Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

223 Ackley Improved

- Thread starter Huckleberry75

- Start date

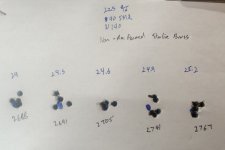

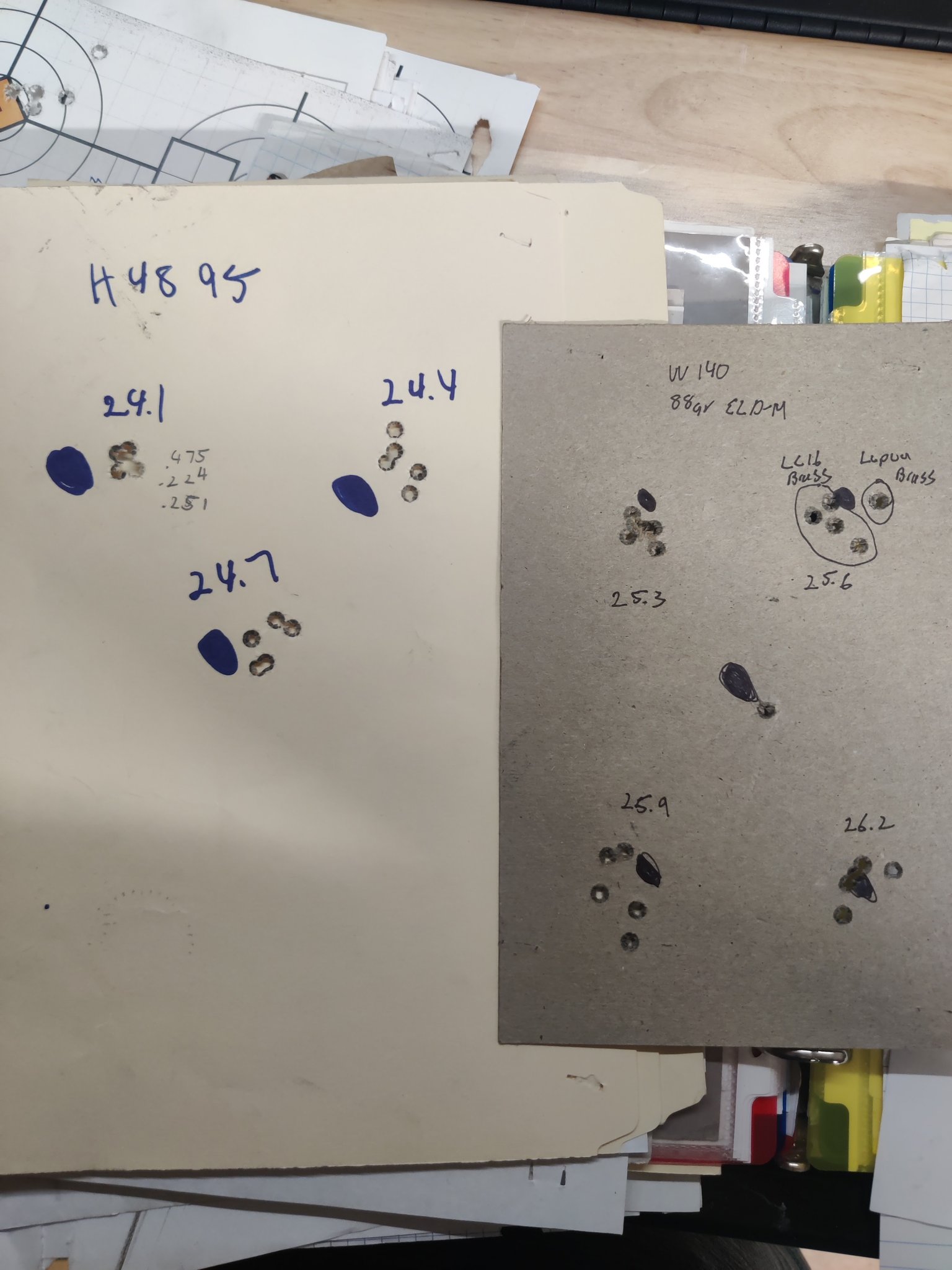

H4895 and n140 are great options. These are with 88s

Last edited:

26" 1/7 barty.Barrel length and FPS?

Was between 2800-2900. The 24.1 h4895 was mid level pressure and 25.3 and over n140 was hot.

Lapua brass held up to the pressure, but I blew primers with LC quite often when I got over 25.6 of n140.

25.2 n140 with 90smks held 6-7 SD and I had minimal issues spotting impacts to 950 or so

XBR 8208 and varget are also excellent choices. XBR got me the most velocity with pretty good accuracy.

Attachments

No, I only use a Co-Ax for sizing. Way back in this thread I mentioned mine 223AI bushing FL sizer has never bumped the shoulder (that I can measure anyway) but the cases chamber with no resistance. I have no real idea why we get no bump with the Redding FL sizers but if I was a betting man I'd have lost money on your sizer die after you chopped it down.

I was not getting any bump with my redding fl type s in a coax either so I sent it back to redding with 5-1x fired cases. When I got it back there was a note in it stating that the die was very slightly out of spec and replaced but my fired cases were still smaller than the 223AI specs and that I should try to chamber them and see if they will chamber without resistance. If they do then I need to measure, reload, and fire them again and see if they continue to grow forming to the chamber. If they don't grow then I have an undersized chamber. I have not yet taken the time to do that yet.No, I only use a Co-Ax for sizing. Way back in this thread I mentioned mine 223AI bushing FL sizer has never bumped the shoulder (that I can measure anyway) but the cases chamber with no resistance. I have no real idea why we get no bump with the Redding FL sizers but if I was a betting man I'd have lost money on your sizer die after you chopped it down.

What barrel length and twist?Here is one of my latest loads developed for a 223AI Tikka T3X. PVA barrel.

LC brass, Hornady 88 ELDM, 25.4gr CFE223, CCI450, 2.530” OAL. Five shots - 2727fps, ES 8.3, SD 3. .5” group.

Will load up more and see how it performs for 20+ rounds

Last edited:

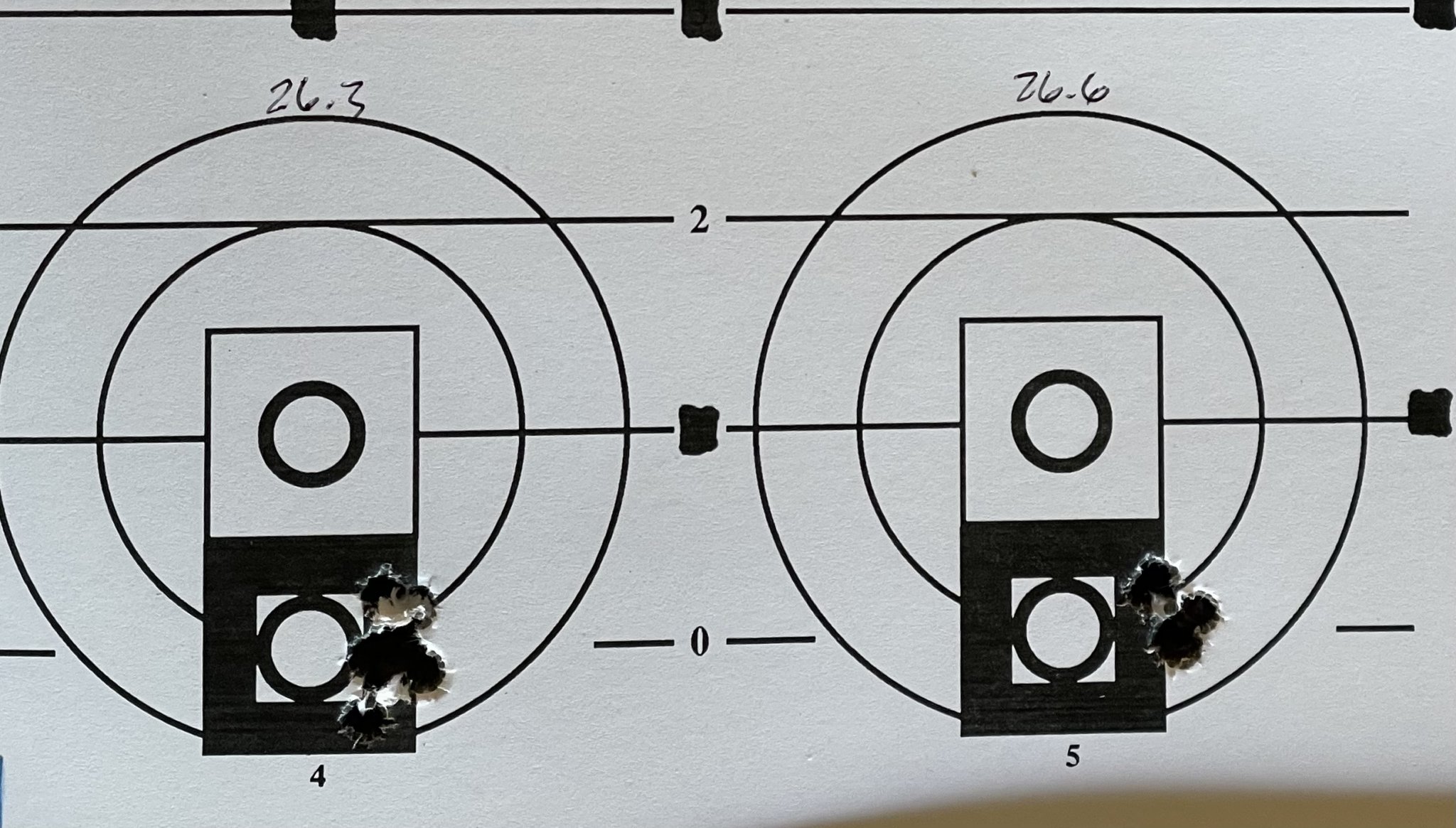

Tested more 223AI loads. Hornady 88 ELDM, CFE223, CCI450, LC Brass. 2.530” OAL. CFE223 - 25.4gr to 26.6gr.

26.3gr 5 shots. 2771fps es 19.3 sd 7.3 .5” group.

26.6gr 5 shots 2809fps es 37.2 Sd 13.3 .3” group

26.3gr 5 shots. 2771fps es 19.3 sd 7.3 .5” group.

26.6gr 5 shots 2809fps es 37.2 Sd 13.3 .3” group

Tested more 223AI loads. Hornady 88 ELDM, CFE223, CCI450, LC Brass. 2.530” OAL. CFE223 - 25.4gr to 26.6gr.

26.3gr 5 shots. 2771fps es 19.3 sd 7.3 .5” group.

26.6gr 5 shots 2809fps es 37.2 Sd 13.3 .3” group

View attachment 8336193

Spreads aren’t great but hard to argue with the groups.

So interesting day at the range today with the .223 AI CDG build with a 22" Proof. I loaded a ladder test with Staball Match, Lapua brass, 80 Grain ELD, and CCI 450 and here are the results. All numbers were 5 shot groups.

Factory Berger 73 grain Avg 2837fps, ES 17.8, SD 7.0

26.0 Staball Match Avg 2863fps, ES 38.9, SD 15.4

26.2 Staball Match Avg 2894, ES 21.1, SD 8.1

26.4 Staball Match Avg 2903, ES 32.7, SD 13.0, .5" or less group (only load that grouped lol)

26.6 Staball Match Avg 2936, ES 12.4, SD 4.5

26.8 Staball Match Avg 2953, ES 17.8, SD 6.3

Then I ran 25 rounds of the 26.2 load for steel out to 900 yards. All targets were IPSC with chest flapper and they were stationed at 600,700, 800, and 900. The load was good enough for steel work and grouped well at range. Numbers ended up being AVG 2898, ES 42.2, SD 12.2.

All numbers were obtained from a Garmin mounted on the rifle. Surprisingly there were no pressure signs and I am starting to think you cannot put enough Staball Match into a .223 case to get pressure lol. I loaded the 26.0 load previously and it was only showing 2812 FPS so that's why I started where I did. Overall accuracy was not impressive, and I believe that I am loading in between nodes or something where I am over the middle node and not quite to the extreme fast node. Running 2950 out of a 22" barrel with an 80 ELD is cooking IMO. I planned on finding a load around 2850 but I overshot it. I will start at 25.0 next time and see what happens.

I am still having an issue resizing my brass as I cannot bump the shoulders but the fired brass chambers with light resistance. The Redding die will go back to them this week with fired brass to see what they say.

Factory Berger 73 grain Avg 2837fps, ES 17.8, SD 7.0

26.0 Staball Match Avg 2863fps, ES 38.9, SD 15.4

26.2 Staball Match Avg 2894, ES 21.1, SD 8.1

26.4 Staball Match Avg 2903, ES 32.7, SD 13.0, .5" or less group (only load that grouped lol)

26.6 Staball Match Avg 2936, ES 12.4, SD 4.5

26.8 Staball Match Avg 2953, ES 17.8, SD 6.3

Then I ran 25 rounds of the 26.2 load for steel out to 900 yards. All targets were IPSC with chest flapper and they were stationed at 600,700, 800, and 900. The load was good enough for steel work and grouped well at range. Numbers ended up being AVG 2898, ES 42.2, SD 12.2.

All numbers were obtained from a Garmin mounted on the rifle. Surprisingly there were no pressure signs and I am starting to think you cannot put enough Staball Match into a .223 case to get pressure lol. I loaded the 26.0 load previously and it was only showing 2812 FPS so that's why I started where I did. Overall accuracy was not impressive, and I believe that I am loading in between nodes or something where I am over the middle node and not quite to the extreme fast node. Running 2950 out of a 22" barrel with an 80 ELD is cooking IMO. I planned on finding a load around 2850 but I overshot it. I will start at 25.0 next time and see what happens.

I am still having an issue resizing my brass as I cannot bump the shoulders but the fired brass chambers with light resistance. The Redding die will go back to them this week with fired brass to see what they say.

That is exactly what I have done in my 223AI and it works fineI have a Criterion 223AI Barrel and Origin Action being delivered next week. I have a bunch of once fired regular 223 reloads with 75 eldm’s in Lapua Brass shot in a Semi Custom Tikka w/ a Bartlein Barrel. Any real downside to using the once fired rounds in the 223AI to fire form them vs virgin brass? I’ll most likely sell the Tikka

I am still having an issue resizing my brass as I cannot bump the shoulders but the fired brass chambers with light resistance. The Redding die will go back to them this week with fired brass to see what they say.

I'm glad I found this thread. I'm having the same problem with my Redding FL Bushing die when resizing 223 AI. It won't bump my shoulder on my fire-formed brass (Lapua brass on a Redding press). FL-sized brass will chamber just fine, but the die isn't move the shoulder back, even with some serious cam-over. @Kadams1563 let me know what you figure out. I'm excited to see how this Remage build will shoot, but I'd like to get the resizing die issue figured out. I'll be trying Berger 80.5, 80 ELDMs, and 88 ELDMs over Varget. I'll post results after my next trip to the ranch.

Sounds like Lee or custom are the way to go. Only issues I’ve seen are specific to the Reddings.

I bought Lees originally before I went custom and never had an issue.

I bought Lees originally before I went custom and never had an issue.

Have you done anything to the Lee FL die or just use it as is?Sounds like Lee or custom are the way to go. Only issues I’ve seen are specific to the Reddings.

I bought Lees originally before I went custom and never had an issue.

I'd usually try to use a bushing die to not over work the brass, but I guess 223 brass is plentiful/cheap enough I don't need to worr about brass life.

Ive just placed an order for a 22cal barrel blank for an AI build. Sounds like enough people having issues with Redding dies I'll just buy some Lee ones and save some money and a headache.I'm glad I found this thread. I'm having the same problem with my Redding FL Bushing die when resizing 223 AI. It won't bump my shoulder on my fire-formed brass (Lapua brass on a Redding press). FL-sized brass will chamber just fine, but the die isn't move the shoulder back, even with some serious cam-over. @Kadams1563 let me know what you figure out. I'm excited to see how this Remage build will shoot, but I'd like to get the resizing die issue figured out. I'll be trying Berger 80.5, 80 ELDMs, and 88 ELDMs over Varget. I'll post results after my next trip to the ranch.

Have you done anything to the Lee FL die or just use it as is?

I'd usually try to use a bushing die to not over work the brass, but I guess 223 brass is plentiful/cheap enough I don't need to worr about brass life.

Just used as is… and my chamber ended up around 3 thou short.

Last edited:

It's strange. I use Redding dies for 10 other cartridges and have always been pleased with their performance. Not sure what the deal is.Ive just placed an order for a 22cal barrel blank for an AI build. Sounds like enough people having issues with Redding dies I'll just buy some Lee ones and save some money and a headache.

I’ve posted about it before, but you can grind/file/sand the top of the shell holder to make the Redding work (as long as you’re not running a co-ax press or something where there is no shell holder).

I had to do that with a Redding BR body die.

Good to know Lee makes a .223 AI die. I’m pretty well done screwing with Redding. I’ve tried 4 of their products. 2 work well, 1 worked with a modified shell holder, one doesn’t work at all. The bitch about Redding is, their stuff is awesome, when it works. And whatever doesn’t work, will be “within spec”.

I’ve not bought a set of Lees in quite a while, but I’ve got 7 sets (that I can think of) running around here and am still amazed at what I got for the money. Hope the quality is stilll there.

I thought RCBS built .223AI dies once upon a time. My RCBS SAAMI .223 sizer die is tits.

I had to do that with a Redding BR body die.

Good to know Lee makes a .223 AI die. I’m pretty well done screwing with Redding. I’ve tried 4 of their products. 2 work well, 1 worked with a modified shell holder, one doesn’t work at all. The bitch about Redding is, their stuff is awesome, when it works. And whatever doesn’t work, will be “within spec”.

I’ve not bought a set of Lees in quite a while, but I’ve got 7 sets (that I can think of) running around here and am still amazed at what I got for the money. Hope the quality is stilll there.

I thought RCBS built .223AI dies once upon a time. My RCBS SAAMI .223 sizer die is tits.

The Lees are surprisingly nice for the ~$30 you pay for the set. I tested case neck runout with the Lee and the custom I had made, and the difference was more or less negligible.

That said, it definitely overworks the brass a little in my experience, especially if using a mandrel to set neck tension. So I would still recommend having a custom one made to your reamer spec if you’re going to be serious about loading AI, but the Lee is more than serviceable if needed.

That said, it definitely overworks the brass a little in my experience, especially if using a mandrel to set neck tension. So I would still recommend having a custom one made to your reamer spec if you’re going to be serious about loading AI, but the Lee is more than serviceable if needed.

My Redding .22BR FL die was sizing the neck down around .018”.

Imagine what it was doing to my Lapua 6BR brass! But Redding told me it was within their “spec”, so, there’s that….

Imagine what it was doing to my Lapua 6BR brass! But Redding told me it was within their “spec”, so, there’s that….

I guess could always open up the lee so it doesn't touch the neck and use a standard 223 bushing die, or even a lee collect die.The Lees are surprisingly nice for the ~$30 you pay for the set. I tested case neck runout with the Lee and the custom I had made, and the difference was more or less negligible.

That said, it definitely overworks the brass a little in my experience, especially if using a mandrel to set neck tension. So I would still recommend having a custom one made to your reamer spec if you’re going to be serious about loading AI, but the Lee is more than serviceable if needed.

Die is heading back to Redding so they can “fix” it or see what they say. I did read they had some .223 ai dies that were out of spec but don’t ask me where I read that.I'm glad I found this thread. I'm having the same problem with my Redding FL Bushing die when resizing 223 AI. It won't bump my shoulder on my fire-formed brass (Lapua brass on a Redding press). FL-sized brass will chamber just fine, but the die isn't move the shoulder back, even with some serious cam-over. @Kadams1563 let me know what you figure out. I'm excited to see how this Remage build will shoot, but I'd like to get the resizing die issue figured out. I'll be trying Berger 80.5, 80 ELDMs, and 88 ELDMs over Varget. I'll post results after my next trip to the ranch.

It’s weird because 5 of us pretty much bought all the same equipment to shoot .223AI and I’m the only one having issues but I’m also the only one loading on a coax. Several of them said they had to grind the die down which I have done but DAMN does are hard as hell to cut in the lathe. That’s some tough ass steel they use lol.

It has been ground down but still not bumping the shoulders so I’m sending it back to the source just to see what they say before I keep chopping the bottom down.

When did you buy your die? Seems like my Redding FL 223AI die is a little tight in the body, losing about .5 gr of capacity with a case full of N133.Die is heading back to Redding so they can “fix” it or see what they say. I did read they had some .223 ai dies that were out of spec but don’t ask me where I read that.

Edit: just measured a FL sized and a fired case. It’s sizing it down .003” at the shoulder. Should be fine I guess?

I honestly don’t know when these were purchased. I bought a set that was older and not a bushing set and my buddy had bought several sets of the bushing and competition seaters so he gave me a set that was new in box.When did you buy your die? Seems like my Redding FL 223AI die is a little tight in the body, losing about .5 gr of capacity with a case full of N133.

Edit: just measured a FL sized and a fired case. It’s sizing it down .003” at the shoulder. Should be fine I guess?

I’m pretty sure any ..223 micrometer seater will work. I’d just order a set of .223AI does and use that seater.

I use a Hornady 223 Rem micrometer seater for both 223 and 223AI. Works great.Can anyone recommend a micrometer seating die that'll work for both 223 and 223AI?

Without reading through again to double-check, it seems it is the Redding FL bushing die that is not bumping the shoulders?

Kadams1563, I also use a Co-Ax with my Redding dies. FWIW, mine are the FL bushing sizer and micrometer seater. I bought mine second hand either on here or over on the Shooters' forum years back. They were either new or near new from the ad. The sizing issue may have been why but who knows.

I probably won't bother sending the sizer back as my current AI barrel will chamber the brass without any tightness that I can feel. It shoots very well even to 600 and has averaged well under 1/2" at 100.

Another interesting side to a 223AI (to me anyway) has to do with ES/SD. There are a plethora (needed to use that in a sentence today) of threads about how to get low sd's or not being able to get low sd's with a straight 223. My 223AI will typically give me sd's in high single digits or low teens. I load all ammo the same (OCD) so it isn't technique, tools, or components. Not very scientific but interesting just the same. Maybe that 40° shoulder and straight walls is good for something.

Kadams1563, I also use a Co-Ax with my Redding dies. FWIW, mine are the FL bushing sizer and micrometer seater. I bought mine second hand either on here or over on the Shooters' forum years back. They were either new or near new from the ad. The sizing issue may have been why but who knows.

I probably won't bother sending the sizer back as my current AI barrel will chamber the brass without any tightness that I can feel. It shoots very well even to 600 and has averaged well under 1/2" at 100.

Another interesting side to a 223AI (to me anyway) has to do with ES/SD. There are a plethora (needed to use that in a sentence today) of threads about how to get low sd's or not being able to get low sd's with a straight 223. My 223AI will typically give me sd's in high single digits or low teens. I load all ammo the same (OCD) so it isn't technique, tools, or components. Not very scientific but interesting just the same. Maybe that 40° shoulder and straight walls is good for something.

Without reading through again to double-check, it seems it is the Redding FL bushing die that is not bumping the shoulders?

Kadams1563, I also use a Co-Ax with my Redding dies. FWIW, mine are the FL bushing sizer and micrometer seater. I bought mine second hand either on here or over on the Shooters' forum years back. They were either new or near new from the ad. The sizing issue may have been why but who knows.

I probably won't bother sending the sizer back as my current AI barrel will chamber the brass without any tightness that I can feel. It shoots very well even to 600 and has averaged well under 1/2" at 100.

Another interesting side to a 223AI (to me anyway) has to do with ES/SD. There are a plethora (needed to use that in a sentence today) of threads about how to get low sd's or not being able to get low sd's with a straight 223. My 223AI will typically give me sd's in high single digits or low teens. I load all ammo the same (OCD) so it isn't technique, tools, or components. Not very scientific but interesting just the same. Maybe that 40° shoulder and straight walls is good for something.

The 40* shoulder and case taper (lack thereof) is exactly why it’s generally more consistent.

As do I.I use a Hornady 223 Rem micrometer seater for both 223 and 223AI. Works great.

Picked up a new 23” 223ai origin recently and finally got to go test some loads today. Have a jug of cfe223 that’s been collecting dust and decided I would use it to form my brass and if it worked well burn up the rest of it running 53vmax’s on prairie dogs this year.

It didn’t disappoint. Went up to 29gn in new Starline brass with no pressure signs and hit 3355fps. Best group looks to be 28.4gn at 3240ish.

Curious to see velocity/accuracy with the formed brass.

It didn’t disappoint. Went up to 29gn in new Starline brass with no pressure signs and hit 3355fps. Best group looks to be 28.4gn at 3240ish.

Curious to see velocity/accuracy with the formed brass.

Attachments

Savage 9 twist 26 in barrel. Norma brass

Fireforming load is

69 Gr Sierra Match King

24.5 Gr H4895

1.9805 to ogive. .010 jam

3 - 10 round groups attached. from left to right, shot on bipod and rear bag, tripod, and front and rear bags. Not terrible for fireforming.

AVG 3062

SD 9.2

ES 28

Fireforming load is

69 Gr Sierra Match King

24.5 Gr H4895

1.9805 to ogive. .010 jam

3 - 10 round groups attached. from left to right, shot on bipod and rear bag, tripod, and front and rear bags. Not terrible for fireforming.

AVG 3062

SD 9.2

ES 28

Attachments

So finally got the die back and was able to run it through its paces. They either shaved a lot more off the bottom of the die much more then I was comfortable going or they replaced it with a new one. The documentation says replaced die with one that will bump shoulders back.I'm glad I found this thread. I'm having the same problem with my Redding FL Bushing die when resizing 223 AI. It won't bump my shoulder on my fire-formed brass (Lapua brass on a Redding press). FL-sized brass will chamber just fine, but the die isn't move the shoulder back, even with some serious cam-over. @Kadams1563 let me know what you figure out. I'm excited to see how this Remage build will shoot, but I'd like to get the resizing die issue figured out. I'll be trying Berger 80.5, 80 ELDMs, and 88 ELDMs over Varget. I'll post results after my next trip to the ranch.

From what I have gathered is My chamber is pretty tight and does not stretch brass very much at all from firing, which makes sense because most of the time he chambers them off of a piece of brass.

Overall the die will now bump them back .005 if I wanted too so it’s all good but now I load completely on a Dillon.

80 ELD

26.1 staball match 2870 fps

Lapua brass

CCI 450

22” barrel.

I have ran multiple ladders and the numbers are not that great no matter what I do honestly but they shoot well enough for steel.

I have the same issue with my redding bushing die. They will chamber a sized brass with a little bit of force.I'm glad I found this thread. I'm having the same problem with my Redding FL Bushing die when resizing 223 AI. It won't bump my shoulder on my fire-formed brass (Lapua brass on a Redding press). FL-sized brass will chamber just fine, but the die isn't move the shoulder back, even with some serious cam-over. @Kadams1563 let me know what you figure out. I'm excited to see how this Remage build will shoot, but I'd like to get the resizing die issue figured out. I'll be trying Berger 80.5, 80 ELDMs, and 88 ELDMs over Varget. I'll post results after my next trip to the ranch.

75gr ELDM

25.3gr Staball 6.5

Virgin Starline brass

These were seated with the boat tail above the neck-shoulder junction. Chamber is throated for 95gr SMKs

Velocity was only 2350fps

It shot the 95s out of formed Lapua brass actually at higher pressures just fine in the 2800fps range and 77gr Nosler CCs loaded to normal 223 specs in LC brass at 2380fps. It has also shot Federal 5.56 (~3000fps) and Berger 73gr (~2600fps) factory loads without issue (the latter is where I got the formed Lapua brass.

Bad batch of Starline? WHAT THE HECK?

25.3gr Staball 6.5

Virgin Starline brass

These were seated with the boat tail above the neck-shoulder junction. Chamber is throated for 95gr SMKs

Velocity was only 2350fps

It shot the 95s out of formed Lapua brass actually at higher pressures just fine in the 2800fps range and 77gr Nosler CCs loaded to normal 223 specs in LC brass at 2380fps. It has also shot Federal 5.56 (~3000fps) and Berger 73gr (~2600fps) factory loads without issue (the latter is where I got the formed Lapua brass.

Bad batch of Starline? WHAT THE HECK?

Attachments

Starline support is working with me thus far. I will keep updated75gr ELDM

25.3gr Staball 6.5

Virgin Starline brass

These were seated with the boat tail above the neck-shoulder junction. Chamber is throated for 95gr SMKs

Velocity was only 2350fps

It shot the 95s out of formed Lapua brass actually at higher pressures just fine in the 2800fps range and 77gr Nosler CCs loaded to normal 223 specs in LC brass at 2380fps. It has also shot Federal 5.56 (~3000fps) and Berger 73gr (~2600fps) factory loads without issue (the latter is where I got the formed Lapua brass.

Bad batch of Starline? WHAT THE HECK?

These were from a batch I ordered in late 2021 from Powder Valley. Just got around to using it. So likely a different lot than you have there. Starline is usually good stuff.Hopefully that’s not the case. I formed between 300-400 starline into 223ai a few weeks ago without issue. I bought 2k starline brass so hopefully it keeps going strong.

These were from a batch I ordered in late 2021 from Powder Valley. Just got around to using it. So likely a different lot than you have there. Starline is usually good stuff.Hopefully that’s not the case. I formed between 300-400 starline into 223ai a few weeks ago without issue. I bought 2k starline brass so hopefully it keeps going strong.

*BTW here's a pic of the Lapua brass loaded with the 95gr SMK

Attachments

What velocity are you getting from the 95s?These were from a batch I ordered in late 2021 from Powder Valley. Just got around to using it. So likely a different lot than you have there. Starline is usually good stuff.

*BTW here's a pic of the Lapua brass loaded with the 95gr SMK

Do you know the throat length and/or throat CBTO and COAL for the loaded rounds?

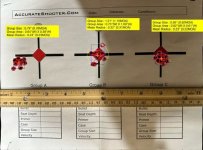

It was a ladder test. Got up to 2844fps with 27gr of Varget. COAL 2.700"What velocity are you getting from the 95s?

Do you know the throat length and/or throat CBTO and COAL for the loaded rounds?

Lightly flattened primers but no other signs of pressure.

I gotta say I'm impressed with GRT's predictive abilities with Varget!

Attachments

Wow, that's fast.It was a ladder test. Got up to 2844fps with 27gr of Varget. COAL 2.700"

Lightly flattened primers but no other signs of pressure.

I gotta say I'm impressed with GRT's predictive abilities with Varget!

After loading and shooting my .223AI and having access to 4 others that shoot the same caliper frequently locally I feel the 75 eldm is probably the best bullet for this cartridge. The extra speed you get over the Berger 80’s makes the door match up almost perfectly in our experience. We load the 75’s for 700 and in. The Berger’s get loaded for past that and man they shoot well.

I am loading the 80 eld’s just fine and have ran them up past 2950 with no pressure but that was on a cool day and I was very surprised they got that fast without issue. I have since backed them down to 2870 and it’s shooting great. My rifle is a 22” proof with a CDG action.

Lapua brass

CCI450

Staball match / 8208 XBR

80 ELD / 75 eldm

CDG / impact actions

22” barrel. / 26” barrels

I am loading the 80 eld’s just fine and have ran them up past 2950 with no pressure but that was on a cool day and I was very surprised they got that fast without issue. I have since backed them down to 2870 and it’s shooting great. My rifle is a 22” proof with a CDG action.

Lapua brass

CCI450

Staball match / 8208 XBR

80 ELD / 75 eldm

CDG / impact actions

22” barrel. / 26” barrels

What magazines are ya’ll using in your bolt guns to run these long 223’s?

Similar threads

- Replies

- 13

- Views

- 4K