this made me chuckle...

View attachment 7431381

essentially,

"we are unable to calculate what(if any) effect this has, but we are going to claim it as a benefit"

View attachment 7431383

View attachment 7431385

........"theoretically"........

also...."supersonic microwave"?

View attachment 7431388

....so the opposing holes "cancel out".....but dont you still have the original stress from the bore of the rifle?

View attachment 7431389

View attachment 7431386

....ok now they are just making up words....

when i see companies throwing out LOTS of engineering technical jargon in an attempt to make it look like their products are "better engineered".....my BS detector immediately starts jumping......most people arent engineers, and they know that, and it seems like they are trying to hide behind that technical jargon.

its like if your doctor came to you and said

"we suspect you have Peripheral oedema brought on by protal hypertension"....and just walking out the door....you dont know what that means, your doctor knows you dont know what that means.....thats why your doctor is going to say

"you have fat ankles because your liver is failing"

posting FEA calculations and cool gifs are essentially meaningless, sure it looks cool, and someone who doesnt have experience with FEA modeling will think "wow theyve done serious engineering"......but i dont know the parameters theyve set for the calculations. just like statistics, i can make FEA calcs reflect what i want them to.

not saying the barrels dont work....im just saying they probably dont work as well as they want you to believe.

1) The FEA modeling you are referring to was done by a third party with absolutely no affiliation to TACOMHQ. Actually, it was a customer who had the modeling done. To NOTE: he did not believe it either. We had a pessimistic 3rd party do the testing. So please don't accuse us of manipulating data. The modeling firm... is an aeronautical firm specializing in structural failure and crash analysis for aircraft.

2) "Probably don't work" - that is some precise engineering jargon too. Have you shot one? Tested one? Know anybody who has? "Probably" is worthless as you have zero experience or data.

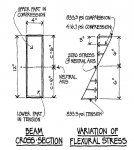

3) Tension and compression- are you arguing that as a tube is bent one side does not go into compression and the other tension? Are you arguing that as the barrel goes into a complex sinosoidal like whip (engineering jargon) that... what...? Tension and compression don't exist? Whip doesn't exist?

Please explain that comment for all of us to understand.

I have had a quite a number of people argue no gain can be had in stiffness of our barrel compared to a solid barrel. I have passed there comments on to structural engineers telling them to return to solid round rods even eliminated shapes as simple as I-beam that they are wasting their time ... Once you prove that the tension-compression component does not exist in a barrel I will pass that on too.

4) Interestingly every single person who has shot our barrel notes a reduced felt recoil. Is it because we have put a "hex" on them? Brainwashed the multiple shooters into believing the gun has less recoil?

5) Let's say we are exaggerating about the recoil event quite as much as you imply: Please explain if the reduced felt recoil is not from the reduced barrel harmonic then what is it? This "phenomena" has been noted on 6mm to .416 Barretts.

6) I will keep in mind that sand blasting does not increase surface area and increase cooling effect. I guess our couple of thousand temperature measurements were "faulty". To note our "faulty" data has noted a positive value every time we have tested polished vs sand blasted.

7) Laying out barrels of similar mass in the sun and heat soaking them for a couple of hours and then putting them back in the shade and plotting time versus temp is ... what?

8) On a 70deg day I can shoot our Norma or .375 10's of rounds past a standard barrel before it even approaches the heat of a standard barrel. I guess consistent SD's, less group migration, smaller group size has no place on this forum. By the way that's all 3rd party testing not TACOMHQ.

I guess the "BS" meter extends to multiple parties beyond TACOMHQ.

9) We had a top F1 team shoot a couple of months ago. Our guns are chassis and not the typical stocks they shoot so they were not comfortable shooting our systems- in fact they shot without the cheek comb in place.

Fact: (or voodoo): side by side weight for weight, caliber specific- our guns exhibit less felt recoil.

Fact: We let them run our 300 Norma. 168gr Sierras at 3,400fps, 190gr Sierras 3100fps, 230gr Bergers 2950fps.

16 rounds of the 230gr Bergers were sub 3/8moa with three shooters. Same point of impact/dot.

4 rounds of the 168 and 4 rounds of the 190 shot 1/4 to 3/8 groups - one long hole 1/2" tall - with a 3/8" shift total left to right from the 230's.

That is not a .5gr change powder ladder test.

How many rounds can your 300 caliber rifle put out to sub 3/8" groups? We test 20-50 round groups.

Can you pick your rifle up by the barrel after 15+ rounds? Here's a concept - reduced barrel mirage. Now that's voodoo.

They also bore scoped the barrels... perhaps their interpretation of the low fire cracking, lack of erosion... was...

Well we will see... they immediately bought barrels. I guess multiple calibers shot by multiple 3rd party are under what kind of illusion?

I agree this is not for every shooter. Most hunters fall outside the gains shown. Price. I don't expect a Malibu to outrun a Z06. Ultra light weight- carbon fiber for sure. If you are at the top of a sport (choose one) and you obtain a 10% gain: What is that worth?

However, commenting on something in which you have zero experience with and calling BS is a pretty big exercise in .... well ... BS.

When comments reach out to the "edge" I find it just as amusing to push the "edge" back a bit.

Now where is my magic wand, I have a series of barrels in process. I need to hex all of those customers into altering their data to make us look good. Darn- I left my Dominion machine at home.

tacomhq.com

tacomhq.com

tacomhq.com

tacomhq.com