I'll go against the grain here...

I have an AMP Mk2 and anneal every firing. I've seen literally no change to my SDs after I started annealing with it, and I'm a few thousand rounds in. In fact, the only change I can see from annealing is at the bench (my shoulder bumps are more accurate, and seating feels more consistent). I haven't seen any increases in my X-count.

I find it really interesting everyone comes in here saying their SDs are way better, because that's not been my findings, nor Litz's for that matter (although I take issue with certain parts of his testing).

That said, I'm doing it because the best in my discipline are doing it, and the theory/concept make sense. It also seems to make my brass grow more, which is kind of nice, because it ensures my Giraud will touch the mouth every time.

As far as the insane conspiracy theories about AMP being out to get "the salt bath industry", that's absolute crazy talk. In the article AMP even tells you to buy a flame annealer if you want a lower cost solution.

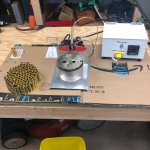

Here's the deal with AMP...unless you're an absolute moron during the Aztec process, you're guaranteed not to over anneal your brass. You can't really say the same with SBA or Propane setups. With an AMP there's zero guess work, and it's consistent 100% of the time.