Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Gunsmithing Our lathe adventures.

- Thread starter D Miller

- Start date

Re: Our lathe adventures.

Run a half inch end mill in to .010" short of finish depth.

Then you can finish single point.

You have to finish single point anyways even with the PTG tool right?

Bolt noses are never the same size after truing. So Id hope the PTG tool is around .670 at the largest, so there's room to finish single point and make it the correct size.

Run a half inch end mill in to .010" short of finish depth.

Then you can finish single point.

You have to finish single point anyways even with the PTG tool right?

Bolt noses are never the same size after truing. So Id hope the PTG tool is around .670 at the largest, so there's room to finish single point and make it the correct size.

Re: Our lathe adventures.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: JFComfort</div><div class="ubbcode-body">K.I.S.S. </div></div>I think you passed that ^ when you started haha, you did for me anyhow.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: JFComfort</div><div class="ubbcode-body">K.I.S.S. </div></div>I think you passed that ^ when you started haha, you did for me anyhow.

Re: Our lathe adventures.

One thing you want to do on a new machine setup. I am sure you leveled it out when you first installed it correct?

Have you re-leveled it since? It is pretty normal for a machine to shift and settle a bit after setting it up. Temperature changes can affect machine levels as well.

I will usually check level every month or so but that often only because where my lathe is set up it bridges an expansion cut in my slab.

One thing you want to do on a new machine setup. I am sure you leveled it out when you first installed it correct?

Have you re-leveled it since? It is pretty normal for a machine to shift and settle a bit after setting it up. Temperature changes can affect machine levels as well.

I will usually check level every month or so but that often only because where my lathe is set up it bridges an expansion cut in my slab.

Re: Our lathe adventures.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Keith at PCR</div><div class="ubbcode-body">

You have to finish single point anyways even with the PTG tool right?

Bolt noses are never the same size after truing. So Id hope the PTG tool is around .670 at the largest, so there's room to finish single point and make it the correct size. </div></div>

The Ptg counterbores are 0.705 as they come from Ptg.

I ground mine down to 0.690 so i can single point finish to my desired diameter on a case by case basis.

I don't turn the nose diameter down when I true a bolt.

I don't want it any thinner up there as it's already too thin in my opinion.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Keith at PCR</div><div class="ubbcode-body">

You have to finish single point anyways even with the PTG tool right?

Bolt noses are never the same size after truing. So Id hope the PTG tool is around .670 at the largest, so there's room to finish single point and make it the correct size. </div></div>

The Ptg counterbores are 0.705 as they come from Ptg.

I ground mine down to 0.690 so i can single point finish to my desired diameter on a case by case basis.

I don't turn the nose diameter down when I true a bolt.

I don't want it any thinner up there as it's already too thin in my opinion.

Re: Our lathe adventures.

Were still waiting on the PTG piece, we'll be shooting the LRPRS match in Phoenix so we will have to attempt cutting the barrel the weekend of the 27th.

Were still waiting on the PTG piece, we'll be shooting the LRPRS match in Phoenix so we will have to attempt cutting the barrel the weekend of the 27th.

Re: Our lathe adventures.

That gives you plenty of time to work on getting new signature banners

Just bustin' you balls, see you Sat and I'm really jealous of your lathe....

That gives you plenty of time to work on getting new signature banners

Just bustin' you balls, see you Sat and I'm really jealous of your lathe....

Re: Our lathe adventures.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: sobrbiker883</div><div class="ubbcode-body">That gives you plenty of time to work on getting new signature banners

Just bustin' you balls, see you Sat and I'm really jealous of your lathe.... </div></div>

Looking forward to it! New banners should be up shortly, Beau is almost finished with them!

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: sobrbiker883</div><div class="ubbcode-body">That gives you plenty of time to work on getting new signature banners

Just bustin' you balls, see you Sat and I'm really jealous of your lathe.... </div></div>

Looking forward to it! New banners should be up shortly, Beau is almost finished with them!

Re: Our lathe adventures.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: sobrbiker883</div><div class="ubbcode-body">Much better. </div></div>

lmao

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: sobrbiker883</div><div class="ubbcode-body">Much better. </div></div>

lmao

Re: Our lathe adventures.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: sobrbiker883</div><div class="ubbcode-body">Much better. </div></div>

I liked the old black ones better.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: sobrbiker883</div><div class="ubbcode-body">Much better. </div></div>

I liked the old black ones better.

Re: Our lathe adventures.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: 2156SMK</div><div class="ubbcode-body"><div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: sobrbiker883</div><div class="ubbcode-body">Much better. </div></div>

I liked the old black ones better. </div></div>

I like that they say USO not NF.....

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: 2156SMK</div><div class="ubbcode-body"><div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: sobrbiker883</div><div class="ubbcode-body">Much better. </div></div>

I liked the old black ones better. </div></div>

I like that they say USO not NF.....

Re: Our lathe adventures.

What sort of sytem are you setting up for cutting fluid? And you will want to move that Jeep out of tha garage when you start reaming the chambers

I would also suggest having kitty litter on hand BEFORE you start.

I would also suggest having kitty litter on hand BEFORE you start.

What sort of sytem are you setting up for cutting fluid? And you will want to move that Jeep out of tha garage when you start reaming the chambers

Re: Our lathe adventures.

Were more than likely going to use a grease can full of cutting oil. Dane has plenty of kitty litter at the house so we should be good on that. I will also make a mental note to move the Jeep outta the way.

Were more than likely going to use a grease can full of cutting oil. Dane has plenty of kitty litter at the house so we should be good on that. I will also make a mental note to move the Jeep outta the way.

Re: Our lathe adventures.

I bought the same lathe from Grizzly but I needed to move it inside my house so the crane truck or a wrecker wouldn't work. I had a bunch of buddies offer...the only ones who did help helped with some 2" square stock and a 2 1/2 ton engine hoist. I moved it all the way from my carport, through the kitchen and living room to the "rifle room" with ease.

The really scary part was when my new 3,500 dollar machine was hanging 40 inches above the floor. That was pure stress. The wiring was a snap and setting the machine up once it was set on the pedistal was easy since I've set them up.

I love it when someone who has no idea I have a mini-machine shop walks through the door. Eyes always pop.

Here are a few pictures from facebook.

It had a rough ride from Missouri. I noted a couple dings on the power box but nothing major.

Getting it ready for the caster dolly's my buddy and I made.

Close up of the gear box dolly.

And there she is ready for work. I had an electrician come in and do the wiring so it was code since it is inside the house.

And a view looking into the room. It was still a little cluttered from the move and set up.

I bought the same lathe from Grizzly but I needed to move it inside my house so the crane truck or a wrecker wouldn't work. I had a bunch of buddies offer...the only ones who did help helped with some 2" square stock and a 2 1/2 ton engine hoist. I moved it all the way from my carport, through the kitchen and living room to the "rifle room" with ease.

The really scary part was when my new 3,500 dollar machine was hanging 40 inches above the floor. That was pure stress. The wiring was a snap and setting the machine up once it was set on the pedistal was easy since I've set them up.

I love it when someone who has no idea I have a mini-machine shop walks through the door. Eyes always pop.

Here are a few pictures from facebook.

It had a rough ride from Missouri. I noted a couple dings on the power box but nothing major.

Getting it ready for the caster dolly's my buddy and I made.

Close up of the gear box dolly.

And there she is ready for work. I had an electrician come in and do the wiring so it was code since it is inside the house.

And a view looking into the room. It was still a little cluttered from the move and set up.

Re: Our lathe adventures.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Keith at PCR</div><div class="ubbcode-body">Next Saturday? See you there hopefully.

</div></div>

Didn't see ya there this weekend.

Anyways we just about have all our ducks in a row to begin. Just need to pick up some cutting oil on the way home from work today.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Keith at PCR</div><div class="ubbcode-body">Next Saturday? See you there hopefully.

</div></div>

Didn't see ya there this weekend.

Anyways we just about have all our ducks in a row to begin. Just need to pick up some cutting oil on the way home from work today.

Re: Our lathe adventures.

We will be busy this weekend, my Shilen barrel took a crap at the AZ LRPRS match so now Dane and I are gonna re-barrel both rifles. I was able to squeeze out 3,100 accurate rounds out of the barrel chambered in 6.5 Creedmoor. I'm looking forward to a fresh tube but unfortunately I'm not positive I'll have it ready to go for the Vegas match.

We will be busy this weekend, my Shilen barrel took a crap at the AZ LRPRS match so now Dane and I are gonna re-barrel both rifles. I was able to squeeze out 3,100 accurate rounds out of the barrel chambered in 6.5 Creedmoor. I'm looking forward to a fresh tube but unfortunately I'm not positive I'll have it ready to go for the Vegas match.

Re: Our lathe adventures.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: D. Miller</div><div class="ubbcode-body"><div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Keith at PCR</div><div class="ubbcode-body">Next Saturday? See you there hopefully.

</div></div>

Didn't see ya there this weekend.

</div></div>

Couldnt make it. I had to take my rifle apart to do some work to it, and didnt have time that week to go sight in and be ready for the match.

Ive had to miss a lot of shooting, to build rifles.

Kinda ironic that I have no time to shoot anymore cause Im building rifles

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: D. Miller</div><div class="ubbcode-body"><div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Keith at PCR</div><div class="ubbcode-body">Next Saturday? See you there hopefully.

</div></div>

Didn't see ya there this weekend.

</div></div>

Couldnt make it. I had to take my rifle apart to do some work to it, and didnt have time that week to go sight in and be ready for the match.

Ive had to miss a lot of shooting, to build rifles.

Kinda ironic that I have no time to shoot anymore cause Im building rifles

Re: Our lathe adventures.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Keith</div><div class="ubbcode-body">Ive had to miss a lot of shooting, to build rifles.

Kinda ironic that I have no time to shoot anymore cause Im building rifles </div></div>

That's the cruel reality of gunsmithing.

I bet they didn't teach you that at school...

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Keith</div><div class="ubbcode-body">Ive had to miss a lot of shooting, to build rifles.

Kinda ironic that I have no time to shoot anymore cause Im building rifles </div></div>

That's the cruel reality of gunsmithing.

I bet they didn't teach you that at school...

Re: Our lathe adventures.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: JFComfort</div><div class="ubbcode-body">We will be busy this weekend, my Shilen barrel took a crap at the AZ LRPRS match so now Dane and I are gonna re-barrel both rifles. I was able to squeeze out 3,100 accurate rounds out of the barrel chambered in 6.5 Creedmoor. I'm looking forward to a fresh tube but unfortunately I'm not positive I'll have it ready to go for the Vegas match. </div></div>

We hoped to have both rifles chambered and shooting after this weekend unfortunately a power problem at my house brought us to a halt.

After some time in the back of the lathe with the schematics and a volt meter the culprit emerged as a bad breaker on my house... I gave the breaker a quick visual inspection that night and when it appeared to be ok i went back to the power box in the lathe. A quick trip to Agent Orange to pick up a new breaker and its back up and running. Hope to have it releveled and gtg tonight.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: JFComfort</div><div class="ubbcode-body">We will be busy this weekend, my Shilen barrel took a crap at the AZ LRPRS match so now Dane and I are gonna re-barrel both rifles. I was able to squeeze out 3,100 accurate rounds out of the barrel chambered in 6.5 Creedmoor. I'm looking forward to a fresh tube but unfortunately I'm not positive I'll have it ready to go for the Vegas match. </div></div>

We hoped to have both rifles chambered and shooting after this weekend unfortunately a power problem at my house brought us to a halt.

After some time in the back of the lathe with the schematics and a volt meter the culprit emerged as a bad breaker on my house... I gave the breaker a quick visual inspection that night and when it appeared to be ok i went back to the power box in the lathe. A quick trip to Agent Orange to pick up a new breaker and its back up and running. Hope to have it releveled and gtg tonight.

Re: Our lathe adventures.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: mattsnuked</div><div class="ubbcode-body">Clock is ticking, I better see you and Dane this weekend. </div></div>

Ill be at the BBQ Friday night, helping out with the match but unfortunately neither of us will be shooting. Only rifle i have ammo and dope for right now is the Barrett.

The lathe is throwing every thing in our way now that we have an actual barrel chucked up in it. Everything went so smooth during steel stock practice i was starting to have a false sense of confidence. They say when stuff goes wrong thats how you really learn to do something...

<span style="font-weight: bold">Anyways. A little help please, Ill try to explain this the best i can...</span>

While threading the tennon we mis-calculated our cut depth and had to go back and chase the threads. I know i should have measured before moving to the next step, but i didnt. The thread chasing went off with out a hitch for the first 2 passes but on the third pass it was trying to jump half a thread ahead. It would have crashed in to the thread but i ran the third pass out .010 to double check and im glad i did. Im at a loss as to what is causing the lag or jump in the threading??????

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: mattsnuked</div><div class="ubbcode-body">Clock is ticking, I better see you and Dane this weekend. </div></div>

Ill be at the BBQ Friday night, helping out with the match but unfortunately neither of us will be shooting. Only rifle i have ammo and dope for right now is the Barrett.

The lathe is throwing every thing in our way now that we have an actual barrel chucked up in it. Everything went so smooth during steel stock practice i was starting to have a false sense of confidence. They say when stuff goes wrong thats how you really learn to do something...

<span style="font-weight: bold">Anyways. A little help please, Ill try to explain this the best i can...</span>

While threading the tennon we mis-calculated our cut depth and had to go back and chase the threads. I know i should have measured before moving to the next step, but i didnt. The thread chasing went off with out a hitch for the first 2 passes but on the third pass it was trying to jump half a thread ahead. It would have crashed in to the thread but i ran the third pass out .010 to double check and im glad i did. Im at a loss as to what is causing the lag or jump in the threading??????

Re: Our lathe adventures.

Just a possibility, but hard to tell without being there. If your part spun or moved back in the chuck just a hair, that will cause this. Some times people will use something wrapped around the work, like tape, and the part may slip while cutting or putting pressure on it with the live center and tail stock. Of this is not what you're talking about, do keep what I just said in mind about trying to protect a surface with tape. Good luck.

Just a possibility, but hard to tell without being there. If your part spun or moved back in the chuck just a hair, that will cause this. Some times people will use something wrapped around the work, like tape, and the part may slip while cutting or putting pressure on it with the live center and tail stock. Of this is not what you're talking about, do keep what I just said in mind about trying to protect a surface with tape. Good luck.

Re: Our lathe adventures.

How did you back the cutter off the part? Did you direct feed it out with the carriage cross slide or did you back it out with the compound slide?

If you backed it out on the compound slide it would appear that the thread had "jumped" because of the travel angle on the slide.

How did you back the cutter off the part? Did you direct feed it out with the carriage cross slide or did you back it out with the compound slide?

If you backed it out on the compound slide it would appear that the thread had "jumped" because of the travel angle on the slide.

Re: Our lathe adventures.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: mattsnuked</div><div class="ubbcode-body">Clock is ticking, I better see you and Dane this weekend. </div></div>

No love Matt, we've been hitting every bump in the road when it’s come to getting our rifles re-barreled. I'll be there to watch you beat up steel during the match. I'm keeping my fingers crossed we still might be able to get the rifles done this weekend but confidence is low.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: mattsnuked</div><div class="ubbcode-body">Clock is ticking, I better see you and Dane this weekend. </div></div>

No love Matt, we've been hitting every bump in the road when it’s come to getting our rifles re-barreled. I'll be there to watch you beat up steel during the match. I'm keeping my fingers crossed we still might be able to get the rifles done this weekend but confidence is low.

Re: Our lathe adventures.

Lets see if this is a better explanation.

We had the threading bit lined up and the half nut locked. We would put the machine in reverse to return it to the starting point while keeping the half nut locked. How ever on the 3rd pass it skipped half a thread when switching it in to reverse. This happens again and again even after we took it out of the chuck and realigned and tightened everything back down.

The jaws are directly on the steel of the tube. Im not as concerned with a mark or two on my personal match gun. It will get banged around many more times in its life.

It was backed out with the carriage cross feed not the angled compound. Im at a loss on this one.

Thanks guys for the help.

Lets see if this is a better explanation.

We had the threading bit lined up and the half nut locked. We would put the machine in reverse to return it to the starting point while keeping the half nut locked. How ever on the 3rd pass it skipped half a thread when switching it in to reverse. This happens again and again even after we took it out of the chuck and realigned and tightened everything back down.

The jaws are directly on the steel of the tube. Im not as concerned with a mark or two on my personal match gun. It will get banged around many more times in its life.

It was backed out with the carriage cross feed not the angled compound. Im at a loss on this one.

Thanks guys for the help.

Re: Our lathe adventures.

Possibly backlash in the half nut if I understand you correctly. Does it return to the correct position if you put in back in forward? If you disengage the half nut before putting it in reverse, does it work correctly? If you aren't cutting metric threads, that is what thenthreading dial is for.

Possibly backlash in the half nut if I understand you correctly. Does it return to the correct position if you put in back in forward? If you disengage the half nut before putting it in reverse, does it work correctly? If you aren't cutting metric threads, that is what thenthreading dial is for.

Re: Our lathe adventures.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: angelballer</div><div class="ubbcode-body">Possibly backlash in the half nut if I understand you correctly. Does it return to the correct position if you put in back in forward? If you disengage the half nut before putting it in reverse, does it work correctly? If you aren't cutting metric threads, that is what thenthreading dial is for.</div></div>

I was thinking the exact same thing, I've had the same problem in the past. Even if you're threading metric, the principle is the same, it's safest to use the same number on the threading dial each time and then you can be sure that you'll get a consistently good thread. It's explained here:

http://www.youtube.com/watch?feature=player_detailpage&v=1IqN0sHupQE#t=402s

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: angelballer</div><div class="ubbcode-body">Possibly backlash in the half nut if I understand you correctly. Does it return to the correct position if you put in back in forward? If you disengage the half nut before putting it in reverse, does it work correctly? If you aren't cutting metric threads, that is what thenthreading dial is for.</div></div>

I was thinking the exact same thing, I've had the same problem in the past. Even if you're threading metric, the principle is the same, it's safest to use the same number on the threading dial each time and then you can be sure that you'll get a consistently good thread. It's explained here:

http://www.youtube.com/watch?feature=player_detailpage&v=1IqN0sHupQE#t=402s

Re: Our lathe adventures.

We have been engaging the half nuts when the threading dial was on "1" everytime both during threading and chasing the thread.

Were going to go back to it this evening and see if we can get it sorted out.

We have been engaging the half nuts when the threading dial was on "1" everytime both during threading and chasing the thread.

Were going to go back to it this evening and see if we can get it sorted out.

Re: Our lathe adventures.

Check the leadscrew and half nut for debris. I also do not follow why you were running the machine in reverse???

Check the leadscrew and half nut for debris. I also do not follow why you were running the machine in reverse???

Re: Our lathe adventures.

You said you took it out of the chuck, correct?

You're going to need to pickup the thread again by moving the carriage and compound around with the half-nut engaged.

If you rotated the part a little, moved the indexing, etc. while you took it out of the chuck you're pretty much starting over.

If something like this happens in the future, don't take the part out of the chuck. You can pickup the thread without pulling it from the chuck

You said you took it out of the chuck, correct?

You're going to need to pickup the thread again by moving the carriage and compound around with the half-nut engaged.

If you rotated the part a little, moved the indexing, etc. while you took it out of the chuck you're pretty much starting over.

If something like this happens in the future, don't take the part out of the chuck. You can pickup the thread without pulling it from the chuck

Re: Our lathe adventures.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: lvcatfish</div><div class="ubbcode-body">Check the leadscrew and half nut for debris. I also do not follow why you were running the machine in reverse???</div></div>

We cleaned the lead screw last night and Dane is going to donate his tooth brush so we can douche out the half nuts. (fingers crossed)

I talked to a smith/machinist in Oklahoma who had some great trouble shooting ideas that were going to give a shot this evening.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: lvcatfish</div><div class="ubbcode-body">Check the leadscrew and half nut for debris. I also do not follow why you were running the machine in reverse???</div></div>

We cleaned the lead screw last night and Dane is going to donate his tooth brush so we can douche out the half nuts. (fingers crossed)

I talked to a smith/machinist in Oklahoma who had some great trouble shooting ideas that were going to give a shot this evening.

Re: Our lathe adventures.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: JFComfort</div><div class="ubbcode-body"><div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: mattsnuked</div><div class="ubbcode-body">Clock is ticking, I better see you and Dane this weekend. </div></div>

No love Matt, we've been hitting every bump in the road when it’s come to getting our rifles re-barreled. I'll be there to watch you beat up steel during the match. I'm keeping my fingers crossed we still might be able to get the rifles done this weekend but confidence is low. </div></div>

Better to take your time and do it right the first time. Then we can see you guys next month down here.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: JFComfort</div><div class="ubbcode-body"><div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: mattsnuked</div><div class="ubbcode-body">Clock is ticking, I better see you and Dane this weekend. </div></div>

No love Matt, we've been hitting every bump in the road when it’s come to getting our rifles re-barreled. I'll be there to watch you beat up steel during the match. I'm keeping my fingers crossed we still might be able to get the rifles done this weekend but confidence is low. </div></div>

Better to take your time and do it right the first time. Then we can see you guys next month down here.

Re: Our lathe adventures.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: mattsnuked</div><div class="ubbcode-body">

Better to take your time and do it right the first time. Then we can see you guys next month down here.</div></div>

Yes Sir, you are absolutly right. Once the rifles are up and running Dane and I need to head down and shoot your match so we can make up for the down time! You heading into town tomorrow evening?

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: mattsnuked</div><div class="ubbcode-body">

Better to take your time and do it right the first time. Then we can see you guys next month down here.</div></div>

Yes Sir, you are absolutly right. Once the rifles are up and running Dane and I need to head down and shoot your match so we can make up for the down time! You heading into town tomorrow evening?

Re: Our lathe adventures.

I want to say <span style="font-weight: bold">thank you</span> for all the help and advice yesterday. A newbie mistake combined with the the wrong technique compounded in to a project stopping disaster. JFC and I were able to get things sorted out and back on track after reading your guys replies and talking to some extremely helpful guys on the phone.

About to thread the tennon before everything went wrong

Dialing back in to pick up the threads and cut them deeper.

It fit and nearly perfect at that too!!

Checking the recess with the bolt for a photo op.

The start of Fridays project!!!!

Thanks again for all the help your time is much appreciated.

I want to say <span style="font-weight: bold">thank you</span> for all the help and advice yesterday. A newbie mistake combined with the the wrong technique compounded in to a project stopping disaster. JFC and I were able to get things sorted out and back on track after reading your guys replies and talking to some extremely helpful guys on the phone.

About to thread the tennon before everything went wrong

Dialing back in to pick up the threads and cut them deeper.

It fit and nearly perfect at that too!!

Checking the recess with the bolt for a photo op.

The start of Fridays project!!!!

Thanks again for all the help your time is much appreciated.

Re: Our lathe adventures.

Very nice. One of these days I will have a lathe in the shop. I have thought about taking a few classes at the tech school here, but I really seem to learn better by just jumping into it.

The last time I used a lathe was in metal shop in high school.

Very nice. One of these days I will have a lathe in the shop. I have thought about taking a few classes at the tech school here, but I really seem to learn better by just jumping into it.

The last time I used a lathe was in metal shop in high school.

Re: Our lathe adventures.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: LoneWolfUSMC</div><div class="ubbcode-body">Very nice. One of these days I will have a lathe in the shop. I have thought about taking a few classes at the tech school here, but I really seem to learn better by just jumping into it.

<span style="text-decoration: underline">The last time I used a lathe was in metal shop in high school.</span> </div></div>

Same here, last lathe usage for me was 15 years ago, before this thread anyways. There is a wealth of knowledge on You tube and in the brains of members on here. I spent a few months reading and watching videos first then jumped in. It can be done.

I thought about taking a class until i found that most trade type classes were no longer available in the LV due to recent budget issues.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: LoneWolfUSMC</div><div class="ubbcode-body">Very nice. One of these days I will have a lathe in the shop. I have thought about taking a few classes at the tech school here, but I really seem to learn better by just jumping into it.

<span style="text-decoration: underline">The last time I used a lathe was in metal shop in high school.</span> </div></div>

Same here, last lathe usage for me was 15 years ago, before this thread anyways. There is a wealth of knowledge on You tube and in the brains of members on here. I spent a few months reading and watching videos first then jumped in. It can be done.

I thought about taking a class until i found that most trade type classes were no longer available in the LV due to recent budget issues.

Re: Our lathe adventures.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: D. Miller</div><div class="ubbcode-body"><div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: LoneWolfUSMC</div><div class="ubbcode-body">Very nice. One of these days I will have a lathe in the shop. I have thought about taking a few classes at the tech school here, but I really seem to learn better by just jumping into it.

<span style="text-decoration: underline">The last time I used a lathe was in metal shop in high school.</span> </div></div>

Same here, last lathe usage for me was 15 years ago, before this thread anyways. There is a wealth of knowledge on You tube and in the brains of members on here. I spent a few months reading and watching videos first then jumped in. It can be done.

I thought about taking a class until i found that most trade type classes were no longer available in the LV due to recent budget issues.</div></div>

Same with me, last time I was working with a lathe was in Rohnert Park, CA Rancho Cotate High School during metal shop class. I'm 28 now so that was 11 years ago, once you get in front of the thing you can figure out a lot fairly quickly. Dane is right about the knowledge out there, we spent a lot of time sitting at his kitchen table sipping a brew, eating some pizza and watching videos on youtube.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: D. Miller</div><div class="ubbcode-body"><div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: LoneWolfUSMC</div><div class="ubbcode-body">Very nice. One of these days I will have a lathe in the shop. I have thought about taking a few classes at the tech school here, but I really seem to learn better by just jumping into it.

<span style="text-decoration: underline">The last time I used a lathe was in metal shop in high school.</span> </div></div>

Same here, last lathe usage for me was 15 years ago, before this thread anyways. There is a wealth of knowledge on You tube and in the brains of members on here. I spent a few months reading and watching videos first then jumped in. It can be done.

I thought about taking a class until i found that most trade type classes were no longer available in the LV due to recent budget issues.</div></div>

Same with me, last time I was working with a lathe was in Rohnert Park, CA Rancho Cotate High School during metal shop class. I'm 28 now so that was 11 years ago, once you get in front of the thing you can figure out a lot fairly quickly. Dane is right about the knowledge out there, we spent a lot of time sitting at his kitchen table sipping a brew, eating some pizza and watching videos on youtube.

Re: Our lathe adventures.

How are you able to steer your bore with the barrel clamped in that big 4 jaw chuck? Do you have a pivot under those jaws of some sort? I can't help but think you are either not able to move it at all or it's putting a big bend in your barrel when you push it around with the spider.

It looks like your indicator is siting on the ways. Are you only dialing in your range rod in one place? I run two indicators at a time resting on the carriage. One will do but two saves some time.

How are you able to steer your bore with the barrel clamped in that big 4 jaw chuck? Do you have a pivot under those jaws of some sort? I can't help but think you are either not able to move it at all or it's putting a big bend in your barrel when you push it around with the spider.

It looks like your indicator is siting on the ways. Are you only dialing in your range rod in one place? I run two indicators at a time resting on the carriage. One will do but two saves some time.

Re: Our lathe adventures.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Hired Gun</div><div class="ubbcode-body">How are you able to steer your bore with the barrel clamped in that big 4 jaw chuck? Do you have a pivot under those jaws of some sort? I can't help but think you are either not able to move it at all or it's putting a big bend in your barrel when you push it around with the spider.

It looks like your indicator is siting on the ways. Are you only dialing in your range rod in one place? I run two indicators at a time resting on the carriage. One will do but two saves some time.

</div></div>

Id love to get a front spider type chuck some day. For now the best that can be done with the curent equipment is adding a loop of 10ga copper wire betwene the chuck and barrel.

It is a pain in the dick to measure multiple points with one dial but we were able to get it within a few ten thousands. You just have to keep moving it back and fourth.

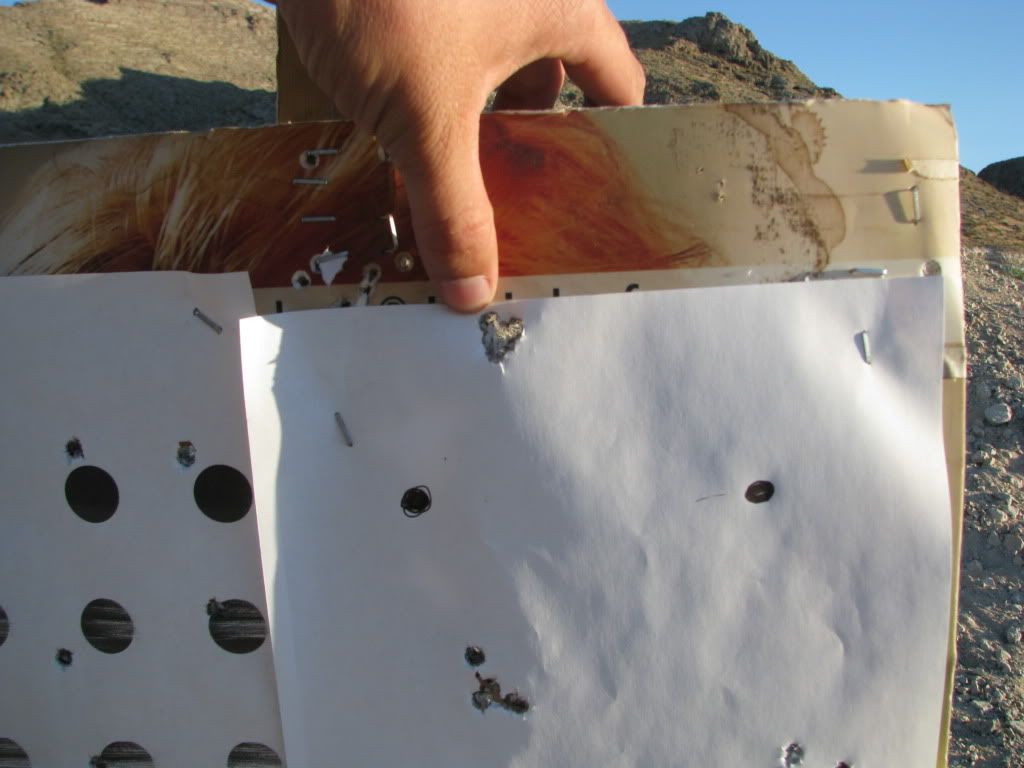

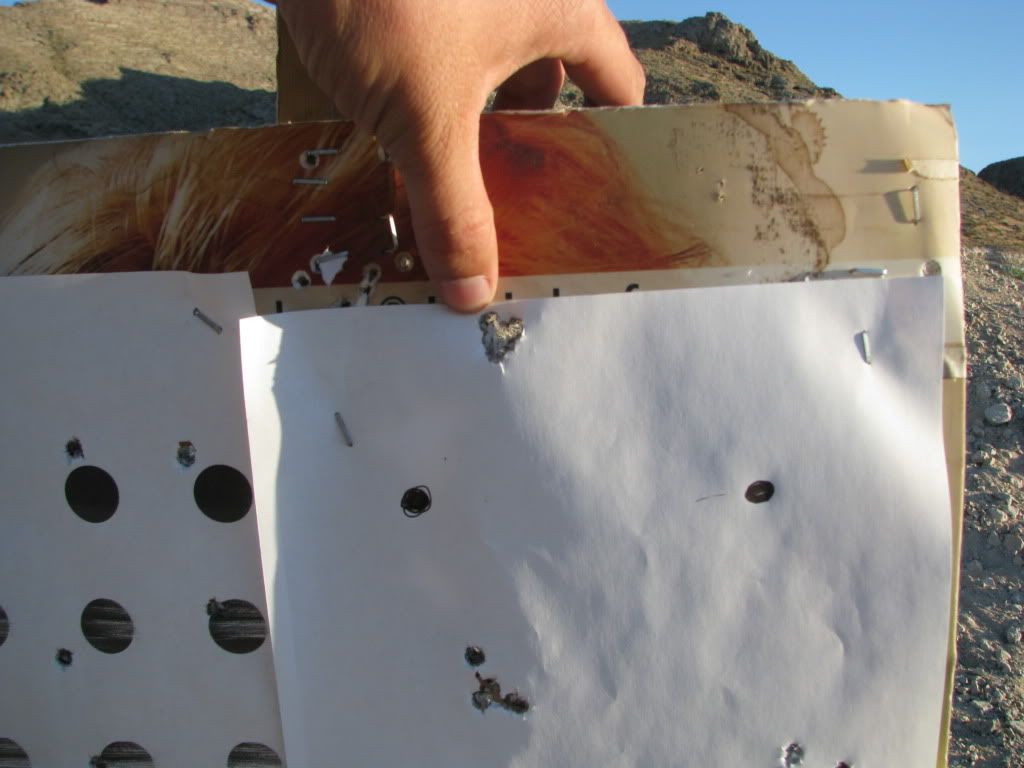

Even with our basic tooling we were able to finish the rifle today and get out to test it. For not having any prior gunsmithing experience im extremely happy with the results. The first few groups were a little rough but that turned out to be shooter fatigue and lack of practice shooting groups. After a cool off period from 106f sun and 2 bottles of water it/i produced a one large

hole group bringing a big smile to joes and myselfs face...

Pics comming tomorrow AM

Thanks again for all the help. You guys helped make this all come together and we appreciate it.

O

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Hired Gun</div><div class="ubbcode-body">How are you able to steer your bore with the barrel clamped in that big 4 jaw chuck? Do you have a pivot under those jaws of some sort? I can't help but think you are either not able to move it at all or it's putting a big bend in your barrel when you push it around with the spider.

It looks like your indicator is siting on the ways. Are you only dialing in your range rod in one place? I run two indicators at a time resting on the carriage. One will do but two saves some time.

</div></div>

Id love to get a front spider type chuck some day. For now the best that can be done with the curent equipment is adding a loop of 10ga copper wire betwene the chuck and barrel.

It is a pain in the dick to measure multiple points with one dial but we were able to get it within a few ten thousands. You just have to keep moving it back and fourth.

Even with our basic tooling we were able to finish the rifle today and get out to test it. For not having any prior gunsmithing experience im extremely happy with the results. The first few groups were a little rough but that turned out to be shooter fatigue and lack of practice shooting groups. After a cool off period from 106f sun and 2 bottles of water it/i produced a one large

hole group bringing a big smile to joes and myselfs face...

Pics comming tomorrow AM

Thanks again for all the help. You guys helped make this all come together and we appreciate it.

O

Re: Our lathe adventures.

Thank you for everyone that helped us on this one!

Today after the Las Vegas Tactical Precision Rifle match at Desert Sportsman Dane and I ran off to finish his rifle! (we will be starting mine tomorrow!)

Dane aka Vegas50

Putting it together

Old barrel vs. new barrel

Go gauge, bolt closes

No go gauge, bolt doesn't close

Finished rifle

It shoots around corners!

Thank you for everyone that helped us on this one!

Today after the Las Vegas Tactical Precision Rifle match at Desert Sportsman Dane and I ran off to finish his rifle! (we will be starting mine tomorrow!)

Dane aka Vegas50

Putting it together

Old barrel vs. new barrel

Go gauge, bolt closes

No go gauge, bolt doesn't close

Finished rifle

It shoots around corners!

Re: Our lathe adventures.

5 round group shot by Dane.

139 gr Lapua Scenar

41.5 H4350

Wolf Primer

COL 2.81"

Didn't shoot them through a chrono so we don't know how fast they are going.

5 round group shot by Dane.

139 gr Lapua Scenar

41.5 H4350

Wolf Primer

COL 2.81"

Didn't shoot them through a chrono so we don't know how fast they are going.

Re: Our lathe adventures.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: DaveD</div><div class="ubbcode-body">Good work guys </div></div>

Thanks Dave, gonna head over to Dane's to start my rifle after a cup of coffee.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: DaveD</div><div class="ubbcode-body">Good work guys </div></div>

Thanks Dave, gonna head over to Dane's to start my rifle after a cup of coffee.

Re: Our lathe adventures.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: DaveD</div><div class="ubbcode-body">Good work guys </div></div>

Thanks man.

That was the longest and most expensive re barrel yet but it should get easier from here on out.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: DaveD</div><div class="ubbcode-body">Good work guys </div></div>

Thanks man.

That was the longest and most expensive re barrel yet but it should get easier from here on out.

Re: Our lathe adventures.

After you guys told me about this at the match, I had to come home and search this out. Bitchin, is all I can think to say. What satisfaction to shoot a 5 shot group like that with a rifle you barreled yourself!

Like you said, we are lacking in smiths here in town. You two could have a nice little side business in your hobby if you so desired.

Ty

After you guys told me about this at the match, I had to come home and search this out. Bitchin, is all I can think to say. What satisfaction to shoot a 5 shot group like that with a rifle you barreled yourself!

Like you said, we are lacking in smiths here in town. You two could have a nice little side business in your hobby if you so desired.

Ty

Re: Our lathe adventures.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: fireguyty</div><div class="ubbcode-body">After you guys told me about this at the match, I had to come home and search this out. Bitchin, is all I can think to say. What satisfaction to shoot a 5 shot group like that with a rifle you barreled yourself!

Like you said, we are lacking in smiths here in town. You two could have a nice little side business in your hobby if you so desired.

Ty </div></div>

Thanks you! We had a great time catching up with you during the match. Great shooting btw, you and that DTA get along well.

Doing Dane and I's barrels was pretty nerve racking. Messing up my stuff is one thing but something that belong to someone else! I'd lose my hair. We have a long way to go before we will be confidant enough to cut on someone else's barrel.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: fireguyty</div><div class="ubbcode-body">After you guys told me about this at the match, I had to come home and search this out. Bitchin, is all I can think to say. What satisfaction to shoot a 5 shot group like that with a rifle you barreled yourself!

Like you said, we are lacking in smiths here in town. You two could have a nice little side business in your hobby if you so desired.

Ty </div></div>

Thanks you! We had a great time catching up with you during the match. Great shooting btw, you and that DTA get along well.

Doing Dane and I's barrels was pretty nerve racking. Messing up my stuff is one thing but something that belong to someone else! I'd lose my hair. We have a long way to go before we will be confidant enough to cut on someone else's barrel.

Re: Our lathe adventures.

Results speak for themselves Joe. Soon as I have something I need barreled I'll pay up, even if it turned out bad for my blank, just to be there and watch my barrel being turned. Also like you say....6 month lead time sucks.

Looking forward to seeing your barrel next.

Ty

Results speak for themselves Joe. Soon as I have something I need barreled I'll pay up, even if it turned out bad for my blank, just to be there and watch my barrel being turned. Also like you say....6 month lead time sucks.

Looking forward to seeing your barrel next.

Ty

Re: Our lathe adventures.

Great job guys!!! No more satisfying feeling than making something with your own hands, and it turning out so well. How do you put a price on that. Congrats!!!!!

Great job guys!!! No more satisfying feeling than making something with your own hands, and it turning out so well. How do you put a price on that. Congrats!!!!!

Similar threads

- Replies

- 20

- Views

- 2K

- Replies

- 151

- Views

- 11K