Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New 6mm Advanced Rifle Cartridge

- Thread starter Gtscotty

- Start date

SWFShooter That pretty much looks like what I am getting on some cases but NOT all of them. Could I have ruined the brass when I undersized it trying to get it to chamber?? I don't believe it is a chamber issue since it is only doing it on some of my brass. What would you do?? Just toss the brass or see if it will form back out after shooting it?? Thanks for all the input guys!!!

I don't suggest anyone do this. I probably hurt the fatigue life of my bolt.

I shot a 62ksi load (for my bolt gun, max published Varget charge) in my AR. Proof research barrel, .136 bolt.

Just above the extractor cut: .437"

On the shiny part: .440"

Round primer, some cratering, baby ejector swipe. 10,000psi over the limit. No belt.

I shot a 62ksi load (for my bolt gun, max published Varget charge) in my AR. Proof research barrel, .136 bolt.

Just above the extractor cut: .437"

On the shiny part: .440"

Round primer, some cratering, baby ejector swipe. 10,000psi over the limit. No belt.

I don't really have anyway to post pictures of the brass but my load is 27grs of Varget with the 108ELDs and 29.5grs of Varget with the 87VMAXs. But I am also using a can so that may make a difference. I have it adjusted so it just locks back the bolt....Post pics of the brass and your load data.

Even if it is a barrel manufacturing issue it often only shows up with warm loads.

If you c

). Compare that change in color to the interior of the Hornady brass, and that should basically line up with the thicker base.

). Compare that change in color to the interior of the Hornady brass, and that should basically line up with the thicker base.

The reason it is called the "Lapua Grendel Belted Magnum" can be seen in the sidewall to base juncture of the Lapua cutaway. I like to monitor the brass base swelling by measuring the bottom of the sidewall, and about 1/8" up and compare to new brass. The normal die will not size that far down, so all brass over 0.4420" has to go through a separate body sizing die before normal resizing.

If you look at the sidewall, you can see the point it expanded to the chamber, where down a bit, closer to the base, is a different shade because it did not expand as much. The configuration of Hornady brass has material that bridges the bolt to barrel connection and will not due the "Lapua Grendel Belted Magnum" see image of Hornady Grendel brass cross-section (I will assume the 6mm ARC brass has the same configuration, I might cut one later, but that stuff is like gold right nowI don't suggest anyone do this. I probably hurt the fatigue life of my bolt.

I shot a 62ksi load (for my bolt gun, max published Varget charge) in my AR. Proof research barrel, .136 bolt.

Just above the extractor cut: .437"

On the shiny part: .440"

Round primer, some cratering, baby ejector swipe. 10,000psi over the limit. No belt.

View attachment 7578288

View attachment 7578289

The reason it is called the "Lapua Grendel Belted Magnum" can be seen in the sidewall to base juncture of the Lapua cutaway. I like to monitor the brass base swelling by measuring the bottom of the sidewall, and about 1/8" up and compare to new brass. The normal die will not size that far down, so all brass over 0.4420" has to go through a separate body sizing die before normal resizing.

Attachments

Great info!!! Now with my Lapua brass that has the "Belted Magnum" on it, can I fire form it back out?? Like I said above, I think mine is from "Over sizing" my brass to much. What are your thoughts on that?? Should I shit can the brass?? Or will it fill back out when firing?? I have a "Pick" that I am checking every case on the inside for the dreaded ring which tells me it is ready to separate. So far I have not found one so that is why I was hoping I could save the brass by "Fireforming" it again........If you c

If you look at the sidewall, you can see the point it expanded to the chamber, where down a bit, closer to the base, is a different shade because it did not expand as much. The configuration of Hornady brass has material that bridges the bolt to barrel connection and will not due the "Lapua Grendel Belted Magnum" see image of Hornady Grendel brass cross-section (I will assume the 6mm ARC brass has the same configuration, I might cut one later, but that stuff is like gold right now). Compare that change in color to the interior of the Hornady brass, and that should basically line up with the thicker base.

The reason it is called the "Lapua Grendel Belted Magnum" can be seen in the sidewall to base juncture of the Lapua cutaway. I like to monitor the brass base swelling by measuring the bottom of the sidewall, and about 1/8" up and compare to new brass. The normal die will not size that far down, so all brass over 0.4420" has to go through a separate body sizing die before normal resizing.

It depends on the die. The RCBS small base Grendel (264-LBC) die will leave a bulge on brass that expanded (or over expanded with a stout loading), I will assume the 6mm ARC small base does the same. Hell, it is so tight, it actually is smaller that new brass, so that die sits in a drawer where it can't kill any more brass. Ther small base will roll the case wall down on fired brass and leave a ring that looks like a skinny belted magnum (kinda), because it can't size that far down. I measure the base of the brass, just above the rim, and any brass over 0.4420" gets a body die, which is actually a modified Lee Grendel die without expander/decap stem. Most dies have too much chamfer at the base and will not size the brass sidewall down far enough, so I had to use the modifed Lee die. There are options for pass-thru dies, but when I first started years ago, I had the Lee laying around. A modified shell holder is another option, but removing material to get the die farther down the sidewall then leads to shoulder bump issues. So put a black/blue/red (whatever color) marker stripe down the sidewall of the brass and see how far your die is sizing, and I am guessing your issue is just below that. Good luck.SWFShooter That pretty much looks like what I am getting on some cases but NOT all of them. Could I have ruined the brass when I undersized it trying to get it to chamber?? I don't believe it is a chamber issue since it is only doing it on some of my brass. What would you do?? Just toss the brass or see if it will form back out after shooting it?? Thanks for all the input guys!!!

If you can see an defined bulge, I say the brass is crap. A measurement over say 0.4440" would probably end up in the scrap bin. You don't want this, trust me, it will get your attention.Great info!!! Now with my Lapua brass that has the "Belted Magnum" on it, can I fire form it back out?? Like I said above, I think mine is from "Over sizing" my brass to much. What are your thoughts on that?? Should I shit can the brass?? Or will it fill back out when firing?? I have a "Pick" that I am checking every case on the inside for the dreaded ring which tells me it is ready to separate. So far I have not found one so that is why I was hoping I could save the brass by "Fireforming" it again........

Attachments

Yeah but it's funny how many people know about the "Grendel belted magnum" yet you think it doesn't exist.We've had this discussion before. I've spun my own ARC and 556 AR barrels and drawn the ARC setup in CAD and there isn't unsupported case where those pictures show it unless you cut the chamfer *too* deep or make the radius *too* large.

I hate to toss Laupa brass but then I sure as hell don't want that to happen!! Thank you so much for sharing your experience it is much appreciated!!! Should a person stay away from the Lapua in this caliber?? What are you using for brass?? Thanks again!!If you can see an defined bulge, I say the brass is crap. A measurement over say 0.4440" would probably end up in the scrap bin. You don't want this, trust me, it will get your attention.

Yeah but it's funny how many people know about the "Grendel belted magnum" yet you think it doesn't exist.

What's funny is your reading comprehension. Find a single post where I've said they don't happen. All I've said from the beginning is that it takes an excessive radius and/or chamfer for it to happen. There's no official specification for the ARC/Grendel chamfer geometry, but if you take 5.56 mil std. geometry/tolerances and scale it in any way that isn't retarded there is no way the cases to be unsupported as far forward as the belted pictures show. Two objects cannot occupy the same space so you tell me how the brass expands there.

You cut the chamfer TOO deep or you put TOO big a radius on it. Now please tell me again that the AR-15 requires more chamfer than a bolt gun... So that I can explain for a fourth time that there is a window that A) Works, and B) doesn't leave that much exposed case...

It' is the industry FN standard. I've produced apx 70000 barrels since 2012. The 5,56s, 7.62x39s, 6.8s, 308s do not get the belted magnum look but the grendel cases sure do now you think the radius is different for a Grendel seriously get real WOA, Compass Lake Wilson Arms (not wilson combat) all use a standard radius they all get the belted look. ER Shaw makes barrels for 10-20 different OEMs including Wilson Combat, Ruger asked them to make 500 barrels a day for them and you think all of those companies are screwing up by using the industry standard ? Ok so why does the Grendel need to be cut different when no other case gets that condition? Look close at the inside corner of the case and how thin the Grendel cases are this photo tells the truth and reason why the Grendel case gets that belted magnum look.

In your opinion what is the best brass to use in the 6ARC to prevent this??? I have 6.5 grendel brass in both Lapua and Starline then some factory 6ARC brass. If you get the belt is this a case for concern or just the nature of the beast???? Thanks!!It' is the industry FN standard. I've produced apx 70000 barrels since 2012. The 5,56s, 7.62x39s, 6.8s, 308s do not get the belted magnum look but the grendel cases sure do now you think the radius is different for a Grendel seriously get real WOA, Compass Lake Wilson Arms (not wilson combat) all use a standard radius they all get the belted look. ER Shaw makes barrels for 10-20 different OEMs including Wilson Combat, Ruger asked them to make 500 barrels a day for them and you think all of those companies are screwing up by using the industry standard ? Ok so why does the Grendel need to be cut different when no other case gets that condition? Look close at the inside corner of the case and how thin the Grendel cases are this photo tells the truth and reason why the Grendel case gets that belted magnum look.

View attachment 7578544

Norma seems to last longer and get less of the belted condition, that is what I use in all of my wildcats. It's expensive so you need to decide if it's worth it. Lapua is great brass and all I use for years but they made the Grendel brass based on their 220 Russian very thin to increase case capacity, it just doesn't hold up when you start pushing the pressure. Lapua set the max operating pressure of the grendel at 52000psi for a reason. Lapuas 6.5x47 brass is a different story, the max is set at 63000psi but it will handle much more and never gets that belted look.In your opinion what is the best brass to use in the 6ARC to prevent this??? I have 6.5 grendel brass in both Lapua and Starline then some factory 6ARC brass. If you get the belt is this a case for concern or just the nature of the beast???? Thanks!!

Last edited:

Don't let the doom and gloom about bolt failures scare you off. It can happen of course, but isn't nearly as common as some online make it out to be.

With that said, the two most important things you can do to ensure the longest possible bolt life are:

1 - True your receiver (and/or shim or thermofit) to promote uniform bolt lug contact. Uneven lug engagement does more to raise stress on bolt lugs than anything else, and in the context of these broken bolt discussions, most rifles are assembled without this preventive measure.

2 - Tune the gas system so the bolt isn't trying to unlock under pressure. Early unlocking adds to the stresses on bolt lugs.

If it makes you feel any better, I've been loading 31.0gr of Lever under the 105 BTHP as my standard load in my 243 LBC rifles (granted, slightly more capacity but not enough to matter that much) for a few years now in 3 different rifles. Two were built on BCM uppers, the thermo-fit tight bore pretty much guarantees barrel extension alignment with the receiver, and the other was trued and shimmed so all of them have very uniform lug engagement. The only issue I've had was a broken extractor on the first 24" rifle after ~600 rounds running a bit over-gassed with a .125 bolt (the extractors are a little weaker and early extraction adds a lot of stress). That load is certainly hotter than Hodgdon's data recommends for an AR, although the numbers correlate very well with their 24" bolt gun velocity for the same load. Load at your own risk and respect the potential for danger, but don't be scared of it; if you follow their AR15 data you're not exactly pushing the ragged edge of safety or anything close to it.

Thanks for the reassurance. I've only known 2 people shooting a grindel. One guy i worked with and another that was in the same squad I was in during a match. They both really liked their's.

The one at the match went down. I don't know the cause but I do know he left the brass lay after each stage and said don't bother picking it up. It's no good.

The guy I worked with said he never had any problems with his but I don't think he reloaded.

On another note, I did have to thermal fit the barrel to the receiver. Was pretty happy about that. First one out of five that I've worked with.

Also when I install the barrel nut it went on hand tight and when I put the wrench on it only turned maybe a half turn and it was tight!

A few other things that I'll have to work out will be possibly an AGB and buffer system.

One thing I did note was the gas port was really small. I might call and see what size it is. It is rifle length on a 20" barrel. Maybe work,maybe not?

Anyway thanks again and maybe I'll get to shoot it in the next few days.

This is an extreme case in a Grendel, "Lapua Grendel belted magnum".

SWFShooter, that picture you posted-- are those your cases and/or do you know the origin of those cases? Are they ARC's or Grendels?

It' is the industry FN standard. I've produced apx 70000 barrels since 2012. The 5,56s, 7.62x39s, 6.8s, 308s do not get the belted magnum look but the grendel cases sure do now you think the radius is different for a Grendel seriously get real WOA, Compass Lake Wilson Arms (not wilson combat) all use a standard radius they all get the belted look. ER Shaw makes barrels for 10-20 different OEMs including Wilson Combat, Ruger asked them to make 500 barrels a day for them and you think all of those companies are screwing up by using the industry standard ? Ok so why does the Grendel need to be cut different when no other case gets that condition? Look close at the inside corner of the case and how thin the Grendel cases are this photo tells the truth and reason why the Grendel case gets that belted magnum look.

View attachment 7578544

I'm admittedly a reactionary dick. I'll be a dick if you're a dick and I don't like being a dick so maybe it's the way you structure typed messages or maybe you really are a dick. I honestly don't know. So my apologies for being short. I understand you make a lot of barrels and used to (maybe still do) make beefy bolt/extensions for various higher pressure applications. That's great. I also read your website and it gave me the impression that you're one of those guys that has a staunch "Wrong kid died!" view of 6.8 vs. 6.5 and honestly it makes me skeptical about your view on the subject... I'd like to work past that and get to the root cause of why belted cases show up because that's beneficial and us being dicks to each other isn't.

I would like to get some clarification. What brands of brass produce belts and at what pressures? Sincere question. I've had multiple Grendels and have multiple ARCs, and have pushed the limits just as much as the next guy and never produced a belted case. I have never known anyone that (I'm aware of) has produced a belted case. I have never been on an internet forum and talked directly to anyone who's produced a belted case (prior to Raptor99, potentially) and have never inspected a barrel, nor pressure tested the ammo that produced said cases. That could be my ignorance, my lack of exposure, or it could be that it is not a very common occurrence. I'd like to figure out which.

From what I have gathered in researching this, it looks like Lapua, Wolf Gold (PPU), and potentially others produced cases that were drawn with thin side walls too far down (i.e. your picture-- which is from circa 2005-2007 IIRC). The Wolf Gold shit was large rifle primer pocket, soft, and trash to begin with. SWFShooter mentions "Lapua belted grendel magnum".

So is it possible and/or likely that the root cause of this is not systemic to the cartridge (SAAMI does not specify case wall thicknesses), but is a combination of Lapua (and maybe others) producing thin-walled draws on (some or all lots of) their Grendel cases (both Lapua and Alexander Arms), by itself or along with the occasional barrel that winds up on the wide end of the manufacturing variance spectrum with more chamfer?

@raptor99 Are the cases you're talking about headstamped 6 ARC or 6.5 Grendel? Are they shot in a 6 ARC or 6.5 Grendel?

I would like to get specific information to clarify if this is a ".445 case head no worky in AR-15", or "Lapua made/makes cases too thin at the base of the body".

Thank you.

Ledzep, All of my brass was 6.5 Grendel brass that was necked down to 6ARC brass. I believe my issues started when some of the brass I bought was "Once fired" brass. Total there was 100 new Lapua cases and 60 or so once fired in a 6.5 Grendel. I didn't pay that much attention when I Sized it all down and loaded it. I ran into issues when I was load testing. I had put about 50rds through it with a can on it and was using LVR and CFE. One or both of these powders is very dirty. I started having issues with a round chambering but failed to fire. I thought the rifle was just getting dirty and that when I formed the brass to 6ARC I "May" not have sized it down quite far enough. Since I only had about 10 rounds left I brought them home and pulled the bullets. I then resized them and while I was at it I "Resized" all of my other brass to make sure I would not have this issue again. By doing this I may have actually created a problem with my brass by undersizing it way to much. Now I am wondering "IF" if have ruined the brass or if it will "Fireform" back out again and be usable...... Thanks!!!!

The bulged cases are mine, 6.5 Grendel necked to 6 Grendel, not 6mm ARC. I added the photo to show the "belted magnum" issue. They are Lapua from an unpublished brass research project. The cross section image was taken by my partner in the project, who had access to a better method of cutting.SWFShooter, that picture you posted-- are those your cases and/or do you know the origin of those cases? Are they ARC's or Grendels?

I'm admittedly a reactionary dick. I'll be a dick if you're a dick and I don't like being a dick so maybe it's the way you structure typed messages or maybe you really are a dick. I honestly don't know. So my apologies for being short. I understand you make a lot of barrels and used to (maybe still do) make beefy bolt/extensions for various higher pressure applications. That's great. I also read your website and it gave me the impression that you're one of those guys that has a staunch "Wrong kid died!" view of 6.8 vs. 6.5 and honestly it makes me skeptical about your view on the subject... I'd like to work past that and get to the root cause of why belted cases show up because that's beneficial and us being dicks to each other isn't.

I would like to get some clarification. What brands of brass produce belts and at what pressures? Sincere question. I've had multiple Grendels and have multiple ARCs, and have pushed the limits just as much as the next guy and never produced a belted case. I have never known anyone that (I'm aware of) has produced a belted case. I have never been on an internet forum and talked directly to anyone who's produced a belted case (prior to Raptor99, potentially) and have never inspected a barrel, nor pressure tested the ammo that produced said cases. That could be my ignorance, my lack of exposure, or it could be that it is not a very common occurrence. I'd like to figure out which.

From what I have gathered in researching this, it looks like Lapua, Wolf Gold (PPU), and potentially others produced cases that were drawn with thin side walls too far down (i.e. your picture-- which is from circa 2005-2007 IIRC). The Wolf Gold shit was large rifle primer pocket, soft, and trash to begin with. SWFShooter mentions "Lapua belted grendel magnum".

So is it possible and/or likely that the root cause of this is not systemic to the cartridge (SAAMI does not specify case wall thicknesses), but is a combination of Lapua (and maybe others) producing thin-walled draws on (some or all lots of) their Grendel cases (both Lapua and Alexander Arms), by itself or along with the occasional barrel that winds up on the wide end of the manufacturing variance spectrum with more chamfer?

@raptor99 Are the cases you're talking about headstamped 6 ARC or 6.5 Grendel? Are they shot in a 6 ARC or 6.5 Grendel?

I would like to get specific information to clarify if this is a ".445 case head no worky in AR-15", or "Lapua made/makes cases too thin at the base of the body".

Thank you.

I had looked at a sizer I believe was called a "rollsizer" but there was no Grendel size option at the time.Ledzep, All of my brass was 6.5 Grendel brass that was necked down to 6ARC brass. I believe my issues started when some of the brass I bought was "Once fired" brass. Total there was 100 new Lapua cases and 60 or so once fired in a 6.5 Grendel. I didn't pay that much attention when I Sized it all down and loaded it. I ran into issues when I was load testing. I had put about 50rds through it with a can on it and was using LVR and CFE. One or both of these powders is very dirty. I started having issues with a round chambering but failed to fire. I thought the rifle was just getting dirty and that when I formed the brass to 6ARC I "May" not have sized it down quite far enough. Since I only had about 10 rounds left I brought them home and pulled the bullets. I then resized them and while I was at it I "Resized" all of my other brass to make sure I would not have this issue again. By doing this I may have actually created a problem with my brass by undersizing it way to much. Now I am wondering "IF" if have ruined the brass or if it will "Fireform" back out again and be usable...... Thanks!!!!

You know how consistent and match winning Lapua brass is right? Do you really think their lots vary?SWFShooter, that picture you posted-- are those your cases and/or do you know the origin of those cases? Are they ARC's or Grendels?

I'm admittedly a reactionary dick. I'll be a dick if you're a dick and I don't like being a dick so maybe it's the way you structure typed messages or maybe you really are a dick. I honestly don't know. So my apologies for being short. I understand you make a lot of barrels and used to (maybe still do) make beefy bolt/extensions for various higher pressure applications. That's great. I also read your website and it gave me the impression that you're one of those guys that has a staunch "Wrong kid died!" view of 6.8 vs. 6.5 and honestly it makes me skeptical about your view on the subject... I'd like to work past that and get to the root cause of why belted cases show up because that's beneficial and us being dicks to each other isn't.

I would like to get some clarification. What brands of brass produce belts and at what pressures? Sincere question. I've had multiple Grendels and have multiple ARCs, and have pushed the limits just as much as the next guy and never produced a belted case. I have never known anyone that (I'm aware of) has produced a belted case. I have never been on an internet forum and talked directly to anyone who's produced a belted case (prior to Raptor99, potentially) and have never inspected a barrel, nor pressure tested the ammo that produced said cases. That could be my ignorance, my lack of exposure, or it could be that it is not a very common occurrence. I'd like to figure out which.

From what I have gathered in researching this, it looks like Lapua, Wolf Gold (PPU), and potentially others produced cases that were drawn with thin side walls too far down (i.e. your picture-- which is from circa 2005-2007 IIRC). The Wolf Gold shit was large rifle primer pocket, soft, and trash to begin with. SWFShooter mentions "Lapua belted grendel magnum".

So is it possible and/or likely that the root cause of this is not systemic to the cartridge (SAAMI does not specify case wall thicknesses), but is a combination of Lapua (and maybe others) producing thin-walled draws on (some or all lots of) their Grendel cases (both Lapua and Alexander Arms), by itself or along with the occasional barrel that winds up on the wide end of the manufacturing variance spectrum with more chamfer?

@raptor99 Are the cases you're talking about headstamped 6 ARC or 6.5 Grendel? Are they shot in a 6 ARC or 6.5 Grendel?

I would like to get specific information to clarify if this is a ".445 case head no worky in AR-15", or "Lapua made/makes cases too thin at the base of the body".

Thank you.

You can go to the Grendel forum and look(search function) for all of the posts involving swelled Grendel brass, I believe Hanka himself called the brass " A Grendel Belted Magnum" many years ago. He owns the Grendel forum, His first screen name was Grendelizer, started around 2006, now I think he goes by bluntforcetrama.

As far back as the early 80s all of the benchrest guys said if the case just above the groove swelled more than .0005" the loads were too hot and you should back off. We didn't have quickload or pressure equipt back then. All we knew was the primers would always fail before the brass so we used primers to tell us to back off before primer failure. You can run Grendel brass up to apx 55000 before the case swells past that .0005" limit. That is using Pressure Trace test equipt after using Hornady ammo as a 52000psi guide. Ben at Hornady confirmed Hornady ammo is loaded to 52000psi.

I tried to get Starline to make a batch of brass for me with a larger radii on the inside corner when I started making the 6mm Predator. The die that keeps the inside dimension must be pretty damn expensive for them to say they could not do it on a 50000 piece order. According to the engineer there they pull the brass over the inside die and the brass is a uniform thickness to less than .001"

Buy a bunch of different brands of brass and section it, that should give you an idea. Some brands of brass is thinner, some is softer.

As far as your remark about the 6.8 being dead, for being a dead cartridge it sure has made us a crap load of money, we just finished building our second house on the ocean in Key West, built out of pocket without a mortgage. Any other smug remarks?

I included a photo of a 74000psi proof load loaded by Hornady. I use them to test my barrels and bolts. This is what a real 74000 psi load looks like. The red die on the bottom is Hornady's mark for proof ammo. Notice the belt and how high up it is but it took 74k to make it.

I didn't mean it as the 6.8 was dead, it's a line from the movie Walk Hard. More in the vein that you've written of the 6.5 variants and are convinced the 6.8 is superior by default.

I'm not sure how Starline makes their brass. That vaguely sounds like reverse drawing but I'm not aware of anyone that does that for cartridge cases. Not sure if that would even work... Most everyone else does fairly straight forward drawing as far as I know, with anneal cycles mixed in between draws and forming operations. C260 brass is harder to work with than more pure copper alloys and the tooling has to be pretty nuts on or you experience... failure. Most likely to make a change to the final drawn part requires minor changes to the entire draw set (going to guess 3-6 stations). Depending on what machines they're running and what kind of tooling they have it's very likely near to a grand per station on the cheap side, easily much more... plus tooling revisions, engineer/operator time, etc. Lots of extra handling time involved with the annealing cycles and other ops, too. They just want the initial order to be worth their development time.

ETA: yeah Starline is doing it the 'normal' way.

As far as Lapua, Yes. Everyone has problems now and then. Everyone has oversights and even with those aside, everyone in manufacturing has variation. Some better than most, but no one's perfect. I've had bad lots of Lapua brass in various cartridges. Shit happens.

The more I look into this, however, the more I think their case design is the reason it exists as a "thing". Searching through various forums and on google, all I find are Lapua and Alexander Arms (Lapua) head stamps. SWFShooter and Raptor99 both are using Lapua brass. By pixel-ratio'ing the pictures with a .445" rim diameter, the belt is anywhere from "okay", to way to far forward. .24" give or take is fairly common, and is where the chamber stops marking my bolt gun and AR brass. Some pictures, however, do have that belt start further up, which would indicate to me that the chamfer is a little more aggressive on some barrels.

Nonetheless, that it shows up anywhere near the .24" mark is reminiscent of an overpressure event, and an indication of one (or both) of two things

- Way over normal operating pressure (as you mention well over 70ksi)

- too thin side wall (can't handle normal, or slightly over normal operating pressure)

What should be happening is either the web of the case (on the inside of the case) goes right up to the chamfer on the barrel, or the unsupported section is so short that it can't fail radially. If you look at most cases, the web has a dent on the inside, around the flash hole to thin out the material where the flash hole pokes through. On the Lapua, their final draw and primer pocket forming creates a flat bottom on the inside (no dent). That effectively makes their web thinner towards the outside and puts the side wall under more stress, even if it is the same thickness-- it has to span a longer distance unsupported.

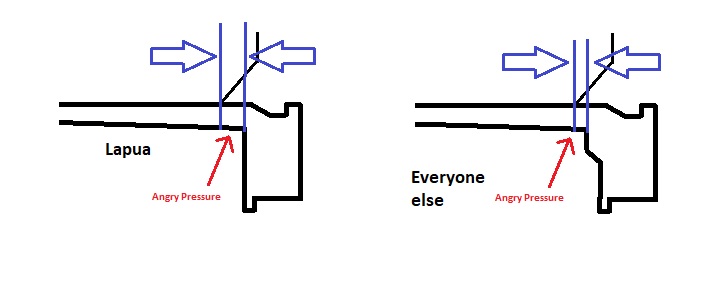

Forgive the MS Paint skills:

I would not be totally surprised if many hand loaders are over 70ksi. Reading through the reloading section here often makes me cringe... but I doubt that's many of them. I'm going to find some different brands of Grendel brass and cross section them and do some pressure vessel analysis on them. What I don't understand is why some shooters (barrels) have it and some don't. I used Lapua brass almost exclusively when I loaded Grendel and never had an issue. The only exception to using Lapua was trying out the Wolf Gold (PPU) stuff and that was a disaster. Blown (large rifle) primers and bullshit abound in general. Could be that it's just right on the threshold. Most don't see it, a few do.

ETA: My theory at this point is that belted Grendel is either

-Lapua Brass

-Belt is over .24" from the case head (Aggressive chamfer)

-Gross over pressure

NOT convinced at all it's inherently related to the 6.5 Grendel (other than Lapua is very popular in that chambering), the 6 ARC, or .445" diameter cartridges in the AR-15 (or any other platform).

I'm not sure how Starline makes their brass. That vaguely sounds like reverse drawing but I'm not aware of anyone that does that for cartridge cases. Not sure if that would even work... Most everyone else does fairly straight forward drawing as far as I know, with anneal cycles mixed in between draws and forming operations. C260 brass is harder to work with than more pure copper alloys and the tooling has to be pretty nuts on or you experience... failure. Most likely to make a change to the final drawn part requires minor changes to the entire draw set (going to guess 3-6 stations). Depending on what machines they're running and what kind of tooling they have it's very likely near to a grand per station on the cheap side, easily much more... plus tooling revisions, engineer/operator time, etc. Lots of extra handling time involved with the annealing cycles and other ops, too. They just want the initial order to be worth their development time.

ETA: yeah Starline is doing it the 'normal' way.

As far as Lapua, Yes. Everyone has problems now and then. Everyone has oversights and even with those aside, everyone in manufacturing has variation. Some better than most, but no one's perfect. I've had bad lots of Lapua brass in various cartridges. Shit happens.

The more I look into this, however, the more I think their case design is the reason it exists as a "thing". Searching through various forums and on google, all I find are Lapua and Alexander Arms (Lapua) head stamps. SWFShooter and Raptor99 both are using Lapua brass. By pixel-ratio'ing the pictures with a .445" rim diameter, the belt is anywhere from "okay", to way to far forward. .24" give or take is fairly common, and is where the chamber stops marking my bolt gun and AR brass. Some pictures, however, do have that belt start further up, which would indicate to me that the chamfer is a little more aggressive on some barrels.

Nonetheless, that it shows up anywhere near the .24" mark is reminiscent of an overpressure event, and an indication of one (or both) of two things

- Way over normal operating pressure (as you mention well over 70ksi)

- too thin side wall (can't handle normal, or slightly over normal operating pressure)

What should be happening is either the web of the case (on the inside of the case) goes right up to the chamfer on the barrel, or the unsupported section is so short that it can't fail radially. If you look at most cases, the web has a dent on the inside, around the flash hole to thin out the material where the flash hole pokes through. On the Lapua, their final draw and primer pocket forming creates a flat bottom on the inside (no dent). That effectively makes their web thinner towards the outside and puts the side wall under more stress, even if it is the same thickness-- it has to span a longer distance unsupported.

Forgive the MS Paint skills:

I would not be totally surprised if many hand loaders are over 70ksi. Reading through the reloading section here often makes me cringe... but I doubt that's many of them. I'm going to find some different brands of Grendel brass and cross section them and do some pressure vessel analysis on them. What I don't understand is why some shooters (barrels) have it and some don't. I used Lapua brass almost exclusively when I loaded Grendel and never had an issue. The only exception to using Lapua was trying out the Wolf Gold (PPU) stuff and that was a disaster. Blown (large rifle) primers and bullshit abound in general. Could be that it's just right on the threshold. Most don't see it, a few do.

ETA: My theory at this point is that belted Grendel is either

-Lapua Brass

-Belt is over .24" from the case head (Aggressive chamfer)

-Gross over pressure

NOT convinced at all it's inherently related to the 6.5 Grendel (other than Lapua is very popular in that chambering), the 6 ARC, or .445" diameter cartridges in the AR-15 (or any other platform).

Last edited:

LedZep, Constructor is right on this. Sometimes it's best to just shut up and realize you don't know everything.

The "Grendel belted magnum" thing is 100% due to the case design and lack of much of a taper near the case head. It is NOT a result of people goofing up chambers and cutting feed ramps too deep. It is specific to the Grendel/PPC case, as many of us have known for years; this isn't new info. Other cases can run at higher pressure with the same feed ramp geometry without ever causing this issue.

Regardless, it takes a fair amount of pressure to cause the belt, but not necessarily enough to loosen primer pockets. Just watch out for it and back off a little if you see mild signs of it. It doesn't mean the barrel was cut wrong.

The "Grendel belted magnum" thing is 100% due to the case design and lack of much of a taper near the case head. It is NOT a result of people goofing up chambers and cutting feed ramps too deep. It is specific to the Grendel/PPC case, as many of us have known for years; this isn't new info. Other cases can run at higher pressure with the same feed ramp geometry without ever causing this issue.

Regardless, it takes a fair amount of pressure to cause the belt, but not necessarily enough to loosen primer pockets. Just watch out for it and back off a little if you see mild signs of it. It doesn't mean the barrel was cut wrong.

That's fair. @Constructor my apologies for hanging onto the deep chamfer idea. I know it can be a reason why it happens because I've seen people do it. But that's another story... Probably some confirmation bias going on.

Nonetheless, it seems brand specific, no? Other than forming Lapua Grendel brass to make ARC brass it would appear to me to be a non-issue for the ARC.

eta: The CAD drawings I did last year regarding this were created with a new 6 ARC web/body for reference... Which looks much better than the Lapua web, and is no doubt a lot of the reason I thought an excessive chamfer was necessary to create this condition. Wires crossed, and you don't know what you don't know. I had not heard of Lapua-specific belting before.

Nonetheless, it seems brand specific, no? Other than forming Lapua Grendel brass to make ARC brass it would appear to me to be a non-issue for the ARC.

eta: The CAD drawings I did last year regarding this were created with a new 6 ARC web/body for reference... Which looks much better than the Lapua web, and is no doubt a lot of the reason I thought an excessive chamfer was necessary to create this condition. Wires crossed, and you don't know what you don't know. I had not heard of Lapua-specific belting before.

Last edited:

still laughing at the "reactionary dick" ... reference. I used to tell my friends Do be a "Semi-Rigid Richard Head. . Learning a bunch here.

In other news, I will be taking a stab at forming the Starline Grendle Basic Brass into ARC using the AMP Annealer. 500 cases on the way and hoping for "one pass" on the die. We will see how they roll.

In other news, I will be taking a stab at forming the Starline Grendle Basic Brass into ARC using the AMP Annealer. 500 cases on the way and hoping for "one pass" on the die. We will see how they roll.

If you lube them well I think you'll be okay. One day I picked up some 6.5 Grendel brass (hdy) that was already on the ground when picking up my ARC cases and didn't notice. They felt very different going through the size die but they formed up fine and I had long-neck ARCs.

This thread is quite thick...is there a resource I check regarding gas drive/system length and other factors to consider when building one of these gassers?

FWIW it’s not just Lapua. Obviously some brands are more susceptible than others but all Grendel & PPC brass has a fairly thin web compared to most other modern cartridges. Also some have asked about converting x39 brass and most of that stuff will form a belt at higher pressure as well.That's fair. @Constructor my apologies for hanging onto the deep chamfer idea. I know it can be a reason why it happens because I've seen people do it. But that's another story... Probably some confirmation bias going on.

Nonetheless, it seems brand specific, no? Other than forming Lapua Grendel brass to make ARC brass it would appear to me to be a non-issue for the ARC.

eta: The CAD drawings I did last year regarding this were created with a new 6 ARC web/body for reference... Which looks much better than the Lapua web, and is no doubt a lot of the reason I thought an excessive chamfer was necessary to create this condition. Wires crossed, and you don't know what you don't know. I had not heard of Lapua-specific belting before.

I’ve never seen the belt caused by a sizing operation; it’s always been from high pressure.

So what is the best brass to use for the ARC?? Stick with Hornady or Starline?? Thanks!!!FWIW it’s not just Lapua. Obviously some brands are more susceptible than others but all Grendel & PPC brass has a fairly thin web compared to most other modern cartridges. Also some have asked about converting x39 brass and most of that stuff will form a belt at higher pressure as well.

I’ve never seen the belt caused by a sizing operation; it’s always been from high pressure.

I still prefer Lapua, Starline is my second choice. The belt doesn’t happen unless you’re pushing pressures too high anyway.So what is the best brass to use for the ARC?? Stick with Hornady or Starline?? Thanks!!!

I shot a lot of 6.5 Grendel back in the day and the only belted case I got were Lapua or Alexander Arms headstamped and when shooting suppressed. I went to an adjustable gas block and Hornady brass. Never saw a belted case again.LedZep, Constructor is right on this. Sometimes it's best to just shut up and realize you don't know everything.

The "Grendel belted magnum" thing is 100% due to the case design and lack of much of a taper near the case head. It is NOT a result of people goofing up chambers and cutting feed ramps too deep. It is specific to the Grendel/PPC case, as many of us have known for years; this isn't new info. Other cases can run at higher pressure with the same feed ramp geometry without ever causing this issue.

Regardless, it takes a fair amount of pressure to cause the belt, but not necessarily enough to loosen primer pockets. Just watch out for it and back off a little if you see mild signs of it. It doesn't mean the barrel was cut wrong.

I do think that is part of my issue. I started off with formed Lapua Grendel to 6ARC and was loading at the top of the scale that Hornady had put out for the ARC semi autos. I went back and looked at my load data and noticed I had several loads with CFE and one with Varget that were .5gr over max. I have an adjustable gas block on mine so I don't know if the can "IS"" causing me any pressure issues. I honestly believe the main problem is the "Once fired" brass that I bought that was fired in a 6.5 Grendel. I am "Hoping" that if I stay in Hornady's guide lines my issue will be resolved.. It really hurts to toss 60+ cases of Lapua brass in the trash.....I shot a lot of 6.5 Grendel back in the day and the only belted case I got were Lapua or Alexander Arms headstamped and when shooting suppressed. I went to an adjustable gas block and Hornady brass. Never saw a belted case again.

Obviously AA brass was made by Lapua, but now is made by Hornady. This is Hornady shot in an over chamfered chamber. The Lapua bulged, Hornady just leaves a line. Similar load, case capacity are different so not exact same load. If your chamfer is spot on even Lapua can be pushed (a bit), but the best Grendel brass is probably Norma. Starline has similar capacity to Lapua and Norma, primer pockets might be the weak link with Starline.I shot a lot of 6.5 Grendel back in the day and the only belted case I got were Lapua or Alexander Arms headstamped and when shooting suppressed. I went to an adjustable gas block and Hornady brass. Never saw a belted case again.

Is now getting into the 6mm arc a bad idea given the shortage of ammo and brass, on top of the shortage of primers and powder? Was thinking to get the 6 arc, but I'm not seeing brass or ammo, or dies. Seems the newer cartridges come in even shorter supply. 6.5 prc for example, haven't had a batch of brass for a year.

Bmghunter, I have a feeling things will start coming back on line this summer. There are already people who are getting powder and some primers. You will find various bullets from time to time too. I am keeping a positive outlook on things. It is really a neat round!! I love mine!!

I've managed to score plenty of brass. I haven't been able to snag bullets but only because I'm being really picky (really want the 90gr TMK). Powder has been hard too (lever) but it only takes finding one 8# jug of it to be good to go for a while. Already have some primers but there have been multiple times I could have picked some up if I really wanted.Is now getting into the 6mm arc a bad idea given the shortage of ammo and brass, on top of the shortage of primers and powder? Was thinking to get the 6 arc, but I'm not seeing brass or ammo, or dies. Seems the newer cartridges come in even shorter supply. 6.5 prc for example, haven't had a batch of brass for a year.

ELD-X in stock at Midway.

Not inexpensive at 43 bucks per box, but if you need some hunting rounds, at least they are available.

www.midwayusa.com

www.midwayusa.com

Not inexpensive at 43 bucks per box, but if you need some hunting rounds, at least they are available.

Hornady Precision Hunter 6mm ARC Ammo 103 Grain Hornady ELD-X Polymer

Loaded with the most advanced all-range hunting bullet available, Precision Hunter Ammunition sets a new standard of accurate, deadly and dependable...

Gone now. At least some has made it into the wild. Hopefully more is in the pipeline, and at a better price.ELD-X in stock at Midway.

Not inexpensive at 43 bucks per box, but if you need some hunting rounds, at least they are available.

Hornady Precision Hunter 6mm ARC Ammo 103 Grain Hornady ELD-X Polymer

Loaded with the most advanced all-range hunting bullet available, Precision Hunter Ammunition sets a new standard of accurate, deadly and dependable...www.midwayusa.com

Beautiful 6mm ARC from Spartan Precision Rifles. 18” Proof stainless barrel, Geissele Mk16 rail and trigger, Surefire 6.5 Warcomp, NXS 2.5-10x 42mm. Looking forward to zeroing tomorrow with some factory 108’s. (Using my old moleskin’d Sopmod until I can find a B5 adjustable)

This thread is quite thick...is there a resource I check regarding gas drive/system length and other factors to consider when building one of these gassers?

Well I put one of these together and after I did I got to wondering the same thing so I called the manufacturer and asked them what they recommend for their barrels as far as buffer systems and bcg. Their answer was, carbine w/ heavy buffer without agb has worked really good for the barrel i have.

That was with their 20"barrel with rifle length gas.

The gas port is .085

That's all I can say for now as I haven't got to shoot it yet.

So as a recap, I take it that if you get the dreaded "Grendel Belt" your brass is basically Junk?? There is no way to get rid of it??? I have a 100+ Lapua cases that all have it. The belt measures anywhere from .442 to .448 most of it falls in the .444 range + or- a .001 Any that I have tired to load most won't chamber all the way. Some will fire if I smack the forward assist and others won't fire I just get a "Click".......

Can you post a pic?So as a recap, I take it that if you get the dreaded "Grendel Belt" your brass is basically Junk?? There is no way to get rid of it??? I have a 100+ Lapua cases that all have it. The belt measures anywhere from .442 to .448 most of it falls in the .444 range + or- a .001 Any that I have tired to load most won't chamber all the way. Some will fire if I smack the forward assist and others won't fire I just get a "Click".......

If the belt is very significant then it may be unsafe to keep using it. However, a mild belt can form of just a few thousandths and isn't a big deal if you don't cause it to get worse.

Just from what you've described, I have to wonder if there's not some other dimension in your brass that's preventing chambering.

Can you screw your resize die down another -003-.004 without causing too much headspace?... on the brass that may still be usable.

If you try that with the brass that has a pretty bad belt it may just make the possibility of separation and rupture worse.

In 07 when I was testing so much I had a 6mmAR/LBC/Grendel case rupture right at the point we are talking about. It blew the bottom of the mag out and down range about 20 yards so don't stick your arm under the mag on the bench.

If you try that with the brass that has a pretty bad belt it may just make the possibility of separation and rupture worse.

In 07 when I was testing so much I had a 6mmAR/LBC/Grendel case rupture right at the point we are talking about. It blew the bottom of the mag out and down range about 20 yards so don't stick your arm under the mag on the bench.

We have issues with the camera not down loading to my email so I can get a picture. Were trying again to see if we can get a picture for you. My brass pretty much looks like the picture at the bottom of the page on 35. I tried cranking the die down a tad and it just makes the belt narrower. When I load a resized case into my AR it closes fine but then I have one hell of a time extracting it. I have to use a hammer handle and hit the charging handle and the rifle on the floor to get it to open......Can you post a pic?

If the belt is very significant then it may be unsafe to keep using it. However, a mild belt can form of just a few thousandths and isn't a big deal if you don't cause it to get worse.

Just from what you've described, I have to wonder if there's not some other dimension in your brass that's preventing chambering.

Attachments

Ok based on that it sounds like your range pickup brass was fired in a chamber with a generous feed ramp, and your barrel is fairly tight. That’s good news for your barrel, but not so much for using that brass. There may be good reason someone left it at the range.We have issues with the camera not down loading to my email so I can get a picture. Were trying again to see if we can get a picture for you. My brass pretty much looks like the picture at the bottom of the page on 35. I tried cranking the die down a tad and it just makes the belt narrower. When I load a resized case into my AR it closes fine but then I have one hell of a time extracting it. I have to use a hammer handle and hit the charging handle and the rifle on the floor to get it to open......

Something to point out though- if you got a minor belt from firing in your rifle, it should fit back in your rifle again with proper resizing. It’s the difference between your chamber and someone else’s that’s giving you trouble.

And of course be extremely cautious about firing any cases that formed a belt; if it’s just a few thousandths it’s probably not a big deal but more than that is scrap IMO.

I have had some of the same issues with the Starline brass. I honestly believe that was an overpressure thing since it also tore up the face of my brass. I don't understand why though I have never exceeded the max on Hornadys load recommendations. I do see now that Hodgdons data is out and they are a gran or two lighter on some of their recommendations. I have backed down my loads to match their data and have had better luck with my brass. I have now had to start all over on my load work up. I went from having two loads with 87s and 108s the shot .5 or better to trying to find something that will shoot well and not destroy the damn brass!!! I was going to ask, my son in law has a RCBS small base die. Do you think running my brass through his SB die will take out the belt?? I have miked every piece of my brass and have kept anything that is .445 or smaller on the belt. Anything over that is in another pile. I am going to try using his die when we get together again. I hope I can save some of it. I have a special made "Pick" that I use to check for a "Parting line" starting on the inside of my brass and if I find one I know it is time to scrap it because I WILL get case separation in the next firing or two. I checked all of my ARC brass and so far it is nice and slick on the inside with no line starting. It just makes me sick because you can NOT find any brass anywhere!!!Ok based on that it sounds like your range pickup brass was fired in a chamber with a generous feed ramp, and your barrel is fairly tight. That’s good news for your barrel, but not so much for using that brass. There may be good reason someone left it at the range.

Something to point out though- if you got a minor belt from firing in your rifle, it should fit back in your rifle again with proper resizing. It’s the difference between your chamber and someone else’s that’s giving you trouble.

And of course be extremely cautious about firing any cases that formed a belt; if it’s just a few thousandths it’s probably not a big deal but more than that is scrap IMO.

I have had some of the same issues with the Starline brass. I honestly believe that was an overpressure thing since it also tore up the face of my brass. I don't understand why though I have never exceeded the max on Hornadys load recommendations. I do see now that Hodgdons data is out and they are a gran or two lighter on some of their recommendations. I have backed down my loads to match their data and have had better luck with my brass. I have now had to start all over on my load work up. I went from having two loads with 87s and 108s the shot .5 or better to trying to find something that will shoot well and not destroy the damn brass!!! I was going to ask, my son in law has a RCBS small base die. Do you think running my brass through his SB die will take out the belt?? I have miked every piece of my brass and have kept anything that is .445 or smaller on the belt. Anything over that is in another pile. I am going to try using his die when we get together again. I hope I can save some of it. I have a special made "Pick" that I use to check for a "Parting line" starting on the inside of my brass and if I find one I know it is time to scrap it because I WILL get case separation in the next firing or two. I checked all of my ARC brass and so far it is nice and slick on the inside with no line starting. It just makes me sick because you can NOT find any brass anywhere!!!

Tearing up the case head sounds like your rifle is over-gassed. Fix that first, and if you're using Lever it needs to be tuned for that, not some other powder. Forget about ejection pattern, adjust the gas so the carrier just barely locks back on the last round in a mag, then back the screw out 1/8-1/4 turn. Depending how badly your rifle is over-gassed, 1/4 turn can make a big difference, so adjust carefully.

Guess I’ll just reach out to CLE and Craddock since this is a reloading thread mostly.Well I put one of these together and after I did I got to wondering the same thing so I called the manufacturer and asked them what they recommend for their barrels as far as buffer systems and bcg. Their answer was, carbine w/ heavy buffer without agb has worked really good for the barrel i have.

That was with their 20"barrel with rifle length gas.

The gas port is .085

That's all I can say for now as I haven't got to shoot it yet.

Similar threads

- Replies

- 21

- Views

- 1K