The official Target of the New Factory Class of American Rimfire Association, Inc. 25 Bulls and numerous sighters. Sold in packs of 100.

www.killoughshootingsports.com

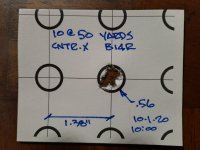

Something like this target see what it scores consistently

I was just introduced to the Bullet Pro 150 target at the LGC, and I really like it. When people use a standard score card, it's very easy to evaluate

how your doing in real time. I don't mean it has to be BP 150 but a standardized ring size seems very desirable. I don't have a shadow graph to view the targets but with dial calipers it looks like the ID of the smallest circle is .38" and it's OD is .50" The maximum possible score is 3000 pts.

One shot per bull allows for a much better read on the wind too. I took one target to my UPS store and had them reproduce them on

.0145" thick card stock. The bullet holes print much better then on regular .0035" note book paper.

I'm really shocked to hear people having issues with their B14Rs.... my all steel version has worked great. I even pulled my Vudoo out of

my MDT LSS gen2 chassis and installed my Trigger Tech Diamond 4 ounce trigger. It caused zero issues. I don't enjoy the factory trigger

bc I prefer them in the 4 to 6 ounce range like my Annie's have. All the same, she shoots fine with it set to 2 pounds 4 ounces.

I was however willing to modify my trigger in January of 2022 with a long nose spring plunger and that lowered the weight to 11

ounces and it provided an adjustable sear engagement too. Cost was $20.00 and 20 minutes of time. It's an easy modification with

a drill and tap at home.

You don't even need to take the trigger apart. Just drill, tap and install. The plunger cost $4.56 and is basically a set screw with a

4.5-pound spring loaded nose. It is shown next to the dime in image #5. I got the one with the nylon locking element to prevent

it from moving. It has a #6-32 body ( .138" OD ) and is about .62" long. It is shown installed in the last photo.

I took the opportunity to cover the Vudoo, Lapua and Ivanhoe logo's on the target and add some lines for information that was useful to me.

Stuff like: Gun, scope, wind, temp, ammo, mirage, etc.