Per Paul the issue in releasing the product, as of mid June, was 3 parts needed to machine. PCBs didn’t seem to be an issue.

Well, he posted that he bought three new CNC machines nearly a year ago to do it all in-house. Interesting, since this was well after several deadlines had already passed.Care to share if it was a delay in machining or an issue machining to the spec he wanted?

Yes Paul told me about the machines when I spoke to him a bit ago. Just curious if it’s a time issue (meaning it’s just going slower than he thought) or a technical production issue that he’s having issues resolving.Well, he posted that he bought three new CNC machines nearly a year ago to do it all in-house. Interesting, since this was well after several deadlines had already passed.

V

he didn’t specify, sorryCare to share if it was a delay in machining or an issue machining to the spec he wanted?

Please don't misunderstand me....IMO, you have zero responsibility to answer for Paul to us.Yes Paul told me about the machines when I spoke to him a bit ago. J

But if you spoke to him a "bit ago", did you ask him what was the current long pole in the schedule tent? Or did he mention anything about the "3 parts needing machining" and why that's not progressing?

Thanks...

When I spoke to him, before jthor, all he told me was that he bought three machines to speed up production thats about it. He didnt go into detail and reading the room, I dont think he would have told me anything beyond that.Please don't misunderstand me....IMO, you have zero responsibility to answer for Paul to us.

But if you spoke to him a "bit ago", did you ask him what was the current long pole in the schedule tent? Or did he mention anything about the "3 parts needing machining" and why that's not progressing?

Thanks...

It's probably the 3d printed parts. FDM printing is not that fast even with a fast printer and depending on the build plate size (a common build plate size is 256x256mm, which is a 10" object), he's only going to be able to print a 1 or maybe a couple objects at a time (per printer) with the print time being several hours, so unless he has a print farm of several dozen printers, this is going to be one of his production limitations. My opinion is based off the 3D printed parts posted in this thread and the relative smoothness of it, which is an indication of a smaller nozzle diameter and smaller layer height.Speed up what production? Something just seems really strange not sure what's going on. Hopefully it gets straightened out but he doesn't communicate anything so its like a guess in the dark.

He can increase his production speed by increasing nozzle diameter and increasing layer height but the visual quality of the 3D printed parts would suffer. Can also make minor changes like reducing wall numbers but it would make for a weaker part.

The 3D printed draft shield for example likely takes up an entire build plate without any space left over for a smaller part. The singular draft shield is probably 1-2 hour print time if not longer due to it having angled surfaces. Angled surfaces print at a slower speed than flat vertical or horizontal walls.

Last edited:

Or send the files STL files to a good 3d printing contract manf.It's probably the 3d printed parts. FDM printing is not that fast even with a fast printer and depending on the build plate size (a common build plate size is 256x256mm, which is a 10" object), he's only going to be able to print a 1 or maybe a couple objects at a time (per printer) with the print time being several hours, so unless he has a print farm of several dozen printers, this is going to be one of his production limitations. My opinion is based off the 3D printed parts posted in this thread and the relative smoothness of it, which is an indication of a smaller nozzle diameter and smaller layer height.

He can increase his production speed by increasing nozzle diameter and increasing layer height but the visual quality of the 3D printed parts would suffer. Can also make minor changes like reducing wall numbers but it would make for a weaker part.

The 3D printed draft shield for example likely takes up an entire build plate without any space left over for a smaller part. The singular draft shield is probably 1-2 hour print time if not longer due to it having angled surfaces. Angled surfaces print at a slower speed than flat vertical or horizontal walls.

For the 3d printed parts, he contracted those out.Or send the files STL files to a good 3d printing contract manf.

I hear Hornady is working on a little suttin-suttin...

They would never copy anyone, ever. I mean sure there's the Henderson trimmer and then Horanady's Hinderson trimmer. Cant wait for their Ingeneuine Precision system.I hear Hornady is working on a little suttin-suttin...

Still nothing.

Wow. It has been so long I couldn’t even remember the name of the company I pre ordered this from. It took forever to find this thread again lol.

Wow. It has been so long I couldn’t even remember the name of the company I pre ordered this from. It took forever to find this thread again lol.

Still nothing.

Wow. It has been so long I couldn’t even remember the name of the company I pre ordered this from. It took forever to find this thread again lol.

BuT iT wAs A nO oBlIgAtIoN PrE-OrDeR

Still nothing.

Wow. It has been so long I couldn’t even remember the name of the company I pre ordered this from. It took forever to find this thread again lol.

If Hornady’s making their ripoff, Ingenuity’s cooked.hang in there. its coming

Honestly, I don't understand why, after all these years, RCBS, Redding or Hornady haven't made a simple dispenser system that can use the scientific scales.If Hornady’s making their ripoff, Ingenuity’s cooked.

That really is all these systems are with their own proprietary app/software. They are hi-speed powder measurers with automatic tricklers.

Yes, I know, it takes effort and design. Which is why I'm surprised they haven't done it

I'm just an old knuckle dragger myself, so wtf do I know

Honestly, I don't understand why, after all these years, RCBS, Redding or Hornady haven't made a simple dispenser system that can use the scientific scales.

That really is all these systems are with their own proprietary app/software. They are hi-speed powder measurers with automatic tricklers.

Yes, I know, it takes effort and design. Which is why I'm surprised they haven't done it

I'm just an old knuckle dragger myself, so wtf do I know

Probably because people like us, who will spend over $500 on just the scale, only make up 5% or less of reloaders. To us, it seems as though everyone is after such a device because we all live in the echo chamber of the hide, but in reality, we are a small subset of high functioning autistic precision minded reloaders.

You’re right.Probably because people like us, who will spend over $500 on just the scale, only make up 5% or less of reloaders. To us, it seems as though everyone is after such a device because we all live in the echo chamber of the hide, but in reality, we are a small subset of high functioning autistic precision minded reloaders.

I taught a class to some senior section guys, and my buddy said “You weaponized autism”

This sums up my entire existence.my buddy said “You weaponized autism”

That’s going to be the majority of folks here.This sums up my entire existence.

Weaponized Autism is what my work place is full of on a daily basisYou’re right.

I taught a class to some senior section guys, and my buddy said “You weaponized autism”

Thats crazy talk - None of us here would ever weaponize Autism - anyways - back to measuring case rim thickness to 1/2 a ten thou of an inch with my Rabbit Hole Precision gauge. Ok, maybe a little autistic.That’s going to be the majority of folks here.

Yet another release date estimate is all but past, so I give it 95% probability or greater that we are looking at September or later. Let me know if you want to bet against me that is 19 to one odds. On a $10 wager, you win $190 if I am wrong and they ship before September

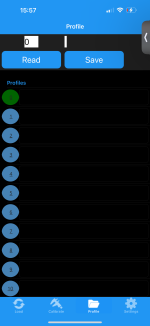

What app is this you speak of?Not that it means anything but the app was updated a few days back.

Not that it means anything but the app was updated a few days back.

App works fine and the updates don’t carry over any of the load data. Not impressed

When I see an app released for iOS is when I will believe its on the market.

Until then keeping the V3 with IP tricker going strong.

Until then keeping the V3 with IP tricker going strong.

If you have the new electronics, they send you the info to download the beta version of the app through TestFlight, which is like a development platform for people to use apps before the public launch. Some of the features in the app are not available using only the electronics (the keypad, basically) because those features are for the IP thrower. A few people have that thrower, but the bulk of current users with the keypad are using Autotrickler v3 thrower with the ingenuity precision trickler.What app is this you speak of?

Yeah, that’s probably safe but I can think of at least one major tech manufacturer that used TestFlight in a production release of its app. Probably took too long for apple to approve the app for the App Store.When I see an app released for iOS is when I will believe its on the market.

Until then keeping the V3 with IP tricker going strong.

I’d happily keep using the app in TestFlight. It works fine for me.

You guys had me worried about the downside of my 19 to one odds wager when you said the app was updated and then I realized it’s the test flight app so I feel confident again

Yeah notice that none of us are taking you upYou guys had me worried about the downside of my 19 to one odds wager when you said the app was updated and then I realized it’s the test flight app so I feel confident again

on your bet.

I’m traveling but aren’t the profiles saved on the electronics and not the app. Once you sync up, the profiles should be there. They were last time I updated anyways.App just did an auto update and deleted my profiles. Double not impressed now.

I’m traveling but aren’t the profiles saved on the electronics and not the app. Once you sync up, the profiles should be there. They were last time I updated anyways.

Mine have always been in the app. I’ll sync and find out.

Similar threads

- Replies

- 8

- Views

- 672

- Replies

- 178

- Views

- 8K

- Replies

- 23

- Views

- 961