Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Coup De Grâce, New Action from American Rifle Company, $899 WOW!

- Thread starter karagias

- Start date

I ordered on the 8th, I think, which was the first day you could.Ditto with me. Nothing on the SA, LA, or wrench I ordered at the same time....

Are your mags bottoming out on the action?

2 were contacting the action and you could not pull down after it latched. The 3rd had a little up and down play after it latched.

Are you running a mdt acc elite by any chance? Gbmaryland gave me the tip of adding the plastic dowels in the maxwell and it's helped alot. Still some hiccup on the 7th round every so often.2 were contacting the action and you could not pull down after it latched. The 3rd had a little up and down play after it latched.

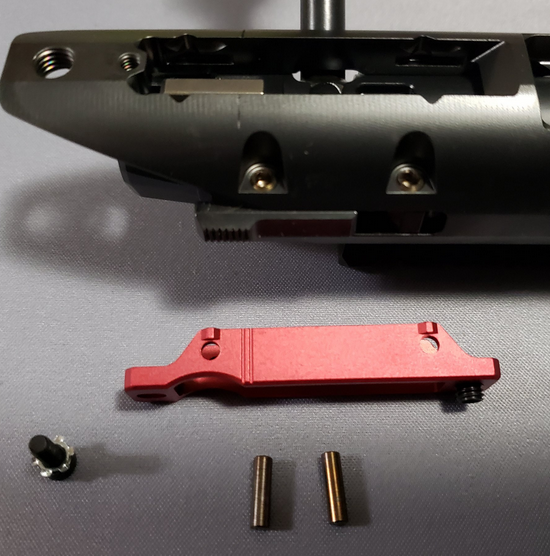

Yes that is an ACC elite in the pic. What kind of hang up were you having?Are you running a mdt acc elite by any chance? Gbmaryland gave me the tip of adding the plastic dowels in the maxwell and it's helped alot. Still some hiccup on the 7th round every so often.

Mostly bolt going over my 6mm gt rounds. It also hung up like yours where the bolt stops at an angle on the case. After installing the dowel, it only does that to me every 8th mag on the 7-8th round. Typically when feeding from the right side of the mag.Yes that is an ACC elite in the pic. What kind of hang up were you having?

The other thing I had to do was add a washer to the rear screw… this way, the rear screw didn’t protrude through the action and impede the bolt. (Forgot about that…)Are you running a mdt acc elite by any chance? Gbmaryland gave me the tip of adding the plastic dowels in the maxwell and it's helped alot. Still some hiccup on the 7th round every so often.

Don’t forget to adjust the mag latch so that it just holds the magazine in with minimal / almost imperceptible amount of play.2 were contacting the action and you could not pull down after it latched. The 3rd had a little up and down play after it latched.

The next thing that might cause some interference, make sure you’ve adjusted the trigger/bolt interaction.

Per @TheOE800 I learned that the front screw on the trigger hanger will make a huge difference in how hard the boatlift is, and how much the bolt is pressing on the trigger itself during use.

That interaction could also be pushing on the bolt up causing feeding issues… (especially a trigger tech).

Take the action out of the chassis, loosen the rear bolt on the trigger hanger, adjust the front bolt until, with the bolt cocked, when you raise and lower the handle, you see no perceptible movement of the firing pin/hammer assembly at the rear of the bolt.

Turns out this is far more important than I thought it would be…

Last edited:

Thanks I’ll try this next. I thought I had the bolt feeling really good. At least in dry fire it does, but I’ll take another look at the rear bolt on the hanger.Don’t forget to adjust the mag latch so that it just holds the magazine in with minimal / almost imperceptible amount of play.

The next thing that might cause some interference, make sure you’ve adjusted the trigger/bolt interaction.

Per @TheOE800 I learned that the front screw on the trigger hanger will make a huge difference in how hard the boatlift is, and how much the bolt is pressing on the trigger itself during use.

That interaction could also be pushing on the bolt up causing feeding issues… (especially a trigger tech).

Take the action out of the chassis, loosen the rear bolt on the trigger hanger, adjust the front bolt until, with the bolt cocked, when you raise and lower the handle, you see no perceptible movement of the firing pin/hammer assembly at the rear of the bolt.

Turns out this is far more important than I thought it would be…

Here’s a video if it helps. You’ll see where it stops and hits a rough spot in feeding.

Thanks I’ll try this next. I thought I had the bolt feeling really good. At least in dry fire it does, but I’ll take another look at the rear bolt on the hanger.

Here’s a video if it helps. You’ll see where it stops and hits a rough spot in feeding.

That spot where your feeling the slight hang is where the back of the case is pushed up into/clips into extractor. i.e. it's where the CRF gains control of the case head. This is normal, you'll never run it that slow.

I did a slight debur massage to the bottom edge of the extractor to smooth it a little. That may help soften the feel when the case head clips in.

Damn kinda disappointing if that is the case. My AI and Curtis feed much smoother going that slow. Ironic. Push feed vs CRF I know, but I definitely don’t remember my TL3 feeling like that. Was years ago tho.That spot where your feeling the slight hang is where the back of the case is pushed up into/clips into extractor. i.e. it's where the CRF gains control of the case head. This is normal, you'll never run it that slow.

I did a slight debur massage to the bottom edge of the extractor to smooth it a little. That may help soften the feel when the case head clips in.

I would say I have ran the bolt almost that slow on certain stage like tow straps or floating platforms. I usually don’t run the bolt very fast at all in general. Good way to make a bad prop worse.

I’ll try the other solutions first, but is everyone dealing with that hang? If they are I wouldn’t be surprised to see these get dumped pretty quick for more impacts or Fuzions in the comp game.

I can't feel it at all just running the bolt normal on a bench. 308 with AW's, however I checked it to ensure the issue below didn't apply.Damn kinda disappointing if that is the case. My AI and Curtis feed much smoother going that slow. Ironic. Push feed vs CRF I know, but I definitely don’t remember my TL3 feeling like that. Was years ago tho.

I would say I have ran the bolt almost that slow on certain stage like tow straps or floating platforms. I usually don’t run the bolt very fast at all in general. Good way to make a bad prop worse.

I’ll try the other solutions first, but is everyone dealing with that hang? If they are I wouldn’t be surprised to see these get dumped pretty quick for more impacts or Fuzions in the comp game.

The below picture is on an ARC Nucleus. Still very similar CRF. At least a dozen of us Hide members picked these up on a special 4th of July deal.

Most had same Rock Creek barrels & there were multiple complaints of poor feeding or hang up as you described, mine included.

What I figured out is outlined below: The CRF bolt doesn't gain control of the round until it pivots level while entering the chamber.

First I tried smoothing the extractor claw to help ease the case in. Helped a little, but the case pivots on the sharp edge @ chamber entry. If that edge is sharp, you'll feel it hang as it wants to stop forward motion. After putting a tiny polished radius on that edge it was night and day. Literally everyone that's ever run rounds through it comments how smooth it is.

In the age of CNC chambers I think this important little detail can get overlooked. I'd bet the reputable builders are aware and address this, but when we just screw it on in the garage it's easily missed.

This is important to a reliable feeding AR also. Same deal the case has to pivot on that point while the head drags across the bolt face/ejector. If you ever look at a Craddock AR barrel you'll immediately notice the mirror finished radius he puts at the chamber entry transition.

This applies to all ARC CRF actions.

Granted I get a little excited in matches & try to focus on smooth is fast.

Last 2 platforms/boats I shot clean. 1 with an AR & 1 with Archimedes, both slung brass 8' lol. Bolt back on forward swing, bolt close on back swing. Maybe I should slow down, then again tell that to my AR. Smooth is fast, slow is just slow!

Last edited:

I’ll definitely look into this as well! Funny I’ve got a Craddock 6.5CM sitting in the safe. Thanks for the pic and explanation. Definitely makes more sense now. Hopefully this is the cause of what I’m experiencing. This is a PVA osprey barrel fwiwI can't feel it at all just running the bolt normal on a bench. 308 with AW's, however I check it to ensure the issue below didn't apply.

The below picture is on an ARC Nucleus. Still very similar CRF. At least a dozen of us Hide members picked these up on a special 4th of July deal.

Most had same Rock Creek barrels & there were multiple complaints of poor feeding or hang up as you described, mine included.

What I figured out is outlined below: The CRF bolt doesn't gain control of the round until it pivots level while entering the chamber.

First I tried smoothing the extractor claw to help ease the case in. Helped a little, but the case pivots on the sharp edge @ chamber entry. If that edge is sharp, you'll feel it hang as it wants to stop forward motion. After putting a tiny polished radius on that edge it was night and day. Literally everyone that's ever run rounds through it comments how smooth it is.

In the age of CNC chambers I think this important little detail can get overlooked. I'd bet the reputable builders are aware and address this, but when we just screw it on in the garage it's easily missed.

This is important to a reliable feeding AR also. Same deal the case has to pivot on that point while the head drags across the bolt face/ejector. If you ever look at a Craddock AR barrel you'll immediately notice the mirror finished radius he puts at the chamber entry transition.

This applies to all ARC CRF actions.

View attachment 8199821

Granted I get a little excited in matches & try to focus on smooth is fast.

Last 2 platforms/boats I shot clean. 1 with an AR & 1 with Archimedes, both slung brass 8' lol. Bolt back on forward swing, bolt close on back swing. Maybe I should slow down, then again tell that to my AR. Smooth is fast, slow is just slow!

let me know if it improves matters. I have a PVA on order so i'm curious as well.I’ll definitely look into this as well! Funny I’ve got a Craddock 6.5CM sitting in the safe. Thanks for the pic and explanation. Definitely makes more sense now. Hopefully this is the cause of what I’m experiencing. This is a PVA osprey barrel fwiw

I've shot a couple hundred 223 rounds thru my CDG using an Accurate mag. All have fed smooth, fast or slow, no problems at all.So far I’ve seen reports of issues with 223AI when slow feeding

Anyone been able to feed perfectly straight 223 rem ? What about 22 BR or Dasher ?

I’d got 2Ks of Berger 80.5 and I’d rather not do a 22 Creed.

My rifle is chambered in 223AI and these were fire forming loads.

You are correct, 223AI rounds have to be fed fast in order to chamber. At least for me...

So far I’ve seen reports of issues with 223AI when slow feeding

Anyone been able to feed perfectly straight 223 rem ? What about 22 BR or Dasher ?

I’d got 2Ks of Berger 80.5 and I’d rather not do a 22 Creed.

No issues with .223 thru my CDG and LRI barrel chambered in .223 Wylde using an Accurate AICS mag.

Also on my LRI barrels the edge where the cone transitions to the chamber is very smooth. It's not sharp like that in the image posted by @357Max.

Yep Chad has been tuning the ARC CRF's from the first run of Mausingfields.No issues with .223 thru my CDG and LRI barrel chambered in .223 Wylde using an Accurate AICS mag.

Also on my LRI barrels the edge where the cone transitions to the chamber is very smooth. It's not sharp like that in the image posted by @357Max.

Curious did LRI barrel the action for you or did you just get the barrel from them? I know they test fire everything they barrel.

Wouldn't surprise me a bit if he breaks that edge on barrels he's not installing.

I have almost 400 rounds on mine now with zero issues, fast or slow. AW mag, 260 master race.

Yep Chad has been tuning the ARC CRF's from the first run of Mausingfields.

Curious did LRI barrel the action for you or did you just get the barrel from them? I know they test fire everything they barrel.

Wouldn't surprise me a bit if he breaks that edge on barrels he's not installing.

MFin’ air rack your bolt gun!

Trivially easy improvement. This post was worth its weight in gold. Is it enough to hit it with like 1200 wetdry on a dowel and just ease the sharp edge?I can't feel it at all just running the bolt normal on a bench. 308 with AW's, however I checked it to ensure the issue below didn't apply.

The below picture is on an ARC Nucleus. Still very similar CRF. At least a dozen of us Hide members picked these up on a special 4th of July deal.

Most had same Rock Creek barrels & there were multiple complaints of poor feeding or hang up as you described, mine included.

What I figured out is outlined below: The CRF bolt doesn't gain control of the round until it pivots level while entering the chamber.

First I tried smoothing the extractor claw to help ease the case in. Helped a little, but the case pivots on the sharp edge @ chamber entry. If that edge is sharp, you'll feel it hang as it wants to stop forward motion. After putting a tiny polished radius on that edge it was night and day. Literally everyone that's ever run rounds through it comments how smooth it is.

In the age of CNC chambers I think this important little detail can get overlooked. I'd bet the reputable builders are aware and address this, but when we just screw it on in the garage it's easily missed.

This is important to a reliable feeding AR also. Same deal the case has to pivot on that point while the head drags across the bolt face/ejector. If you ever look at a Craddock AR barrel you'll immediately notice the mirror finished radius he puts at the chamber entry transition.

This applies to all ARC CRF actions.

View attachment 8199821

Granted I get a little excited in matches & try to focus on smooth is fast.

Last 2 platforms/boats I shot clean. 1 with an AR & 1 with Archimedes, both slung brass 8' lol. Bolt back on forward swing, bolt close on back swing. Maybe I should slow down, then again tell that to my AR. Smooth is fast, slow is just slow!

Last edited:

To change the geometry of steel its better to start at a lower grit. 600g to start to 2000 to polish should do it. I'm afraid 1200 to start would just polish.Trivially easy improvement. This post was worth its weight in goal. Is it enough to hit it with like 1200 wetdry on a dowel and just ease the sharp edge?

Yep Chad has been tuning the ARC CRF's from the first run of Mausingfields.

Curious did LRI barrel the action for you or did you just get the barrel from them? I know they test fire everything they barrel.

Wouldn't surprise me a bit if he breaks that edge on barrels he's not installing.

I had ARC ship the action, bolt faces and action wrench to LRI. LRI chambered two 24" M24 barrels for me in 6.5 Creedmoor and .223 Wylde.

I made the decision after exchanging a few emails and speaking with them. LRI wanted the action in hand to properly fit the action. As I was told, close enough is not good enough. Although this may no longer be a requirement since they have fitted more barrels for the CDG.

One of the deciding factors is that they test fire the action and barrel to insure that it functions properly.

LRI is good about keeping you updated as the barrels move thru the shop. Below are pictures that they provided at different stages:

Attachments

Yep Chad has been tuning the ARC CRF's from the first run of Mausingfields.

Curious did LRI barrel the action for you or did you just get the barrel from them? I know they test fire everything they barrel.

Wouldn't surprise me a bit if he breaks that edge on barrels he's not installing.

What action is that

@Ichi - Glad to hear they still test fire them all. Last one he did for me, he had to load a wildcat just to test fire (25SST). LRI is a class act.

Got a use what you have, but I'd recommend 600 first to take the edge off.Trivially easy improvement. This post was worth its weight in goal. Is it enough to hit it with like 1200 wetdry on a dowel and just ease the sharp edge?

ARC Mausingfield, I beleive it was the first run of them. Video is like 5 years old.What action is that

Every edge leading into a chamber should be broken and polished smooth. This is just something that should be automatic.I can't feel it at all just running the bolt normal on a bench. 308 with AW's, however I checked it to ensure the issue below didn't apply.

The below picture is on an ARC Nucleus. Still very similar CRF. At least a dozen of us Hide members picked these up on a special 4th of July deal.

Most had same Rock Creek barrels & there were multiple complaints of poor feeding or hang up as you described, mine included.

What I figured out is outlined below: The CRF bolt doesn't gain control of the round until it pivots level while entering the chamber.

First I tried smoothing the extractor claw to help ease the case in. Helped a little, but the case pivots on the sharp edge @ chamber entry. If that edge is sharp, you'll feel it hang as it wants to stop forward motion. After putting a tiny polished radius on that edge it was night and day. Literally everyone that's ever run rounds through it comments how smooth it is.

In the age of CNC chambers I think this important little detail can get overlooked. I'd bet the reputable builders are aware and address this, but when we just screw it on in the garage it's easily missed.

This is important to a reliable feeding AR also. Same deal the case has to pivot on that point while the head drags across the bolt face/ejector. If you ever look at a Craddock AR barrel you'll immediately notice the mirror finished radius he puts at the chamber entry transition.

This applies to all ARC CRF actions.

View attachment 8199821

Granted I get a little excited in matches & try to focus on smooth is fast.

Last 2 platforms/boats I shot clean. 1 with an AR & 1 with Archimedes, both slung brass 8' lol. Bolt back on forward swing, bolt close on back swing. Maybe I should slow down, then again tell that to my AR. Smooth is fast, slow is just slow!

Received my LA, RH, Magnum CdG on Thursday (ordered on opening day). Finished the rifle up yesterday. PVA pre-fit barrel. Diamond TT 2-stage, w/Savage marked AICS long mags. Xylo chassis. Everything went together perfectly. No issues with the trigger at all. The trigger hanger design is both elegant and worked exactly as advertised. Mags fit tightly w/zero play. The finish/machining is fantastic. Really happy. Can't wait to get to the range and try her out.

Only small nit to pick, I ordered a spare 0.588" bolt head and ARC shipped the head and extractor, but no extractor ball and spring. It would be nice if they included these or just assembled the bolt head.

Also want to give a shout-out to PVA - that muzzle brake is a work of art!

Only small nit to pick, I ordered a spare 0.588" bolt head and ARC shipped the head and extractor, but no extractor ball and spring. It would be nice if they included these or just assembled the bolt head.

Also want to give a shout-out to PVA - that muzzle brake is a work of art!

Hi- I am sorry, these are supposed to come assembled with the ball and spring. Please send me an email to [email protected], so we can get this corrected!Received my LA, RH, Magnum CdG on Thursday (ordered on opening day). Finished the rifle up yesterday. PVA pre-fit barrel. Diamond TT 2-stage, w/Savage marked AICS long mags. Xylo chassis. Everything went together perfectly. No issues with the trigger at all. The trigger hanger design is both elegant and worked exactly as advertised. Mags fit tightly w/zero play. The finish/machining is fantastic. Really happy. Can't wait to get to the range and try her out.

Only small nit to pick, I ordered a spare 0.588" bolt head and ARC shipped the head and extractor, but no extractor ball and spring. It would be nice if they included these or just assembled the bolt head.

Also want to give a shout-out to PVA - that muzzle brake is a work of art!

Bella

Thanks Bella - Will do!Hi- I am sorry, these are supposed to come assembled with the ball and spring. Please send me an email to [email protected], so we can get this corrected!

Bella

Additionally, wanted to mention that the CRF works perfectly (.300 Win Mag), and I can single feed rounds on an empty mag without issue.

Has anybody been able to confirm how the .300 Norma Mag runs with the large bolt faces? I'm curious whether it CRFs or not.

Has anybody been able to confirm how the .300 Norma Mag runs with the large bolt faces? I'm curious whether it CRFs or not.

Great to see a presence here from someone that actually works at ARC - We all know that we clicked a box saying we wouldn't complain while our orders are fulfilled. I have a suggestion, can you add another box that says

"I am buying this action to use, not to to resell on sniperhide"

It's frustrating to be queued behind a bunch of folks that are essentially speculators and have no intention of using the product.

www.snipershide.com

www.snipershide.com

www.snipershide.com

www.snipershide.com

www.snipershide.com

www.snipershide.com

www.snipershide.com

www.snipershide.com

www.snipershide.com

www.snipershide.com

"I am buying this action to use, not to to resell on sniperhide"

It's frustrating to be queued behind a bunch of folks that are essentially speculators and have no intention of using the product.

SOLD - ARC Coup de Grace Bolt Action - NIB

Brand new, never installed American Rifle Company’s Coup de Grace action. Short Action, Right hand, Classic bolt knob, 20 MOA rail, Fluted bolt, Pivoting handle. Both a 0.473” (6.5cr/308) & 0.378” (223) bolt faces included. Selling it exactly as I received it from ARC. $1150 - Free Shipping...

Firearms - RH American Rifle Company Coup De Grace Actions.

I have two actions coming in very soon. I was told within a couple days now. I have one RH .308 bolt face fluted bolt with pivot handle in red hourglass. 30moa SOLD!!! I have one RH .223 bolt face fluted bolt with pivot handle in red hourglass. 30moa If you’re interested let me know and I’ll...

SOLD - ARC Coup De Grace SA , Right , .473" bolt face, 20 MOA

Brand New! Taken out of box for pictures. ARC Coup De Grace. SA , Right hand , .473" bolt face , Hourglass , 20 MOA , Red , Not Fluted , Pivoting. $1,075 to your FFL from my FFL. $1,000 for face to face sale at my FFL or yours in the Boise, Idaho area. Venmo , Zelle , USPS Money order or...

SOLD - WTS: ARC Coup De Grâcem SA, .535 mag bolt face, 30MOA Rail, fluted/pivoting

Ordered this planning to build a 6.5 PRC but have since changed my mind. Its in my hands now and ready to ship out to your FFL (Will ship from an FFL). Just looking to get my cost back out of it - $925 shipped. Payment via Zelle preferred, can do USPS Money Order or cashiers check as well (up...

SOLD - ARC Coup De Grâce Action SPF

I have 2 actions that I need to move due to I am in the process of purchasing a home. The actions are new and have sequential serial numbers. One action has a 223 bolt face and the other is a standard 308 (sold) bolt face. They have fluted bolts and non pivoting handles. I also have an action...

So what? They ordered like anyone else. You may not like it but that’s how things work. We hardly need more rules and why would any manufacturer restrict who buys their product?

I understand your frustration and impatience, but be realistic.

I understand your frustration and impatience, but be realistic.

Plus at least two of those listings appear to have been people who intended to build but circumstances changed. Should there be a check box for that too?Great to see a presence here from someone that actually works at ARC - We all know that we clicked a box saying we wouldn't complain while our orders are fulfilled. I have a suggestion, can you add another box that says

"I am buying this action to use, not to to resell on sniperhide"

It's frustrating to be queued behind a bunch of folks that are essentially speculators and have no intention of using the product.

SOLD - ARC Coup de Grace Bolt Action - NIB

Brand new, never installed American Rifle Company’s Coup de Grace action. Short Action, Right hand, Classic bolt knob, 20 MOA rail, Fluted bolt, Pivoting handle. Both a 0.473” (6.5cr/308) & 0.378” (223) bolt faces included. Selling it exactly as I received it from ARC. $1150 - Free Shipping...www.snipershide.com

Firearms - RH American Rifle Company Coup De Grace Actions.

I have two actions coming in very soon. I was told within a couple days now. I have one RH .308 bolt face fluted bolt with pivot handle in red hourglass. 30moa SOLD!!! I have one RH .223 bolt face fluted bolt with pivot handle in red hourglass. 30moa If you’re interested let me know and I’ll...www.snipershide.com

SOLD - ARC Coup De Grace SA , Right , .473" bolt face, 20 MOA

Brand New! Taken out of box for pictures. ARC Coup De Grace. SA , Right hand , .473" bolt face , Hourglass , 20 MOA , Red , Not Fluted , Pivoting. $1,075 to your FFL from my FFL. $1,000 for face to face sale at my FFL or yours in the Boise, Idaho area. Venmo , Zelle , USPS Money order or...www.snipershide.com

SOLD - WTS: ARC Coup De Grâcem SA, .535 mag bolt face, 30MOA Rail, fluted/pivoting

Ordered this planning to build a 6.5 PRC but have since changed my mind. Its in my hands now and ready to ship out to your FFL (Will ship from an FFL). Just looking to get my cost back out of it - $925 shipped. Payment via Zelle preferred, can do USPS Money Order or cashiers check as well (up...www.snipershide.com

SOLD - ARC Coup De Grâce Action SPF

I have 2 actions that I need to move due to I am in the process of purchasing a home. The actions are new and have sequential serial numbers. One action has a 223 bolt face and the other is a standard 308 (sold) bolt face. They have fluted bolts and non pivoting handles. I also have an action...www.snipershide.com

From the perspective of a manufacturer, I feel like I would want the first group of customers to be actual users, especially if the initial batch is billed as a pre-order. This would make it easier to iterate and improve the action based upon actual user feedback.So what? They ordered like anyone else. You may not like it but that’s how things work. We hardly need more rules and why would any manufacturer restrict who buys their product?

I understand your frustration and impatience, but be realistic.

We have already seen evidence of ARC revising their designs in this thread right?

We are essentially opting in to beta test their pre-released product right? How useful is that if you are not beta-testing it, but selling a "to be revised" version of the action?

Last edited:

Jesus christ, it's Jason Bourne.Great to see a presence here from someone that actually works at ARC - We all know that we clicked a box saying we wouldn't complain while our orders are fulfilled. I have a suggestion, can you add another box that says

"I am buying this action to use, not to to resell on sniperhide"

It's frustrating to be queued behind a bunch of folks that are essentially speculators and have no intention of using the product.

SOLD - ARC Coup de Grace Bolt Action - NIB

Brand new, never installed American Rifle Company’s Coup de Grace action. Short Action, Right hand, Classic bolt knob, 20 MOA rail, Fluted bolt, Pivoting handle. Both a 0.473” (6.5cr/308) & 0.378” (223) bolt faces included. Selling it exactly as I received it from ARC. $1150 - Free Shipping...www.snipershide.com

Firearms - RH American Rifle Company Coup De Grace Actions.

I have two actions coming in very soon. I was told within a couple days now. I have one RH .308 bolt face fluted bolt with pivot handle in red hourglass. 30moa SOLD!!! I have one RH .223 bolt face fluted bolt with pivot handle in red hourglass. 30moa If you’re interested let me know and I’ll...www.snipershide.com

SOLD - ARC Coup De Grace SA , Right , .473" bolt face, 20 MOA

Brand New! Taken out of box for pictures. ARC Coup De Grace. SA , Right hand , .473" bolt face , Hourglass , 20 MOA , Red , Not Fluted , Pivoting. $1,075 to your FFL from my FFL. $1,000 for face to face sale at my FFL or yours in the Boise, Idaho area. Venmo , Zelle , USPS Money order or...www.snipershide.com

SOLD - WTS: ARC Coup De Grâcem SA, .535 mag bolt face, 30MOA Rail, fluted/pivoting

Ordered this planning to build a 6.5 PRC but have since changed my mind. Its in my hands now and ready to ship out to your FFL (Will ship from an FFL). Just looking to get my cost back out of it - $925 shipped. Payment via Zelle preferred, can do USPS Money Order or cashiers check as well (up...www.snipershide.com

SOLD - ARC Coup De Grâce Action SPF

I have 2 actions that I need to move due to I am in the process of purchasing a home. The actions are new and have sequential serial numbers. One action has a 223 bolt face and the other is a standard 308 (sold) bolt face. They have fluted bolts and non pivoting handles. I also have an action...www.snipershide.com

Let's say they check the mark that they won't sell, how would you hold them to it? ARC has other shit to worry about, why make them do more work? Are you an officer in the military? Cause your ideas are exactly what our top leaders think like. Just kidding, don't take the joke too personal.From the perspective of a manufacturer, I feel like I would want the first group of customers to be actual users, especially if the initial batch is billed as a pre-order. This would make it easier to iterate and improve the action based upon actual user feedback.

We have already seen evidence of ARC revising their designs in this thread right?

We are essentially opting in to beta test their pre-released product right? How useful is that if you are not beta-testing it, but selling a "to be revised" version of the action?

Speak for yourself, we leftys are getting a highly refined product.From the perspective of a manufacturer, I feel like I would want the first group of customers to be actual users, especially if the initial batch is billed as a pre-order. This would make it easier to iterate and improve the action based upon actual user feedback.

We have already seen evidence of ARC revising their designs in this thread right?

We are essentially opting in to beta test their pre-released product right? How useful is that if you are not beta-testing it, but selling a "to be revised" version of the action?

From the perspective of the manufacturer: I doubt they want to deal with anymore headaches than necessary from whiny bitches.From the perspective of a manufacturer, I feel like I would want the first group of customers to be actual users, especially if the initial batch is billed as a pre-order. This would make it easier to iterate and improve the action based upon actual user feedback.

We have already seen evidence of ARC revising their designs in this thread right?

We are essentially opting in to beta test their pre-released product right? How useful is that if you are not beta-testing it, but selling a "to be revised" version of the action?

Their dollar spends just the same as yours.

Pissy you didn't order early enough? FFS, maybe ARC should do an in home consult and range trip with each buyer as well so they can vet that you have a safe space and are qualified to own the product.Great to see a presence here from someone that actually works at ARC - We all know that we clicked a box saying we wouldn't complain while our orders are fulfilled. I have a suggestion, can you add another box that says

"I am buying this action to use, not to to resell on sniperhide"

It's frustrating to be queued behind a bunch of folks that are essentially speculators and have no intention of using the product.

SOLD - ARC Coup de Grace Bolt Action - NIB

Brand new, never installed American Rifle Company’s Coup de Grace action. Short Action, Right hand, Classic bolt knob, 20 MOA rail, Fluted bolt, Pivoting handle. Both a 0.473” (6.5cr/308) & 0.378” (223) bolt faces included. Selling it exactly as I received it from ARC. $1150 - Free Shipping...www.snipershide.com

Firearms - RH American Rifle Company Coup De Grace Actions.

I have two actions coming in very soon. I was told within a couple days now. I have one RH .308 bolt face fluted bolt with pivot handle in red hourglass. 30moa SOLD!!! I have one RH .223 bolt face fluted bolt with pivot handle in red hourglass. 30moa If you’re interested let me know and I’ll...www.snipershide.com

SOLD - ARC Coup De Grace SA , Right , .473" bolt face, 20 MOA

Brand New! Taken out of box for pictures. ARC Coup De Grace. SA , Right hand , .473" bolt face , Hourglass , 20 MOA , Red , Not Fluted , Pivoting. $1,075 to your FFL from my FFL. $1,000 for face to face sale at my FFL or yours in the Boise, Idaho area. Venmo , Zelle , USPS Money order or...www.snipershide.com

SOLD - WTS: ARC Coup De Grâcem SA, .535 mag bolt face, 30MOA Rail, fluted/pivoting

Ordered this planning to build a 6.5 PRC but have since changed my mind. Its in my hands now and ready to ship out to your FFL (Will ship from an FFL). Just looking to get my cost back out of it - $925 shipped. Payment via Zelle preferred, can do USPS Money Order or cashiers check as well (up...www.snipershide.com

SOLD - ARC Coup De Grâce Action SPF

I have 2 actions that I need to move due to I am in the process of purchasing a home. The actions are new and have sequential serial numbers. One action has a 223 bolt face and the other is a standard 308 (sold) bolt face. They have fluted bolts and non pivoting handles. I also have an action...www.snipershide.com

oh, and you checked the box, acknowledged it, and now you're bitching anyway. LOL. If anything, the box should say if you do bitch and we find out who you are you get your CDG after all the left handed magnum titanium hunting actions are out.

Great to see a presence here from someone that actually works at ARC - We all know that we clicked a box saying we wouldn't complain while our orders are fulfilled. I have a suggestion, can you add another box that says

"I am buying this action to use, not to to resell on sniperhide"

It's frustrating to be queued behind a bunch of folks that are essentially speculators and have no intention of using the product.

SOLD - ARC Coup de Grace Bolt Action - NIB

Brand new, never installed American Rifle Company’s Coup de Grace action. Short Action, Right hand, Classic bolt knob, 20 MOA rail, Fluted bolt, Pivoting handle. Both a 0.473” (6.5cr/308) & 0.378” (223) bolt faces included. Selling it exactly as I received it from ARC. $1150 - Free Shipping...www.snipershide.com

Firearms - RH American Rifle Company Coup De Grace Actions.

I have two actions coming in very soon. I was told within a couple days now. I have one RH .308 bolt face fluted bolt with pivot handle in red hourglass. 30moa SOLD!!! I have one RH .223 bolt face fluted bolt with pivot handle in red hourglass. 30moa If you’re interested let me know and I’ll...www.snipershide.com

SOLD - ARC Coup De Grace SA , Right , .473" bolt face, 20 MOA

Brand New! Taken out of box for pictures. ARC Coup De Grace. SA , Right hand , .473" bolt face , Hourglass , 20 MOA , Red , Not Fluted , Pivoting. $1,075 to your FFL from my FFL. $1,000 for face to face sale at my FFL or yours in the Boise, Idaho area. Venmo , Zelle , USPS Money order or...www.snipershide.com

SOLD - WTS: ARC Coup De Grâcem SA, .535 mag bolt face, 30MOA Rail, fluted/pivoting

Ordered this planning to build a 6.5 PRC but have since changed my mind. Its in my hands now and ready to ship out to your FFL (Will ship from an FFL). Just looking to get my cost back out of it - $925 shipped. Payment via Zelle preferred, can do USPS Money Order or cashiers check as well (up...www.snipershide.com

I think we need a No Complaint in the resell section too for you. Check that Box or get some Vagiseal to close that hatchet mark up.

It’s frustrating to read moronic posts like this junk shit of yours.Great to see a presence here from someone that actually works at ARC - We all know that we clicked a box saying we wouldn't complain while our orders are fulfilled. I have a suggestion, can you add another box that says

"I am buying this action to use, not to to resell on sniperhide"

It's frustrating to be queued behind a bunch of folks that are essentially speculators and have no intention of using the product.

SOLD - ARC Coup de Grace Bolt Action - NIB

Brand new, never installed American Rifle Company’s Coup de Grace action. Short Action, Right hand, Classic bolt knob, 20 MOA rail, Fluted bolt, Pivoting handle. Both a 0.473” (6.5cr/308) & 0.378” (223) bolt faces included. Selling it exactly as I received it from ARC. $1150 - Free Shipping...www.snipershide.com

Firearms - RH American Rifle Company Coup De Grace Actions.

I have two actions coming in very soon. I was told within a couple days now. I have one RH .308 bolt face fluted bolt with pivot handle in red hourglass. 30moa SOLD!!! I have one RH .223 bolt face fluted bolt with pivot handle in red hourglass. 30moa If you’re interested let me know and I’ll...www.snipershide.com

SOLD - ARC Coup De Grace SA , Right , .473" bolt face, 20 MOA

Brand New! Taken out of box for pictures. ARC Coup De Grace. SA , Right hand , .473" bolt face , Hourglass , 20 MOA , Red , Not Fluted , Pivoting. $1,075 to your FFL from my FFL. $1,000 for face to face sale at my FFL or yours in the Boise, Idaho area. Venmo , Zelle , USPS Money order or...www.snipershide.com

SOLD - WTS: ARC Coup De Grâcem SA, .535 mag bolt face, 30MOA Rail, fluted/pivoting

Ordered this planning to build a 6.5 PRC but have since changed my mind. Its in my hands now and ready to ship out to your FFL (Will ship from an FFL). Just looking to get my cost back out of it - $925 shipped. Payment via Zelle preferred, can do USPS Money Order or cashiers check as well (up...www.snipershide.com

SOLD - ARC Coup De Grâce Action SPF

I have 2 actions that I need to move due to I am in the process of purchasing a home. The actions are new and have sequential serial numbers. One action has a 223 bolt face and the other is a standard 308 (sold) bolt face. They have fluted bolts and non pivoting handles. I also have an action...www.snipershide.com

Looks like the ARC crew has been keeping an eye on us hoodlums in this thread.

Noticed the long actions that shipped now have the trigger hanger notched for the safety. A+

Noticed the long actions that shipped now have the trigger hanger notched for the safety. A+

Fucken retard proof now, ehLooks like the ARC crew has been keeping an eye on us hoodlums in this thread.

Noticed the long actions that shipped now have the trigger hanger notched for the safety. A+

View attachment 8200887

Don’t worry, we’ll refine a few of our retards to take care of that problemFucken retard proof now, eh

Long action ordered 2/8 @7:00pm central time. Got the shipping notice today.

I order my LA magnum bolt head about the same time and received my email today too.

As an industrial and manufacturing engineer, we were always being told to design machinery that was idiot proof. My standard answer was, that is not possible because idiots are so damned ingenious.Don’t worry, we’ll refine a few of our retards to take care of that problem

Last edited:

Similar threads

- Replies

- 12

- Views

- 2K

Left Hand Sale

WTS/SOLD: WTT ARC Coup De Grace LA

- Replies

- 3

- Views

- 775

- Replies

- 5

- Views

- 974