Re: Our lathe adventures.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: fireguyty</div><div class="ubbcode-body">Results speak for themselves Joe. Soon as I have something I need barreled I'll pay up, even if it turned out bad for my blank, just to be there and watch my barrel being turned. Also like you say....6 month lead time sucks.

Looking forward to seeing your barrel next.

Ty</div></div>

Don't worry about paying up, we'll work something out!

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: STR</div><div class="ubbcode-body">Great job guys!!! No more satisfying feeling than making something with your own hands, and it turning out so well. How do you put a price on that. Congrats!!!!!</div></div>

Thank you Sir and thank you for your help!

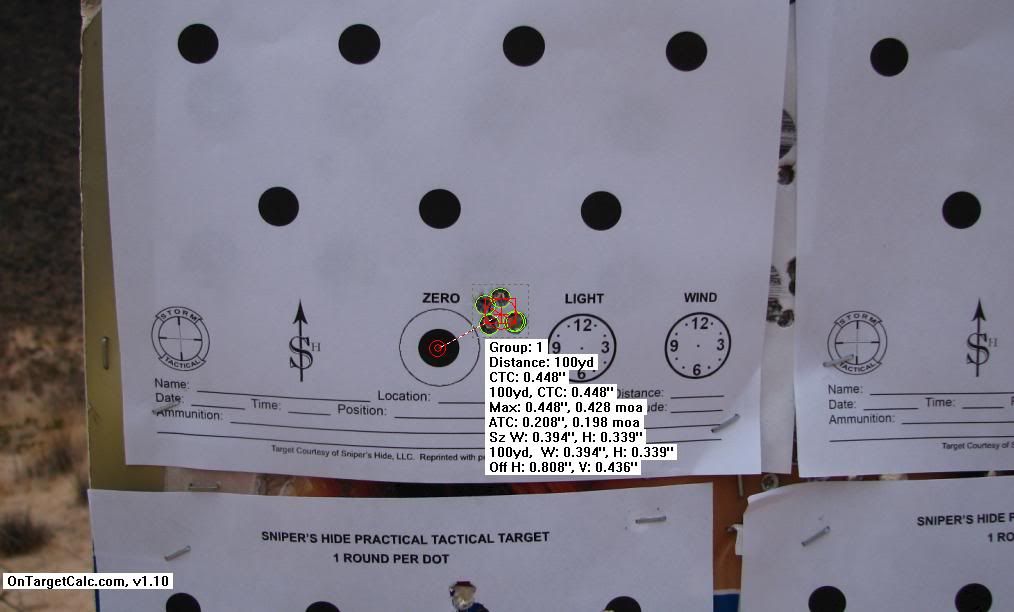

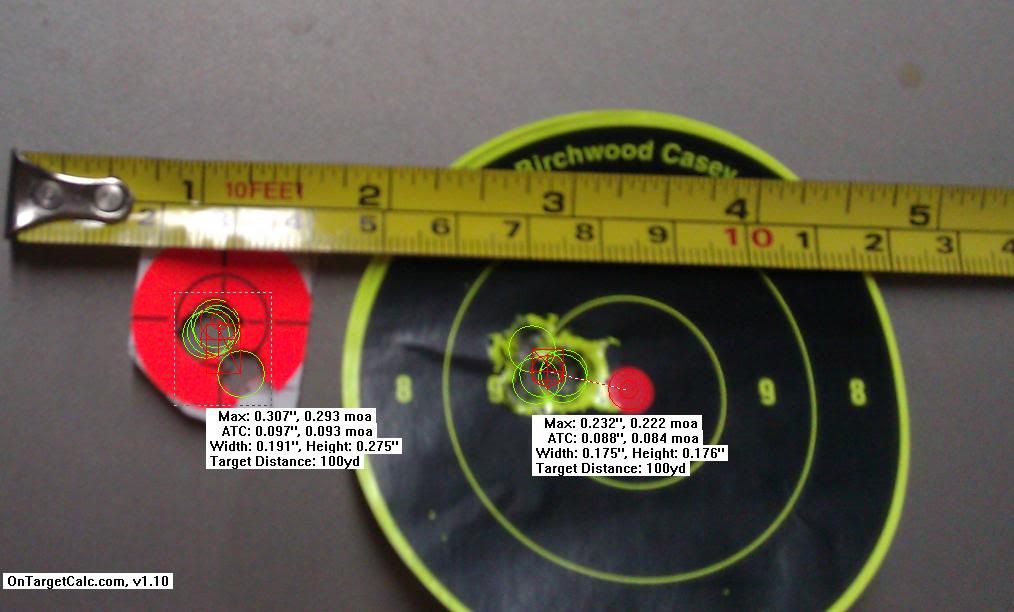

We got started after 8 this morning. Dane and I were able to get my rifle pretty much wrapped up. We still have to face the muzzle end, crown it, then thread it for a muzzle brake. Were going to practice clocking a bit more on one of the take off barrels then take care of both rifles.

While I was turning away on the lathe Dane made some adjustments to his JP chassis to accept the MTU contour barrel. Yesterday it wasn't fitting correctly so we put it in the AICS to make sure it shot well.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: fireguyty</div><div class="ubbcode-body">Results speak for themselves Joe. Soon as I have something I need barreled I'll pay up, even if it turned out bad for my blank, just to be there and watch my barrel being turned. Also like you say....6 month lead time sucks.

Looking forward to seeing your barrel next.

Ty</div></div>

Don't worry about paying up, we'll work something out!

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: STR</div><div class="ubbcode-body">Great job guys!!! No more satisfying feeling than making something with your own hands, and it turning out so well. How do you put a price on that. Congrats!!!!!</div></div>

Thank you Sir and thank you for your help!

We got started after 8 this morning. Dane and I were able to get my rifle pretty much wrapped up. We still have to face the muzzle end, crown it, then thread it for a muzzle brake. Were going to practice clocking a bit more on one of the take off barrels then take care of both rifles.

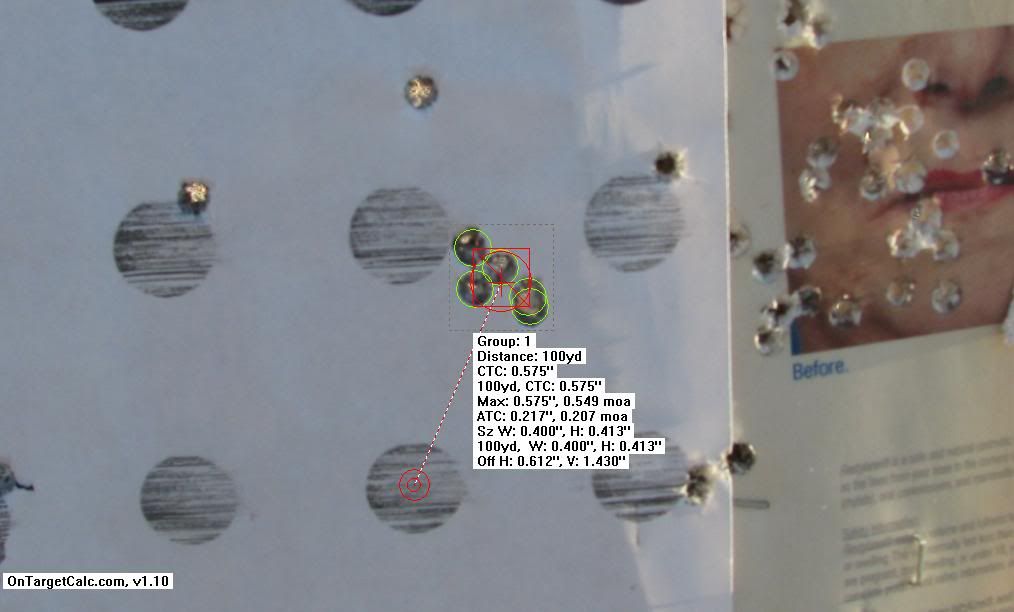

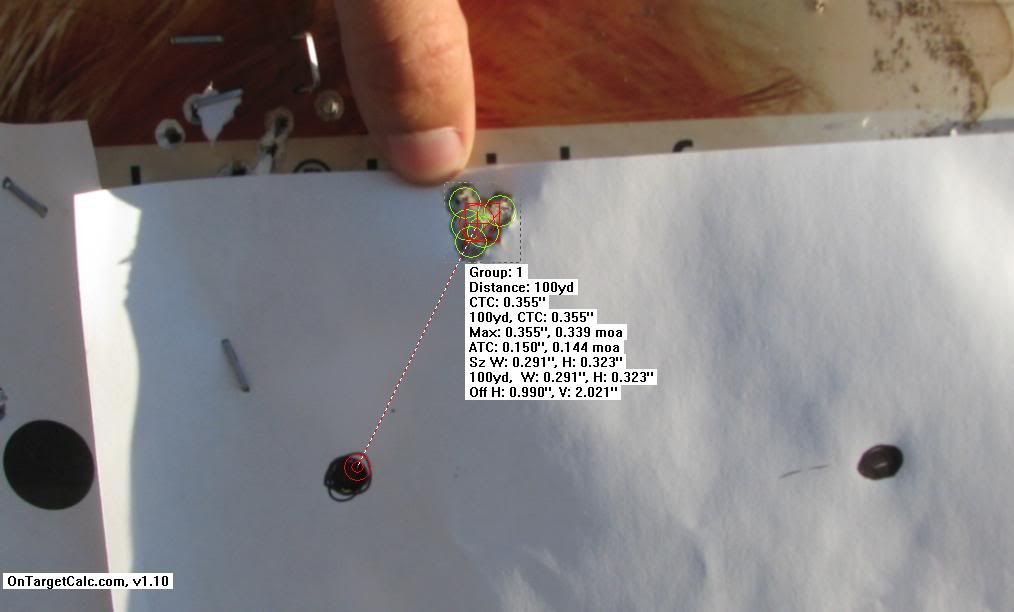

While I was turning away on the lathe Dane made some adjustments to his JP chassis to accept the MTU contour barrel. Yesterday it wasn't fitting correctly so we put it in the AICS to make sure it shot well.