Great idea! Now the more difficult part is to find me a reloading room with space, sturdy concrete slab, higher current 3phase panel for the Bridgeport and a gunsmith lathe…. most likely not more in my lifetime, but I can dream about it right?I Already have 3 reloading rooms..

Two are more conventional, one has machine tools available. I like the Bridgeport mill table for reloading....its adjustable, and extremely sturdy for reloading, forming brass, barrel removal, timing breaks, drilling gas ports, etc, plus a quick on off feature for removal or adding different presses.

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Building the Perfect Reloading Room

- Thread starter sirhrmechanic

- Start date

I wish I had a dedicated room in my house but you can't have everything. Not as nice as many but it works for me.

Back wall of my garage with cleaning bench in the foreground:

gosh... i am so jealous...

I originally built my "den" around the idea of simple loading so i can go to the range more often. My den is only 6x10. What i didnt plan on was getting absolutely hooked on ELR and precision shooting/reloading. Now my bench is filled with some of the more sophisticated equipment like what you have but there is no room to work on my gun. If i need to work on my gun, i open up my shooting tripod and use it as a bench. My case cleaning is done on a table in the garage. In short, I have had to get really creative on how to organize my den for efficient reloading.

I have made it work for me but my friends keep trying to convince me to convert one of my (3) bays in the garage into a dedicated gun room.

Ive thought about converting one of my bays into a dedicated gun area but I have a 3 car slot with 2 cars in the garage and the rest are racks of crap. Anyways, we all seem to make due with what we have. It does get hot in the summer when the outside temp is 110! Good luck!gosh... i am so jealous...

I originally built my "den" around the idea of simple loading so i can go to the range more often. My den is only 6x10. What i didnt plan on was getting absolutely hooked on ELR and precision shooting/reloading. Now my bench is filled with some of the more sophisticated equipment like what you have but there is no room to work on my gun. If i need to work on my gun, i open up my shooting tripod and use it as a bench. My case cleaning is done on a table in the garage. In short, I have had to get really creative on how to organize my den for efficient reloading.

I have made it work for me but my friends keep trying to convince me to convert one of my (3) bays in the garage into a dedicated gun room.

Just a heads up for everyone, the store "buy buy baby" is going out of business and they are selling their displays. They have 4'x4' panels with tracks built into them that they use for hanging clothes for $30. They would be great for a reloading bench to be the back wall of the bench to be able to hang stuff up.

Got my shelving built behind automated presses for storage. Time to get room organized and set up so I can start running brass/ammo again

Any updates?

Yeah, Bed Bath and Beyond is going out of business and has been selling everything in the store for cheap. I bought 8 pcs of 4'x4' Slot-Wall (that's what it's called). This isn't the regular slot wall, it has aluminum inserts in the slots, it's white and in perfect shape. It's going to be the surround for my new loading room. I also bought many different baskets and such to hang on it as well as some metal shelves to hang on it. Got it all for $284.00Just a heads up for everyone, the store "buy buy baby" is going out of business and they are selling their displays. They have 4'x4' panels with tracks built into them that they use for hanging clothes for $30. They would be great for a reloading bench to be the back wall of the bench to be able to hang stuff up.

Yea same stuff. Bb&b is owned by the same company. I thought it would be pretty sweet but I'm about to move cross country again.

Now there ain't one damn thing wrong with this bench.All I have to say is Wow! Y'all have some great stuff. Here is my humble setup.

Sent from my SAMSUNG-SM-G890A using Tapatalk

Mine will be very similar. If I had the luxury of an out building

or basement to my have my way with, I might do something elaborate

as I usually need to go to the extreme with things. It's a character flaw.

Therapist said there was no hope for me with that. Smile!

Also . . . where does one find the track that gets inlaid, mortised into the top?

Also . . . where does one find the track that gets inlaid, mortised into the top?

F Bezos,

Go to Rockler woodworking for T track.

It comes in Dillon Blue.

Go to Rockler woodworking for T track.

It comes in Dillon Blue.

Mine is a mess right now, getting organized, stuffing things everywhere. Went from a 30x30 to a 5x12 off the garage. Custom built my cabinets. Still not enough space for everything but Inline Fabrication has helped me solve a lot of space issues.

I need to take more pictures and get them uploaded.

It's actually waaaaay more packed than these pics illustrate.

So it didn't take me long to realize that the cabinets, once full, would weigh about a half ton ... so I engineered a cable system to add strength by hanging them from the rafters.

Then I started loading them, once I got the cables strung and tightened.

Didn't take me long to realize there was not going to be enough room to fit 100k primers at the time (just before the pandemic started, now down to about 50k)

There is a lot of overflow so I was also building benches to go down below.

I've still got to build doors for those custom wall mounted cabinets and the floor benches. But I had to get it to the point where I could get in there and start rolling some-up.

I've burned through some of that, a lot of that actually, but added a lot more as I countinue to roll'em out, shoot'em up, stash it away.

I'll take pictures of the Inline Fabrication wall mounts tomorrow ... to be continued.

I stacked all the brass up on top, pre-sorted, in containers. Up where the cable system was put in place.

Dies and accessories, etc., are on the benches and in drawers ... I'll get pictures of those up tomorrow.

I got rid of the Dillons, actually made a profit on those, have gone strictly to a T7 and a couple of Rock Chuckers and a Rebel. Trying to keep it all green stuff.

It'll make more sense when I get the other pics uploaded although it's packed insanely tight in that little space right now. Never thought I'd get as much in there as I have but I've had to sacrifice some of the bigger stuff since I am no longer shooting IDPA or IPSC or 3-gun anything.

Still having fun on my range though, and doing some teaching.

I need to take more pictures and get them uploaded.

It's actually waaaaay more packed than these pics illustrate.

So it didn't take me long to realize that the cabinets, once full, would weigh about a half ton ... so I engineered a cable system to add strength by hanging them from the rafters.

Then I started loading them, once I got the cables strung and tightened.

Didn't take me long to realize there was not going to be enough room to fit 100k primers at the time (just before the pandemic started, now down to about 50k)

There is a lot of overflow so I was also building benches to go down below.

I've still got to build doors for those custom wall mounted cabinets and the floor benches. But I had to get it to the point where I could get in there and start rolling some-up.

I've burned through some of that, a lot of that actually, but added a lot more as I countinue to roll'em out, shoot'em up, stash it away.

I'll take pictures of the Inline Fabrication wall mounts tomorrow ... to be continued.

I stacked all the brass up on top, pre-sorted, in containers. Up where the cable system was put in place.

Dies and accessories, etc., are on the benches and in drawers ... I'll get pictures of those up tomorrow.

I got rid of the Dillons, actually made a profit on those, have gone strictly to a T7 and a couple of Rock Chuckers and a Rebel. Trying to keep it all green stuff.

It'll make more sense when I get the other pics uploaded although it's packed insanely tight in that little space right now. Never thought I'd get as much in there as I have but I've had to sacrifice some of the bigger stuff since I am no longer shooting IDPA or IPSC or 3-gun anything.

Still having fun on my range though, and doing some teaching.

Mine is a mess right now, getting organized, stuffing things everywhere. Went from a 30x30 to a 5x12 off the garage. Custom built my cabinets. Still not enough space for everything but Inline Fabrication has helped me solve a lot of space issues.

I need to take more pictures and get them uploaded.

It's actually waaaaay more packed than these pics illustrate.

So it didn't take me long to realize that the cabinets, once full, would weigh about a half ton ... so I engineered a cable system to add strength by hanging them from the rafters.

Then I started loading them, once I got the cables strung and tightened.

Didn't take me long to realize there was not going to be enough room to fit 100k primers at the time (just before the pandemic started, now down to about 50k)

There is a lot of overflow so I was also building benches to go down below.

I've still got to build doors for those custom wall mounted cabinets and the floor benches. But I had to get it to the point where I could get in there and start rolling some-up.

I've burned through some of that, a lot of that actually, but added a lot more as I countinue to roll'em out, shoot'em up, stash it away.

I'll take pictures of the Inline Fabrication wall mounts tomorrow ... to be continued.

I stacked all the brass up on top, pre-sorted, in containers. Up where the cable system was put in place.

Dies and accessories, etc., are on the benches and in drawers ... I'll get pictures of those up tomorrow.

I got rid of the Dillons, actually made a profit on those, have gone strictly to a T7 and a couple of Rock Chuckers and a Rebel. Trying to keep it all green stuff.

It'll make more sense when I get the other pics uploaded although it's packed insanely tight in that little space right now. Never thought I'd get as much in there as I have but I've had to sacrifice some of the bigger stuff since I am no longer shooting IDPA or IPSC or 3-gun anything.

Still having fun on my range though, and doing some teaching.

That's a proper-ass fucken bench, yo.View attachment 8158111

Wish I still had my old setup, but this will work for now. Time to get all the machines set up, so I can get rocking

Haha this is my disaster. I have 2 actually but one is currently devoted to mycology.

So, more pics of progress (not happening as fast as I hoped but it's getting there).

Got the doors built and hung (3 hinges each). I've still gotta get the steel inserts cut and installed. (Was originally going with glass but steel is more practical long term plus it allows me to pin notes and such with magnets) I've only got the Kilz coat on them now, had to let it cure.They look dirty but they're not. I've been sanding them as they cure and then filling every pinhole. Already drilled for hardward, going with solid brushed stainless knobs. Should have them all finished, final few coats of paint on them and the inserts installed and knobs-on, hopefully, by the end of the month.

I had to move all the primers, in ammo boxes, down to one of the benches. Even though I'm down to around 30k or so (from over 100k), there wasn't enough room to keep them in the cabinets.

I've kept tumblers and the annealer in the garage. Just no room for them in this little room. Was lucky to have room for chrono. Big difference between 30x30 and 12x5. I miss the old reloading room, the old house, but with age and stage it was time to downsize. It can be done it's just taking some spacial reasoning and ingenuity. It's difficult to grasp.

Here's the link to the album. PW is HideAF

photobucket.com

photobucket.com

Got the doors built and hung (3 hinges each). I've still gotta get the steel inserts cut and installed. (Was originally going with glass but steel is more practical long term plus it allows me to pin notes and such with magnets) I've only got the Kilz coat on them now, had to let it cure.They look dirty but they're not. I've been sanding them as they cure and then filling every pinhole. Already drilled for hardward, going with solid brushed stainless knobs. Should have them all finished, final few coats of paint on them and the inserts installed and knobs-on, hopefully, by the end of the month.

I had to move all the primers, in ammo boxes, down to one of the benches. Even though I'm down to around 30k or so (from over 100k), there wasn't enough room to keep them in the cabinets.

I've kept tumblers and the annealer in the garage. Just no room for them in this little room. Was lucky to have room for chrono. Big difference between 30x30 and 12x5. I miss the old reloading room, the old house, but with age and stage it was time to downsize. It can be done it's just taking some spacial reasoning and ingenuity. It's difficult to grasp.

Here's the link to the album. PW is HideAF

AF Man Cave

Store your photos and videos online with secure storage from Photobucket. Available on iOS, Android and desktop. Securely backup your memories and sign up today!

It’s too fookin’ nice. I reload in a windowless furnace room that’s too cold in the summer and too hot in the winter (but always very dry).

I have to say, I built mine in a spare bedroom and I sit on a nice computer chair in central air and heat. It’s amazing what one can do when the kids are long gone from the house. My wife has the other bedroom set up for her crafts etc and mine is a shared reloading/mycology room with 1/3 being our home office.It’s too fookin’ nice. I reload in a windowless furnace room that’s too cold in the summer and too hot in the winter (but always very dry).

Yep, so down here in South Cackalacki it's rarely cold enough to need a space heater but, nine months outta the year it's too hot out there to pull a press arm without breaking a sweat.

I bought this DeLonghi floor model AC unit thinking it would work out there but I don't think I'm going-to have enough space to make it work. So, next week my Son is coming to help me and we're going-to crawl up under the house and extend the HVAC duct work over to my man cave and then cut a hole in the bricks and put a vent-in. I was wary of putting a fan in there because I've had fans and the slightest breeze will mess with my scales so, hopefully, having the vent nearer the floor and behind the bigger bench, it will cut-back on any risk of a breeze hitting my scales.

I bought this DeLonghi floor model AC unit thinking it would work out there but I don't think I'm going-to have enough space to make it work. So, next week my Son is coming to help me and we're going-to crawl up under the house and extend the HVAC duct work over to my man cave and then cut a hole in the bricks and put a vent-in. I was wary of putting a fan in there because I've had fans and the slightest breeze will mess with my scales so, hopefully, having the vent nearer the floor and behind the bigger bench, it will cut-back on any risk of a breeze hitting my scales.

Indeed, I had to put a diverter over the a/c vent in my reloading room for that same reason. It caused visible fluctuations for no apparent reason until the a/c switched off and everything settled.Yep, so down here in South Cackalacki it's rarely cold enough to need a space heater but, nine months outta the year it's too hot out there to pull a press arm without breaking a sweat.

I bought this DeLonghi floor model AC unit thinking it would work out there but I don't think I'm going-to have enough space to make it work. So, next week my Son is coming to help me and we're going-to crawl up under the house and extend the HVAC duct work over to my man cave and then cut a hole in the bricks and put a vent-in. I was wary of putting a fan in there because I've had fans and the slightest breeze will mess with my scales so, hopefully, having the vent nearer the floor and behind the bigger bench, it will cut-back on any risk of a breeze hitting my scales.

LoL

Update from my Feb 2020 post #546. We moved from town to 15 acres in the country. I now have a 40x80 shop with a insulated, heated/ac 16x32 office /reloading room across the back 1/5 of the shop. It's still a work in progress as any of you who have moved know what a chore it is to find unpack and organize. I'm probably going to remove the wood stove as I have a electric heat pump/ac that is a lot safer and less messy considering the amount of primers , powder and loaded ammo in the room. In the process of building new shelving and 8'x 10' L shaped countertop on the opposite side of the safes.

Nice. Please send updated pics.Update from my Feb 2020 post #546. We moved from town to 15 acres in the country. I now have a 40x80 shop with a insulated, heated/ac 16x32 office /reloading room across the back 1/5 of the shop. It's still a work in progress as any of you who have moved know what a chore it is to find unpack and organize. I'm probably going to remove the wood stove as I have a electric heat pump/ac that is a lot safer and less messy considering the amount of primers , powder and loaded ammo in the room. In the process of building new shelving and 8'x 10' L shaped countertop on the opposite side of the safes.

View attachment 8229006View attachment 8229007View attachment 8229009

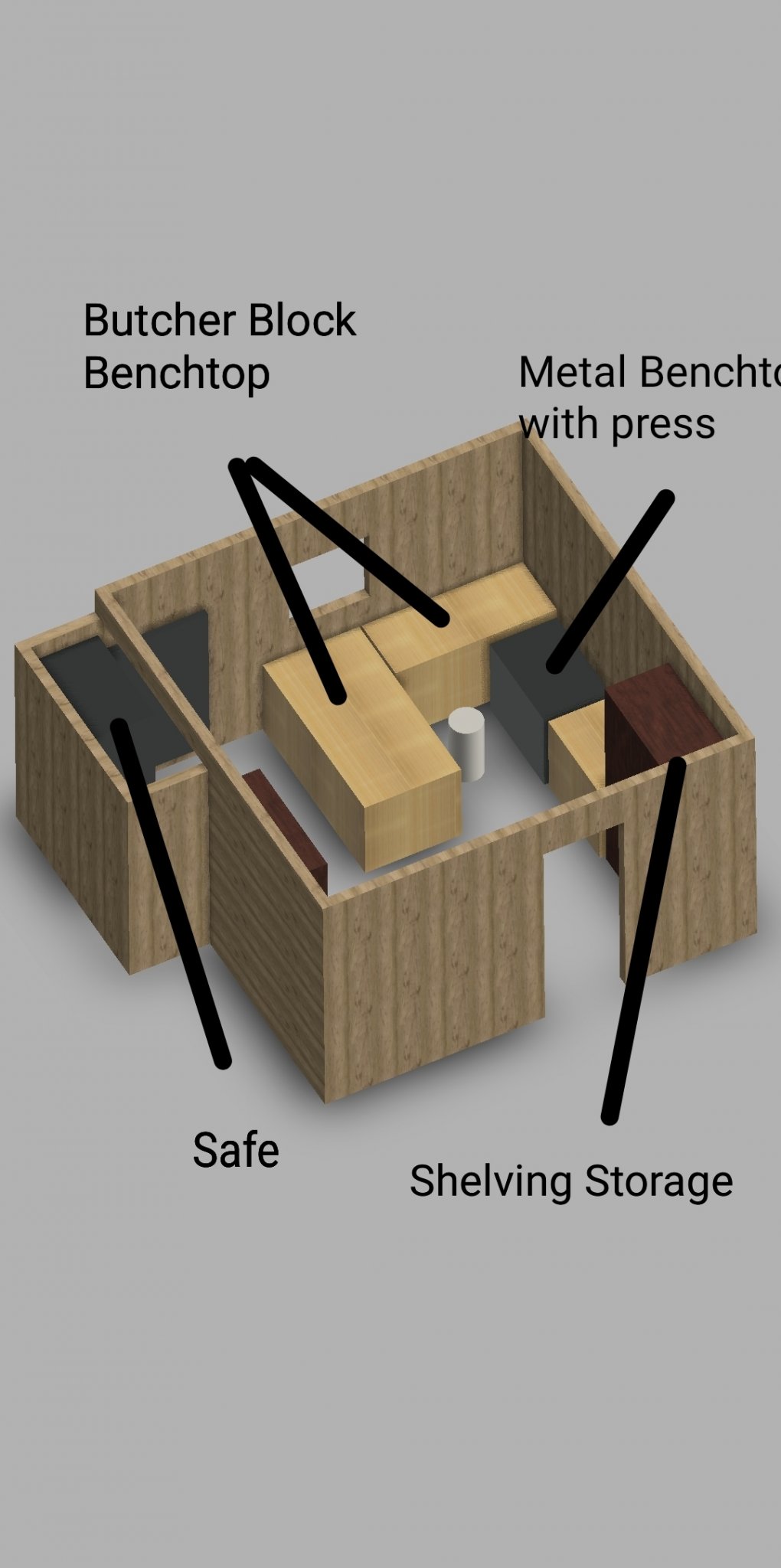

I'm in the planning stages of mine. I want some sort of bench sticking into the room for cleaning guns and to mount a vise to. I also see most assembly line benches, has anyone tried a u shaped bench for reloading?

Dude, whatever works for you. Everybody has different likes. Setup looks very effocient, but maybe a bit crowded once you actually start using it.I'm in the planning stages of mine. I want some sort of bench sticking into the room for cleaning guns and to mount a vise to. I also see most assembly line benches, has anyone tried a u shaped bench for reloading?

View attachment 8229786

Love the safe area!!!

Not quite an ultimate reloading room but I finally got my bench done after the giant pain in the ass of moving. 10ft long 24wide. Hopefully as heavy duty as it looks!

That's one helluva bench.Not quite an ultimate reloading room but I finally got my bench done after the giant pain in the ass of moving. 10ft long 24wide. Hopefully as heavy duty as it looks!

View attachment 8229828View attachment 8229829View attachment 8229830

One thing I'm really happy with so far on mine is my decision to have 3" of overhang .... 2.5" thick. Comes in handy mounting things with C-Clamps and such, without having to bolt or screw anything to the bench permanently.

3.5" is too thick for smaller C-clamps.

From where did you find those brackets?

I'm finally getting more than a closet sized area so just trying to make the most of it.Dude, whatever works for you. Everybody has different likes. Setup looks very effocient, but maybe a bit crowded once you actually start using it.

Love the safe area!!!

The safe is actually going in the closet and it's under a duct. I like how it doesn't intrude much into the room.

I'm in the planning stages of mine. I want some sort of bench sticking into the room for cleaning guns and to mount a vise to. I also see most assembly line benches, has anyone tried a u shaped bench for reloading?

In my mind, the corner countertops are inconvenient to work on or store things, especially with how deep those are depicted. I'd rather have a galley kitchen style with two countertops and shelving/cabinets underneath. That way, the full length of countertop and storage under it is reachable and usable. You're not reaching across a corner table or elbow deep in a corner cabinet. The corners end up being clutter magnets around here.

Impressive. Like the corner braces. I have built several work benches and the one I built with bolts has a tendency to work loose. However, I would bet with braces, yours will be as solid as a rock. (My bench was built to be taken down and moved, the reason why I used bolts.). My benches built for permanent placement use wood glue and dowels. They seem to last forever for me. At least as long as I have built them. My first work bench is still solid after being in use for 15 years.Not quite an ultimate reloading room but I finally got my bench done after the giant pain in the ass of moving. 10ft long 24wide. Hopefully as heavy duty as it looks!

View attachment 8229828View attachment 8229829View attachment 8229830

I really wish I could get solid 4x4’s like yours. Have to make mine out of 2x4’s, glued and fastened with dowels and then cut square with a table saw. They seem to work but yours are better. We can get treated 4x4’s but I prefer not to use treated wood in a closed shop/room

Good job on the bench.

You can usually find Fir 4x4 at lowes. Just fyiImpressive. Like the corner braces. I have built several work benches and the one I built with bolts has a tendency to work loose. However, I would bet with braces, yours will be as solid as a rock. (My bench was built to be taken down and moved, the reason why I used bolts.). My benches built for permanent placement use wood glue and dowels. They seem to last forever for me. At least as long as I have built them. My first work bench is still solid after being in use for 15 years.

I really wish I could get solid 4x4’s like yours. Have to make mine out of 2x4’s, glued and fastened with dowels and then cut square with a table saw. They seem to work but yours are better. We can get treated 4x4’s but I prefer not to use treated wood in a closed shop/room

Good job on the bench.

not at any of the two in our area, only treated. Somehow, someway, we always get shorted in the boonies.You can usually find Fir 4x4 at lowes. Just fyi

Boos makes "industrial" countertops for a lot less than actual butcher block countertops that go in residential kitchens.

www.johnboos.com

www.johnboos.com

I called the factory and got a 1 3/4X24X48 that was a factory blem for $250. It weighs 60+lbs and has proven to be a very solid reloading table. I didn't even have to anchor it to the studs (but I did anyway). You can't just buy online though. You have to call and actually talk to them to see what belms and factory seconds they have on hand at any given time. I would also look at Lowe's bamboo countertops. I'm sure they get some in that are messed up from shipping they'll sell at a discount. It's quite a bit lighter than the maple, so you have to go thicker, but it's great stuff. I have some cutting boards made of bamboo that are bomber.

My point is that you can get a pretty amazing top for your reloading if you just take the time to talk to people and hunt for deals. Of course, you can just point and click and pay a grand or more for something that's beautiful, but how many of us actually care? I like the idea of sistering 2X4s together too, but with prices today I'm sure that adds up quickly as well. I went to re-deck my 20' float trailer and wanted oak planks, but it was so expensive I went with 2X8 pine boards and just water-sealed the hell out of them.

I honestly think the ultimate would be those HS, chemistry class, black, basalt tables that are impervious to everything. It would be hard to figure out a rail system on one, but I can think of no more stable and sturdier table I've ever used...

1-3/4″ Thick – Maple Work Tops 24″ Wide (Industrial Series) - John Boos & Co

Our Boos Block Industrial Worktops feature a 1-3/4" thickness and comes standard with our oil finish. The tops are made from a variety of blended wood rails that may include small nots on the underside of the top but may be completely clear of defects on the work surface side. These industrial...

I called the factory and got a 1 3/4X24X48 that was a factory blem for $250. It weighs 60+lbs and has proven to be a very solid reloading table. I didn't even have to anchor it to the studs (but I did anyway). You can't just buy online though. You have to call and actually talk to them to see what belms and factory seconds they have on hand at any given time. I would also look at Lowe's bamboo countertops. I'm sure they get some in that are messed up from shipping they'll sell at a discount. It's quite a bit lighter than the maple, so you have to go thicker, but it's great stuff. I have some cutting boards made of bamboo that are bomber.

My point is that you can get a pretty amazing top for your reloading if you just take the time to talk to people and hunt for deals. Of course, you can just point and click and pay a grand or more for something that's beautiful, but how many of us actually care? I like the idea of sistering 2X4s together too, but with prices today I'm sure that adds up quickly as well. I went to re-deck my 20' float trailer and wanted oak planks, but it was so expensive I went with 2X8 pine boards and just water-sealed the hell out of them.

I honestly think the ultimate would be those HS, chemistry class, black, basalt tables that are impervious to everything. It would be hard to figure out a rail system on one, but I can think of no more stable and sturdier table I've ever used...

Nothing wrong with using treated wood unless you plan on licking it. It does not give off any harmful gases and is only mentioned as a concern if you rub the wood and then rub your eyes or you rub the wood the with your fingers and then stick them in your mouth. If it is a major concern, use some stain and seal it or use some paint and paint it. In a reloading room with lead, solvents, gunpowder, and other things that have been determined to be "not good for you", a bit of treated wood is nothing.

Maybe a good point, but a 4x4 treated 8 foot long runs at least $15.00. Makes two legs. A 2x4 stud, costs $3.00 and two of them, ($6.00) makes two legs. Treated is considerably more expensive and makes no point. Sawing, cutting and inserting dowels is all on my time. (a dowel rod is good for quite a few legs and a bottle of good wood glue lasts for quite some time)Nothing wrong with using treated wood unless you plan on licking it. It does not give off any harmful gases and is only mentioned as a concern if you rub the wood and then rub your eyes or you rub the wood the with your fingers and then stick them in your mouth. If it is a major concern, use some stain and seal it or use some paint and paint it. In a reloading room with lead, solvents, gunpowder, and other things that have been determined to be "not good for you", a bit of treated wood is nothing.

So, if untreated 4x4’s were available it would be nice. Reality, treated wood used inside a shop or home is wasted dollars. In these days and times with biden’s minions running the economy, saving $$ is a priority.

I was in a similar situation where I live. The only option I had for 4x4s in my area where treated. I built one bench and when I went back about a year later to build a second one, the price of wood and materials almost doubled. I used 8” screws in mine and I think that was the most expensive part of each bench. I had some old garage paint sitting around so I painted mine.

Thanks! Yeah I did roughly 2.5- 3” of overhang as well. I’ll just have to hang the small clamps somewhere. I got the brackets from Amazon, they’re made by Eastwood @ 150 for the set. There are cheaper ones on there but I’d rather buy American if I can. I think they were worth it, they made squaring the whole thing up a breeze.That's one helluva bench.

One thing I'm really happy with so far on mine is my decision to have 3" of overhang .... 2.5" thick. Comes in handy mounting things with C-Clamps and such, without having to bolt or screw anything to the bench permanently.

3.5" is too thick for smaller C-clamps.

From where did you find those brackets?

I’m hoping it’ll stay tight but time will tell. I used lock washer and a good bit of torque but if I have to go back and thread lock then I will. I hope I don’t ever have to move this thing haha! I thought about using 2xs but the 4x was only a few dollars more so why not. Thanks manImpressive. Like the corner braces. I have built several work benches and the one I built with bolts has a tendency to work loose. However, I would bet with braces, yours will be as solid as a rock. (My bench was built to be taken down and moved, the reason why I used bolts.). My benches built for permanent placement use wood glue and dowels. They seem to last forever for me. At least as long as I have built them. My first work bench is still solid after being in use for 15 years.

I really wish I could get solid 4x4’s like yours. Have to make mine out of 2x4’s, glued and fastened with dowels and then cut square with a table saw. They seem to work but yours are better. We can get treated 4x4’s but I prefer not to use treated wood in a closed shop/room

Good job on the bench.

You need to hinge a bottom shelf on top of those floor joists and turn that into hidden storage space. Put some cardboard or rubber shelf lining in the spaces to keep your goodies off the concrete and ypu could stash your millions in cash, gold bullion and ammo down in there along with a couple of gats just incase .... you know, for a rainy day.I’m hoping it’ll stay tight but time will tell. I used lock washer and a good bit of torque but if I have to go back and thread lock then I will. I hope I don’t ever have to move this thing haha! I thought about using 2xs but the 4x was only a few dollars more so why not. Thanks man

That’s a great idea, dam I love it! You just made my day.You need to hinge a bottom shelf on top of those floor joists and turn that into hidden storage space. Put some cardboard or rubber shelf lining in the spaces to keep your goodies off the concrete and ypu could stash your millions in cash, gold bullion and ammo down in there along with a couple of gats just incase .... you know, for a rainy day.

This is my set up before,

The build for the frame work

Starting the install

The rustic hickory top and shelves

Final move in.

Last thing to do is install a hickory cupboard.

The build for the frame work

Starting the install

The rustic hickory top and shelves

Final move in.

Last thing to do is install a hickory cupboard.

World Class setup.This is my set up before,

View attachment 8241869

The build for the frame work

View attachment 8241870

Starting the install

View attachment 8241874

The rustic hickory top and shelves

View attachment 8241875

Final move in.View attachment 8241876

Last thing to do is install a hickory cupboard.

Got my cabinet guy coming Monday to install my cabinets for my new loading room boys. I used cabinets that they had already from over orders or whatever so that I could get a decent amount of cabinets cheap.

The tops are the next question. I am thinking just do butcher block on top of the base cabinets and continue it all the way around the room for "3 sides " so to speak. I will frame up in between the cabinets on each short wall and then just wrap the framing with cedar or something on the fronts.

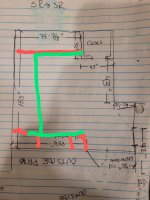

This is just my quick sketch to show where they will go. The red is the base cabinets and the green line would be the front edge of the top.

Any suggestions ?

The tops are the next question. I am thinking just do butcher block on top of the base cabinets and continue it all the way around the room for "3 sides " so to speak. I will frame up in between the cabinets on each short wall and then just wrap the framing with cedar or something on the fronts.

This is just my quick sketch to show where they will go. The red is the base cabinets and the green line would be the front edge of the top.

Any suggestions ?

Attachments

Freakin awesome job! It’s a thing of beauty!This is my set up before,

View attachment 8241869

The build for the frame work

View attachment 8241870

Starting the install

View attachment 8241874

The rustic hickory top and shelves

View attachment 8241875

Final move in.View attachment 8241876

Last thing to do is install a hickory cupboard.

That's awesome man. Looks slick tooThis is my set up before,

View attachment 8241869

The build for the frame work

View attachment 8241870

Starting the install

View attachment 8241874

The rustic hickory top and shelves

View attachment 8241875

Final move in.View attachment 8241876

Last thing to do is install a hickory cupboard.

WOW!!!This is my set up before,

View attachment 8241869

The build for the frame work

View attachment 8241870

Starting the install

View attachment 8241874

The rustic hickory top and shelves

View attachment 8241875

Final move in.View attachment 8241876

Last thing to do is install a hickory cupboard.

You can’t make 13’? Cmon dude. LolGot my cabinet guy coming Monday to install my cabinets for my new loading room boys. I used cabinets that they had already from over orders or whatever so that I could get a decent amount of cabinets cheap.

The tops are the next question. I am thinking just do butcher block on top of the base cabinets and continue it all the way around the room for "3 sides " so to speak. I will frame up in between the cabinets on each short wall and then just wrap the framing with cedar or something on the fronts.

This is just my quick sketch to show where they will go. The red is the base cabinets and the green line would be the front edge of the top.

Any suggestions ?

I will be moving in a year, year and half. Once moved I hope to make a bench of the beauty and utility as this one displayed above. Such a great job, and obviously sturdy as well as just plain beautiful. Outstanding!

I now have a target, overall quality-wise, for my work. The challenge will be substantial lol

I now have a target, overall quality-wise, for my work. The challenge will be substantial lol

This is the cabinet layout. Seriously, no one has any suggestions? I'd really like this to be as good as it can be so please do give suggestions if you have any. The middle space on the uppers will be some shelves I will make and install later. The other side with 2 base units will function as a desk type space so I can sit at it if need be. The top will go all around "3 sides" so to speak.

Attachments

I would go shelves instead of cabinets, but that just me. I like to include personal items on my shelves to display other interests and hobbies. But that’s me. You do you as you choose.This is the cabinet layout. Seriously, no one has any suggestions? I'd really like this to be as good as it can be so please do give suggestions if you have any. The middle space on the uppers will be some shelves I will make and install later. The other side with 2 base units will function as a desk type space so I can sit at it if need be. The top will go all around "3 sides" so to speak.

Yeah I will have a good bit of shelves also, they just aren't shown because I will make them. The long wall will have slot- wall on it with shelvesI would go shelves instead of cabinets, but that just me. I like to include personal items on my shelves to display other interests and hobbies. But that’s me. You do you as you choose.

Similar threads

- Replies

- 66

- Views

- 3K

- Replies

- 103

- Views

- 5K