Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

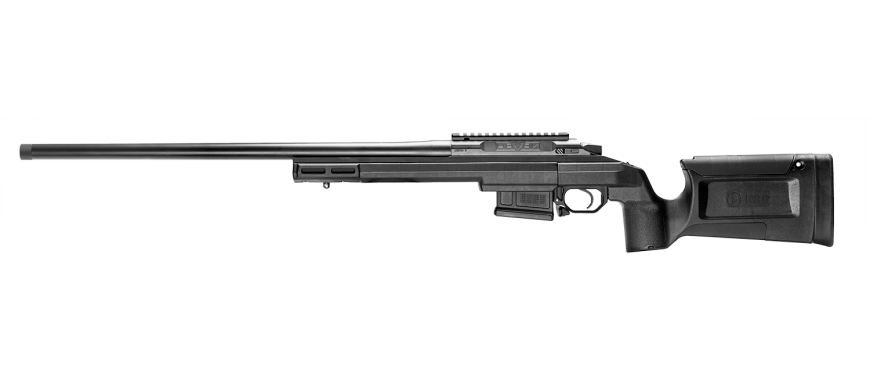

Seekins HAVAK Precision Rifle

- Thread starter Lowlight

- Start date

OK how do you take the damn bolt apart?

And that bolt handle is glued in place I think. Even with heat and channel locks it's not twisting off.

I haven't tried to take the bolt apart yet, but I'm sure it's the same as most others.

Pretty sure they dabbed a touch of LocTite on there....It's a bugger for sure.

I haven't tried to take the bolt apart yet, but I'm sure it's the same as most others.

Pretty sure they dabbed a touch of LocTite on there....It's a bugger for sure.

Mine was too loose. It kept coming loose when I didn't want it to. It's got thread locker on it now.

Don't be afraid to hit a little harder than you think you need to with the heat. Mine was really tight too. As I explained in an earlier post, don't be surprised when you see the bolt knob with the male thread, not the bolt handle............

I had a male to male extension made to fit a Remington style knob, the extended (steel) part is just a hair shy of 3/4".

I had a male to male extension made to fit a Remington style knob, the extended (steel) part is just a hair shy of 3/4".

Well, I drank some koolaid and just ordered a 28 Nosler I found in stock months ago. Should be here by the end of the week. I’m going to try factory 175 gr and 160 gr Nosler Ammo since I’m about to spend 9 months on an all expense paid trip with our Uncle Sam and don’t have time to get multiple range trips in for load data. If I like it, it will get a full paint job at CGC, we shall see.

Seekins Facebook shows a new addition to the Havak Tactical Line with a KRG Bravo with the metal finished in black. Says full release tomorrow. Sorry if this has already been discussed lol.

Last edited:

https://www.seekinsprecision.com/product/havak/havak-bravo.html

HAVAK BRAVO

6/6.5 creedmoor

6.5 PRC

308 Winchester

FDE/Black/Sako green

HAVAK BRAVO

6/6.5 creedmoor

6.5 PRC

308 Winchester

FDE/Black/Sako green

Pelican is what I was expecting to be at the top. Wasn't sure what other experiences people had with other brands. Guess I need to figure out if a larger double case would suit me. I just want to use it for more than just a single rifle and accessories.

I’ve got several Pelicans, and have given even more of them away. The ONLY time I use one is if I’m flying. They’re far too large and cumbersome. I don’t care about protecting my rifles for daily usage. They get thrown around in the truck and side by side and keep working just fine.

I'm going to hunt around for a soft case as well for the range days. The Pelican would serve as a long drive carry case when I have extended trips to other locations.

That would be the best route IMO. The double soft cases can be quite handy for normal usage.I'm going to hunt around for a soft case as well for the range days. The Pelican would serve as a long drive carry case when I have extended trips to other locations.

I'm going to hunt around for a soft case as well for the range days. The Pelican would serve as a long drive carry case when I have extended trips to other locations.

The SKB double rifle case is my favorite for hauling big rifles around. It won't handle the longest barrels, but it's great for 26" bbls with a couple inches of muzzle brake.

Might’ve missed it somewhere, but can anyone guess as to what contour these are running from the factory? What is the muzzle diameter as well?

I am planning on building a similar rifle on an FN action, debating between a light palma or a Bartlien 3b at 20”, .308, 1-10 twist. Will have an A3 stock and a hinged floorplate.

I am planning on building a similar rifle on an FN action, debating between a light palma or a Bartlien 3b at 20”, .308, 1-10 twist. Will have an A3 stock and a hinged floorplate.

Thanks, I now saw where a #4 was very similar, sounds like a light palma is in order for my build.

Thank you.

Thank you.

Regarding the reporting of the "tight" bolt; has anyone tried a little lapping compound on the bolt mating surfaces??

It seems to my non-gunsmithing mind that this would make for a little smoother action after some working of the bolt while, say, watching a movie at home. Don't shoot me, just an idea .....

I posted earlier in this thread on this, but it’s a long thread to keep up on and I’ve since remedied my issues to my satisfaction.

Commenting on the 'tight lock-up':

First, there's a fair amount of cock-on-close with this action. Some people really hate any cock-on-close in their actions. I'm undecided at this point. I like the idea of spreading the cocking effort out for an overall lighter bolt manipulation... and the bolt lift is indeed, light.

Second, and more importantly, on one of my Havak 6.5 PRC’s the factory head-space was only about 0.001" over virgin brass so there was bolt binding/brass contact on bolt close. I don’t shoot factory ammo, so once the issue was discovered, it became a non-issue for me. I ran the virgin brass through my FL sizer die and bumped the shoulder another 0.001”. From there, bolt close was just slightly more than other comparable actions, due to the cock-on-close, but not ‘tight on lock-up’. No more effort to close on an empty chamber, than on a round.

First picture below if of a piece of brass fired 3X, neck-sized only:

The next picture is of a piece of virgin brass:

Just got a call from Seekins about my 300 WM. They duplicated my accuracy issues, maybe to a slightly lesser extent based on what they said on the phone.

Anyway, they will be rebarreling and rebedding my rifle or sending me a new one with a proof target grouping. Early on I was a bit pessimistic about customer service, largely because their responses started going to my junk email folder and I thought they weren't responding. They have handled the situation as well as can be asked for. I still have my concerns about the deep spiral flutes on a 300 WM but hopefully those concerns are removed with the next barrel or rifle.

I will update again once I get the rifle back out on the range.

Anyway, they will be rebarreling and rebedding my rifle or sending me a new one with a proof target grouping. Early on I was a bit pessimistic about customer service, largely because their responses started going to my junk email folder and I thought they weren't responding. They have handled the situation as well as can be asked for. I still have my concerns about the deep spiral flutes on a 300 WM but hopefully those concerns are removed with the next barrel or rifle.

I will update again once I get the rifle back out on the range.

So I received my Havak in 6 Creedmoor last week. Took it to the lease last weekend, but didn’t get a chance to put anything down with it. It was wearing a PST II 3-15 while my glass came in.

I took a box of ammo to the range yesterday with it still wearing the PST, and was able to keep a sub 5” 3 shot group with my last 3 rounds at 1020. The rest of the box had been confirming dope from 300-770. This is the first rifle I’ve shot factory ammo from in a long time (and bought it specifically for that reason). I’m very pleased with the way it shoots. Just got it topped with an ATACR 4-16 MILC this afternoon, so now I need to get back to the range.

I took a box of ammo to the range yesterday with it still wearing the PST, and was able to keep a sub 5” 3 shot group with my last 3 rounds at 1020. The rest of the box had been confirming dope from 300-770. This is the first rifle I’ve shot factory ammo from in a long time (and bought it specifically for that reason). I’m very pleased with the way it shoots. Just got it topped with an ATACR 4-16 MILC this afternoon, so now I need to get back to the range.

I just picked up a Havak PH1 in 6.5 Creedmoor today. Impressions so far are very positive. Fit and finish are excellent; it’s well machined. The stock is on par with any McMillan or Manners I’ve owned. It’s also very light....much lighter and better balanced in hand than I expected. The action has a heavy bolt lift and doesn’t cycle super smooth, but I suspect this will improve over time and round count.

I’ll run it through it’s paces tomorrow to zero and establish mechanical accuracy. I expect good things.

I’ll run it through it’s paces tomorrow to zero and establish mechanical accuracy. I expect good things.

I went with the TMOA. What did you go with?

I went with the impact 23moa reticle and I love it.

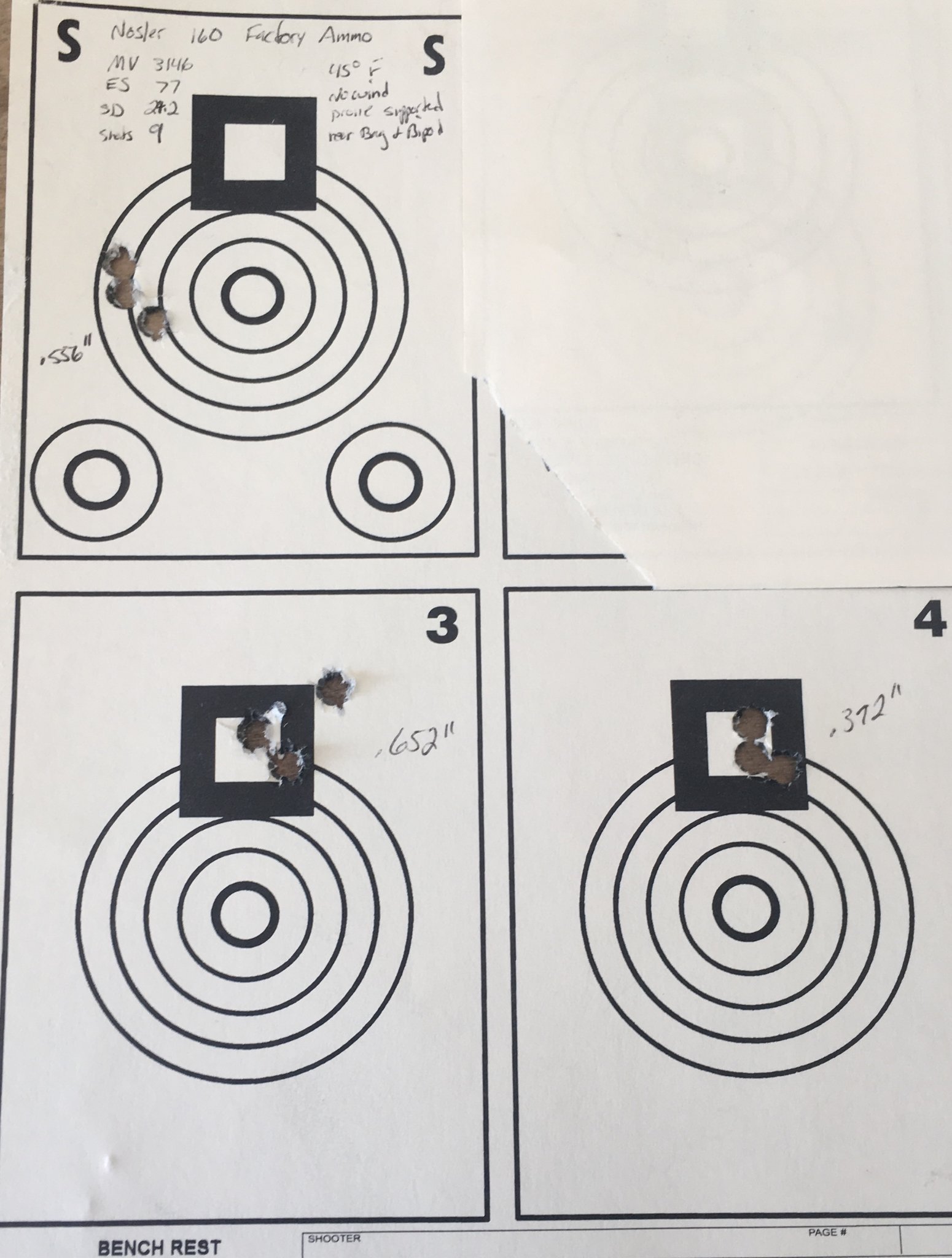

Well, I took the 28 Nosler out and shot some factory ammo through it in order to harvest the brass. It shot 160 Nosler Ammo descent, .53” average over 9 rounds in 3 x 3 rd groups. It shot 175’s like smashed ass hole at 100 (1.5” average) but pretty descent at 823 yards. I had 4 rds left and remembered I had a piece of steel that was still fresh since the last time I was home. I shot twice, (the left two) my father in law and my wife shot the other two with a different windhold, off the back of my truck cover. Sub MOA group with three different people shooting isn’t too bad considering.

I’ll be charging up some 180 Berger hybrids this week when I get home and see how it does. So far though, not bad for a factory rig with factory Ammo.

Anyone slap an APA or PVA Brake on one of these? I’m not sure there is enough meat on the shoulder on it for one of these. I used as seamless brake off my wife’s 7RM in the interim.

I’ll be charging up some 180 Berger hybrids this week when I get home and see how it does. So far though, not bad for a factory rig with factory Ammo.

Anyone slap an APA or PVA Brake on one of these? I’m not sure there is enough meat on the shoulder on it for one of these. I used as seamless brake off my wife’s 7RM in the interim.

Well, I took the 28 Nosler out and shot some factory ammo through it in order to harvest the brass. It shot 160 Nosler Ammo descent, .53” average over 9 rounds in 3 x 3 rd groups. It shot 175’s like smashed ass hole at 100 (1.5” average) but pretty descent at 823 yards. I had 4 rds left and remembered I had a piece of steel that was still fresh since the last time I was home. I shot twice, (the left two) my father in law and my wife shot the other two with a different windhold, off the back of my truck cover. Sub MOA group with three different people shooting isn’t too bad considering.

I’ll be charging up some 180 Berger hybrids this week when I get home and see how it does. So far though, not bad for a factory rig with factory Ammo.

Anyone slap an APA or PVA Brake on one of these? I’m not sure there is enough meat on the shoulder on it for one of these. I used as seamless brake off my wife’s 7RM in the interim. View attachment 6991957View attachment 6991958

Keep us updated on that 28. I think in 19’ I’m either building a 28 or buying a Havak in 28. Right now I’m leaning towards the build, but I haven’t ruled out the Havak. I sure am liking my 6 Creed Havak.

Keep us updated on that 28. I think in 19’ I’m either building a 28 or buying a Havak in 28. Right now I’m leaning towards the build, but I haven’t ruled out the Havak. I sure am liking my 6 Creed Havak.

@Aescobar17 how accurate is your 6 creed Havak? I am debating on buying one in 6 creed; there just isn’t a lot of reports on the Havak in that caliber. Thanks

@Aescobar17 how accurate is your 6 creed Havak? I am debating on buying one in 6 creed; there just isn’t a lot of reports on the Havak in that caliber. Thanks

I’ve only had mine roughly two weeks, and have made it out twice briefly to put a few rounds through it. Once to sight it in, and the other to confirm dope before heading to the lease. I’ve put a couple hundred rounds through another Havak in 6 though, and it loved the Hornady 108 factory loads, so I snagged a case to try in mine. I was able to get it dialed in then shot a 1/2” 5 shot group. Good enough for me, and called it a day. Then last week I took a box and briefly ran out to the range over lunch to confirm velocity and dope to 730ish. My rifle was tracking right along from 310-730, so the last 4 I ran out to 1020. Took one sighter as I miscalled my wind. Next 3 landed within 5” at 1020.

Heading out Friday for 4 days to my lease, and will probably put some good time behind it then.

Anyone slap an APA or PVA Brake on one of these? I’m not sure there is enough meat on the shoulder on it for one of these. I used as seamless brake off my wife’s 7RM in the interim.

The area 419 hellfire and seekins atc brakes work fine on the 300wm so I assume the same for the 28.

The area 419 hellfire and seekins atc brakes work fine on the 300wm so I assume the same for the 28.

Do you have a pic of the hellfire on the havak? I was really wanting to go APA LB for aesthetics, but will ultimately rock whatever I have too.

ETA: Called APA and they said it has less shoulder than they recommend, but if I use loctite it will be okay. Ordered a LB Gen 2.

Last edited:

Get a small punch and push out the silver pin that holds the mag catch latch. Be careful of the spring as you remove the latch. Take a file and shave down the top of the latch a little at a time until the mag will lock in place. Mine took about 11 passes over my file, you should only have to shave a few thousandths off.

Also AI AW mags will work way better as the lugs can pass between the wider lips. If you use AICS mags after you get the mag to seat you may need to trim down the feed lips on the mags a little to avoid contact with the bolt lugs. It’s definitely not hard, but just an added step of adjustment.

Also AI AW mags will work way better as the lugs can pass between the wider lips. If you use AICS mags after you get the mag to seat you may need to trim down the feed lips on the mags a little to avoid contact with the bolt lugs. It’s definitely not hard, but just an added step of adjustment.

Anyone run a can on the Havak ph1 6.5 creed? I put my Silencerco Hybrid on today and it changed my zero quite a bit. It was 6 inches low and 2 inches right at 100 yards. With no can its right on at 100. Is that normal? The can is pretty heavy for that size of barrel i feel. Any advice on this?

Seekins gets Rem 700 inletted Bravo's from us but their action isn't totally a Rem 700 pattern so they cut the mag catches down a bit. I don't know what that cut is off hand but they might have missed one. On the other hand, AW mags require a bit higher mag catch height than AICS so you could try using one of those.

Justin

Justin

I sure wish they had options on barrel length.....it would make the 6.5prc decision a lot harder to choose a bighorn origin with a 26" rock creek and a seekins precision with a 26" barrel as both can have replaceable bolt heads and easy to install switch barrel type setups.

Anyone run a can on the Havak ph1 6.5 creed? I put my Silencerco Hybrid on today and it changed my zero quite a bit. It was 6 inches low and 2 inches right at 100 yards. With no can its right on at 100. Is that normal? The can is pretty heavy for that size of barrel i feel. Any advice on this?

Why not just zero with the can on and not worry about?

Anyone run a can on the Havak ph1 6.5 creed? I put my Silencerco Hybrid on today and it changed my zero quite a bit. It was 6 inches low and 2 inches right at 100 yards. With no can its right on at 100. Is that normal? The can is pretty heavy for that size of barrel i feel. Any advice on this?

Are you running the can direct thread or ASR? Direct thread should have very minimal shift, but I’ve seen a ton of shift out of some ASR mounts.

i direct threadAre you running the can direct thread or ASR? Direct thread should have very minimal shift, but I’ve seen a ton of shift out of some ASR mounts.

Thats what i ended up doing. Only bad thing is if i decide to hunt with it its one long sum bitch. O well i guessWhy not just zero with the can on and not worry about?

i direct thread

That’s a significant shift for that use then. Are you positive that the threads are concentric to the bore and not to the OD of the barrel? I run #4 and 5 barrels and have never seen even remotely that much shift from them on a direct thread can. I do have one ASR can that had significant shift on a SAC spun Varmint contour about 5-6 years ago, but that was the mounting system and nothing to do with barrel or threads.

He's running a 17oz can on a barrel with a muzzle diameter of 0.700, what do you expect?

Lol not 6” of shift. I run an 11oz can and a 17oz can on my Havak with less than a 1/2” shift from either. That’s more than barrel harmonics.

As long as its repeatable, just dial it out in the scope. I’ve had the same can on 4 rifles and it affects each differently from little variation to significant and it’s not directly related to barrel thickness. But they have all been repeatable to within a .25 Moa or less so it’s easy to adjust zero for suppressed/unsuppressed. If your not getting baffle strikes then it’s just weight affecting the poi change as nothing touches the bullet past the muzzle. The weight affects barrel harmonics, it also adds stress to the receiver and it’s mounting to the stock. So don’t overly stress about the POI variation, just ensure you don’t have baffle strikes, it’s repeatable, and it’s not significantly changing accuracy of the rifle.

Anyone successfully developed loads for a 300WM version of the havak yet? I tried RL23 and 200g accubonds. Struggling to get below 1.5 MOA. Shooting 20thou off lands and best node at 70.5g. Since RL26 is a unicorn powder now I may try H4831 again, although I saw similar results the first go around. I’m also getting horrible copper fouling. 18 rounds and the lands were near coated 5” from muzzle to crown.

Tried a box of hornady custom 180g interlocks and it grouped about 3.5”.

Tried a box of hornady custom 180g interlocks and it grouped about 3.5”.

Last edited:

Just got a call from Seekins about my 300 WM. They duplicated my accuracy issues, maybe to a slightly lesser extent based on what they said on the phone.

Anyway, they will be rebarreling and rebedding my rifle or sending me a new one with a proof target grouping. Early on I was a bit pessimistic about customer service, largely because their responses started going to my junk email folder and I thought they weren't responding. They have handled the situation as well as can be asked for. I still have my concerns about the deep spiral flutes on a 300 WM but hopefully those concerns are removed with the next barrel or rifle.

I will update again once I get the rifle back out on the range.

Ah crap just saw this.. I’m having issues with my 300wm as well.

Just read enough in this thread to contact them ASAP. I’ll admit I was extremely disappointed for the $$. I even bought a hyskore dual damper rest to make sure I wasn’t just loosing my touch. I shot a .3 7 shot group breaking in a new proof carbon barrel on my 308 at the same time I was load testing the 300wm so good to know I’m not crazy.

Last edited:

Similar threads

- Replies

- 3

- Views

- 253

- Replies

- 20

- Views

- 2K

- Replies

- 0

- Views

- 157