Seeing several good home made annealing machines built, I'm sure we have some smarter than me fellas around here.

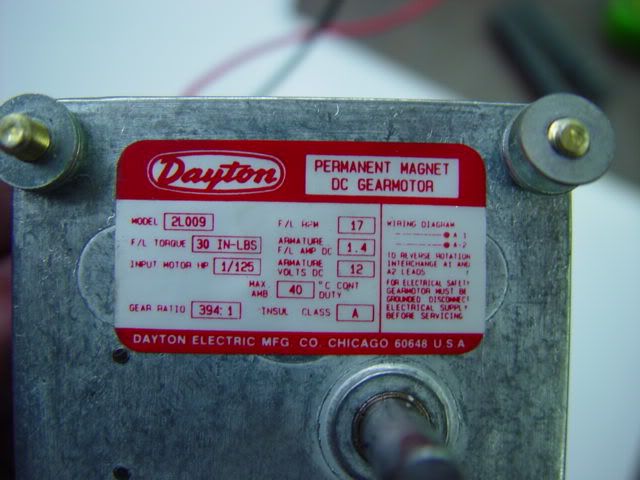

Outlines of the idea, old saw blade or aluminum round piece, on a center bearing, with about 6 posts downward near the center. Idea being a servo or motor that controlled via a an interruptor like a blinker switch or rheostat will bump the posts 60 degrees every X seconds, putting a new piece of brass in the flame to anneal for X seconds. The 60 degree separation should prevent next or last brass from starting or continuing to be annealed in my estimation. I have the whole mechanics completed in my head, but I'm a little shy on the electric/motor/servo side. I imagine the easiest will be a rheostat with a 12v power inverter, but I'd need a 100% duty cycle motor of around 50rpm tops in my quick estimations. What do you guys who know these parts better than me recommend for a motor, power supply, and rheostat/interruptor, which method to go with as well? Thanks guys!

Outlines of the idea, old saw blade or aluminum round piece, on a center bearing, with about 6 posts downward near the center. Idea being a servo or motor that controlled via a an interruptor like a blinker switch or rheostat will bump the posts 60 degrees every X seconds, putting a new piece of brass in the flame to anneal for X seconds. The 60 degree separation should prevent next or last brass from starting or continuing to be annealed in my estimation. I have the whole mechanics completed in my head, but I'm a little shy on the electric/motor/servo side. I imagine the easiest will be a rheostat with a 12v power inverter, but I'd need a 100% duty cycle motor of around 50rpm tops in my quick estimations. What do you guys who know these parts better than me recommend for a motor, power supply, and rheostat/interruptor, which method to go with as well? Thanks guys!