Should be easy. I’m getting 2875 w/a 27”25x47 using the 135 LRHT.Hoping to see 2800-2900 fps

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

7mm SAW

- Thread starter Temper

- Start date

I ordered a TBAC Ultra 7 from Capital Armory. Thanks for your recommendation.I have a Harvester 300 that I sent back twice for "baffle failures". It worked flawlessly for approximately 2,000 rounds on a 22" 7-08, a 21.5" .243., and a 22" .280 Ackley. I then put it on an 18" 6.5x47 and started to run into trouble. Both times, the baffle closest to the crown broke/failed. The first time it happened was after about 500 rounds from the 6.5x47. The second time was after a few hundred on the same rifle, fresh from the "re-core". I was pretty anal about not letting it get too hot, cooling down, and only shooting 3 shot strings, but the same exact failure happened again. (Note: these were perfectly safe loads. Primers looked good, no ejector swipe, no heavy bolt lift, brass life was great, etc.) Silencerco fixed it both times in less than a week no questions asked, but I decided that the harvester just doesn't mix well with shorter barrels when paired with rounds that tend to run at higher pressures (SRP like the 6.5x47, 7 saw, etc.).

I still have the harvester, but it is dedicated to my longer/standard barreled rigs. I fixed my short barrel suppressor problem by buying a TBAC Ultra 7. Three years later, running the same short barrel "loads", the TBAC has been stellar and worth every penny.

Anyone care to share their data using Varget for 22” barrels? I’m currently running 42 grains of Varget (22” cf proof) and getting about 2727 which seems slow compared to what I have been seeing from similar setups, but I am getting significant primer flow on some rounds and ejector swipes on some as well. I have some h4350 I could try as well, but it seems 4350 is generally slower than Varget. After my initial barrel speed up last year I had written down that I was getting about 2800 (my target velocity) with the same load of Varget, but I’m wondering if I wrote it down wrong

Im at 42 Sw Precision getting 2700 fps 60 degrees at with my 24" barrel. New barrel and hasnt had 20 rounds down the barrel.Anyone care to share their data using Varget for 22” barrels? I’m currently running 42 grains of Varget (22” cf proof) and getting about 2727 which seems slow compared to what I have been seeing from similar setups, but I am getting significant primer flow on some rounds and ejector swipes on some as well. I have some h4350 I could try as well, but it seems 4350 is generally slower than Varget. After my initial barrel speed up last year I had written down that I was getting about 2800 (my target velocity) with the same load of Varget, but I’m wondering if I wrote it down wrong

22” proof carbon / virgin brass @ 2760fps. Started getting a slight sticky bolt past 43gr. Barrel isn’t broken in yet.Anyone care to share their data using Varget for 22” barrels? I’m currently running 42 grains of Varget (22” cf proof) and getting about 2727 which seems slow compared to what I have been seeing from similar setups, but I am getting significant primer flow on some rounds and ejector swipes on some as well. I have some h4350 I could try as well, but it seems 4350 is generally slower than Varget. After my initial barrel speed up last year I had written down that I was getting about 2800 (my target velocity) with the same load of Varget, but I’m wondering if I wrote it down wrong

Attachments

https://www.longrangehunting.com/threads/7-saw-barrel-for-impact.347614/

In case someone needs a barrel.

25 SAW barrel is in production at Preffered barrel blanks.

Getting a Foundation Revelation made for this new setup.

In case someone needs a barrel.

25 SAW barrel is in production at Preffered barrel blanks.

Getting a Foundation Revelation made for this new setup.

Had a lesson in reloading today.

Back in the summer I started load development. Worked up in .5 increments to find pressure signs. At 42.5 gr of IMR 4166 I found ejector swipes, nothing at 42.0, so I decided 42.0 was max. Have been working up from 41.5 to 42.0 to find a consistent charge and the last range trip I was playing with different seating depths at 41.8 and 41.9.

Loading up another 50 rounds tonight and more than half of them had loose primer pockets. Zero friction when seating primers. I take a look at the case and they had ejector swipes on them. Some of them with 2. There's been no heavy bolt lift or anything that would indicate high pressure otherwise. It's been close to 0⁰ C the last 2 times I've gone also, so I didn't think it would be necessary to look at the case head without a heavy bolt lift in colder weather. I'm pretty annoyed as the case of brass has 3 firings on them at the most.

Back in the summer I started load development. Worked up in .5 increments to find pressure signs. At 42.5 gr of IMR 4166 I found ejector swipes, nothing at 42.0, so I decided 42.0 was max. Have been working up from 41.5 to 42.0 to find a consistent charge and the last range trip I was playing with different seating depths at 41.8 and 41.9.

Loading up another 50 rounds tonight and more than half of them had loose primer pockets. Zero friction when seating primers. I take a look at the case and they had ejector swipes on them. Some of them with 2. There's been no heavy bolt lift or anything that would indicate high pressure otherwise. It's been close to 0⁰ C the last 2 times I've gone also, so I didn't think it would be necessary to look at the case head without a heavy bolt lift in colder weather. I'm pretty annoyed as the case of brass has 3 firings on them at the most.

Just a follow up on my last post.

What I thought was ejector marks on the brass is actually from the slot in the bolt face for the mechanical ejector. The case head has been flattened a bit, except for a small part where the slot in the bolt face is cut out. See below picture at 3 o'clock and 9 o'clock for the left and right case respectively.

The case on the left was fired at 41.8 grs IMR 4166 and is part of the batch that had loose primer pockets. The case on the right was virgin, once fired at time of this photo, at 41.5 grs. 41.5 grs also produced some good groups, with the 2 best here:

I want to load up more to shoot some 5 shot groups to confirm, but I'm wondering if I'm over pressure at this load or if it's a brass issue? I know there's been issues with non OCD brass in other cartridges. Velocity was about 2770 for both groups. I shot some more today at 41.2 and 41.3 grs but groups opened up. I'd hate to keep dropping the charge weight if I didn't need to.

What I thought was ejector marks on the brass is actually from the slot in the bolt face for the mechanical ejector. The case head has been flattened a bit, except for a small part where the slot in the bolt face is cut out. See below picture at 3 o'clock and 9 o'clock for the left and right case respectively.

The case on the left was fired at 41.8 grs IMR 4166 and is part of the batch that had loose primer pockets. The case on the right was virgin, once fired at time of this photo, at 41.5 grs. 41.5 grs also produced some good groups, with the 2 best here:

I want to load up more to shoot some 5 shot groups to confirm, but I'm wondering if I'm over pressure at this load or if it's a brass issue? I know there's been issues with non OCD brass in other cartridges. Velocity was about 2770 for both groups. I shot some more today at 41.2 and 41.3 grs but groups opened up. I'd hate to keep dropping the charge weight if I didn't need to.

What i normally do. Just checking my optionsuse a piece of brass and scotch tape?

I’m thinking about punching-out my Ridgeline FFT 7mm-08 chamber to 7 SAW… Or getting an Origin prefit made so I can switch barrels on my Solus between .25 CM & 7 SAW…

Im running 7mm saw and 25 saw. 25 saw is being put together as soon as my hawkins bm comes in. Both barrels came from Preferred Barrel BlanksI’m thinking about punching-out my Ridgeline FFT 7mm-08 chamber to 7 SAW… Or getting an Origin prefit made so I can switch barrels on my Solus between .25 CM & 7 SAW…

I did the 708AI thing last year...it was quite the learning experience.

308 Lapua brass sized to 708 for fireforming

708 fireformed brass to 708AI created a donut in the case neck

Had to neck turn the .016 thick case necks to .013 for enough case neck chamber clearance, and to flush out the donut.

I found no donuts formed in the step down from 308 to 708, just when 708 fireformed, so a 7 SAW is appealing.

Just as a comparison:

26" 708AI velocities W760, RL17, H100V with 162ELDM COAL 2.880, MV: 2820s, 24" same components MV: 2760s. (Teetering on pressure, but allowing more than 5 loads per brass)

Anybody able to post a 7 SAW I and II reamer print?

308 Lapua brass sized to 708 for fireforming

708 fireformed brass to 708AI created a donut in the case neck

Had to neck turn the .016 thick case necks to .013 for enough case neck chamber clearance, and to flush out the donut.

I found no donuts formed in the step down from 308 to 708, just when 708 fireformed, so a 7 SAW is appealing.

Just as a comparison:

26" 708AI velocities W760, RL17, H100V with 162ELDM COAL 2.880, MV: 2820s, 24" same components MV: 2760s. (Teetering on pressure, but allowing more than 5 loads per brass)

Anybody able to post a 7 SAW I and II reamer print?

https://westtexordnance.com/7mm-saw/I did the 708AI thing last year...it was quite the learning experience.

308 Lapua brass sized to 708 for fireforming

708 fireformed brass to 708AI created a donut in the case neck

Had to neck turn the .016 thick case necks to .013 for enough case neck chamber clearance, and to flush out the donut.

I found no donuts formed in the step down from 308 to 708, just when 708 fireformed, so a 7 SAW is appealing.

Just as a comparison:

26" 708AI velocities W760, RL17, H100V with 162ELDM COAL 2.880, MV: 2820s, 24" same components MV: 2760s. (Teetering on pressure, but allowing more than 5 loads per brass)

Anybody able to post a 7 SAW I and II reamer print?

Read through all of that, just didn't see reamer prints.

Here is my 708AI print for example:

Last edited:

I get 2760 FPS out of my 162 ELD-M at 2.935” coalI did the 708AI thing last year...it was quite the learning experience.

308 Lapua brass sized to 708 for fireforming

708 fireformed brass to 708AI created a donut in the case neck

Had to neck turn the .016 thick case necks to .013 for enough case neck chamber clearance, and to flush out the donut.

I found no donuts formed in the step down from 308 to 708, just when 708 fireformed, so a 7 SAW is appealing.

Just as a comparison:

26" 708AI velocities W760, RL17, H100V with 162ELDM COAL 2.880, MV: 2820s, 24" same components MV: 2760s. (Teetering on pressure, but allowing more than 5 loads per brass)

Anybody able to post a 7 SAW I and II reamer print?

23in Bartlein

Type 2 reamer

42.3gr varget

RL17 gave me 2800 FPS but I couldn’t get the accuracy of varget, it’s also not temp stable

My main hunting load is 145 LRX at 2.875 (to accommodate the Hawkins flush magazine) - also the LRX likes the jump

Just waiting on my Hawkins bottom metal for my 25 SAW build. Will be loading H4831SC with 134 eldm.

Have any of you guys tried Hammer bullets? I just got some in HHT in 145 grs that I'm going to test.

Yup. Lethal AF. I’d recommend the 132 HHT or the 145 you stated.Have any of you guys tried Hammer bullets? I just got some in HHT in 145 grs that I'm going to test.

Has anyone had issues with not being able to seat at the full "mag length" in a type 2 chamber? Have noticed a few others had some short findings caused by carbon rings. I looked with a scope and did find a nice little carbon ring. Cleaned it up and gained another 40-50 thou of seating but can still only seat 162 ELD at about 2.880, pretty heavy rifling marks when chambering at 2.900+ and hard to eject live round if attempted.

Do you know the jump then when seated 2.880?Has anyone had issues with not being able to seat at the full "mag length" in a type 2 chamber? Have noticed a few others had some short findings caused by carbon rings. I looked with a scope and did find a nice little carbon ring. Cleaned it up and gained another 40-50 thou of seating but can still only seat 162 ELD at about 2.880, pretty heavy rifling marks when chambering at 2.900+ and hard to eject live round if attempted.

Maybe i misread my measurments. With modified case and oal gauge bullet gets stuck in rifling at 3.10xx so i shouldnt have any contact when seated at the mag length or 10 to 15 thou under mag length, perhaps still had some remaining build up at beginning of rifled when measuring previously.Do you know the jump then when seated 2.880

OK, because I load my 708 and 708AI at 2.880 and it's the perfect jump. IIRC .030ish.

That would make the freebore on that SAW 2 reamer close to my 708AI reamer.

That would make the freebore on that SAW 2 reamer close to my 708AI reamer.

Saw2 is .150OK, because I load my 708 and 708AI at 2.880 and it's the perfect jump. IIRC .030ish.

That would make the freebore on that SAW 2 reamer close to my 708AI reamer.

Could you help me understand what the throat dimensions in this mean?What I was sent from WTO:

View attachment 8342760

Coming out of the case area I see a .2845" dimension, I believe that's the .161" Freebore. Then a 1.5 degree lead into a .2802 section, then another 1.5 degree lead. Is this saying that it has what might be called a +P throat, or is the first 1.5 degree angle the Leade, and the farther 1.5 degree cut just a feature for the reamer?

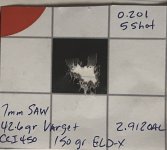

Stupid question. What headspace comparator is everyone using. For my 15 saw, Im sizing brass down in two steps. 289 281 then 257 expander ball. I fired a few shots with 42gr of shooters world long rifle. And getting this with 134gr eldm at 2875 fps at 55 degrees. I triple checked my headspace. Its all good. I will load a few at 40gr and see what happens. Definitely still have some case capacity left.

I use the hornady comparator set. Using the 375 on saw brass.Stupid question. What headspace comparator is everyone using. For my 15 saw, Im sizing brass down in two steps. 289 281 then 257 expander ball. I fired a few shots with 42gr of shooters world long rifle. And getting this with 134gr eldm at 2875 fps at 55 degrees. I triple checked my headspace. Its all good. I will load a few at 40gr and see what happens. Definitely still have some case capacity left.View attachment 8350115

I was using the 400. Let me see if that makes a difference.I use the hornady comparator set. Using the 375 on saw brass.

Yeah, that is some reamer specific measurements since they go smaller than bore diameter.Could you help me understand what the throat dimensions in this mean?

Coming out of the case area I see a .2845" dimension, I believe that's the .161" Freebore. Then a 1.5 degree lead into a .2802 section, then another 1.5 degree lead. Is this saying that it has what might be called a +P throat, or is the first 1.5 degree angle the Leade, and the farther 1.5 degree cut just a feature for the reamer?

Getting ready for spring bear season. Still have a box of 166 ATIPs so I’ll work up a load similar to the 162 ELD-M

Right now I’m doing 45.3 H4350 at 2.945” and it shot decent (was hitting the 4in plate at 500m with ease) but the speed was only 2670 FPS. My varget with 162 Eld-m was getting me 2750 FPS

Can’t find N550 anywhere so I’ll try 42.0 for varget and 45.9 H4350. As long as I can get over 2700 FPS I’ll be happy.

Also put a Leica 2.5-15x56 since they were 40% off over the holidays and will probably drop my 22in anTI Bartlein 3B into a HNT26 and should be around 8lbs with Hawkins direct mount.

Right now I’m doing 45.3 H4350 at 2.945” and it shot decent (was hitting the 4in plate at 500m with ease) but the speed was only 2670 FPS. My varget with 162 Eld-m was getting me 2750 FPS

Can’t find N550 anywhere so I’ll try 42.0 for varget and 45.9 H4350. As long as I can get over 2700 FPS I’ll be happy.

Also put a Leica 2.5-15x56 since they were 40% off over the holidays and will probably drop my 22in anTI Bartlein 3B into a HNT26 and should be around 8lbs with Hawkins direct mount.

Have you tried Winchester StaBall 6.5? It jumped my standard 7mm-08 over 200 FPS MV with the Berger 175 Elite Hunters in a 20" barrel. I was pretty impressed. Groups also stayed pretty much the same size (1/4-1/3 MOA).Getting ready for spring bear season. Still have a box of 166 ATIPs so I’ll work up a load similar to the 162 ELD-M

Right now I’m doing 45.3 H4350 at 2.945” and it shot decent (was hitting the 4in plate at 500m with ease) but the speed was only 2670 FPS. My varget with 162 Eld-m was getting me 2750 FPS

Can’t find N550 anywhere so I’ll try 42.0 for varget and 45.9 H4350. As long as I can get over 2700 FPS I’ll be happy.

Also put a Leica 2.5-15x56 since they were 40% off over the holidays and will probably drop my 22in anTI Bartlein 3B into a HNT26 and should be around 8lbs with Hawkins direct mount.

I actually have an unopened 8lbs jug of the stuff next to some old stash of RL17.Have you tried Winchester StaBall 6.5? It jumped my standard 7mm-08 over 200 FPS MV with the Berger 175 Elite Hunters in a 20" barrel. I was pretty impressed. Groups also stayed pretty much the same size (1/4-1/3 MOA).

I might give it a try but I thought it wasn’t temp stable unlike the Hogdon line of varget / 4350 / 4831 and the VV N5xx line.

Also seems like QL numbers for velocity for Staball are under estimated.

50gr of Staball would give me 100% Case fill, 100% burn but only 2685 FPS for 60K PSI which is roughly was QL gives me for 42.3 varget. Should be probably in the 2775 - 2800 range with Staball.

I might load a few 162 ELD-M at 49->50.0

50gr of Staball would give me 100% Case fill, 100% burn but only 2685 FPS for 60K PSI which is roughly was QL gives me for 42.3 varget. Should be probably in the 2775 - 2800 range with Staball.

I might load a few 162 ELD-M at 49->50.0

what's your barrel length?Getting ready for spring bear season. Still have a box of 166 ATIPs so I’ll work up a load similar to the 162 ELD-M

Right now I’m doing 45.3 H4350 at 2.945” and it shot decent (was hitting the 4in plate at 500m with ease) but the speed was only 2670 FPS. My varget with 162 Eld-m was getting me 2750 FPS

Can’t find N550 anywhere so I’ll try 42.0 for varget and 45.9 H4350. As long as I can get over 2700 FPS I’ll be happy.

Also put a Leica 2.5-15x56 since they were 40% off over the holidays and will probably drop my 22in anTI Bartlein 3B into a HNT26 and should be around 8lbs with Hawkins direct mount.

my 2840fps loads from a 27" are 42.4 varget and 45.5 H4350. same COAL.

getting more H4350 was very tough. like electric toothbrush vibrating tough

22inwhat's your barrel length?

my 2840fps loads from a 27" are 42.4 varget and 45.5 H4350. same COAL.

getting more H4350 was very tough. like electric toothbrush vibrating tough

Thats what I thought just making sure I read it right. Is say your speeds are pretty in line considering a 5" difference 100-125fps22in

I think maybe by having a shorter barrel that’s probably why H4530 isn’t getting me the speed since I can’t get 100% burn compared to faster powders like Varget.Thats what I thought just making sure I read it right. Is say your speeds are pretty in line considering a 5" difference 100-125fps

I’m curious about trying Staball, RL17 gave me crazy speeds with no pressure but wasn’t temp stable enough.

I'm shooting 41.6 grain Varget and getting 2700 fps with ES of 4.

This is with 180 ELDM and 28" barrel

This is with 180 ELDM and 28" barrel

After having a few issues with my barrels and brass. I reached out to Preferred Barrel Blanks. Theey asked me to send them the barrels and a few pieces of my converted brass to them. After a few days they got back to me and stated the issues they found. They suggested i bump my neck 10 thou deeper with my bushing die. Well today i screwed my barrel on. Used the 7mm saw headspace gauges i rented from WTO. Tried a piece of my convert brass and the bolt wouldnt close. Ran one piece in my die set a little tighter and now my brass fits as should.

LESSON LEARNED TODAY. Just because you can set headspace with brass and a piece of tape on the back doesnt mean it works 100% of the time. This is the one time it bit me

LESSON LEARNED TODAY. Just because you can set headspace with brass and a piece of tape on the back doesnt mean it works 100% of the time. This is the one time it bit me

Attachments

FYI, 708AI - W760, H100V, RL17 give 2800fps 28” barrel 162ELDM. RL17 1.5gr less than other two.

SAW so similar I bet same performance

SAW so similar I bet same performance

Holy smokes, Staball 6.5 is a screamer in this caliber.

I went 49.5gr with the 162 ELD-M at 2.945 and got 2855 FPS 6.5 SD 20 ES oven 10 shots

I also did 49.0gr with the 166 ATIP at 2.945. Roughly same SD, decent accuracy for a lightweight gun (honest 3/4 moa 5 round group). Gives me 2810 FPS which is good enough for a 500m max hunting setup. No signs of pressure but it was a pretty cold day.

This is almost 7 SAUM speed. Out of my 31in Saum I get 3050 FPS with H4831sc, if I were to cut it down to 22in I’d probably be in the high 2800s or low 2900s.

That’s an incredibly efficient case/powder.

It also was quite temp stable since it was quite cold today and there was no POI shift when the chamber got hot.

I also tried to bump H4350 to its max at 46gr and while I was getting very good accuracy and even smaller SDs, I couldn’t get it faster than 2680 FPS. It’s a .4 mil difference at 500m and quite a bit more energy.

I went 49.5gr with the 162 ELD-M at 2.945 and got 2855 FPS 6.5 SD 20 ES oven 10 shots

I also did 49.0gr with the 166 ATIP at 2.945. Roughly same SD, decent accuracy for a lightweight gun (honest 3/4 moa 5 round group). Gives me 2810 FPS which is good enough for a 500m max hunting setup. No signs of pressure but it was a pretty cold day.

This is almost 7 SAUM speed. Out of my 31in Saum I get 3050 FPS with H4831sc, if I were to cut it down to 22in I’d probably be in the high 2800s or low 2900s.

That’s an incredibly efficient case/powder.

It also was quite temp stable since it was quite cold today and there was no POI shift when the chamber got hot.

I also tried to bump H4350 to its max at 46gr and while I was getting very good accuracy and even smaller SDs, I couldn’t get it faster than 2680 FPS. It’s a .4 mil difference at 500m and quite a bit more energy.

You were absolutely right.Have you tried Winchester StaBall 6.5? It jumped my standard 7mm-08 over 200 FPS MV with the Berger 175 Elite Hunters in a 20" barrel. I was pretty impressed. Groups also stayed pretty much the same size (1/4-1/3 MOA).

Well... I guess "the village idiot" might know what he's talking about every now and then...You were absolutely right.

Glad to see it performed for you the same it does in mine. StaBall 6.5 really is a game-changer for the short-action world.

Well, alias accounts congratulating yourself doesn't count!Well... I guess "the village idiot" might know what he's talking about every now and then...

Glad to see it performed for you the same it does in mine. StaBall 6.5 really is a game-changer for the short-action world.

If we could ship powders I would send you what I have left of my 6.5SB. Mine must be faster burning lot.

I only have the one account, but nice try…Well, alias accounts congratulating yourself doesn't count!

If we could ship powders I would send you what I have left of my 6.5SB. Mine must be faster burning lot.

Similar threads

- Replies

- 16

- Views

- 817

- Replies

- 18

- Views

- 1K

- Replies

- 37

- Views

- 2K