Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

.22 br

- Thread starter Dai Bando

- Start date

Can anyone tell me What bullet jump do the 88 eld’s like in there 22br?

.020" works for me with the 88gr and 3 different powders so far.

FWIW, I did a little measuring and re-measuring with my cheap calipers and ball mic.

My Redding FL die was crushing some shoulders (really pissing me off). I was running cases up in the die with the expander ball removed. Then running them back over the expander (read a long time ago that helped with concentricity, dunno if it really does or not). They were harder to run back over the expander than any other caliber I had ever done that with. Something just didn't seem like it was jiving.

Lapua 6mmBR necks measured .267". Ran up into the die, they were ran all the way down to .232" (!), then having to bump all the way back up to .250" (all dimensions outside diameter). In contrast, my RCBS .223 dies run case necks down to .238" then back up to .243". I get that the Lapua 6BR necks were thicker than the Remington .223 brass (.013 6BR, .014 .22BR vs. .011 or so for the .223) I compared it to, but up and down .018" seems (and feels) way excessive vs. .005".

I ordered a Redding Bushing Neck die with .259" (for a step down when sizing virgins) and .250" bushings.

Then I emailed back and forth with Redding and explained what I had going on. A.J. at Redding told me to send the FL die to them and they'd look into it. Dropped it into the mail Saturday.

I'll let you all know what I find out.........

My Redding FL die was crushing some shoulders (really pissing me off). I was running cases up in the die with the expander ball removed. Then running them back over the expander (read a long time ago that helped with concentricity, dunno if it really does or not). They were harder to run back over the expander than any other caliber I had ever done that with. Something just didn't seem like it was jiving.

Lapua 6mmBR necks measured .267". Ran up into the die, they were ran all the way down to .232" (!), then having to bump all the way back up to .250" (all dimensions outside diameter). In contrast, my RCBS .223 dies run case necks down to .238" then back up to .243". I get that the Lapua 6BR necks were thicker than the Remington .223 brass (.013 6BR, .014 .22BR vs. .011 or so for the .223) I compared it to, but up and down .018" seems (and feels) way excessive vs. .005".

I ordered a Redding Bushing Neck die with .259" (for a step down when sizing virgins) and .250" bushings.

Then I emailed back and forth with Redding and explained what I had going on. A.J. at Redding told me to send the FL die to them and they'd look into it. Dropped it into the mail Saturday.

I'll let you all know what I find out.........

I had the exact same problem with my die working the brass down then expanding it back out. It was giving me terrible concentricity. The good news is it is a Forster die. A trip to Forster and they honed the die out so now it’s only working the brass about 4 thousandths of an inch. The concentricity is now spot on and the brass full length sizes with very little effort.

I had the exact same problem with my die working the brass down then expanding it back out. It was giving me terrible concentricity. The good news is it is a Forster die. A trip to Forster and they honed the die out so now it’s only working the brass about 4 thousandths of an inch. The concentricity is now spot on and the brass full length sizes with very little effort.

My Redding FL die is doing the same thing! I would be interested to know what they tell you. Please keep up posted.FWIW, I did a little measuring and re-measuring with my cheap calipers and ball mic.

My Redding FL die was crushing some shoulders (really pissing me off). I was running cases up in the die with the expander ball removed. Then running them back over the expander (read a long time ago that helped with concentricity, dunno if it really does or not). They were harder to run back over the expander than any other caliber I had ever done that with. Something just didn't seem like it was jiving.

Lapua 6mmBR necks measured .267". Ran up into the die, they were ran all the way down to .232" (!), then having to bump all the way back up to .250" (all dimensions outside diameter). In contrast, my RCBS .223 dies run case necks down to .238" then back up to .243". I get that the Lapua 6BR necks were thicker than the Remington .223 brass (.013 6BR, .014 .22BR vs. .011 or so for the .223) I compared it to, but up and down .018" seems (and feels) way excessive vs. .005".

I ordered a Redding Bushing Neck die with .259" (for a step down when sizing virgins) and .250" bushings.

Then I emailed back and forth with Redding and explained what I had going on. A.J. at Redding told me to send the FL die to them and they'd look into it. Dropped it into the mail Saturday.

I'll let you all know what I find out.........

So, I’ve refined my .22br brass process. It’s long, but it seems to be much easier on brass.

Run 6mm expander mandrel

Turn necks to .0115

Run through .22br non bushing die

Run .22 expander mandrel

Trim to length

Run through FL bushing die

Run .224 mandrel

(Brass is back up to ~.012 neck (guessing from the sizing down)

Final chamfer/deburr

Seat (about 50psi as the necks are clean)

This is getting me about a .247 loaded diameter on a .252 reamer

Prior I was sizing down, running mandrel, trimming, turning and then back to FL bushing die. But I was deal with more friction with the mandrels and it was pretty tight on the turning mandrel. Even flattened some shoulders with mandrel.

After first firing I’m expecting seating pressure to go down and being up to use .002 under mandrel for neck tension.

Run 6mm expander mandrel

Turn necks to .0115

Run through .22br non bushing die

Run .22 expander mandrel

Trim to length

Run through FL bushing die

Run .224 mandrel

(Brass is back up to ~.012 neck (guessing from the sizing down)

Final chamfer/deburr

Seat (about 50psi as the necks are clean)

This is getting me about a .247 loaded diameter on a .252 reamer

Prior I was sizing down, running mandrel, trimming, turning and then back to FL bushing die. But I was deal with more friction with the mandrels and it was pretty tight on the turning mandrel. Even flattened some shoulders with mandrel.

After first firing I’m expecting seating pressure to go down and being up to use .002 under mandrel for neck tension.

Finally feeling halfway decent from the shot show fungus. Brand new barrel.

.050 reamer throated to .100 freebore.

88 eld and 85.5 Berger with 28.5gr varget. Both loaded .020 off lands to start.

88 didn’t do well on es/sd as I ended up using a .2245 mandrel to get them to seat in my hydro press without going off the gauge. Didn’t feel like messing with lube as I’m getting firing brass and barrel sped up.

85.5 I used a .224 mandrel. Es/sd: 7/15 so not bad.

Eld was at 2940 and 85.5 was 2950

These were slightly cherry picked. Once the barrel was fouled, all groups were in the .3moa area or less.

Smallest group in two pics is 88eld

.050 reamer throated to .100 freebore.

88 eld and 85.5 Berger with 28.5gr varget. Both loaded .020 off lands to start.

88 didn’t do well on es/sd as I ended up using a .2245 mandrel to get them to seat in my hydro press without going off the gauge. Didn’t feel like messing with lube as I’m getting firing brass and barrel sped up.

85.5 I used a .224 mandrel. Es/sd: 7/15 so not bad.

Eld was at 2940 and 85.5 was 2950

These were slightly cherry picked. Once the barrel was fouled, all groups were in the .3moa area or less.

Smallest group in two pics is 88eld

Attachments

Is this for varmint or prairie dog hunting?I know most of you are shooting the heavy pills but any info on the 53vmax or pills on the lighter side? I have a 12 twist barrel on order.

Hey brother, check out 6mmbr.com. Most of their stuff is a bit dated, but the overall data is still excellent. They focus more on the light varmint and flat base match bullets.Pdog

To bring everyone up to date. I've been back and forth with A.J. at Redding over their FL die.

He emailed me this morning as said he "gauged" it, and it was right on the money. In a nutshell, I replied that it may be their spec, but their spec was pretty terrible (in much nicer words) and re-explained the jacked up dimensions that I had measured. I told him to hang on to the die (I ain't usin' it), and actually size some Lapua or Norma Brass and see how it goes. If it runs swimmingly, I'm the idiot. If he has to lay on the press handle and buckle shoulders, their spec has an issue.

Honestly, I don't expect much. The guy is an engineer. Which likely means he has the "can't help its". If it measured according to spec, it has to be right. He's likely incapable of savvying that the spec itself could be screwed up.

He did say that I could have a machine shop hone the neck as they didn't offer that service, but it would void the warranty (HA!). If any of you know of a shop capable of doing such work, I'd appreciate their info.

I did buy the Redding neck/bushing die. Along with a .259 and .250 TiN coated bushings. They seem to work pretty well. There were a couple of odd things about it, but I'm away from my notes, so I'll go into detail later.

He emailed me this morning as said he "gauged" it, and it was right on the money. In a nutshell, I replied that it may be their spec, but their spec was pretty terrible (in much nicer words) and re-explained the jacked up dimensions that I had measured. I told him to hang on to the die (I ain't usin' it), and actually size some Lapua or Norma Brass and see how it goes. If it runs swimmingly, I'm the idiot. If he has to lay on the press handle and buckle shoulders, their spec has an issue.

Honestly, I don't expect much. The guy is an engineer. Which likely means he has the "can't help its". If it measured according to spec, it has to be right. He's likely incapable of savvying that the spec itself could be screwed up.

He did say that I could have a machine shop hone the neck as they didn't offer that service, but it would void the warranty (HA!). If any of you know of a shop capable of doing such work, I'd appreciate their info.

I did buy the Redding neck/bushing die. Along with a .259 and .250 TiN coated bushings. They seem to work pretty well. There were a couple of odd things about it, but I'm away from my notes, so I'll go into detail later.

If you really want the full length die then Forster is the way to go they will hone the neck for $15.

I might've been a bit too rough on A.J. in my above post. Past experience has left me with little patience for engineers and accountants.

He did reply to my email (his responses have always been prompt) and said that the neck gauged .242 on that die. I'm not sure how, as my necks measure .232, but I told him I'd re-check and check my calipers to sure they hadn't lost their mind.

More importantly, in his reply he stated that he DID size a few cases and that he didn't have a problem. He did not indicate which brand cases.

The only thing I need a full length die for at this point is to bump shoulders back on occasion, but I will need something for that. Also, when initially sizing 6BR brass, I suspected that a FL die would leave less of a donut than bushing dies. It feels like I get less donut with the bushing dies. Go figure.

He did reply to my email (his responses have always been prompt) and said that the neck gauged .242 on that die. I'm not sure how, as my necks measure .232, but I told him I'd re-check and check my calipers to sure they hadn't lost their mind.

More importantly, in his reply he stated that he DID size a few cases and that he didn't have a problem. He did not indicate which brand cases.

The only thing I need a full length die for at this point is to bump shoulders back on occasion, but I will need something for that. Also, when initially sizing 6BR brass, I suspected that a FL die would leave less of a donut than bushing dies. It feels like I get less donut with the bushing dies. Go figure.

If you really want the full length die then Forster is the way to go they will hone the neck for $15.

Think its safe to custom Forster hone and size to 22BR in one shot without messing up the brass?

I used the std Forestor die to take my 6br brass down to 22br. It worked well but a honed put die would have been better. I have a honed one on backorder. I use several of there honed dies for my rifles. I am using a Redding FL Type S die now and it works very well also.Think its safe to custom Forster hone and size to 22BR in one shot without messing up the brass?

I have a few MTM BR cases I picked up this summer.What are you guys using for ammo boxes??

These BR boxes work very well. They are small and do not take up much room in a pack at all.I have a few MTM BR cases I picked up this summer.

A couple updates and a couple questions.....

I've not been back and forth with Redding for a few weeks on my FL die. I was out of town (and out of the country for 8 days) for most of February. Last contact I had, they had measured, re-checked, sized some cases (I wonder if they were old Remingtons) and A.J. told me it met their spec. I need to just tell him to send it back to me. If there's enough room, I may just pour it full of lead and stick it in the stock of my Bravo for ballast. That's where it'll do the most good. Then call Forster and tell them what I want.

I did shoot the Long Range Steel Challenge at Dead Zero in Spencer TN last Saturday. Out of 24 shooters, I won the cold bore shot (on the electronic target at 1,000 yards)! But then I didn't shoot worth a crap on the gongs. Out of 45 possible points, 38 won it, 26 was third place, I only shot a 16 (which still put me bottom middle of the pack). The wind was a mother and the layout of that range makes it even trickier. I think the biggest problem was that was first time I had ever shot in a match, I wasn't trusting my own dope, and I couldn't get out of my own head.

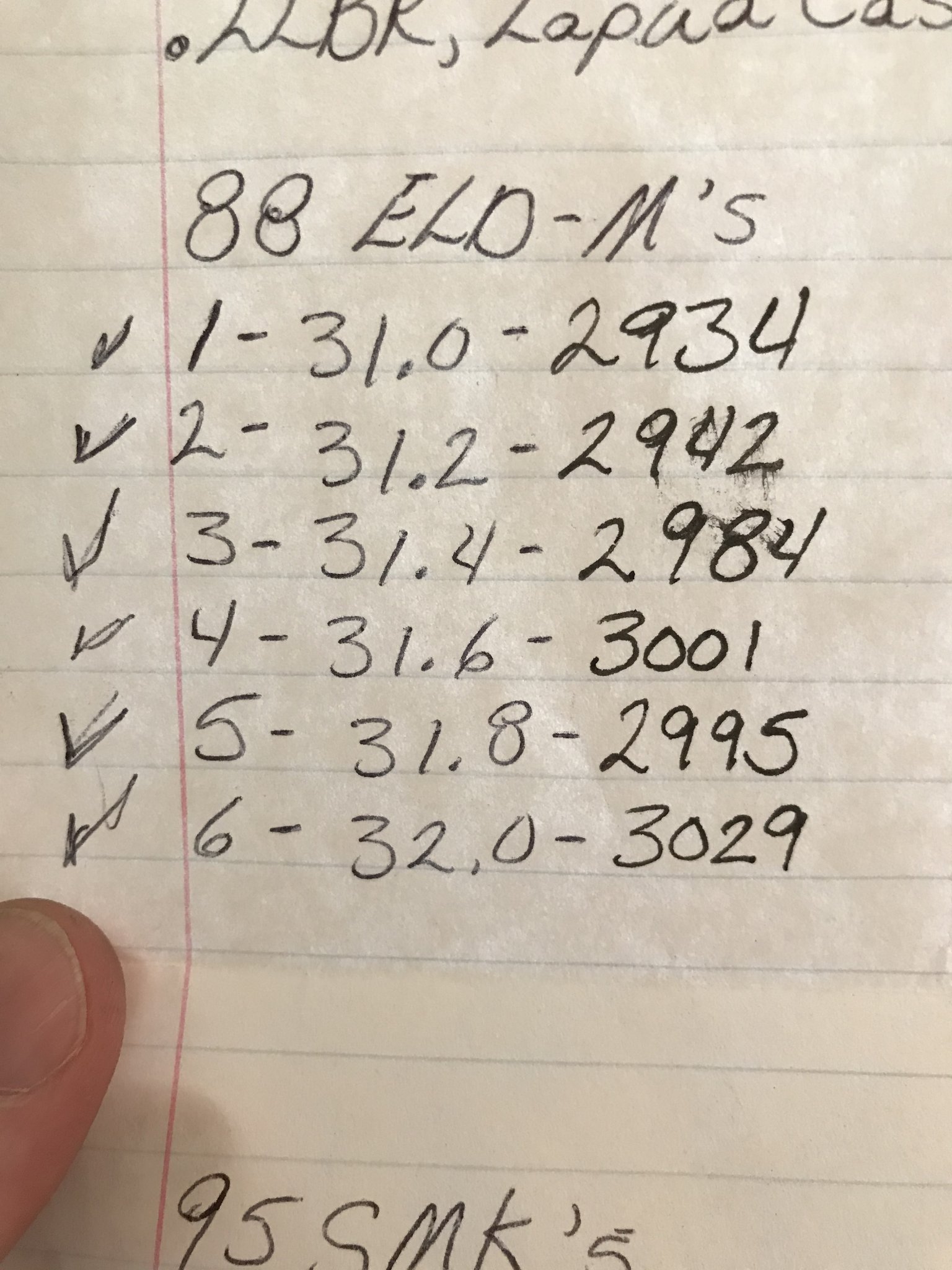

There is another issue. When I initially chronied my load (30 grains of Leverevolution, 88 ELD), I fired three rounds. There was no real load workup (I just spitballed the load) and was mostly just making sure I was somewhere at or below 3,000fps. Of the three rounds, there was a 57fps extreme spread. I rolled with it, but my groups run around .7 at 600 to 1.2 minutes at 1000 of mostly vertical. Then, a couple weeks ago, a buddy with a magentospeed clocked 5 out of it. Averaged 2995fps with an ES in the 60's. Sooooo, I'm about to attempt a ladder test with 88 ELD's and 95 SMK's, both with RL-16. The plan is to use his magnetospeed and a 400 yard target.

My question is where to start? Thinking 30.5 to 32.5 with 88's and 29.0 to 31.0 with 95's? I'm dealing with a .080" throat, so I'm sure that's gonna play in. Load a couple each at the upper end of the ladder, chrony, and go from there?

I've always just sort of guessed a charge weight according to what data I read, loaded it, ran it over my cheap chrony to be sure I wasn't leaving to much room or running to hot, shot a group at 100, and went from there. Working with a 2 grain range of charge weights is new to me.

We will run a seating depth test after the charge weight ladder. I think that'll take care of some of my horizontal, which isn't near the issue the vertical is at this point.

I've not been back and forth with Redding for a few weeks on my FL die. I was out of town (and out of the country for 8 days) for most of February. Last contact I had, they had measured, re-checked, sized some cases (I wonder if they were old Remingtons) and A.J. told me it met their spec. I need to just tell him to send it back to me. If there's enough room, I may just pour it full of lead and stick it in the stock of my Bravo for ballast. That's where it'll do the most good. Then call Forster and tell them what I want.

I did shoot the Long Range Steel Challenge at Dead Zero in Spencer TN last Saturday. Out of 24 shooters, I won the cold bore shot (on the electronic target at 1,000 yards)! But then I didn't shoot worth a crap on the gongs. Out of 45 possible points, 38 won it, 26 was third place, I only shot a 16 (which still put me bottom middle of the pack). The wind was a mother and the layout of that range makes it even trickier. I think the biggest problem was that was first time I had ever shot in a match, I wasn't trusting my own dope, and I couldn't get out of my own head.

There is another issue. When I initially chronied my load (30 grains of Leverevolution, 88 ELD), I fired three rounds. There was no real load workup (I just spitballed the load) and was mostly just making sure I was somewhere at or below 3,000fps. Of the three rounds, there was a 57fps extreme spread. I rolled with it, but my groups run around .7 at 600 to 1.2 minutes at 1000 of mostly vertical. Then, a couple weeks ago, a buddy with a magentospeed clocked 5 out of it. Averaged 2995fps with an ES in the 60's. Sooooo, I'm about to attempt a ladder test with 88 ELD's and 95 SMK's, both with RL-16. The plan is to use his magnetospeed and a 400 yard target.

My question is where to start? Thinking 30.5 to 32.5 with 88's and 29.0 to 31.0 with 95's? I'm dealing with a .080" throat, so I'm sure that's gonna play in. Load a couple each at the upper end of the ladder, chrony, and go from there?

I've always just sort of guessed a charge weight according to what data I read, loaded it, ran it over my cheap chrony to be sure I wasn't leaving to much room or running to hot, shot a group at 100, and went from there. Working with a 2 grain range of charge weights is new to me.

We will run a seating depth test after the charge weight ladder. I think that'll take care of some of my horizontal, which isn't near the issue the vertical is at this point.

I shot 30.2 grains of RL16 this weekend (just threw something together) and averaged 2930. SD was a little high with this virgin brass but I had an SD of around 6 before I had a couple hot ones.

I just chalked it up to different sizing methods I had used and will just leave all my shit alone now to see if my SD/ES settle down.

During an RL16 ladder, I got to 3170 before I got bad plunger marks, around 32.4 gr iirc

I just chalked it up to different sizing methods I had used and will just leave all my shit alone now to see if my SD/ES settle down.

During an RL16 ladder, I got to 3170 before I got bad plunger marks, around 32.4 gr iirc

Thanks guys! Looks like my guess wasn't too far off. MTETM, I'd be interested in where your at now, and why you backed off.

I'm getting a pretty consistent ejector mark and some minor primer cratering at 30 grains of 'Lever, but I'm chalking that up to mashing the bolt closed on the donut on virgin hulls. The donut got a bit better after I switched from the aforementioned FL die to a Redding Neck Bushing die, but the primers and ejector mark remained. Might be the donut. Might be a touch warm. Either way, I'm thinking I want to stick to at or just a bit below 3,000fps with 88's. Guessing I need to be down around 2,850fps with 95's. 24" 7" twist 5R Bartlien, suppressed.

I'm getting a pretty consistent ejector mark and some minor primer cratering at 30 grains of 'Lever, but I'm chalking that up to mashing the bolt closed on the donut on virgin hulls. The donut got a bit better after I switched from the aforementioned FL die to a Redding Neck Bushing die, but the primers and ejector mark remained. Might be the donut. Might be a touch warm. Either way, I'm thinking I want to stick to at or just a bit below 3,000fps with 88's. Guessing I need to be down around 2,850fps with 95's. 24" 7" twist 5R Bartlien, suppressed.

I'm using a .249 bushing with 6BR Hornady match dies.

1-6.5 Bartlein 4 groove 1.25" straight suppressed.

Leverevolution is temp sensitive so be careful.

1-6.5 Bartlein 4 groove 1.25" straight suppressed.

Leverevolution is temp sensitive so be careful.

Last edited:

Had read Leverevolution is temp-ermental, hence the move to RL16. Warmest she's been ran so far was 65 degrees. That'll change here pretty quick.

Hoping my 7" twist will spin the 95's. They came in today.

Hoping my 7" twist will spin the 95's. They came in today.

My small daughter is shooting the 22BR. We wanted zero bolt lift issue regardless of weather conditions including rain. The wind difference between the velocities did not make it worth pushing any pressure, so we went lower to maintain consistency, a touch less recoil and smooth extraction. The 29xx loads worked well for her. Looking back at the notes last night, she shot 30.0 last summer and fall. They were at 2930 or so. This was after the cases were turned and fireformed. SD for 15 round strings were in the single digits. ES in the teens.

RE16, because you get good case fill, consistent numbers, good velocity and it isn't Varget... We also shoot RE16 in the BRX's and GT. We have a short pile of Precision that will be testing in the coming week with the 22 and 6 BR's.

RE16, because you get good case fill, consistent numbers, good velocity and it isn't Varget... We also shoot RE16 in the BRX's and GT. We have a short pile of Precision that will be testing in the coming week with the 22 and 6 BR's.

SW Precision gave me a busted case at 30.2 gr and ejector swipes from 29.0 and up.

Didn't actually test below 29gr which was 2980.

Didn't actually test below 29gr which was 2980.

Last edited:

Thank You for the info. That is good to know. Seems a much lower starting point will be in order. I am not too worried about top end velocity, just has to be consistent..

SW Precision gave me a busted case and 30.2 gr and ejector swipes from 29.0 and up.

Didn't actually test below 29gr which was 2980.

View attachment 7270760

I know most of you are shooting the heavy pills but any info on the 53vmax or pills on the lighter side? I have a 12 twist barrel on order.

I loaded some 53gr V-Max over 32gr of Varget and shot them out of my 1-7" Bartlein. Barrel had less than 50 rounds out of it and I shot it without the brake in case they blew up. First 3 hit the target in a tight little group, so I put the brake and the magneto speed on. Shot 5 at 100, 3595fps average and 5 sd. Shot the last 15 at a plate at 416 yards. Might have to cut down and set back my 1800 round barrel for a coyote calling gun.

Not to steal the thread about heavier bullets, but I have a 22BR barrel (rem 700) built by Mike Bryant for sale. Lost my PD hunting area, so I rebarreled to a 260. It has about 200 rounds thru it. Also have Lapua brass, dies, and loaded rounds. It is a 14 twist set up for 52 and under weight bullets. It is a tack driver with 40 grain vmaxes.

I just had a 22br built and I have a pound of varget and a pound of ramshot tac I am trying to decide what bullets to use would you guys recommend eld(m) over Sierra matchkings and it’s set up to shoot heavy bullets I am just not sure what grain you try and starting and max powder loads

Thank you for the help my friends were saying buy 5 or 6 powders and 3 different brands of bullets so it’s confusing me but thanks for the help kind sir!Try 28.5gr Varget with 88 ELDM's and work up. Betting after you get 100 - 150 rds on the barrel you'll be up at 29 - 29.5gr. I've found Ramshot TAC to be a similiar burn speed to Varget so I'd imagine equivalent charge weights, but...temp sensitive....and it's spring. Hot and Cold days

Soooo....did my first "ladder test" yesterday. I put "ladder test" in quotations because I'm quite certain that I did not follow the process to the letter, but it was still informative.

A bit of background. I started out with 30.0 grns. of LeverRevolution and 88's. It shot well enough (at around 2,950 or so), but the couple times I chronographed it, the extreme spread was terrible (I only ran 3 rounds over my chrony, thought it may be "just my cheap chrony", but a friend's magnetospeed gave the same result), around 60-65 fps for just a few rounds! I had always just picked out a load that looked good, chronied it to be sure I wasn't too hot, shot a couple groups at one or two hundred yards and started yanking the press handle. I though only benchrest guys and guys that like to pick fly crap out of pepper worried about extreme spread and standard deviation, but when I figured out that spread meant about a foot of variation at 1,000 yards, it got my attention.

First, the 88 ELDM's and RL-16. I had ran a few over my old chrony to figure out what charge range I wanted to "ladder". I may have prejudiced my own results in the process, but I didn't want to be really slow, and didn't want to push things too much. We ran a magnetospeed and shot at 300 yards. Unfortunately, circumstances didn't allow us to drive back and forth to the target, and neither of us owns a spotting scope worth a crap. So I wasn't able to number the bullet holes in the target. But, looking at the numbers, I shouldn't be hard to figure out who landed where.

Rifle specs; Bighorn Origin, 24" Bartlein 5R, Rem Varmint/Sendero contour, .080" throat, chambered by Southern Precision. KRG Bravo, Burris XTR II 5-25, 9" SAS Arbiter Suppressor. I've posted a pic of it here before.

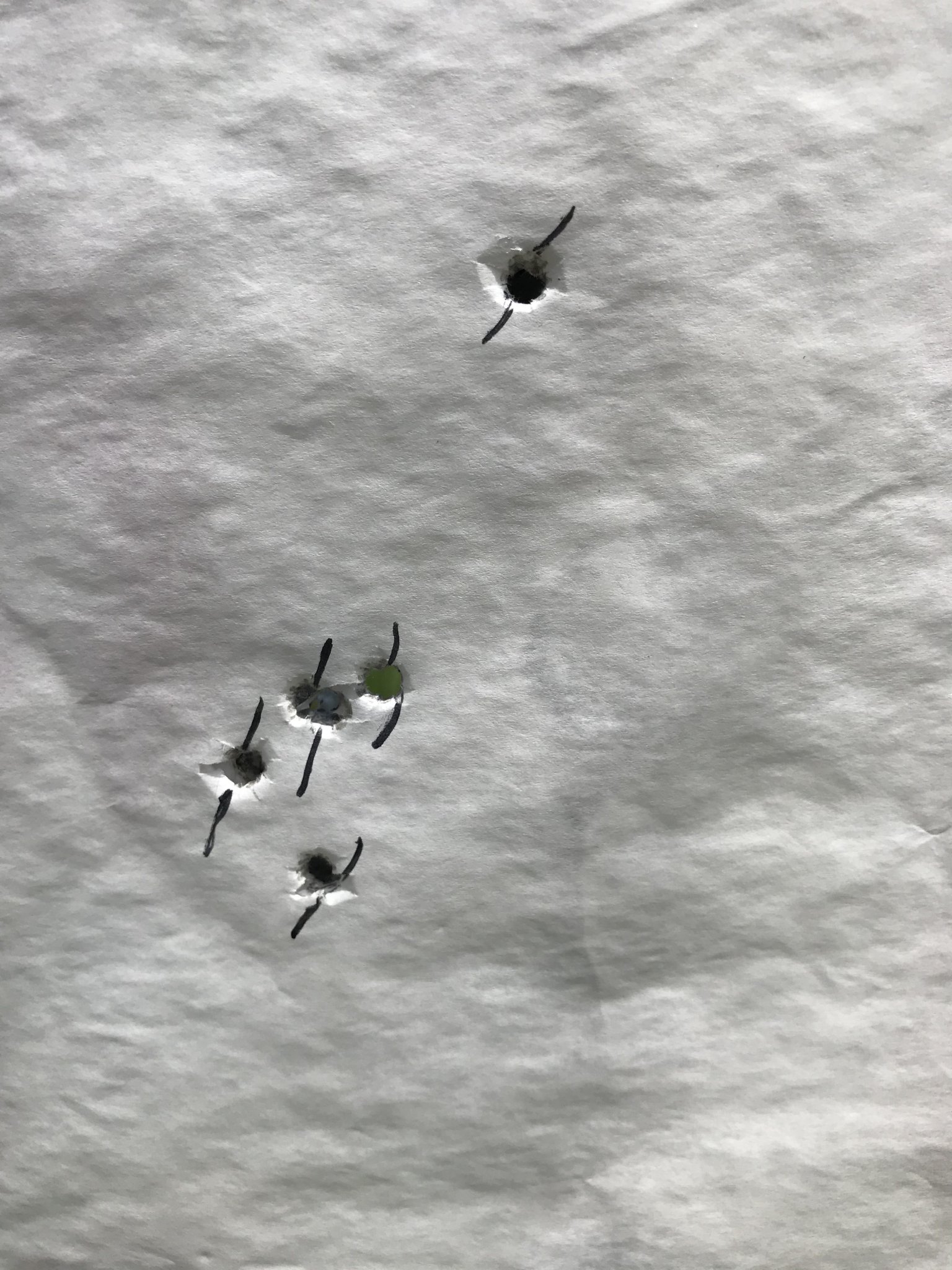

The round out of the group was #1. That was out of a cold bore. Everything else went into 1". Two of them into the same ragged hole. Looks like 31.6 is where I want to be.

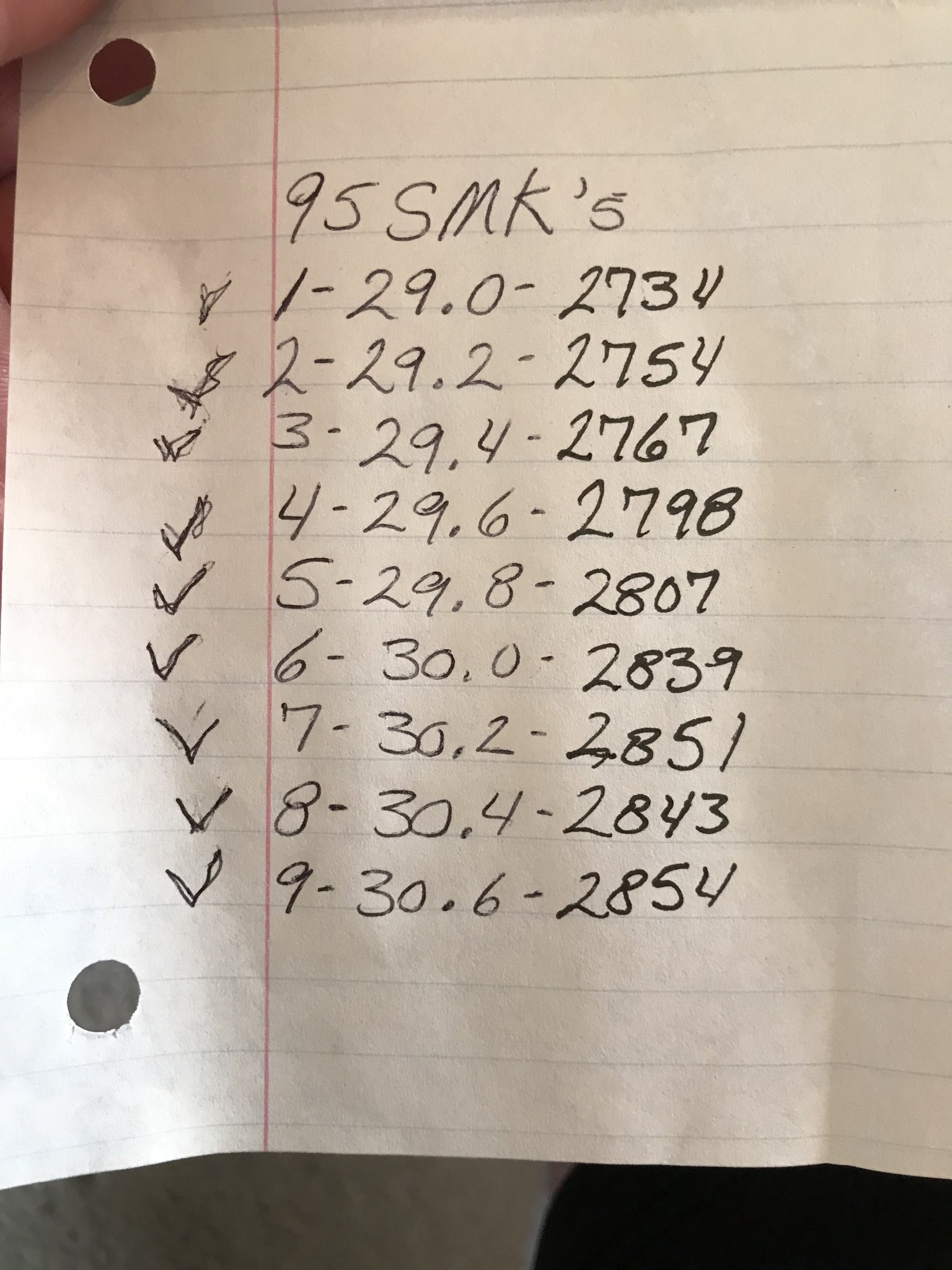

Now the 95's and RL-16.

The wind kicked up a bit shooting 95's, and I felt like I may have pulled a couple. But it was all still in 4" and I'm betting I know where the three in the middle came from. Gonna load a few at 30.3 and see what happens on this one.

As far as seating depth, the 88's were loaded at 2.350" OAL. The 95's at 2.310" OAL.

As I've said, I'm aware we didn't run this test exactly how it needs to be done. But I would welcome any observations or opinions.

Thanks!

A bit of background. I started out with 30.0 grns. of LeverRevolution and 88's. It shot well enough (at around 2,950 or so), but the couple times I chronographed it, the extreme spread was terrible (I only ran 3 rounds over my chrony, thought it may be "just my cheap chrony", but a friend's magnetospeed gave the same result), around 60-65 fps for just a few rounds! I had always just picked out a load that looked good, chronied it to be sure I wasn't too hot, shot a couple groups at one or two hundred yards and started yanking the press handle. I though only benchrest guys and guys that like to pick fly crap out of pepper worried about extreme spread and standard deviation, but when I figured out that spread meant about a foot of variation at 1,000 yards, it got my attention.

First, the 88 ELDM's and RL-16. I had ran a few over my old chrony to figure out what charge range I wanted to "ladder". I may have prejudiced my own results in the process, but I didn't want to be really slow, and didn't want to push things too much. We ran a magnetospeed and shot at 300 yards. Unfortunately, circumstances didn't allow us to drive back and forth to the target, and neither of us owns a spotting scope worth a crap. So I wasn't able to number the bullet holes in the target. But, looking at the numbers, I shouldn't be hard to figure out who landed where.

Rifle specs; Bighorn Origin, 24" Bartlein 5R, Rem Varmint/Sendero contour, .080" throat, chambered by Southern Precision. KRG Bravo, Burris XTR II 5-25, 9" SAS Arbiter Suppressor. I've posted a pic of it here before.

The round out of the group was #1. That was out of a cold bore. Everything else went into 1". Two of them into the same ragged hole. Looks like 31.6 is where I want to be.

Now the 95's and RL-16.

The wind kicked up a bit shooting 95's, and I felt like I may have pulled a couple. But it was all still in 4" and I'm betting I know where the three in the middle came from. Gonna load a few at 30.3 and see what happens on this one.

As far as seating depth, the 88's were loaded at 2.350" OAL. The 95's at 2.310" OAL.

As I've said, I'm aware we didn't run this test exactly how it needs to be done. But I would welcome any observations or opinions.

Thanks!

Last edited:

Soooo....did my first "ladder test" yesterday. I put "ladder test" in quotations because I'm quite certain that I did not follow the process to the letter, but it was still informative.

A bit of background. I started out with 30.0 grns. of LeverRevolution and 88's. It shot well enough (at around 2,950 or so), but the couple times I chronographed it, the extreme spread was terrible (I only ran 3 rounds over my chrony, thought it may be "just my cheap chrony", but a friend's magnetospeed gave the same result), around 60-65 fps for just a few rounds! I had always just picked out a load that looked good, chronied it to be sure I wasn't too hot, shot a couple groups at one or two hundred yards and started yanking the press handle. I though only benchrest guys and guys that like to pick fly crap out of pepper worried about extreme spread and standard deviation, but when I figured out that spread meant about a foot of variation at 1,000 yards, it got my attention.

First, the 88 ELDM's and RL-16. I had ran a few over my old chrony to figure out what charge range I wanted to "ladder". I may have prejudiced my own results in the process, but I didn't want to be really slow, and didn't want to push things too much. We ran a magnetospeed and shot at 300 yards. Unfortunately, circumstances didn't allow us to drive back and forth to the target, and neither of us owns a spotting scope worth a crap. So I wasn't able to number the bullet holes in the target. But, looking at the numbers, I shouldn't be hard to figure out who landed where.

Rifle specs; Bighorn Origin, 24" Bartlein 5R, Rem Varmint/Sendero contour, .080" throat, chambered by Southern Precision. KRG Bravo, Burris XTR II 5-25, 9" SAS Arbiter Suppressor. I've posted a pic of it here before.

View attachment 7296691View attachment 7296692

The round out of the group was #1. That was out of a cold bore. Everything else went into 1". Two of them into the same ragged hole. Looks like 31.6 is where I want to be.

Now the 95's and RL-16. View attachment 7296694View attachment 7296695

The wind kicked up a bit shooting 95's, and I felt like I may have pulled a couple. But it was all still in 4" and I'm betting I know where the three in the middle came from. Gonna load a few at 30.3 and see what happens on this one.

As far as seating depth, the 88's were loaded at 2.350" OAL. The 95's at 2.310" OAL.

As I've said, I'm aware we didn't run this test exactly how it needs to be done. But I would welcome any observations or opinions.

Thanks!

I shot a match last year running 31.6 of Rl16 in my old barrel. It stormed off and on and I found out I was over pressure with wet ammo. I have a ladder loaded with Rl16 for my new barrel starting at 30 and going up to 31.3 grains. I ran some of the 31.6 loads left from last year out of the new barrel and they averaged 3110 fps. I had the best accuracy out of my old barrel at 3000-3050 fps, so I am going to see if I can find a lower mode that I can run in the rain if needed.

It might not be a terrible idea to see what it does from, say, 30.6 to 31.2. It looks to me like there's a low node hanging out around 31.0 to 31.2, but I don't know how wide it is and it looks like it pops up pretty sharp at 31.4 or maybe even 31.3.

Your speeds are higher than mine, but you're probably running a longer barrel (I'm at 24").

I'll probably play at 31.6 or 31.7 for the time being.

Your speeds are higher than mine, but you're probably running a longer barrel (I'm at 24").

I'll probably play at 31.6 or 31.7 for the time being.

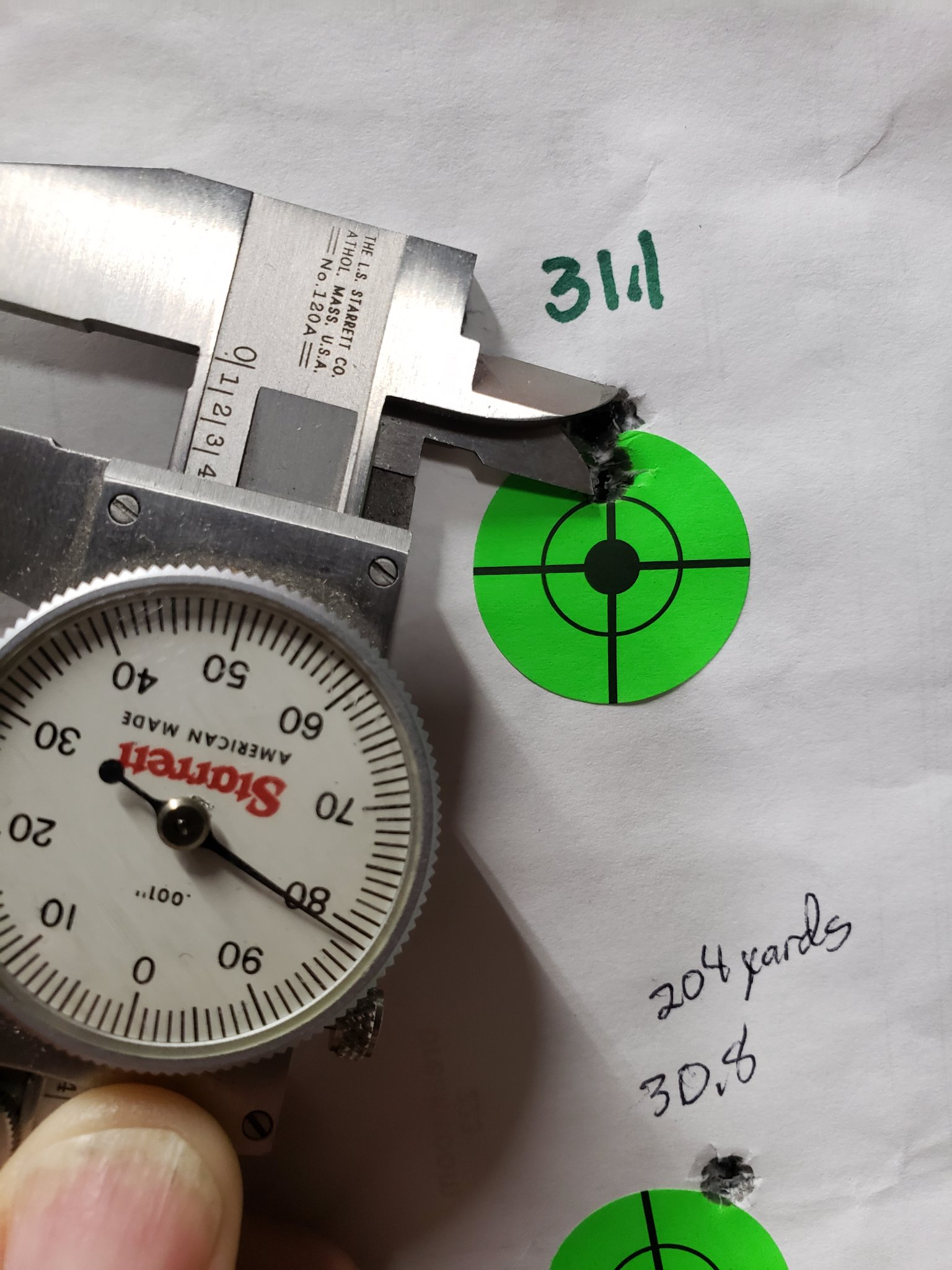

Shot some 88gr ELDMs over Rl16 last week. Loaded some at 30gr in brass with loose primer pockets to get a baseline. They were the only ones over .5 moa at 204 yards.

4x fired Lapus brass

Rl16

CCI450

88gr ELDM .020" off the lands

5 shots at each weight

30.2gr 2958 fps average 9 SD

30.5gr 2983 fps average 5 SD

30.8gr 3001 fps average 5 SD

31.1gr 3038 fps average 5 SD

31.3gr 3050 fps average 8 SD

Going to to try 30.8,30.9, 31.0 and 31.1 and see where I end up.

4x fired Lapus brass

Rl16

CCI450

88gr ELDM .020" off the lands

5 shots at each weight

30.2gr 2958 fps average 9 SD

30.5gr 2983 fps average 5 SD

30.8gr 3001 fps average 5 SD

31.1gr 3038 fps average 5 SD

31.3gr 3050 fps average 8 SD

Going to to try 30.8,30.9, 31.0 and 31.1 and see where I end up.

31.1 RL 16 ended up being the load. Less than 1.5" vertical at 415 yards in heavy mirage and a .16" 5 shot round robin group at 100. Match got canceled for the 25th due to the governor extending the stay at home until May 3rd. Will test it out to 800 soon.

Going to test the 88 gr eld m next week.

Just got my gun back together after changing the chassi, scope and stuff.

Going to continue with N150 as it seems be awesome in this calibre. Extremely temp stable and doesn't get the bore as dirty as some other powders...

Also got a bunch of 95 gr smk, going to test those to just for fun. But it's only a 1:7" twist barell so i'm not sure they are going to work well with that. Bought those for the next barell which will be a 1:6.5" twist. Not 100% sure on caliber yet tho, most likely another 22 BR but have a 22 Dasher reamer on order(but might take a while to get it now)...

Just got my gun back together after changing the chassi, scope and stuff.

Going to continue with N150 as it seems be awesome in this calibre. Extremely temp stable and doesn't get the bore as dirty as some other powders...

Also got a bunch of 95 gr smk, going to test those to just for fun. But it's only a 1:7" twist barell so i'm not sure they are going to work well with that. Bought those for the next barell which will be a 1:6.5" twist. Not 100% sure on caliber yet tho, most likely another 22 BR but have a 22 Dasher reamer on order(but might take a while to get it now)...

Hey guys, anyone running a 20" or shorter barrel and if so what speeds were you getting?

Thinking of doing a 20" 22BR/BRA for club PRS out to 550 yards max and curious to speak to anyone who might have something similar.

Cheers

Thinking of doing a 20" 22BR/BRA for club PRS out to 550 yards max and curious to speak to anyone who might have something similar.

Cheers

Hey guys, anyone running a 20" or shorter barrel and if so what speeds were you getting?

Thinking of doing a 20" 22BR/BRA for club PRS out to 550 yards max and curious to speak to anyone who might have something similar.

Cheers

Haven't done it yet, but I have a 26" barrel with 1800 rounds on it that I am going to chop and set back to 20" and try it suppressed on coyotes.

I'm at 22" getting 2930 suppressed with 88eldm. This is not the top node but it shot so well, I left it alone.

30.2 RL16

30.2 RL16

Last edited:

Is anyone still running the lighter heavies; 75 A Max's ,77 & 80 SMK's ? At the time I had mine built I only had a 300 yd. range, and a $hit pot full of the mentioned bullets so I went with a 26" 8T. Just got some H 4350, RL-16 & some 4451.

Similar threads

- Replies

- 4

- Views

- 456

- Replies

- 1

- Views

- 184