Can anyone report on their experiences switching between Federal to Lapua brass using an already established load? I'm just wondering if I can plan on pressure/speed going up, down or stay the same. I know its probably different for everyone, just seeing what your guys experiences have been to compare results.

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

.308 Winchester

- Thread starter Two Shoes

- Start date

44 grains is a half minute load in most of my 308s. Very stable and predictable load.4064 is a good powder for the .308

I just tried a load this past weekend, accuracy was good, not great, but conditions were not good either.

I loaded 44.5 grains of 4064 and a Hornady 168 BTHP, not the AMAX.

It is important to note, I used Winchester brass. According to the Hodgdon website, 45 grains is max with Winchester brass.

Winchester brass is roomy, Hornady, Federal etc... are not so you MUST start lower.

Good SDs and ESs as well. Not the best but certainly acceptable.

Last edited:

You’re going from one of the lowest case capacities to a case that is usually in the middle of the pack concerning case capacity. Most likely you will need to test current load then in small increments higher to see if accuracy holds up. They will most likely be slower as well in the Lapua. More so if the FC load was compressed.Can anyone report on their experiences switching between Federal to Lapua brass using an already established load? I'm just wondering if I can plan on pressure/speed going up, down or stay the same. I know its probably different for everyone, just seeing what your guys experiences have been to compare results.

Sierra Game King 165 #2140 load data.

I can't get my hands on a Sierra book, everyone's out.

Maybe a snapshot of the page?

I’m being overly helpful because I need help.

Anyone running VV N540? I have 155s, 168s, 178s and 180s and 3.75 pounds of this powder to use up.

I’m sure someone has broke the code on it, would hate to use it just for fireforming duties.

Anyone running VV N540? I have 155s, 168s, 178s and 180s and 3.75 pounds of this powder to use up.

I’m sure someone has broke the code on it, would hate to use it just for fireforming duties.

If you Google. 308 sierra loadmap it usually pops up. Think I got it from accurate shooter.Many thanks to @fdkay

That will get me rolling a batch for my son to hunt with after testing.

I noticed H335 in there might try it.

Maybe the last lb of varget since a low round count use.

Did you get the book digital?

I didn't see that option on thier site today.

Just finished swage, reem and uniform 100+ of some first fired from his gun today.

Thank you very much.

Can anyone report on their experiences switching between Federal to Lapua brass using an already established load? I'm just wondering if I can plan on pressure/speed going up, down or stay the same. I know its probably different for everyone, just seeing what your guys experiences have been to compare results.

The best advice is for you to measure a good sample of YOUR brass to see what the difference is. Just be sure to measure "fired" cases and not sized cases and that they are both trimmed to the same length. Brass volume can vary some from lot to lot, though the better one's like Lapua will tend to have much smaller variances. Also, when comparing, you'll want to use virgin brass and note compare brass that has been fired different amounts of time to where various trimming has taken place.

I use both Federal and Lapua brass and when I measured mine I found only a small difference of .1 gr H2O (see pic below; numbers on left are case weight and volume on the right). So, I load my FC and Lapua brass the same with no apparent difference in results on paper as I typically get well under .5 MOA. Though I will say that FC brass volumes are not as consistent as Lapua, so I will weight sort FC brass to find those outliers. For some lots of FC brass I found they can have volumes .4 gr less than Lapua and that difference certainly does affect what I see on paper.

Lapua Brass sorting by case weight:

Last edited:

There are numerous ways to check capacity without using water. You can use a funnel to compare loads directly from case to case until you have a sample size big enough to draw a conclusion. The real test will come when you reach max compression. That’s the true test for capacity.

Thanks for your input. Dumb new guy question, what if any prep do I do on the new Lapuas? Just trim, champfer/debur or should I run them through my FL die thats bumping the shoulder on fireformed cases .002?The best advice is for you to measure a good sample of YOUR brass to see what the difference is. Just be sure to measure "fired" cases and not sized cases and that they are both trimmed to the same length. Brass volume can vary some from lot to lot, though the better one's like Lapua will tend to have much smaller variances. Also, when comparing, you'll want to use virgin brass and note compare brass that has been fired different amounts of time to where various trimming has taken place.

I use both Federal and Lapua brass and when I measured mine I found only a small difference of .1 gr H2O (see pic below; numbers on left are case weight and volume on the right). So, I load my FC and Lapua brass the same with no apparent difference in results on paper as I typically get well under .5 MOA. Though I will say that FC brass volumes are not as consistent as Lapua, so I will weight sort FC brass to find those outliers. For some lots of FC brass I found they can have volumes .4 gr less than Lapua and that difference certainly does affect what I see on paper.

View attachment 7710464

Lapua Brass sorting:

View attachment 7710465

I run virgin brass through fls, mandrell, trim and champher.

Sometimes it doesn't size much on some brands but you want it to fit your chamber and neck tension.

I trimmed some first fired yesterday and they were up to + 0.015 now the batch is +/- 0.001.

Some brass comes untrimmed.

Pretend it's clean range brass and check every thing.

Sometimes it doesn't size much on some brands but you want it to fit your chamber and neck tension.

I trimmed some first fired yesterday and they were up to + 0.015 now the batch is +/- 0.001.

Some brass comes untrimmed.

Pretend it's clean range brass and check every thing.

New Lapua gets run thru a mandrel and loaded. I never full length size until after its been fired.

Thanks for your input. Dumb new guy question, what if any prep do I do on the new Lapuas? Just trim, champfer/debur or should I run them through my FL die thats bumping the shoulder on fireformed cases .002?

I typically find that my virgin Lapua brass is pretty short for the most part and with a lot more variance than I care for. And because they need to be fire formed, I just don't bother trimming until after the first firing or any of the other case prep like FL sizing. Virgin case necks are often dented or maybe a little out of round due to the jostling they get during packaging and shipping and so running an expander mandrel through the neck is a good idea to be sure to get them uniformly round and to get the neck tension you want. I find that the bullet seating typically requires more effort than it should be, some of which is a result of the case mouth edge being a little rolled and or rough. So, rather than use an expander mandrel, I'll use a Lee Collet Die that gives the necks a good squeeze and takes care of all these issues making bullet seating in virgin brass more consistent.

All I have is an RCBS full length die, any reccomendations on the expander mandrel?I typically find that my virgin Lapua brass is pretty short for the most part and with a lot more variance than I care for. And because they need to be fire formed, I just don't bother trimming until after the first firing or any of the other case prep like FL sizing. Virgin case necks are often dented or maybe a little out of round due to the jostling they get during packaging and shipping and so running an expander mandrel through the neck is a good idea to be sure to get them uniformly round and to get the neck tension you want. I find that the bullet seating typically requires more effort than it should be, some of which is a result of the case mouth edge being a little rolled and or rough. So, rather than use an expander mandrel, I'll use a Lee Collet Die that gives the necks a good squeeze and takes care of all these issues making bullet seating in virgin brass more consistent.

All I have is an RCBS full length die, any reccomendations on the expander mandrel?

I like my Sinclair Expander Die and Carbide Expander Mandrels; using either the .306 or .307 depending on the brass and how thick I've turned the necks. Using carbide mandrels makes the operation smoother and less hassle than the SS mandrels and they'll last forever.

Note, I wouldn't use a sizing die at all . . . just the expander on virgin brass. If you use the sizing die, use it without the spindle and expander button then expand with an expander mandrel. You don't want to overwork the brass.

SINCLAIR INTERNATIONAL Products for Sale Online - 237 Products

237 SINCLAIR INTERNATIONAL Products For Sale Up To 91% Off including Reloading, Tools & Cleaning, and Gear.

Last edited:

I was under the impression that the sizing die had an expander mandrel in it, is there a sizing die that has interchangeable mandrels or does it have to be a seperate die? Do I need to do it the same way once the brass has been fired once?I like my Sinclair Expander Die and Carbide Expander Mandrels; using either the .306 or .307 depending on the brass and how thick I've turned the necks. Using carbide mandrels makes the operation smoother and less hassle than the SS mandrels and they'll last forever.

Note, I wouldn't use a sizing die at all . . . just the expander on virgin brass. If you use the sizing die, use it without the spindle and expander button then expand with an expander mandrel. You don't want to overwork the brass.

SINCLAIR INTERNATIONAL Products for Sale Online - 237 Products

237 SINCLAIR INTERNATIONAL Products For Sale Up To 91% Off including Reloading, Tools & Cleaning, and Gear.www.sinclairintl.com

View attachment 7711998

They do have an expander ball / button in them.

You could go forever with just that.

But they don't produce as consistant neck tension as a mandrell that's why I Basterdise mine by grossly undersizing them and use it to straiten case mouths and start the neck expansion a little.

You could go forever with just that.

But they don't produce as consistant neck tension as a mandrell that's why I Basterdise mine by grossly undersizing them and use it to straiten case mouths and start the neck expansion a little.

As mentioned above, sizing dies have "expander balls" on their spindles to draw the neck against the die. Expander Mandrels are not part of sizing dies as you can see in the pic I posted where the Expander Mandrel fits into its own die. Sizing dies with their expander balls tend to produce quite a bit of neck runout. There ARE some high end sizing dies with really well designed expander balls that minimize that problem. Going with Expander Mandrels tends to produce a lot less runout, especially if the necks are annealed and/or expanded minimally to the desired neck tension. Like I use Forster sizing dies without the expander button having had Forster ream the die so that when I FL size my cases I'll only need to expand the neck ~.002 more with an expander mandrel to get the neck tension I'm after. For virgin brass, the Expander Mandrel only sizes the neck making them round there the interior diameter is quite uniform as it moves the variable thickness of the brass to the outside diameter. This movement of the thickness variance away from the inside to the outside is what helps produce more concentric bullet alignment when seating them.I was under the impression that the sizing die had an expander mandrel in it, is there a sizing die that has interchangeable mandrels or does it have to be a seperate die? Do I need to do it the same way once the brass has been fired once?

If you're sizing virgin brass, then you'll be using the same procedure for subsequently fired brass. If you're using quality brass like Lapua or Peterson's, you don't really NEED to size them except to address the issue of dented necks.

Last edited:

Glad I waited to do anything with the Lapua brass then. How do I go about figuring the correct size mandrel to run?As mentioned above, sizing dies have "expander balls" on their spindles to draw the neck against the die. Expander Mandrels are not part of sizing dies as you can see in the pic I posted where the Expander Mandrel fits into its own die. Sizing dies with their expander balls tend to produce quite a bit of neck runout. There ARE some high end sizing dies with really well designed expander balls that minimize that problem. Going with Expander Mandrels tends to produce a lot less runout, especially if the necks are annealed and/or expanded minimally to the desired neck tension. Like I use Forster sizing dies without the expander button having had Forster ream the die so that when I FL size my cases I'll only need to expand the neck ~.002 more with an expander mandrel to get the neck tension I'm after. For virgin brass, the Expander Mandrel only sizes the neck making them round there the interior diameter is quite uniform as it moves the variable thickness of the brass to the outside diameter. This movement of the thickness variance away from the inside to the outside is what helps produce more concentric bullet alignment when seating them.

If you're sizing virgin brass, then you'll be using the same procedure for subsequently fired brass. If you're using quality brass like Lapua or Peterson's, you don't really NEED to size them except to address the issue of dented necks.

Decide on the neck tension you want. If you want .002, simply subtract that from the bullet's diameter. And that's the size mandrel you'll want to use. If you want to be more precise, you'll want to allow for some spring back, which can be ~.0005 and get a mandrel that's larger by that amount to get you to the .002 neck tension your after. So, for a .308 case, you can go with a .306 mandrel or a .3065.Glad I waited to do anything with the Lapua brass then. How do I go about figuring the correct size mandrel to run?

I do 0.002 under caliber for everything.

AR rounds may get a small crimp additionally (lee collet) if necessary.

I think BR guys do one thousands under?

AR rounds may get a small crimp additionally (lee collet) if necessary.

I think BR guys do one thousands under?

As mentioned above, sizing dies have "expander balls" on their spindles to draw the neck against the die. Expander Mandrels are not part of sizing dies as you can see in the pic I posted where the Expander Mandrel fits into its own die. Sizing dies with their expander balls tend to produce quite a bit of neck runout. There ARE some high end sizing dies with really well designed expander balls that minimize that problem. Going with Expander Mandrels tends to produce a lot less runout, especially if the necks are annealed and/or expanded minimally to the desired neck tension. Like I use Forster sizing dies without the expander button having had Forster ream the die so that when I FL size my cases I'll only need to expand the neck ~.002 more with an expander mandrel to get the neck tension I'm after. For virgin brass, the Expander Mandrel only sizes the neck making them round there the interior diameter is quite uniform as it moves the variable thickness of the brass to the outside diameter. This movement of the thickness variance away from the inside to the outside is what helps produce more concentric bullet alignment when seating them.

If you're sizing virgin brass, then you'll be using the same procedure for subsequently fired brass. If you're using quality brass like Lapua or Peterson's, you don't really NEED to size them except to address the issue of dented necks.

Great explanation of a subject that's rarely clarified. To throw the loads I'm using into the hat:

Barnes TTSX 150

42.5 H4895

Win brass

Fed 210M primer

2650 FPS, ~MOA performance. My "anything in NA at reasonable hunting distances" load.

Hammer Hunter 152

45.0 grains Varget

Win brass

Fed 210M primer

2725FPS, 3/4MOA average

Great explanation of a subject that's rarely clarified. To throw the loads I'm using into the hat:

Barnes TTSX 150

42.5 H4895

Win brass

Fed 210M primer

2650 FPS, ~MOA performance. My "anything in NA at reasonable hunting distances" load.

Hammer Hunter 152

45.0 grains Varget

Win brass

Fed 210M primer

2725FPS, 3/4MOA average

Nice!

Just a heads up to any reloaders that might consider using these loads . . . keep in mind that Winchester brass has thinner brass resulting in substantially more case volume than most other brass; often about 1.5 gr H2O more (e.g. Win Brass: 57.7 gr H2O vs Lapua Brass: 56.0 gr H2O), meaning higher pressures due to the smaller volumes.

In my gun with a 26" barrel:

42.5 grs H4895 pushes my 175 SMK's to 2785 fps (not so good MOA with this load for me @1.3 MOA)

45 grs of Varget pushes my 155 gr SMK's to 2792 fps with MOA's in the .3's.

Just recently did some load testing of Sierra's new 169 gr. SMK's that are a essentially a redesigned 168 SMK with a much better BC at .527. AR-Comp did really well for my 168's and doing well for these 169's so far.

Nice!

Just a heads up to any reloaders that might consider using these loads . . . keep in mind that Winchester brass has thinner brass resulting in substantially more case volume than most other brass; often about 1.5 gr H2O more (e.g. Win Brass: 57.7 gr H2O vs Lapua Brass: 56.0 gr H2O), meaning higher pressures due to the smaller volumes.

In my gun with a 26" barrel:

42.5 grs H4895 pushes my 175 SMK's to 2785 fps (not so good MOA with this load for me @1.3 MOA)

45 grs of Varget pushes my 155 gr SMK's to 2792 fps with MOA's in the .3's.

Just recently did some load testing of Sierra's new 169 gr. SMK's that are a essentially a redesigned 168 SMK with a much better BC at .527. AR-Comp did really well for my 168's and doing well for these 169's so far.

View attachment 7714295

Great SA on this. Definitely work up loads with an extra degree or two of caution with Win brass in .308.

About to start working on loads with new brass. Anyone have experience with RWS???

How does it compare to Lapua for case volume etc?

Thanks

How does it compare to Lapua for case volume etc?

Thanks

About to start working on loads with new brass. Anyone have experience with RWS???

How does it compare to Lapua for case volume etc?

Thanks

View attachment 7714474

I don't have any direct experience with them, but I've read on several occasions that this RWS brass is a little thicker than Lapua and having a little less case volume; also some have said they weigh heavier than Lapua, which also suggest less case volume. Otherwise, I haven't seen any numbers for the volume. Whatever other people have measured, it always a good idea to measure your own brass as there can be differences between lots. . . especially over time.

How sensitive do you find the TMKs are to seating depth? Im working with the original 155 smks 2155s because I didnt have much luck with the ELDs. Working with a mag that barely fits 2.79 and change. Going to try the book seating depth with the 155s which is 2.755" if I remember correctly.

IMR 4895 is my favorite powder that I have personally tried so far with a 308 and 155's.

I'm shooting a 26" Proof Prefit barrel for an Impact action. I'm a grain under book max and am getting slightly over 3000 FPS with the 155 TMK's. I was holding 3.4 mils to 600 yards last weekend. Not that far off from the way a lot of people load their dashers.

I do still want to try IMR8208XBR also.

So far, I have tried Varget, IMR 4166, Accurate 2520, and Accurate 4064.

IMR4895 is definitely my favorite then the 4166 but I can't get the same velocities with the 4166 and the SD's are really close.

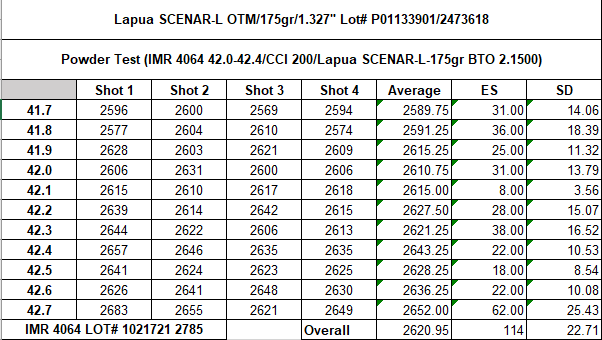

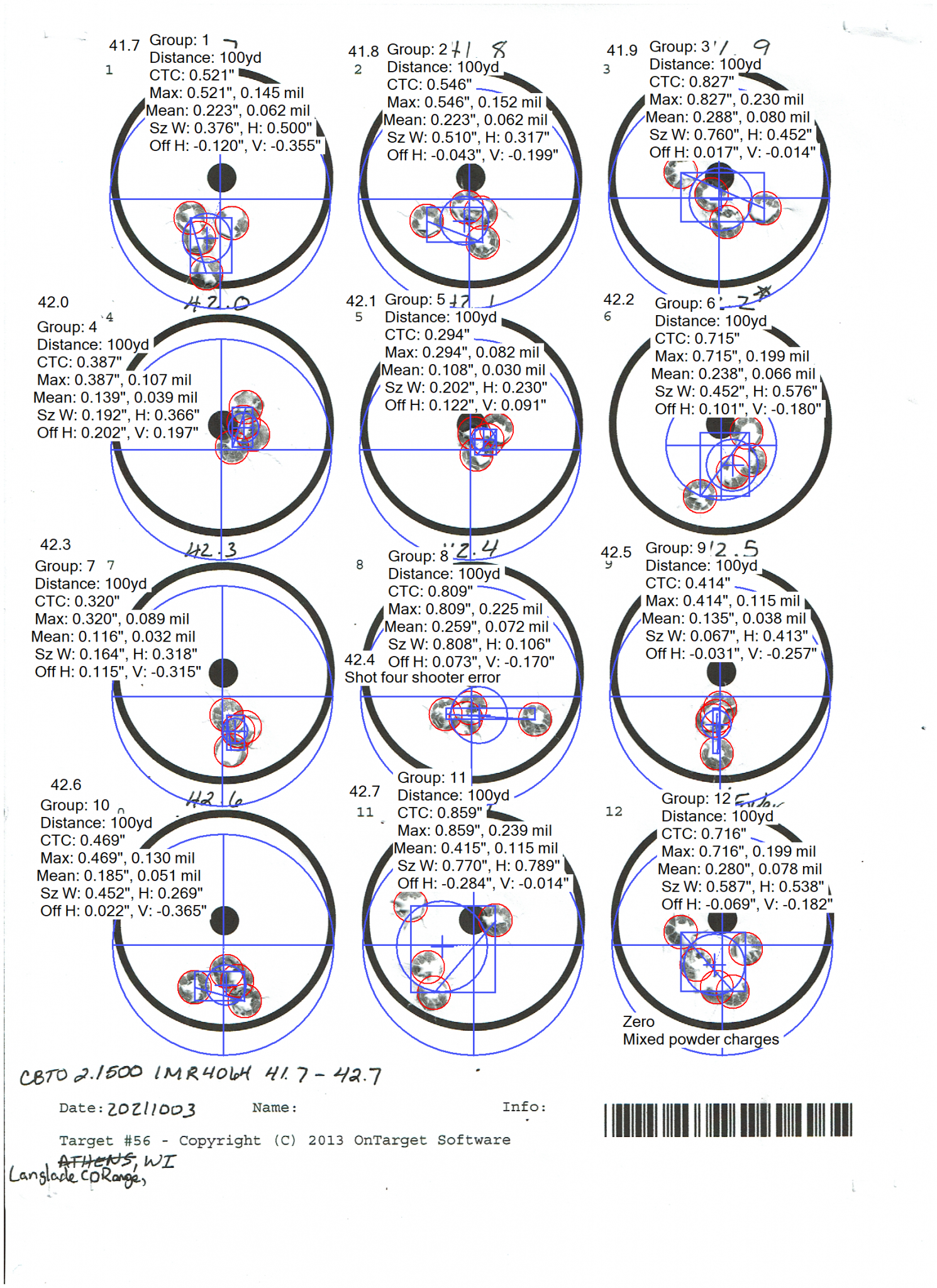

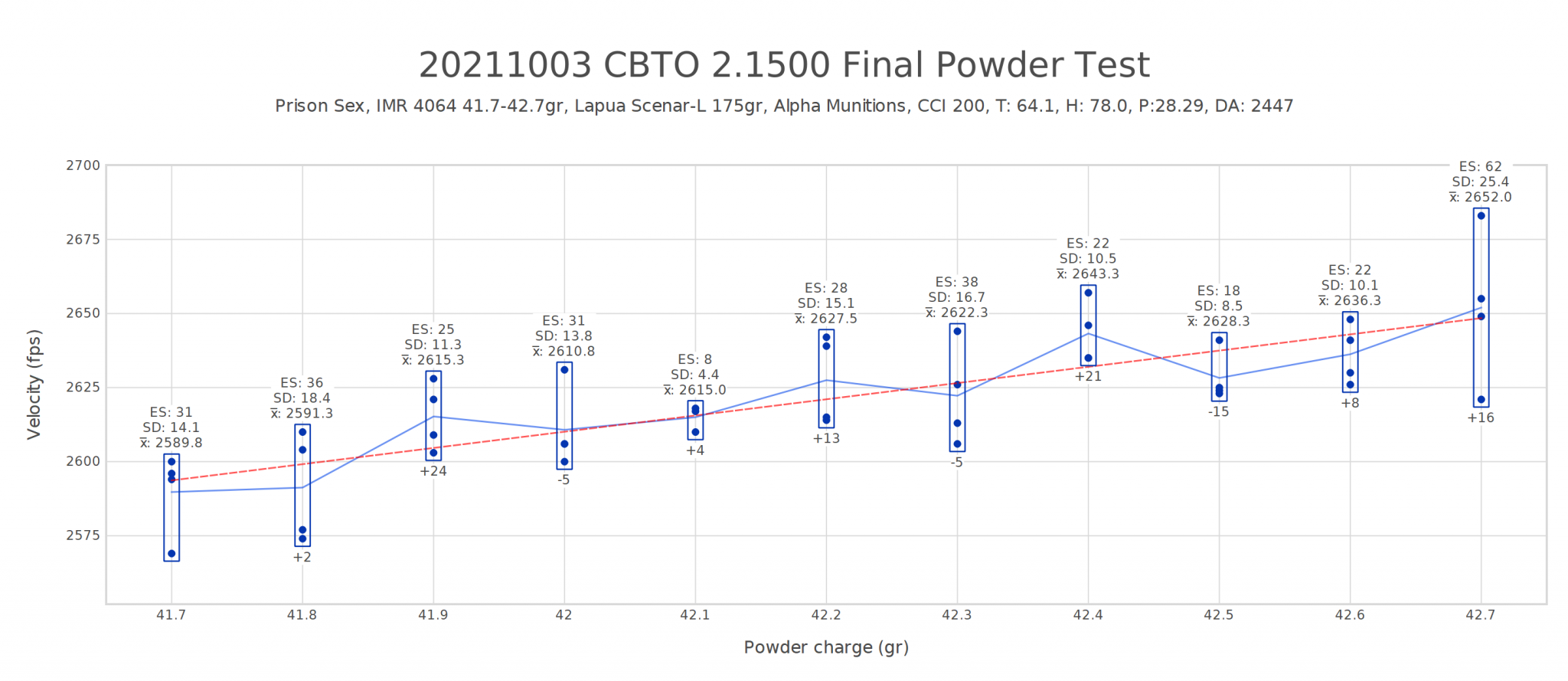

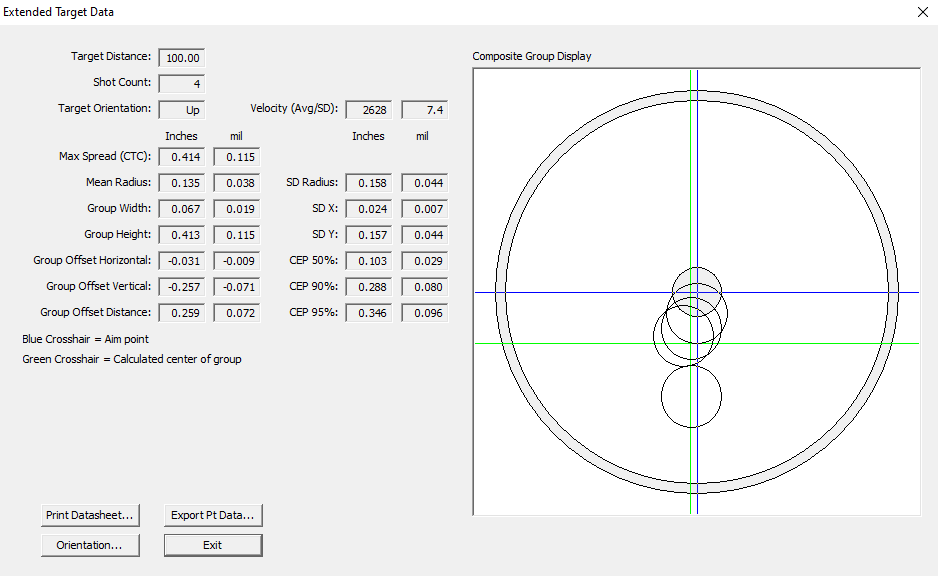

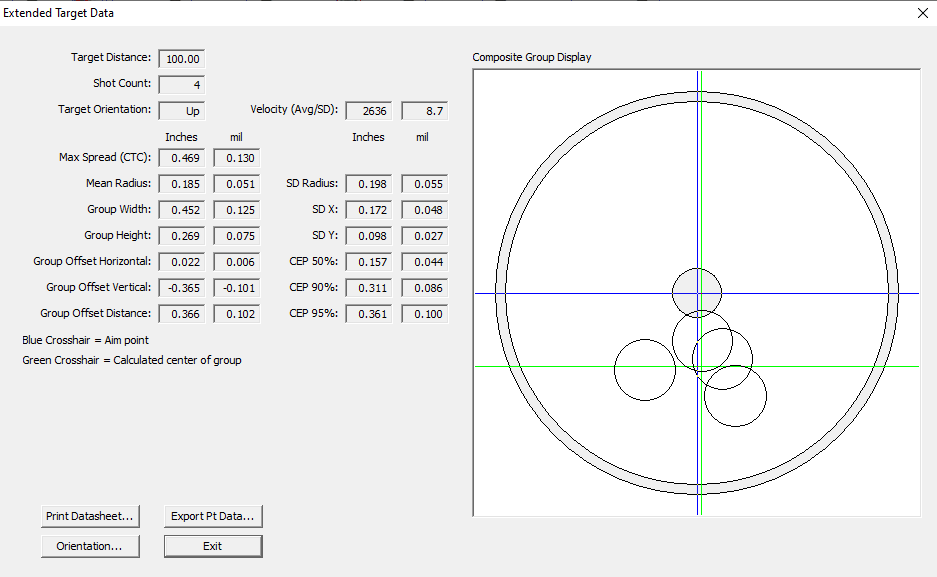

Recently changed out my firing pin assembly, so I redid some things and shot this confirming a load...

22" 1:10 SS Bartlein, TL3 SA action, IMR 4064, CCI 200, Scenar-L 175gr

T: 64.1

P: 28.29

H: 78.0%

DA: 2447

The data:

Groups:

Graph of the data:

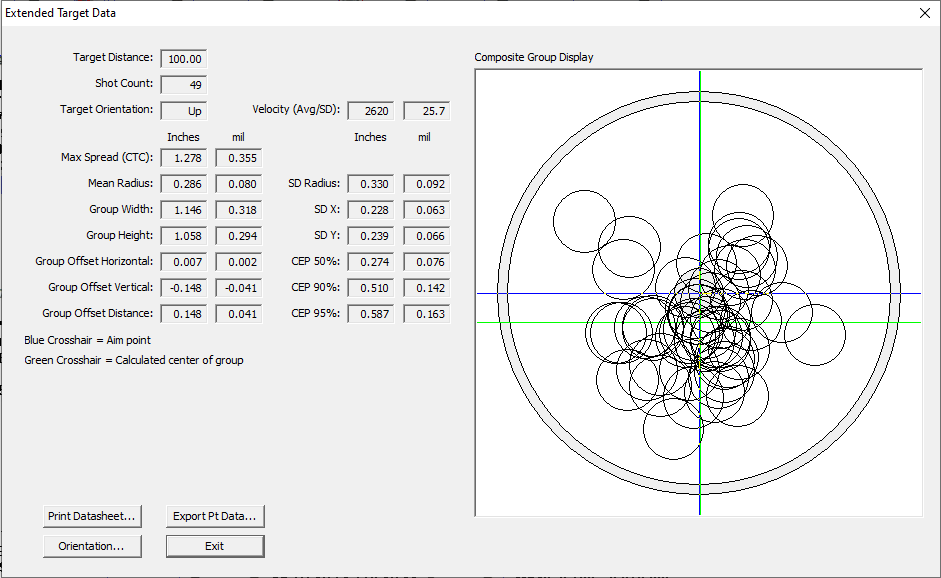

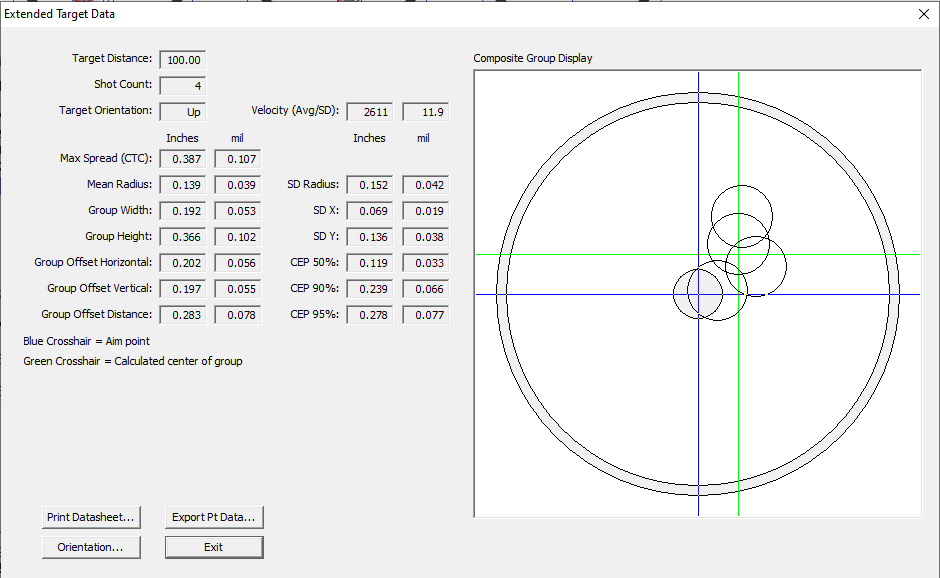

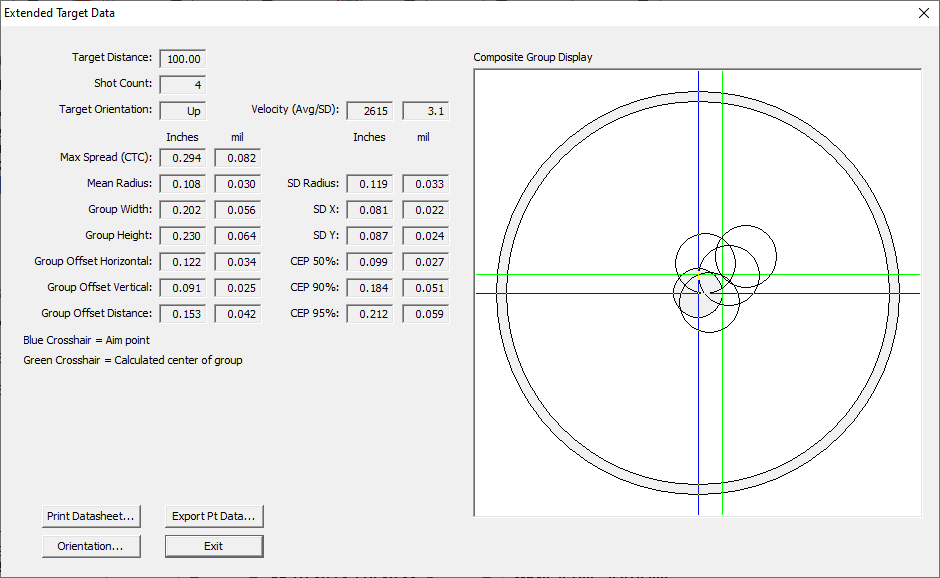

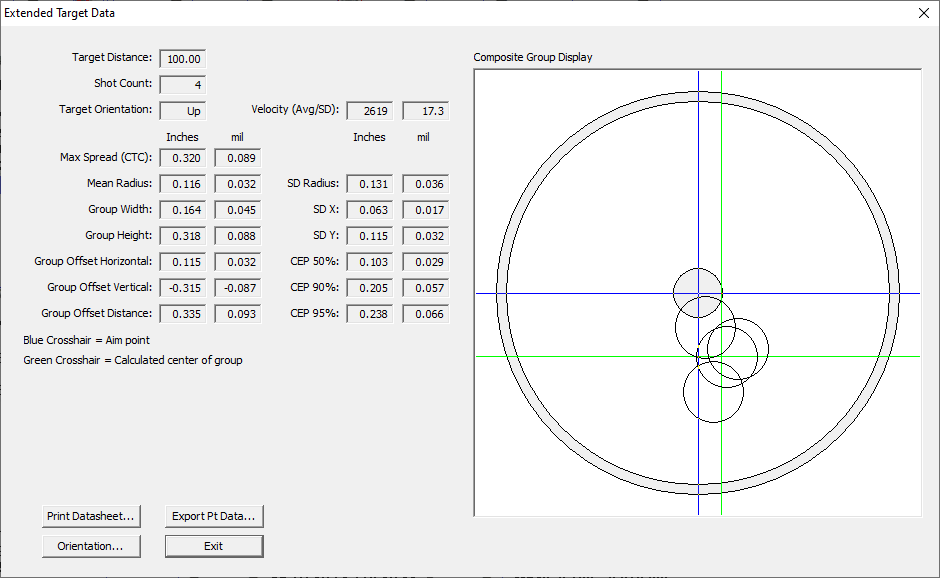

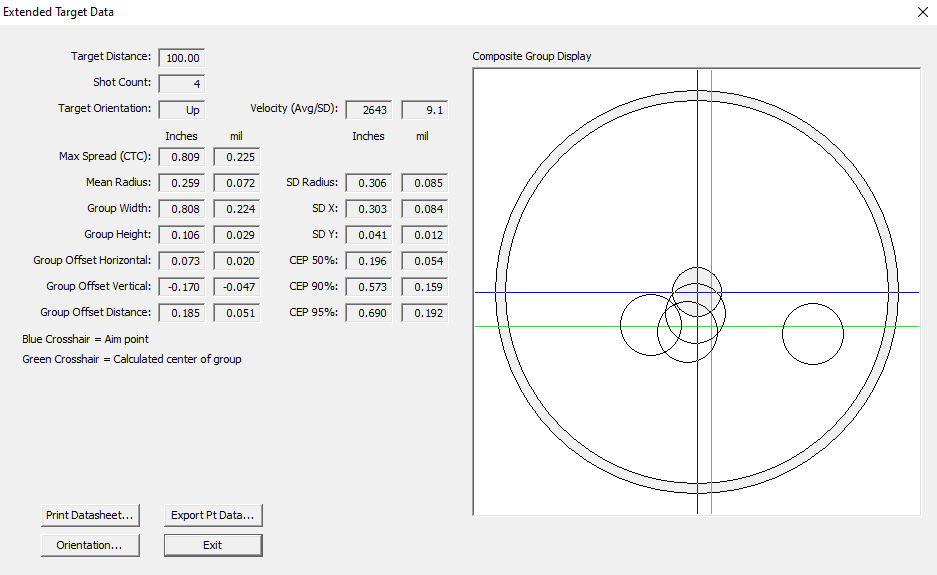

Analysis of the groups of interest in order: Overall groups, Groups 4-5 (42.0-42.1gr) & Groups 7-10 (42.3-42.6gr)

Overall:

Group 4 @ 42.0gr

Group 5 @ 42.1gr

Group 7 @ 42.3gr

Group 8 @ 42.4gr

Group 9 @ 42.5gr

Group 10 @ 42.6gr

Happy Shooting everyone

22" 1:10 SS Bartlein, TL3 SA action, IMR 4064, CCI 200, Scenar-L 175gr

T: 64.1

P: 28.29

H: 78.0%

DA: 2447

The data:

Groups:

Graph of the data:

Analysis of the groups of interest in order: Overall groups, Groups 4-5 (42.0-42.1gr) & Groups 7-10 (42.3-42.6gr)

Overall:

Group 4 @ 42.0gr

Group 5 @ 42.1gr

Group 7 @ 42.3gr

Group 8 @ 42.4gr

Group 9 @ 42.5gr

Group 10 @ 42.6gr

Happy Shooting everyone

I finally took the time to find jam using Erik Cortina's method after struggling to get ELDs to shoot at mag length out of my factory Howa barrel.

COAL 2.9190

CBTO 2.3275

with the 155 SMK 2155#.

Seems like an extremely long throat, which was my suspicion. Nosler 175 CC and Sierra 155 SMKs shot much better than the ELDs at mag length (2.79 and change). I still experimenting with powder charge and the 155s. Going to load some to Sierra book length of 2.755 and then load some to single feed .002 off the lands. Surprisingly enough so far the 155s have shot the best out of everything Ive tried in this rifle even jumping that far.

Anyone with a Howa have similar experience? I have heard of Howas having long throats before. The barrel has shown promise though.

Picture is the jam length.

COAL 2.9190

CBTO 2.3275

with the 155 SMK 2155#.

Seems like an extremely long throat, which was my suspicion. Nosler 175 CC and Sierra 155 SMKs shot much better than the ELDs at mag length (2.79 and change). I still experimenting with powder charge and the 155s. Going to load some to Sierra book length of 2.755 and then load some to single feed .002 off the lands. Surprisingly enough so far the 155s have shot the best out of everything Ive tried in this rifle even jumping that far.

Anyone with a Howa have similar experience? I have heard of Howas having long throats before. The barrel has shown promise though.

Picture is the jam length.

Attachments

I'm having reasonable results with Shooters World Precision Rifle.So having a few strange things go on with my loads. Will post that as soon as I get pictures from my son.

What powder is the best replacement for Varget?

I found a good load using IMR 4064 @ 42.1gr with scenar-l 175gr. .3 groups with a couple of .25s in there.So having a few strange things go on with my loads. Will post that as soon as I get pictures from my son.

What powder is the best replacement for Varget?

Anyone ever run IMR 3031? got a pound of it laying around and say in the ole reloading book that it can be used. Curious if anyone has a good load with it out of a 26" barrel.

I’m being overly helpful because I need help.

Anyone running VV N540? I have 155s, 168s, 178s and 180s and 3.75 pounds of this powder to use up.

I’m sure someone has broke the code on it, would hate to use it just for fireforming duties.

I have a N540 load for the 178 eld-m. It was 44.5gr seated 20 off in a 700 5R 24" in Fed GMM brass. Shot cloverleafs @ 200.

39.5gr over a 168 Match King was the old Federal Match load way back in the day. It was the military match M14 ammo before M852 was developed.Anyone ever run IMR 3031? got a pound of it laying around and say in the ole reloading book that it can be used. Curious if anyone has a good load with it out of a 26" barrel.

I have a N540 load for the 178 eld-m. It was 44.5gr seated 20 off in a 700 5R 24" in Fed GMM brass. Shot cloverleafs @ 200.

I stopped too soon. I didnt see pressure but the load data for this is all over the map. I will try it this week in Lapua Palma brass. What velocities did you get?

Last edited:

I stopped too soon. I didnt see pressure but the load data for this is all over the map. I will try it this week in Lapua Palma brass. What velocities did you get?

I haven't shot those for a couple of years and didn't see my velocity or COAL - moved to the 208 eld-m. However, my 700 5R has a porn star throat, so I imagine the COAL was quite long.

Attachments

That's some good loading and shooting Mr Toast! I will load up some 43.7, 44.1 and 44.5 at 2.830 in Lapua brass. Im figuring you were running them at 2.880 or so.I haven't shot those for a couple of years and didn't see my velocity or COAL - moved to the 208 eld-m. However, my 700 5R has a porn star throat, so I imagine the COAL was quite long.

What 4166 loads have you worked up so far?IMR 4166 is a close varget substitute

That's some good loading and shooting Mr Toast! I will load up some 43.7, 44.1 and 44.5 at 2.830 in Lapua brass. Im figuring you were running them at 2.880 or so.

Thanks, FYI my 208 eld-m COAL is 3.043, and my 175 TMK COAL was 2.90. Weird I can't find the 178, but your barrel will be different. Just in case you have to load shorter, maybe back off a bit more on the charge.

Last edited:

^With 208 eld-m's @1000 yds, I'm @ 9.3 mils drop, but only 1.6 mils for full wind (10mph). They do recoil more, though.

Awesome i did not know that, i got everything i need for that then, Thanks!39.5gr over a 168 Match King was the old Federal Match load way back in the day. It was the military match M14 ammo before M852 was developed.

Run the numbers with the new 200gr SMK #2231..2 mil difference in windage at 1000 yards

Significantly less drop for any ranging errors and much more short action mag length friends for tuning and much less recoil also View attachment 7720527View attachment 7720528

What COAL? With both powders. To get those speeds you’re compressing. Suggest a charge window for both as have them but haven’t shot them with 155s. I have Scenars.I've tried it in a few different 308 projectiles

What I've tried it in the most is Sierra 155 TMK. I got almost the exact same velocity with book max of varget and book max of 4166. It was right around the 2930 FPS range out of a 26" Proof Steel Prefit for an Impact. Great temp stability and I got good SD's with it

I settled on IMR4895 because I'm getting a little over 3000FPS with it with the 155 Sierra TMK's

That is exactly how much Varget Im running with the 155 Scenar at 2.838 MAG Length. 46.6 shot better but I wasnt getting consistent seating depth. I made a small ball of JB weld then stuck it in the seating plug. Then lubed a heavily crimped dummy round and let it set at full stroke. That "custom stem" works really well in seating that short and not deforming the bullet.2.96” coal

I’m at 46.2 grains of IMR 4895 and if I use a drop tube, I’m getting consistent seating depths

I've got some 195 TMK laying around, might branch out from those to supplement my factory ammo consumption. My weak search-fu only shows one result in this thread for those bullets... which surprises me. Am I missing something? Are the 200.20X and the like just that much better? Is it that the 155s are the hotness for those that aren't going heavy?

Either way, I've been able to scrounge a few pounds of IMR 4166, so I guess I know where I'm starting.

Either way, I've been able to scrounge a few pounds of IMR 4166, so I guess I know where I'm starting.

I used to really shoot a lot of the 155s. I switched to the 175 SMK and I'm just about out, and thinking about switching back again. Of course there are none available anywhere!I've got some 195 TMK laying around, might branch out from those to supplement my factory ammo consumption. My weak search-fu only shows one result in this thread for those bullets... which surprises me. Am I missing something? Are the 200.20X and the like just that much better? Is it that the 155s are the hotness for those that aren't going heavy?

Either way, I've been able to scrounge a few pounds of IMR 4166, so I guess I know where I'm starting.

Similar threads

- Replies

- 36

- Views

- 2K

- Replies

- 8

- Views

- 671

- Replies

- 20

- Views

- 1K

- Replies

- 0

- Views

- 2K