Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

6gt

- Thread starter Dthomas3523

- Start date

I'm running 36.0gr h4350 behind 105gr bthp at 2853fps for break in. It shot great. I might drop down pending tonight's results.When I used h4350 36.0 got me right around 2850. Alot of my buddies had that be their same load too.

I'm having fun with this one.

My old range I could just turn off the lights when I was done. Miss that placeNothing like an after dark range trip . Less wind and no crowds.

I run 36.6gr H4350 in my 28" bartlein with 109s at 2920 -40k shoots pretty dang good there. 3 other local gt shooters are at same speed. My last barrel was 108s at 2940 with rl16.I saw a light ejector swipe at 38.6gr H4350 but no flattened primers or heavybolt lift. I hit 3042fps at the top end and if I wasn't paying attention I wouldn't have noticed the light plunger mark. I couldn't feel it but it was there.

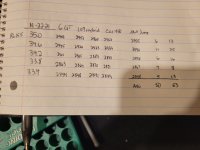

Looking at my velocities 36.3gr to 37.3gr is where I'm going to work on. Average speed is closer to 2940fps. I'm going to the range now and willpost my results.

What was your round count when you pulled your barrel and the accuracy it still held at distance?I run 36.6gr H4350 in my 28" bartlein with 109s at 2920 -40k shoots pretty dang good there. 3 other local gt shooters are at same speed. My last barrel was 108s at 2940 with rl16.

Last night's range trip was not as good as I was hoping. I was off and not able to shoot a decent group to save my life. It was not a waste, I did collect some good data on both my 6GT and my new 30 Sherman Magnum. It wasn't a bust overall.

I think I'm going to slow my load some. I had decent ES and SD numbers at the lower charge weights. I don't have my notes but they were in the single digits and grew as the charge increased. I started at 36.3gr and was shooting 5 round groups. 36.3 and 36.5 shot the best. I'm going to test 36.0, 36.1, 36.2 and 36.3gr.

My barrel is definitely speeding up still so I might hold off and keep shooting my 105gr bthp load. I just hit 120 rounds. I will hopefully get some more range time over the holiday weekend and dial in my load.

How many rounds do most of you put through a new barrel before you dial in the load? Should I just continue dialing in the load using the 108gr ELDM'S?

I think I'm going to slow my load some. I had decent ES and SD numbers at the lower charge weights. I don't have my notes but they were in the single digits and grew as the charge increased. I started at 36.3gr and was shooting 5 round groups. 36.3 and 36.5 shot the best. I'm going to test 36.0, 36.1, 36.2 and 36.3gr.

My barrel is definitely speeding up still so I might hold off and keep shooting my 105gr bthp load. I just hit 120 rounds. I will hopefully get some more range time over the holiday weekend and dial in my load.

How many rounds do most of you put through a new barrel before you dial in the load? Should I just continue dialing in the load using the 108gr ELDM'S?

That 236 bore Krieger was the best shooting barrel I'd ever ran until 800 rounds, and I started having pressure issues. I used iosso, kroil, jb, chameleon, boretech you name it, still had problems. I learned a lesson, don't run tight bore match barrels on prs rigs. The thing still shot well in the mid 2800s but I might as well be shooting 6br in that case. I then had a 237 bore bartlein mod400 spun and have been very happy with it.What was your round count when you pulled your barrel and the accuracy it still held at distance?

Last edited:

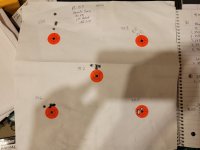

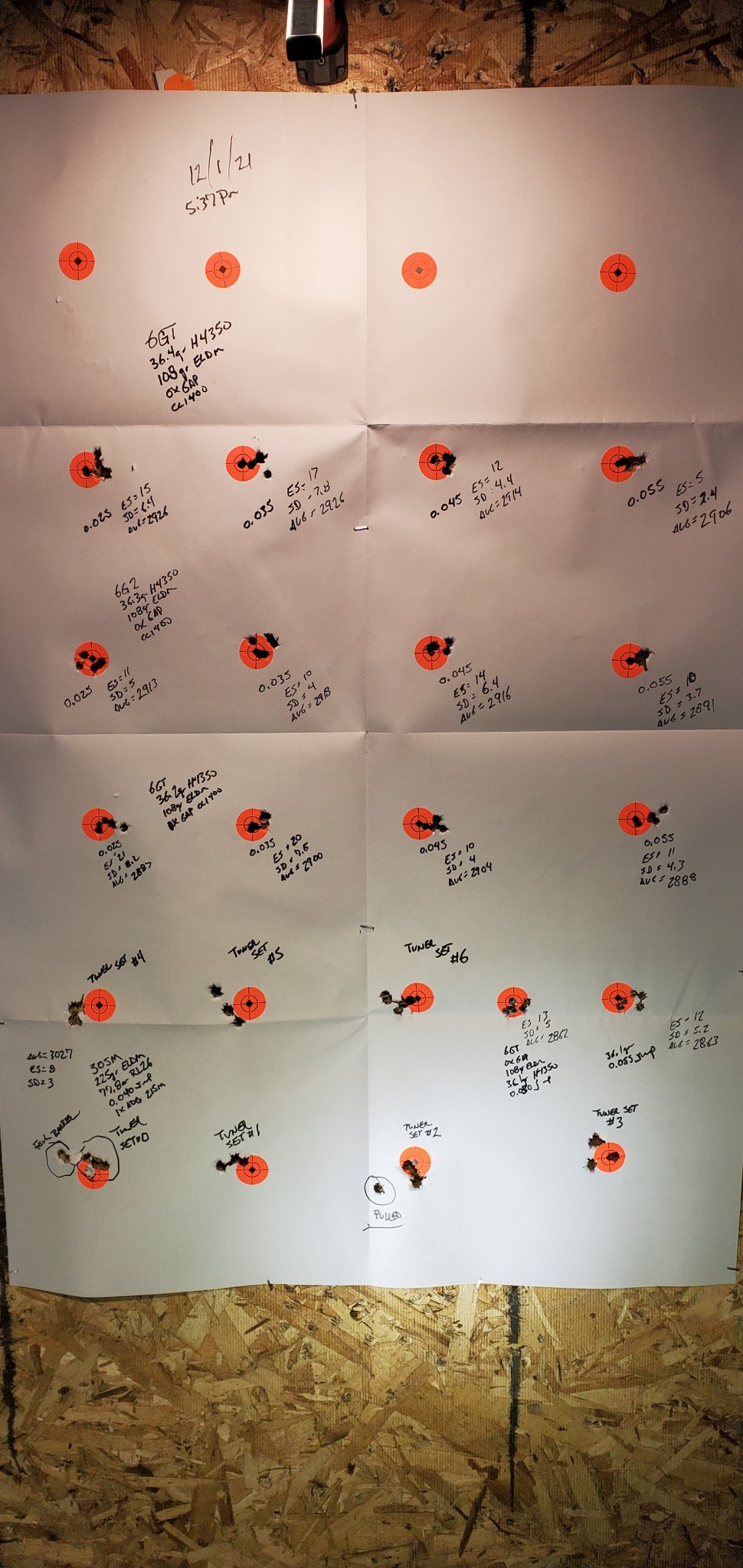

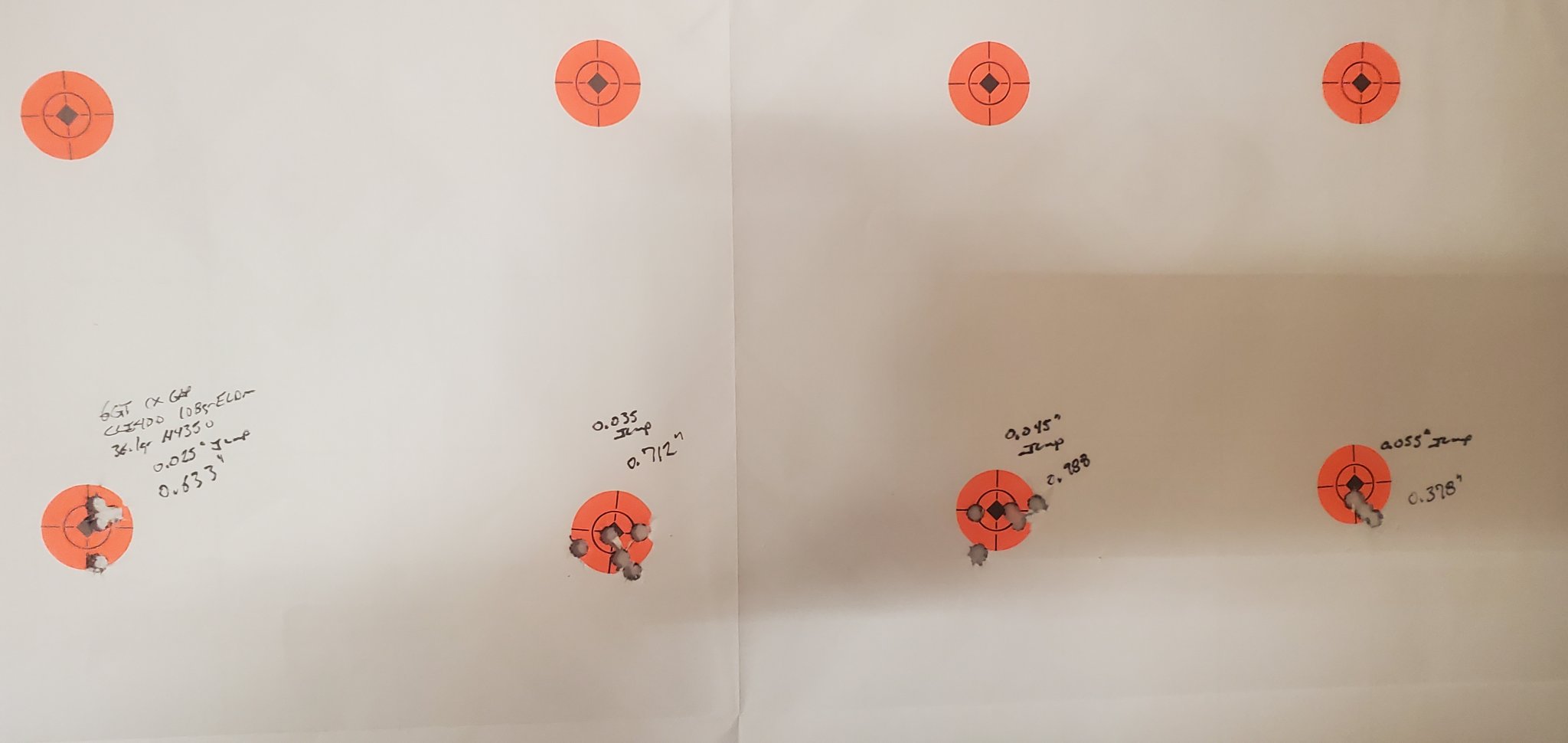

Ive been sick as hell this week and decided to get out and work on my 6GT and 30 Sherman Magnum loads. I seems like the 108gr eldm like around 0 050" of jump. Just did a range trip working on powder charges and seating depth test. Not my best day for accuracy but it still shows me where I need to be.

MPA PMR Pro 26" 7twist barrel

Strike Eagle 5-25 x 56

atlas cal bipod wiebad mini fortune cookie bag..

off barrel mounted v3 magnetospeed

0x Gap/Hornady brass

108gr Eldm

CCI400 SRP

36.1 to 36.4gr of H4350

Overall results seen in picture.

I shot the 36.1gr loads without a magnetospeed a couple days ago. I was shooting a little better. Still shows 0.055" jump to be ideal. See second picture.

I'm leaning towards the following load.

36.3gr H4350

108gr Eldm

Hornady brass

Cci400 srp

0.055" jump 1.935" cbto

Coal: 2.495"

Average speed: 2891fps

MPA PMR Pro 26" 7twist barrel

Strike Eagle 5-25 x 56

atlas cal bipod wiebad mini fortune cookie bag..

off barrel mounted v3 magnetospeed

0x Gap/Hornady brass

108gr Eldm

CCI400 SRP

36.1 to 36.4gr of H4350

Overall results seen in picture.

I shot the 36.1gr loads without a magnetospeed a couple days ago. I was shooting a little better. Still shows 0.055" jump to be ideal. See second picture.

I'm leaning towards the following load.

36.3gr H4350

108gr Eldm

Hornady brass

Cci400 srp

0.055" jump 1.935" cbto

Coal: 2.495"

Average speed: 2891fps

Last edited:

I've been through a couple hundred 108gr ELDs and 112gr MB, and can't seem to get my GT to reliably stay much under 0.6-0.7". That's a little disappointing since my 6.5 RPR put down several sub 0.4" groups when it was new, before I stopped load development and started the real shooting, and my CTR was similar... Oh well I think it's time to take the better performers, pump them out in volume and get to the fun part of shooting.

I've been through a couple hundred 108gr ELDs and 112gr MB, and can't seem to get my GT to reliably stay much under 0.6-0.7". That's a little disappointing since my 6.5 RPR put down several sub 0.4" groups when it was new, before I stopped load development and started the real shooting, and my CTR was similar... Oh well I think it's time to take the better performers, pump them out in volume and get to the fun part of shooting.

Specs on the rifle build?

Origin ActionSpecs on the rifle build?

MDT XRS chassis

TT Diamond

PVA Rock Creek button shouldered prefit 23"

Vortex Razor AMG in M10 rings

Certainly not suggesting it's a chamber related issue, and I probably should have gone more main line on the barrel, but the PVA was basically the only 6GT shouldered prefit I could get in a fairly short timeframe. Mostly tired of driving an hour and a half each way to the long range to load develop at 200-300 yds with the 1,200 yd range right next to me empty and calling lol. Figure I'll take a load it likes ok like 34.5gr Varget under 112gr 110 thou off and run it on out, if it is good enough for my casual purposes then I'll stick with that, if not, maybe it's new barrel time.

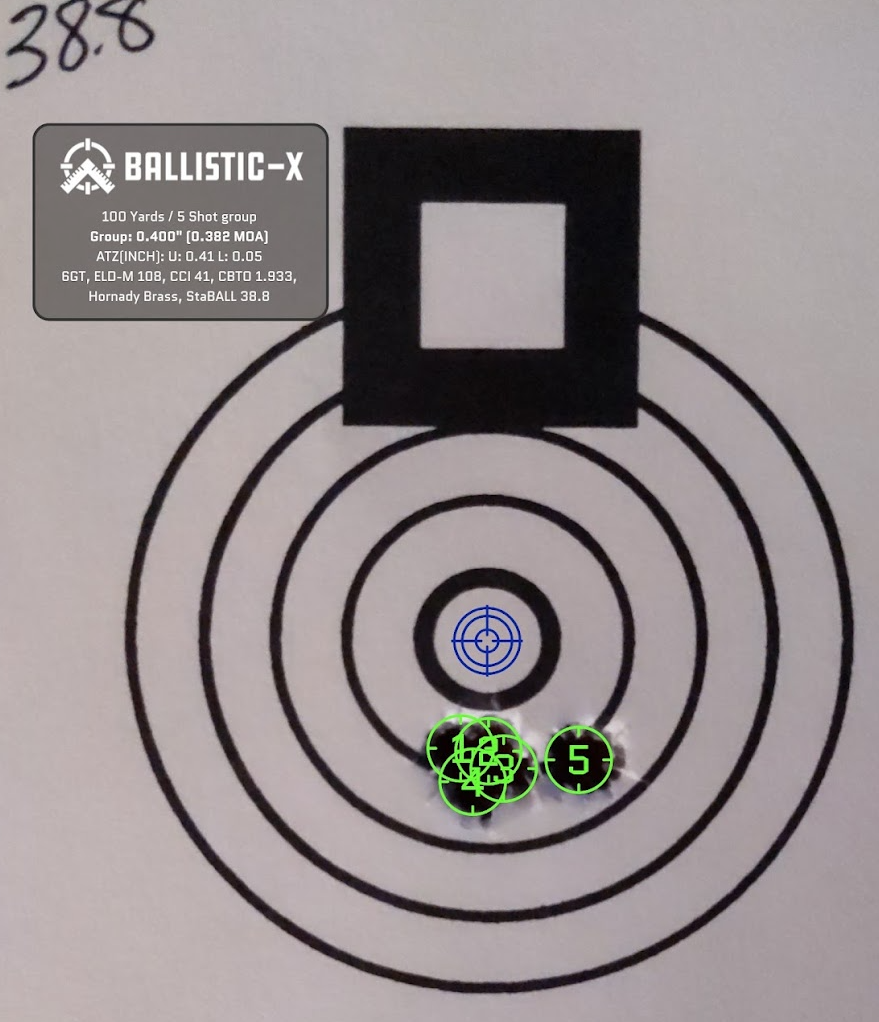

I've made it through a few sessions of finding the velocity nodes (Chrono issues) with the 108g ELD-M's, StaBALL, CCI41's, and Hornady brass. My next outing will be doing the seating depth tests and then repeat with the tuner brake.

I too am starting to wear out of my 60-75 min drive for my development. haha I sure wish I had something closer that had RSO to keep people from barrel sweeping me. EEECK!

I'll report back if I'm able to get consistent good groups with this combo.

I too am starting to wear out of my 60-75 min drive for my development. haha I sure wish I had something closer that had RSO to keep people from barrel sweeping me. EEECK!

I'll report back if I'm able to get consistent good groups with this combo.

Could

could just be the bullets. Berger 105 hybrids, 109 hybrids and Hornady 110 A-Tips all shot one hole groups for me.I've made it through a few sessions of finding the velocity nodes (Chrono issues) with the 108g ELD-M's, StaBALL, CCI41's, and Hornady brass. My next outing will be doing the seating depth tests and then repeat with the tuner brake.

I too am starting to wear out of my 60-75 min drive for my development. haha I sure wish I had something closer that had RSO to keep people from barrel sweeping me. EEECK!

I'll report back if I'm able to get consistent good groups with this combo.

Could be, I've been looking for Berger 105s and 109s and just haven't been able to find them.Could

could just be the bullets. Berger 105 hybrids, 109 hybrids and Hornady 110 A-Tips all shot one hole groups for me.

My barrel should be fully up to speed, and now that I'm done just looking at velocities (with peeking at some groups from time to time), I'm hoping I can focus on seeing how the ELD-M's can consistently group.

Here are a couple of examples that it can group decently with the ELD-M 108's, so I'm excited to see what it can do. If it can't do it, I'll move on to the SMK 107's and use these ELD-M's for my 6ARC. haha

Here are a couple of examples that it can group decently with the ELD-M 108's, so I'm excited to see what it can do. If it can't do it, I'll move on to the SMK 107's and use these ELD-M's for my 6ARC. haha

My barrel should be fully up to speed, and now that I'm done just looking at velocities (with peeking at some groups from time to time), I'm hoping I can focus on seeing how the ELD-M's can consistently group.

Here are a couple of examples that it can group decently with the ELD-M 108's, so I'm excited to see what it can do. If it can't do it, I'll move on to the SMK 107's and use these ELD-M's for my 6ARC. haha

View attachment 7758684 View attachment 7758686

Looks like you're good to go, can you give the details on your rig?

I never know if I just got lucky with the groups. haha But, it shot some Copper Creek ammo with the ELD-M's very well (see embedded image below), and it was with a brand-new barrel. In fact, I haven't been able to get my loads to match theirs, so there is hope I can squeeze it in some.Looks like you're good to go, can you give the details on your rig?

My rig is my first humble build:

- Savage 12 FV (pulled a never shot 6.5 CM barrel off)

- Savage Pre-fit Criterion Barrel - Stainless Steel, 1:7.5 Twist, MTU Contour, 26"

- EC Tuner Brake (Stainless Steel 6.5 version) - Have not used the tuning part yet, but IMO a great brake

- 20 MOA Rail

- Vortex Viper PST 6-24x50 EBR-1x (Gen 1)

- MDT XRS Chassis with added weight and forend accessories

This is the 5-shot group I got with the Copper Creek ELD-M 108's - with it being just the 14th-18th shot through the barrel... So, it is showing great potential.

You are correct. I have found the best accuracy around 2900-2920fps. Just verified my alpha ocd brass load today.You'll likely find best accuracy 2900-2920 or just up on the top side of 3k. That 3k velocity node may be warm/hot in your rifle with Hdy brass.

MPA 26" 7 twist barrel

1x Alpha OCD Brass

Cci400 srp

36.3gr H4350

108gr ELDM

CBTO 1.940" with 0.050" jump.

Average speeds around 2920fps so far.

Speeds are about 10 to 15fps slower than virgin brass loaded with the same amount of powder. I've only ran a handful of 1x brass and am liking the results. Both virgin and fired brass shoot fantastic.

Alpha Brass, 450s, Berger 109, 36.7gr H4350 right at 2940. Shoots .2-.3's. Bartlien 7.5 twist barrel @ 26".

That is with virgin brass.

Now to see how it shoots with annealed, neck bushing sized, mandreled and Henderson trimmed. I think it may even shoot better.

That is with virgin brass.

Now to see how it shoots with annealed, neck bushing sized, mandreled and Henderson trimmed. I think it may even shoot better.

Last edited:

I will be wrapping up my ELD-M/StaBALL (my quick throw) load today, and will move on to my accuracy/extreme low SD/ES load development.

Just due to availability, I will be using SMK 107's for this, but I'm going back and forth between H4350 and Varget. From what I've seen in this thread, both powders can produce very accurate results.

Is there a reason to use one over the other?

Just due to availability, I will be using SMK 107's for this, but I'm going back and forth between H4350 and Varget. From what I've seen in this thread, both powders can produce very accurate results.

Is there a reason to use one over the other?

H4350 needs more powder to achieve the same results, granted we are talking 3-4 grains but still it's there.I will be wrapping up my ELD-M/StaBALL (my quick throw) load today, and will move on to my accuracy/extreme low SD/ES load development.

Just due to availability, I will be using SMK 107's for this, but I'm going back and forth between H4350 and Varget. From what I've seen in this thread, both powders can produce very accurate results.

Is there a reason to use one over the other?

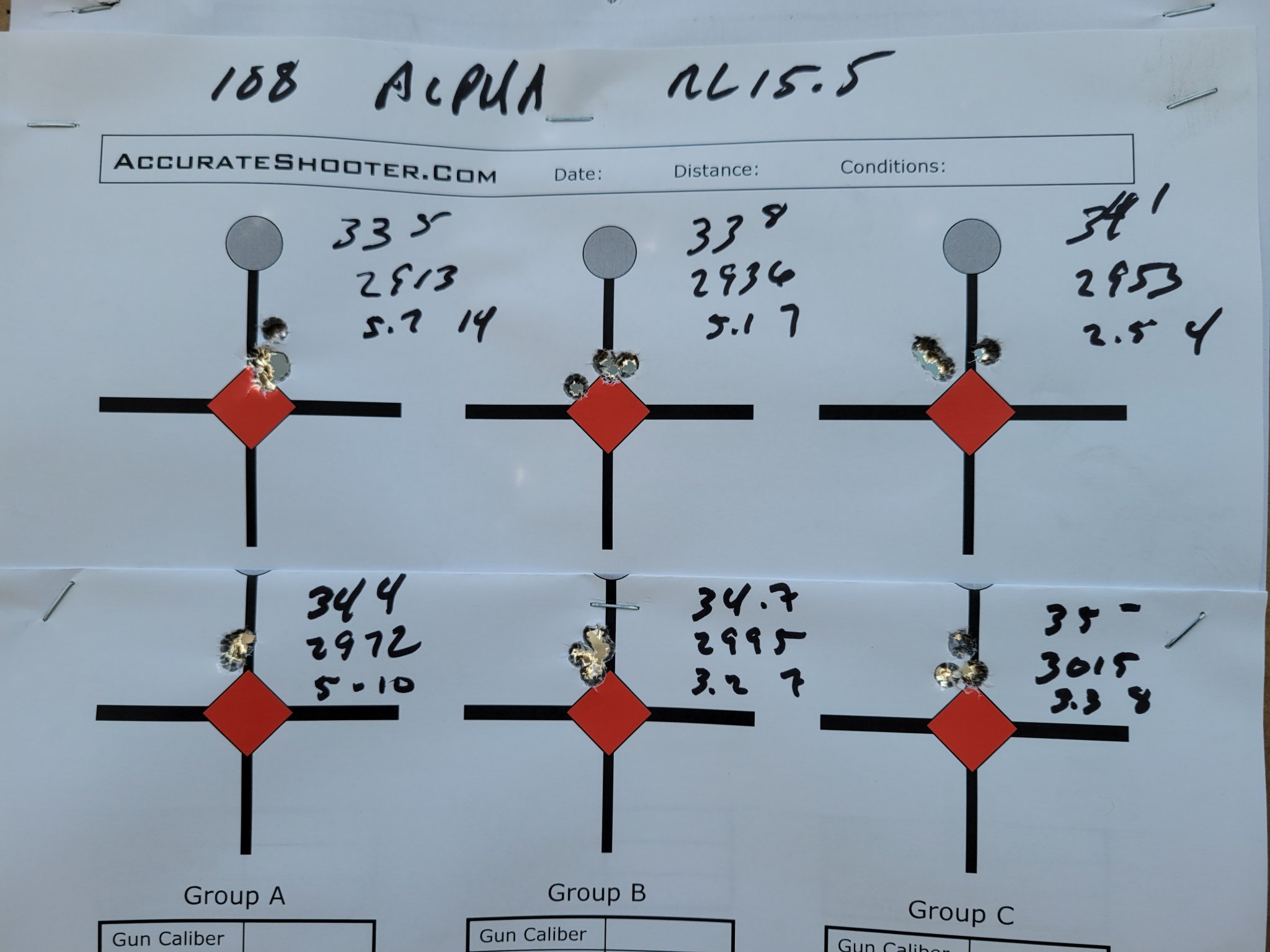

Outing with RL15.5 and 108 Berger BT target in virgin Alpha OCD brass.

Chambers / throat /lead ? Would all of you all guess to say that all of your GT chambers were all cut with reamers made from the same spec. sheet ? With the amount of lead time involved when ordering a new barrel, I'm planning to order one soon. If all the reamers are the same there won't be any hunting.

What I'm after is being able to load H 108 ELD M's so they touch the rifling's and have the gas ring / base of a full Cal. bullet at the neck/body junction.

I've asked a few sellers of prefit barrels ,and am waiting to hear back.

What I'm after is being able to load H 108 ELD M's so they touch the rifling's and have the gas ring / base of a full Cal. bullet at the neck/body junction.

I've asked a few sellers of prefit barrels ,and am waiting to hear back.

I bought mine through MPA. I'm going to be buying another barrel from them. Probably going to ask them to use the same reamer if possible. Damn thing just shoots. The weak spot in the system is me.Chambers / throat /lead ? Would all of you all guess to say that all of your GT chambers were all cut with reamers made from the same spec. sheet ? With the amount of lead time involved when ordering a new barrel, I'm planning to order one soon. If all the reamers are the same there won't be any hunting.

What I'm after is being able to load H 108 ELD M's so they touch the rifling's and have the gas ring / base of a full Cal. bullet at the neck/body junction.

I've asked a few sellers of prefit barrels ,and am waiting to hear back.

I recently wanted to see if I was wasting my time neck turning my brass. I ran 108gr eldm, alpha ocd brass, cci400 primers and 36.3gr H4350. CBTO 1.940 with 0.050" jump. I loaded 25 with neck turned brass and 25 with brass not neck turned. Needless to say I am now neck turning the last of my brass.

Neck turned brass had on average better ES by 5, better SD by 2 and shot better between 1/16-1/8 moa at 100 yards. Managed my best group yet while doing this test. Neck turned brass.

Neck turned brass had on average better ES by 5, better SD by 2 and shot better between 1/16-1/8 moa at 100 yards. Managed my best group yet while doing this test. Neck turned brass.

Chambers / throat /lead ? Would all of you all guess to say that all of your GT chambers were all cut with reamers made from the same spec. sheet ? With the amount of lead time involved when ordering a new barrel, I'm planning to order one soon. If all the reamers are the same there won't be any hunting.

What I'm after is being able to load H 108 ELD M's so they touch the rifling's and have the gas ring / base of a full Cal. bullet at the neck/body junction.

I've asked a few sellers of prefit barrels ,and am waiting to hear back.

My Reamer is a JGS.

My COAL when touching the lands with Hornady ELD-M 108gn is 2.550".

That puts the shank of the bullet .246 (85%) into the neck according to GRT.

My experience with the ELD-M's is that the Ogive is quite a bit forward compared to the Bergers so the OAL's are on average about .040" shorter.

Lapua ScenarL 105gn are even shorter. They are 2.530" when touching the lands which seats them .250" (87%) into the neck.

PTG reamer .120 freebore. I made a bunch of dummies to see where they sat and the 108 eldms were almost at neck shoulder junction at .030 jump, sit deep in case. I had more room with 105s and 108 BT targets. I am going to stick with 108 BT targets.

Just picked up my GAP PPR today.

Ive been able to get some 108 ELDm, have Hornady brass and plenty of primers. But powder I’m hurting on. I only have a pound each of varget and RL16 and not sure when I’ll be able to find more. So in looking at other possibilities, a local shop has a couple bottles of StaBall I could get and they have a ton of Superformance.

I havent seen anyone really talk about Superformance, though it is on the Hodgdon reload data. I’d like to start with something I can have plenty of so I can find something that works and just shoot awhile without worrying if I’ll be able to find more of the same powder.

Anyone using Superformance? Should I grab a couple pounds of StaBall or just break in the gun with the RL16 or Varget and then use the other for a load and hope I can get more before long?

Any advice appreciated.

Ive been able to get some 108 ELDm, have Hornady brass and plenty of primers. But powder I’m hurting on. I only have a pound each of varget and RL16 and not sure when I’ll be able to find more. So in looking at other possibilities, a local shop has a couple bottles of StaBall I could get and they have a ton of Superformance.

I havent seen anyone really talk about Superformance, though it is on the Hodgdon reload data. I’d like to start with something I can have plenty of so I can find something that works and just shoot awhile without worrying if I’ll be able to find more of the same powder.

Anyone using Superformance? Should I grab a couple pounds of StaBall or just break in the gun with the RL16 or Varget and then use the other for a load and hope I can get more before long?

Any advice appreciated.

I'm running superformance in my 6.5cm to save my H4350 for my 6GT. Superformance did okay but I struggled to get my extreme spreads where I like so . As far as staball, it's supposed to work well. I picked up a lb to try but haven't yet.Just picked up my GAP PPR today.

Ive been able to get some 108 ELDm, have Hornady brass and plenty of primers. But powder I’m hurting on. I only have a pound each of varget and RL16 and not sure when I’ll be able to find more. So in looking at other possibilities, a local shop has a couple bottles of StaBall I could get and they have a ton of Superformance.

I havent seen anyone really talk about Superformance, though it is on the Hodgdon reload data. I’d like to start with something I can have plenty of so I can find something that works and just shoot awhile without worrying if I’ll be able to find more of the same powder.

Anyone using Superformance? Should I grab a couple pounds of StaBall or just break in the gun with the RL16 or Varget and then use the other for a load and hope I can get more before long?

Any advice appreciated.

Superformance working well in 6.5?

I didn’t mention above, I do have a few pounds of H4350, but use that for 6.5 so didn’t really want to use it. But I guess if Superformance works better in 6.5, I could buy that and change that load and use the H4350 for the GT.

Thanks for the feedback.

I didn’t mention above, I do have a few pounds of H4350, but use that for 6.5 so didn’t really want to use it. But I guess if Superformance works better in 6.5, I could buy that and change that load and use the H4350 for the GT.

Thanks for the feedback.

I was running 140gr hornady match bthp, hornady brass, 210m primers and 44.9gr superformance. Shooting around 1/2 moa with a Bergara HMR B14 Wilderness.Superformance working well in 6.5?

I didn’t mention above, I do have a few pounds of H4350, but use that for 6.5 so didn’t really want to use it. But I guess if Superformance works better in 6.5, I could buy that and change that load and use the H4350 for the GT.

Thanks for the feedback.

Avg: 2770fps

ES:15

SD: 7

Congratulations, I have had mine for one year next month. I used Varget 42.3 that I liked but ran out. So, I switched to StayBall 6.5 that is recommended by Gardner. I load. 38.5 with either 105 Bergers. They told me that the same load will work for their 109, but work up the load.Just picked up my GAP PPR today.

Ive been able to get some 108 ELDm, have Hornady brass and plenty of primers. But powder I’m hurting on. I only have a pound each of varget and RL16 and not sure when I’ll be able to find more. So in looking at other possibilities, a local shop has a couple bottles of StaBall I could get and they have a ton of Superformance.

I havent seen anyone really talk about Superformance, though it is on the Hodgdon reload data. I’d like to start with something I can have plenty of so I can find something that works and just shoot awhile without worrying if I’ll be able to find more of the same powder.

Anyone using Superformance? Should I grab a couple pounds of StaBall or just break in the gun with the RL16 or Varget and then use the other for a load and hope I can get more before long?

Any advice appreciated.

Can you find IMR 4166 or 4451, SW Precision, SW 4350 or Long rifle?Just picked up my GAP PPR today.

Ive been able to get some 108 ELDm, have Hornady brass and plenty of primers. But powder I’m hurting on. I only have a pound each of varget and RL16 and not sure when I’ll be able to find more. So in looking at other possibilities, a local shop has a couple bottles of StaBall I could get and they have a ton of Superformance.

I havent seen anyone really talk about Superformance, though it is on the Hodgdon reload data. I’d like to start with something I can have plenty of so I can find something that works and just shoot awhile without worrying if I’ll be able to find more of the same powder.

Anyone using Superformance? Should I grab a couple pounds of StaBall or just break in the gun with the RL16 or Varget and then use the other for a load and hope I can get more before long?

Any advice appreciated.

I’m on the lookout for all those powders, but right now online there is nothing out there unless you get lucky.

The local shop (still 40 min away) only has those I mentioned and IMR4895. They have other random stuff and pistol powder, but those are the only rifle ones that might work.

I may just grab a couple lbs of the StaBall, that will at least get me going for a few hundred rounds and I can keep an eye out for other powders to come along.

The local shop (still 40 min away) only has those I mentioned and IMR4895. They have other random stuff and pistol powder, but those are the only rifle ones that might work.

I may just grab a couple lbs of the StaBall, that will at least get me going for a few hundred rounds and I can keep an eye out for other powders to come along.

Has anybody tried Alliant Reloder 17? Its right next to H4350 on my burn rate chart.

I happen to have 8 lbs of the stuff, but can't find data on it for the 6GT anywhere.

I happen to have 8 lbs of the stuff, but can't find data on it for the 6GT anywhere.

I dont have any first hand experience using reloader 17. But here is some data using Gordons Loader tool. Hope it helps. And obviously start low and work your way up.Has anybody tried Alliant Reloder 17? Its right next to H4350 on my burn rate chart.

I happen to have 8 lbs of the stuff, but can't find data on it for the 6GT anywhere.

Attachments

Thanks . I just ordered an upgrade for my old Windows 7 version of Quick-Load and will check this out when it arrives (30 days). I think RL17 is kind of a long shot idea, but I'm going to check it out since my stock of Varget is gone and H4350 likely to be gone around mid-summer.

I am just about out of 105 hybrids and can’t find any. I can get regular Berger 105 target. Has anyone had success transitioning these?

I’ll have to give one of those a shot. Thanks.I run the Berger 108 BT Target. Easy to tune and very good bullet. I would assume the 105s would be the same. Tangent ogive like Sierra match kings.

Precision Reloading had both in stock a couple of days ago. I got some 108s. Works well with .120 freebore.

Perfect. Pretty soon we’ll have to start casting our own.Precision Reloading had both in stock a couple of days ago. I got some 108s. Works well with .120 freebore.

that is a nice rifle!

thats said my suggestion would be to stop shooting load development and or shooting groups to verify a load at 200 and 300yds because the smallest movement on your part becomes a huge disappointment on target...i know because ive been here myself.

i would take your 38.5g load and run a seating test starting at .010 off the lands or as close as your mag will allow you to....load 3 rounds each...personally id load 4 each just in case you call a pulled shot... jumping .010 at a time to about .100 off if the case allows you to without crushing powder...so .010 off .020 off .030 off ECT until your at .100 off WITHOUT changing anything else.

you see when you start changing multiple things at once your going to have a hard time figuring out what the problem is so one thing at a time.

i picked the 38.5g load because your 3/10s of a grain on either side and the velocity does not change much so id say thats a pretty stable load and at this point your just trying to figure out if bullets are the problem nothing else.

bring your targets in to 100yds...if a load shoots at 100yds 99% of the time its going to shoot good all the way out...ive only had 1 time a load shot at 100yds and not good at distance...this will also help eliminate shooter error to a point.

once you find a good load at 100yds shoot it at 200 or 300yds if you like to check the load...do not take this wrong but looking at your groups at 300yds im going to guess you are most of the problem not the gun or bullets...again do not take that wrong im just being honest with what i see on paper...the ONLY decent group i see is the 39.5g load at .060 off the lands but yet i see 1 round approximately 2" or so off to the right.

Well when you're right, your right, it looks like my biggest problem with my rifle and loads was.... My crappy bipod technique.

Went back to front bags yesterday and only shot at 100yds since I was at the long range and there are no 200-300 berms there.

Might work on the Varget load a little more, I was running out of ammo towards the end but it showed some promise further out.

Back on the bipod, but here were the last two 39.5 StaBall loads, and three 34.5 Varget loads at 1,000.

I also tried 37gr RL16 25 off and it had some horizontal, but pretty narrow vertically and looked like it wanted to group, so I might try it 60 off and see how that goes. Other than that, it's time to load up a bunch with 39.5 of StaBall and get more practice in.

Exactly my load forAlpha Brass, 450s, Berger 109, 36.7gr H4350 right at 2940. Shoots .2-.3's. Bartlien 7.5 twist barrel @ 26".

That is with virgin brass.

Now to see how it shoots with annealed, neck bushing sized, mandreled and Henderson trimmed. I think it may even shoot better.

My benchmark barrel. 2000 through. Starting my new 5R barrel spun by GA. Hope it shoots 108elds as good. Can’t find 109’s

Similar threads

- Replies

- 7

- Views

- 852

- Replies

- 19

- Views

- 989