Sorry about this, I did some quick tests and then lost track of this thread and got swamped with other things.

I ran some annealing and extraction force testing on some of our 6.5 PRC brass. I took our brass right off the press, trimmed it up myself and ran it through our annealer at different settings to get some different hardness levels and then seated Hornady 143 gr ELD-X projectiles to 2.950" OAL.

40 cases of 6.5 PRC brass with average mouth ID as measured on our CMM of .2620" with SD of .0003".

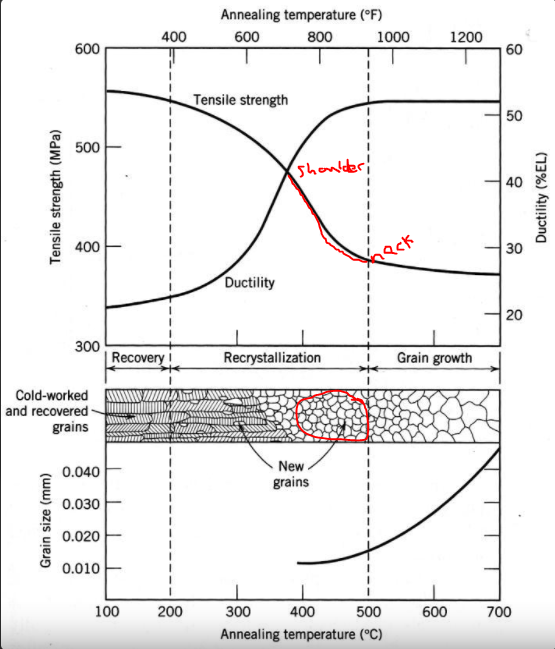

I ran the parts through our annealer for 4 different target hardnesses (measured on Vickers scale).

Group 1 was to get the brass glowing visually, which resulted in an average hardness of 84.8

Group 2 was just before glowing which resulted in average hardness of 98.4

Group 3 was our normal anneal with an average hardness of 113

Group 4 was un-annealed with average hardness of 205

Extraction force was measured as the peak force (lb/ft) required to entirely remove the projectile from the casing.

Group 1 average force: 57.1 lbf

Group 2 average force: 71.6 lbf

Group 3 average force: 105.7 lbf

Group 4 average force: 208.5 lbf

@White_Shark - Thank you for taking the time to do this. Your data seems to have been somewhat glossed over in the thread.

The test was removal force which is the reverse of what reloaders focus on. That said, removal force is probably a better test for the brass since it is a better representation of total bullet grip the brass is providing on a loaded round. Correct me if I'm wrong but I suspect the peak force you measured is probably occurring right as the bullet starts to move i.e. while fully engaged. Whereas measuring seating pressure is affected by a lot of variables such as chamfer & seating speed.

You had the test set up with .002" interference fit (+-.00015).

Group 1 Vickers 84.8 = 57.1 lbf force (ES?)

Group 2 Vickers 98.4 = 71.6 lbf force (ES?) This 16% increase in Vickers = a 25% increase in force.

Group 3 Vickers 113 = 105.7 lbf force (ES?) This additional 15% in Vickers = + 48% increase in force

Group 3 deserves emphasis since it represents the average target "anneal"/Vickers hardness.

I'm putting anneal in Quotation marks For you pedantic's (you know who you are). I'm not talking about the scientific definition. Whenever I use the term anneal on this forum, going forward,

forever, I'm referring to the cartridge case neck/shoulder Vickers condition.

This group 3 also seems to pretty closely represent what most of us are shooting for with our reloading process.

Ok back to group 3

target anneal for Jagemann Brass. Founded in 1949 & currently producing 300 Million cases per year (Clue).

Group 3 represents a 33% increase on the Vickers from a Brass Glowing (fully scientifically annealed?) state & this equated to a 85% increase in force with a .002 interference fit. Very significant jump in force!

Group 4 Full hard. For the pedantic's, full hard as defined in the cartridge context; meaning as hard as Jagemann deems is ideal for the lower portion of the brass that will not get Vickers conditioned (annealed). Brass can be made considerably harder then this.

Vickers 205 is 81% harder than group 3 & results in 97% more force.

So from full Glowy annealed to full hard/same as cartridge base we have 142% increase in Vickers hardness that results in a 265% increase in effective force at .002 (+-.00015) interference fit.

@White_Shark - I would really love to see you repeat the above test with 2 modifications.

- Provide extreme spreed for the Vickers & force data data in each group.

- Run the 4 groups again with .003 or .004 interference fit. I strongly suspect the Glowy/soft brass will plateau on force regardless of the added interference fit. I'm very curious at what interference this plateau occurs?

From the data White Shark provided it should be pretty damn clear that you are not controlling neck tension with your bushings & mandrels. You are controlling interference fit. Actual tension also does not equate to seating force because it does not account for friction. Are you using coated bullets?, what neck lube?, & how polished is the inside of the neck?

What we don't know yet is at what point of interference fit does the full Glowy/wrecked brass fail to add additional force (actual tension)???? Does this happen at .008 interference or .0015? This is information that we could benefit from.

@918v has rightly pointed out multiple times that the annealed/Vickers state of your brass matters most in mag fed ammo that is jumping to the lands or auto loaders where there is a min required tension/force to prevent dislocating bullets during high speed/high G cycling.

If your game is bench rest and your soft seating with a .015 jam, tight neck chamber, & concentric turned necks, then all you really need the neck for is to prevent spilling the damn powder while you deliver the bullet to the lands. Go ahead and light your brass up like a light bulb if it floats your boat. Sure it may be technically fully scientifically annealed, but what have you gained?

To suggest that all the major brass manufacturers, Mil, & top level competitors are wrong to partially anneal targeting +- 110 Vickers via an annealing

process is fucking absurd! It seems there are some that cant see the forest for the trees. The goal is not to fully anneal the necks. The goal is to use a reliable repeatable annealing

process to condition & maintain necks in an ideal temper range that is purpose driven.

My game is mag fed bolt and auto loader & for that yes you can wreck your brass and no you cannot control tension via bushing/mandrel regardless of the Vickers condition of your necks. Thats not how this works, that's not how any of this works. Interference fit & tension are two completely different things.

A given Vickers hardness will have a maximum potential tension capability that will be reached at __? interference fit. If your application requires more tension (auto loader) then a full annealed/full soft/84.8 Vickers can deliver then your brass is trashed.

There is a damn good reason no brass manufacturer supplies brass with the necks technically fully annealed.

For any Newbs reading this fuster cluck of a thread I'd suggest you apply decernment. Mark the thread and come back to it once you've gotten a good baseline understanding of terminology used in fire arms context, a better feel for who some of us characters are, and what experience and background is being brought to the table.

If your mag feeding, jumping bullets to the lands, or loading for field type shooting where your not treating brass like fine jewelry then yes the state of anneal/Vickers condition matters. How much is like anything it depends on application, goals, & expectations.

I target somewhere between Group 2-3 based on White Sharks description. I use flame via a Mike reloading bench annealer & tune it to drop brass right as flame changes color. I find that the time can vary a good bit within the same caliber between brass manufacturers. I use the method in

@orkan video for the flame color change & it is a great indicator prior to the case starting to glow.

I've got 4 x reloads on some 6GT brass running109's @ 2925 fps annealed each time. I anneal it while dirty, then de-cap & tumble with ss pins, then resize for .0015 - .002 shoulder bump with a non honed/no bushing Whidden FL sizer, & then prime + dry graphite in necks before 21st Century mandrel. In this example the brass is malleable enough to easily resize. Yet hard enough that changing the mandrel +-.0005 interference makes a difference on seating force/effective tension. The Whidden FL sizer is working the necks pretty hard -.010. Still I'm getting consistent seating pressure, 5-7 SD, and consistent MV across 4x loading's so far.

The Gay Tiger is pretty easy to load for as by design there is plenty of ogive engaged in my free bore when chambered. On the other hand my DPMS 308 is mag limited @2.822. A 168 SMK is sitting on the lands @2.820 & shoots great @2.800. A 168 TMK @2.822 is jumping .110 with the ogive barely starting to engaged free bore when chambered. This is where concentric necks matter as does anneal. I completely agree with

@918v The case neck has to support and guide the bullet into the free bore. If my case neck is too damn soft it will just flatten to the chamber before the bullet is squared up in the free bore.

@918v - Here's my stab at why the color change only happens when brass is new. No evidence to back it up, but I think it has to due with lubricant used by the manufacturer during forming & drawing. I'm thinking it's kind of embedded in the surface and the first anneal burns the lube out causing the case hardened look. From that point on it's gone. I don't think lanolin or one shot gets embedded by us via resizing the same way it would when drawing and forming.