Thought I would toss up some data for H4350 with 88ELDMs. Ran OCW from 26.2-27.4 at 2.300" OAL. I should note that this barrel was at 100 rounds when I ran the OCW and 150 when I ran the seating depth test. In my experience, flyers don't settle down until around 200-250 rounds through the tube. In fact, you can see the difference below.

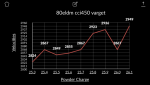

H4350 ran from 2702fps to 2800fps out of my 26" barrel. I get about 8.3fps per .1grain increment, and it's quite linear overall. That means if I can keep loads to +- .1gr, I should see an SD around 8-10, which is exactly what I found in the middle groups.

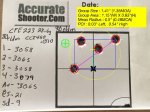

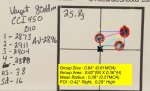

I selected 26.8gr, the largest group of the bunch and worst flyers. But it was also in the low SD node (26.4-27.0gr), had a fairly consistent POI relative to charge below and above. And lastly, had a tight cluster of 3 shots. I thought it would be a good test to my theory of barrel wear and flyers.

View attachment 7022373

Note the red circles for the flyers; 100% not me and I think it is bullets that become deformed/damaged by gas port getting tossed or flying apart.

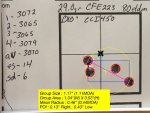

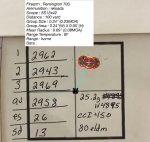

Then ran a seating depth test from 2.240-2.300" in .010" increments. Target was shot left to right (2 groups in first warmup, then 5 shot groups for each seating depth). Interestingly, the flyers I have show up toward the end but are significantly closer to group center and becoming more predictable.

The last two groups are same as first two groups as a control (2.300" with 26.8gr H4350). I do this to see if I have a major change in groups from begining to end of session.

View attachment 7022375

As soon as I shot the 2.270" group that is a dead vertical line, I predicted the next group would tighten considerably and BANG! .6", .5", .7 and .6". The red circles flyers are getting much closer to group center and at 2.300" (last two groups) they disappeared.

Will reshoot next weekend to confirm, but this is my new winter load. CFE works great in summer but is too picky with temps at certain nodes, so I'm hoping I can see an improvement in temp sensitivity with this load as weather warms into summer.