Any pics of the trigger inlet work?I picked up my 223 defacto two days ago. It's pretty sweet so far. I've got a couple things to do to make everything work with the x-ray, but nothing too out of the ordinary I'd say. I'll try to update once I get it all worked out. View attachment 7916414

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

(New) Ultimatum DeFacto action (Tikka T3) Barreled action+trigger deal

- Thread starter 2aBaC̶a̶

- Start date

That's what I still need to do to the chassis. But I'll update once I get that done!Any pics of the trigger inlet work?

Hope you beat me to itThat's what I still need to do to the chassis. But I'll update once I get that done!

I’ll try to post pics when I get mine done as well.

A few marks from shipping. They would have benefited from more than 1 layer of bubble wrap in the box together.

Interesting marks in the recoil lug on both actions, I have no doubt they won’t affect function, just curious.

The 6.5CM bolt was in the fired position, making it impossible to insert into the rifle. Easily remedied but a novice would probably be a bit lost.

Now for the 10 day wait in California…

View attachment 7915620View attachment 7915621View attachment 7915622View attachment 7915623

So both actions had those marks on the recoil lug?

Looks almost like bite marks from the jaws of a pipe wrench or something similar.

Yes both do.So both actions had those marks on the recoil lug?

Looks almost like bite marks from the jaws of a pipe wrench or something similar.

It’s in the recessed recoil lug area

Interesting.Yes both do.

It’s in the recessed recoil lug area

Obviously not from shipping - looks like marks from sort of tool or tooling.

Wonder what's the cause of it. Certainly not something you would expect to see on such an expensive product.

Does yours have the same tooling marks in the recoil lug recess that mine do?

same 4 marks, just not as dark, but they are there

They are meaningless really but if you're into complaining its a reason

personally I would have never looked if you didn't ask, that is under the lug, so who will see it ?

Then again, shit like this just doesn't bother me

They are meaningless really but if you're into complaining its a reason

personally I would have never looked if you didn't ask, that is under the lug, so who will see it ?

Then again, shit like this just doesn't bother me

I mentioned i didn’t expect it to cause any issues with the function of the rifle, just curious if it was mine alone or a common problem.same 4 marks, just not as dark, but they are there

They are meaningless really but if you're into complaining its a reason

personally I would have never looked if you didn't ask, that is under the lug, so who will see it ?

Then again, shit like this just doesn't bother me

A person new to precision rifles might be surprised to see this though

Frank,same 4 marks, just not as dark, but they are there

They are meaningless really but if you're into complaining its a reason

personally I would have never looked if you didn't ask, that is under the lug, so who will see it ?

Then again, shit like this just doesn't bother me

I still am waiting for my BAs to clear California 10 day wait… but.

As I look at these marks in my pictures, I have a gut wrenching thought that these are a breaching of the action threads breaking through the action from the barrel tennon.

I plan on pulling a barrel the moment I get mine back this Saturday and see if i see any daylight.

That almost looks like barrel threads to meA few marks from shipping. They would have benefited from more than 1 layer of bubble wrap in the box together.

Interesting marks in the recoil lug on both actions, I have no doubt they won’t affect function, just curious.

The 6.5CM bolt was in the fired position, making it impossible to insert into the rifle. Easily remedied but a novice would probably be a bit lost.

Now for the 10 day wait in California…

View attachment 7915620View attachment 7915621View attachment 7915622View attachment 7915623

See the post above yours…That almost looks like barrel threads to me

it could be barrel thread

The Tikka-style action is pretty small, so busting through could definitely happen.

The Tikka-style action is pretty small, so busting through could definitely happen.

Frank,

I still am waiting for my BAs to clear California 10 day wait… but.

As I look at these marks in my pictures, I have a gut wrenching thought that these are a breaching of the action threads breaking through the action from the barrel tennon.

I plan on pulling a barrel the moment I get mine back this Saturday and see if i see any daylight.

Damn, I just dropped mine off at my local gunsmith to inlet my chassis for the safety. Definitely going to take a look at that when I get it back. I noticed marks there but didn't really think twice about it. Say the threads are busting through, and while I'd say that is rather poor design, and something that would've been easily caught in CAD or at the very least the first prototype. Is it a huge problem? I'm really just trying to playing devils advocate. In my mind there is still a ton of thread engagement. Is it kinda lousy? Yes, will it keep me from buying a second defacto? Probably. But if mine shoots I don't know that I'm that worried about it. Time will tell if I'm wrong I guess.

That's what I'm thinking, and mine is a 223, so not lot of recoil or anything. But I agree, rough and not ideal.Totally pulling it out of my ass but I bet there's no negative affect on accuracy or longevity. Assuming your inlet or bedding job works around the minor area. But still. That's rough.

Personally I would want some testing and engineering analysis done on the action to ensure it's safe. Having threads coming out of the action body has to impair the structural integrity to some degree.

But that's just me.

But that's just me.

By the fact they are showing threads, it would be easy to deduct that they are in area that is forward of the recoil lugs, and in the barrel shank area that is more than adequately reinforced by the barrel for the cartridge firing.Personally I would want some testing and engineering analysis done on the action to ensure it's safe. Having threads coming out of the action body has to impair the structural integrity to some degree.

But that's just me.

From a safety standpoint, I wouldn’t anticipate any glaring issues.

From a rigidity standpoint, there might be a different story.

The recoil forces will transfer to the front edge of the recoil lug pocket, forward of the screw protrusion. I would assume this would not support quite as well as it should be.

I inlet my chassis on Friday and shoot them on Saturday.

I’ll be shooting factory Hornady 147 ELDM 6.5cm and Prime 77gr 223.

We shall see.

I'm not a fan of making assumptions when there's a 65k psi explosion happening inches from my face.

You're probably right in that it won't result in anything material, but this conversation reminds me of Tracey Morgan's "pretty sure" commercials:

You're probably right in that it won't result in anything material, but this conversation reminds me of Tracey Morgan's "pretty sure" commercials:

I think the rationale behind going for the bigger Savage thread, instead of the normal Tikka thread is to potentially use standard Savage barrels, just like the Ultimatum action. This sounds like a good idea to me.

Now regarding the issue of the thread breaking through because of this, there are two possible reasons that I can think off:

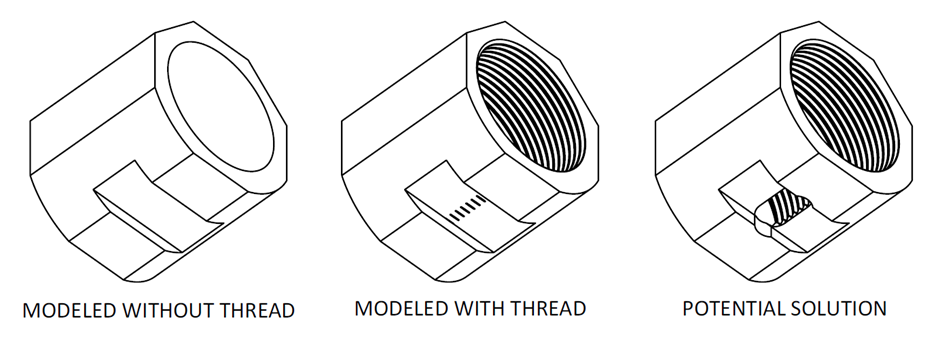

If this is an issue, yet they want to keep the Savage tenon, I would look into cutting a slot to clean up the threads as shown below. This will reduce recoil lug engagement, but it should still be enough.

Now regarding the issue of the thread breaking through because of this, there are two possible reasons that I can think off:

- The designer knew that it will happen, but the benefit of being able to use a standard Savage barrel on the action outweighs the issue of the thread breaking through.

- The designer did not know that it will happen and just saw the benefit of using a standard Savage barrel. Some might think, with modern CAD technology, how can a designer not see that this will happen and the answer is very simple. Many designers do not model threads, as it can be time consuming and technical drawings does not require a model with detailed thread. All that is required is to model the Major Diameter (for a male thread) and Minor Diameter (for a female thread) and then specify the detailed thread specification on the drawing “1 1/16 – 20”. This can cause an unforeseen scenario of the thread breaking through, only to be realized after metal has been cut.

If this is an issue, yet they want to keep the Savage tenon, I would look into cutting a slot to clean up the threads as shown below. This will reduce recoil lug engagement, but it should still be enough.

Ultimatum probably could've used you on their team two years ago when they announced the defacto!I think the rationale behind going for the bigger Savage thread, instead of the normal Tikka thread is to potentially use standard Savage barrels, just like the Ultimatum action. This sounds like a good idea to me.

Now regarding the issue of the thread breaking through because of this, there are two possible reasons that I can think off:

Or…

- The designer knew that it will happen, but the benefit of being able to use a standard Savage barrel on the action outweighs the issue of the thread breaking through.

Will it affect the safety and accuracy of the rifle? In my option, no. The barrel itself is strong enough to contain the pressure in the chamber and the thread breaking through in the middle of the tenon does not affect the bearing length (look at the Accuracy Internal AXMC thread locking method). There is also plenty of thread engagement to prevent the barrel from popping out of the action. Apart from it visually not looking good (which most people will never see), the only slight potential issue I see with it is the risk of a burr forming and seizing the barrel when screwed in or out.

- The designer did not know that it will happen and just saw the benefit of using a standard Savage barrel. Some might think, with modern CAD technology, how can a designer not see that this will happen and the answer is very simple. Many designers do not model threads, as it can be time consuming and technical drawings does not require a model with detailed thread. All that is required is to model the Major Diameter (for a male thread) and Minor Diameter (for a female thread) and then specify the detailed thread specification on the drawing “1 1/16 – 20”. This can cause an unforeseen scenario of the thread breaking through, only to be realized after metal has been cut.

If this is an issue, yet they want to keep the Savage tenon, I would look into cutting a slot to clean up the threads as shown below. This will reduce recoil lug engagement, but it should still be enough.

View attachment 7929902

Why would it sound like a good idea to use a Savage thread when there's a shit ton of Tikka prefits available?I think the rationale behind going for the bigger Savage thread, instead of the normal Tikka thread is to potentially use standard Savage barrels, just like the Ultimatum action. This sounds like a good idea to me.

Now regarding the issue of the thread breaking through because of this, there are two possible reasons that I can think off:

Or…

- The designer knew that it will happen, but the benefit of being able to use a standard Savage barrel on the action outweighs the issue of the thread breaking through.

Will it affect the safety and accuracy of the rifle? In my option, no. The barrel itself is strong enough to contain the pressure in the chamber and the thread breaking through in the middle of the tenon does not affect the bearing length (look at the Accuracy Internal AXMC thread locking method). There is also plenty of thread engagement to prevent the barrel from popping out of the action. Apart from it visually not looking good (which most people will never see), the only slight potential issue I see with it is the risk of a burr forming and seizing the barrel when screwed in or out.

- The designer did not know that it will happen and just saw the benefit of using a standard Savage barrel. Some might think, with modern CAD technology, how can a designer not see that this will happen and the answer is very simple. Many designers do not model threads, as it can be time consuming and technical drawings does not require a model with detailed thread. All that is required is to model the Major Diameter (for a male thread) and Minor Diameter (for a female thread) and then specify the detailed thread specification on the drawing “1 1/16 – 20”. This can cause an unforeseen scenario of the thread breaking through, only to be realized after metal has been cut.

If this is an issue, yet they want to keep the Savage tenon, I would look into cutting a slot to clean up the threads as shown below. This will reduce recoil lug engagement, but it should still be enough.

View attachment 7929902

At this stage (or even 1-2 yrs ago) you are only getting a couple more prefit options going with a Savage thread over a standard Tikka.

I'm not an engineer, but if there's an engineering reason I'm not understanding the logic, so I'm interested in hearing you expound. But if it's for prefit options, that doesn't seem like a good reason.

They already have the tooling and inspection equipment to cut the Savage thread, so ideally you would want to use it on all other actions. Less tooling to maintain is a good thing. Logistics is a big challenge and keeping it simple reduces costs, while increasing efficiency and quality. It also means their current clients can swap barrels between all their actions for what it is worth, assuming the headspace is the same. Consistency is key.Why would it sound like a good idea to use a Savage thread when there's a shit ton of Tikka prefits available?

At this stage (or even 1-2 yrs ago) you are only getting a couple more prefit options going with a Savage thread over a standard Tikka.

I'm not an engineer, but if there's an engineering reason I'm not understanding the logic, so I'm interested in hearing you expound. But if it's for prefit options, that doesn't seem like a good reason.

You would think something like this would come up during design reviews though... The question of what is/isn't CAD showing us has always come up during the design reviews I have participated in.I think the rationale behind going for the bigger Savage thread, instead of the normal Tikka thread is to potentially use standard Savage barrels, just like the Ultimatum action. This sounds like a good idea to me.

Now regarding the issue of the thread breaking through because of this, there are two possible reasons that I can think off:

Or…

- The designer knew that it will happen, but the benefit of being able to use a standard Savage barrel on the action outweighs the issue of the thread breaking through.

Will it affect the safety and accuracy of the rifle? In my option, no. The barrel itself is strong enough to contain the pressure in the chamber and the thread breaking through in the middle of the tenon does not affect the bearing length (look at the Accuracy Internal AXMC thread locking method). There is also plenty of thread engagement to prevent the barrel from popping out of the action. Apart from it visually not looking good (which most people will never see), the only slight potential issue I see with it is the risk of a burr forming and seizing the barrel when screwed in or out.

- The designer did not know that it will happen and just saw the benefit of using a standard Savage barrel. Some might think, with modern CAD technology, how can a designer not see that this will happen and the answer is very simple. Many designers do not model threads, as it can be time consuming and technical drawings does not require a model with detailed thread. All that is required is to model the Major Diameter (for a male thread) and Minor Diameter (for a female thread) and then specify the detailed thread specification on the drawing “1 1/16 – 20”. This can cause an unforeseen scenario of the thread breaking through, only to be realized after metal has been cut.

If this is an issue, yet they want to keep the Savage tenon, I would look into cutting a slot to clean up the threads as shown below. This will reduce recoil lug engagement, but it should still be enough.

View attachment 7929902

Reviving this pony....did Defacto get bought out or closed up shop? Their website says no new orders

Last edited:

Reviving this pony....did Ultimatum get bought out or closed up shop? Their website says no new orders

My understanding is that IBI took it over.

Not sure what that means for Ultimatum going into the future, and what the plans for the brand are though.

My understanding is that IBI took it over.

Not sure what that means for Ultimatum going into the future, and what the plans for the brand are though.

Reviving this pony....did Ultimatum get bought out or closed up shop? Their website says no new orders

They were indeed bought out by Ultimatum. Sounds like they honored existing DeFacto orders and aren't taking any more:

They instead have a 700 clone of sorts coming out:

I find this comment most intriguing though: sounds like they have a lightweight action on the horizon:

Similar threads

- Replies

- 11

- Views

- 2K

- Replies

- 2

- Views

- 920

- Replies

- 427

- Views

- 40K

- Replies

- 8

- Views

- 1K