I think the zinc parkerizing is the lighter finish of the two, and manganese is the blacker. Parkerizing is still my favorite finish, and I've had them all except birdsong. I now have a DLC bolt and bolt carrier for one of my AR's, so we'll see how she holds up. I've destroyed every finish except the finishes on my issue M4, which is parkerizing and whatever that ultra flat, 3000 grit type finish is on the aluminum; some sort of anno I'm guessing. Parkerizing's my favorite. Though now that I can see that you can black oxide stainless, I should get my rifle oxided...

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Gunsmithing Remington 700 DBM opinions from guys that put them in.....and use them.

- Thread starter pmclaine

- Start date

I think the zinc parkerizing is the lighter finish of the two, and manganese is the blacker. Parkerizing is still my favorite finish, and I've had them all except birdsong. I now have a DLC bolt and bolt carrier for one of my AR's, so we'll see how she holds up. I've destroyed every finish except the finishes on my issue M4, which is parkerizing and whatever that ultra flat, 3000 grit type finish is on the aluminum; some sort of anno I'm guessing. Parkerizing's my favorite. Though now that I can see that you can black oxide stainless, I should get my rifle oxided...

Do you like walks on the beach at sunset, holding hands?

You are speaking porn to me....

Last edited:

Am I the only one who watches the @LongRifles Inc. tracker like a crazy person?

I may be even more excited about this build than I was with the first one. Knowing their quality, now I’m hooked. Welcome to December everyone!

I may be even more excited about this build than I was with the first one. Knowing their quality, now I’m hooked. Welcome to December everyone!

lol. And welcome to the insanity that is the shooting sports world in 2020... I didn't realize how spoiled I was just one year ago with finding parts, ordering them, having them come to my house, and not worrying about ammo... At least all the gun companies and smiths are getting money though. I'm glad for that. I'm sure if I had LRI do my rifles last year they would have taken a lot less time.

Exactly. Chad and his team are awesome. I have to remember sometimes he is running a business, not just building MY gun.lol. And welcome to the insanity that is the shooting sports world in 2020... I didn't realize how spoiled I was just one year ago with finding parts, ordering them, having them come to my house, and not worrying about ammo... At least all the gun companies and smiths are getting money though. I'm glad for that. I'm sure if I had LRI do my rifles last year they would have taken a lot less time.

Exactly. Chad and his team are awesome. I have to remember sometimes he is running a business, not just building MY gun.

Lets agree on one thing........My gun before yours.

To be fair, yours was in before mine.Lets agree on one thing........My gun before yours.

Oh for sure; LRI probably has 150 rifles there as we speak. There are way more shooters that prefer high end guns in this country than I previously thought. When there's an 8 month backlog for 500 dollar rifle barrels, (not due to material shortages) that means theres a TON of well heeled shooters in America lol.

My Favorite! Got an LRI Tracker....

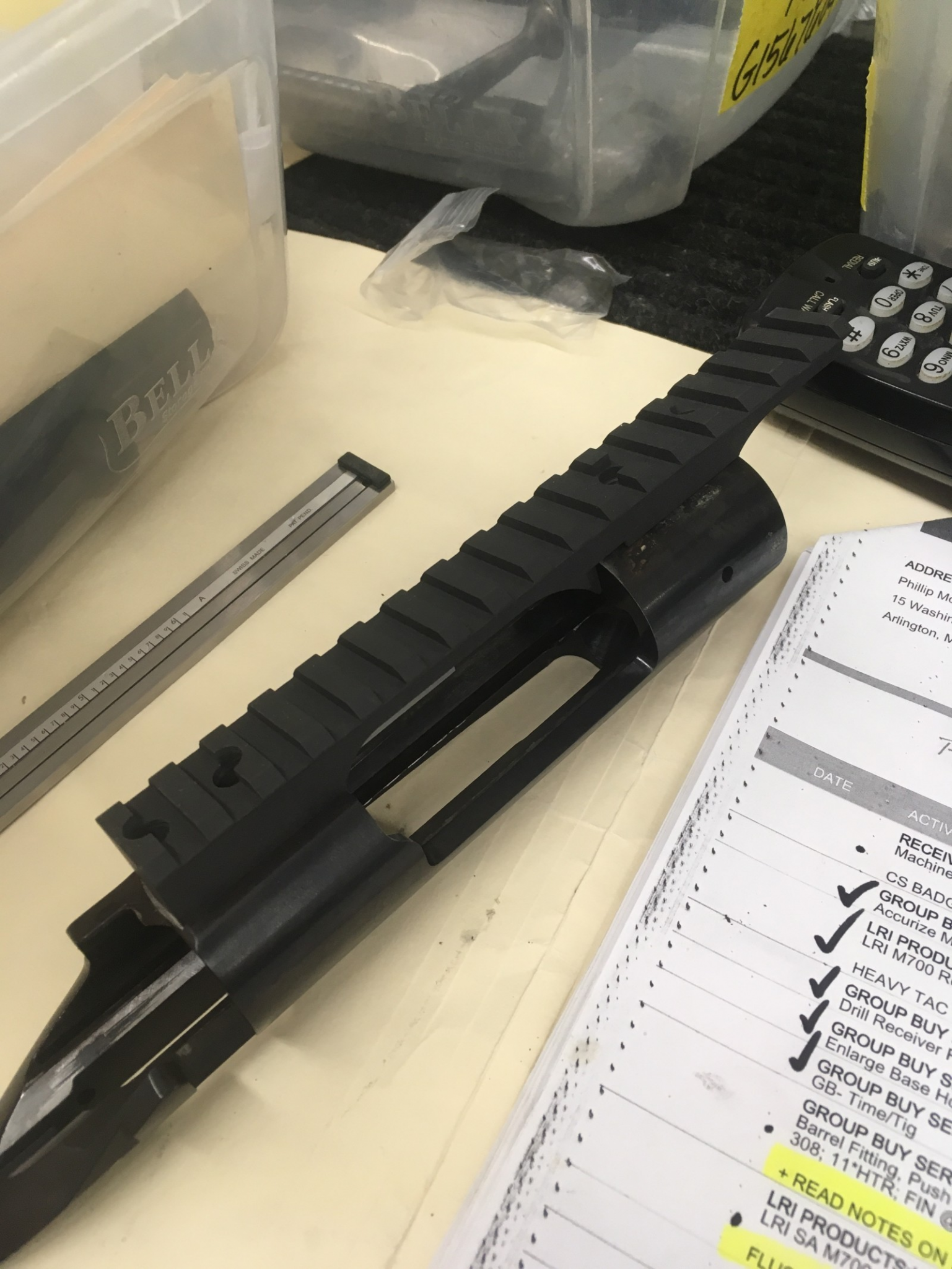

@LongRifles Inc. you did this next receiver cut perfect. I was afraid my direction would be unclear, but you guys nailed it. The right side thumb cut transition to the scope rail is USMC beautiful and I really like this added detail cut matching the receiver to the rail on the left side.

Too late to change from Parkerized finish to pink cerakote?

Just kidding....please dont.

@LongRifles Inc. you did this next receiver cut perfect. I was afraid my direction would be unclear, but you guys nailed it. The right side thumb cut transition to the scope rail is USMC beautiful and I really like this added detail cut matching the receiver to the rail on the left side.

Too late to change from Parkerized finish to pink cerakote?

Just kidding....please dont.

Last edited:

Still plenty more to do.Christmas 14 days early is how I see it.

you wanted to see pic right?

Still plenty more to do.

you wanted to see pic right?

I love pictures...

They are worth 1000 words.

Mine is headed to barreling now. Looks like I had more receiver work than you.

What we are really going to be treated to is when LRI posts pictures of my DBM and associated stock work.

Please keep posting.

Will do.

I did just call and add a feed ramp notch, so that will probably slow me down slightly. Then fluting and cerakote.

I did just call and add a feed ramp notch, so that will probably slow me down slightly. Then fluting and cerakote.

Your Bling is showing.......

Very nice!

I hope we three are in a little rotation at the bench here and one of us is updating every few days or so.

Its my turn today....

Barreled...

Test Fired...

Stand by because this build will get really interesting as it moves into the Bottom Metal and stock work........

Barreled...

Test Fired...

Stand by because this build will get really interesting as it moves into the Bottom Metal and stock work........

Rock and roll!View attachment 7501962

Very nice missed this update.....

I came here to ask if anything new had updated with either of the other two rifles mentioned here.

My turn will probably come up after the holiday......

Rock and roll!View attachment 7501962

Looking good! What Cerakote color is that? This is very similar to the 2nd 700 I'm going to have LRI do for me.

Sniper greyLooking good! What Cerakote color is that? This is very similar to the 2nd 700 I'm going to have LRI do for me.

Mine shipped on Thursday. Depending on Usps, should be here Tuesday next week.Very nice missed this update.....

I came here to ask if anything new had updated with either of the other two rifles mentioned here.

My turn will probably come up after the holiday......

Mine shipped on Thursday. Depending on Usps, should be here Tuesday next week.

Pictures......lots of pictures.

And I hate to worry you but USPS has been a soup sandwich as of late.

They work for Jeff Bozo only, Corona has determined he will be the one and only retailer.

Will do. I’m in Denver, so I’m sure it will be delayed some. Stock should be in soon from getting dipped at Applied Hydrographics. Will be sure to send pics when she’s together.Pictures......lots of pictures.

And I hate to worry you but USPS has been a soup sandwich as of late.

They work for Jeff Bozo only, Corona has determined he will be the one and only retailer.

Believe it or not, it came a day early! I’ll get some pics out soon.Pictures......lots of pictures.

And I hate to worry you but USPS has been a soup sandwich as of late.

They work for Jeff Bozo only, Corona has determined he will be the one and only retailer.

Glad to have found this thread. Being new to the precision shooting game, this is one of the places where I learn how things are done. I tried to have my local gunsmith do something similar not long ago (on a much less ambitious scale) and it didn't work out as well. After putting my Remington 700 in a Magpul Hunter stock I did see an increase in accuracy (small one) but I really enjoyed having the convenience of the DBM. What I missed, however, was the soul of the very nice wood stock the rifle came out of.

I took the Magpul bottom metal (plastic) to him and had him modify the stock for it, along with one of the magazines. $75 later I was very pleased to have a wood stocked DBM rifle.

Then I got it home to find out my other 2 mags dragged on the bolt. Oh, it fed fine. Everything worked, but it wasn't as it should have been. Differences in the molded plastic mags...? Who knows. It's just that there was a drag as you worked the bolt. The mag I gave him worked fine. Bolt operated smooth as factory. Not so my other 2. Probably wouldn't have hurt anything having the bottom of the bolt rubbing on the top of a plastic magazine slightly, but I'm sure it wouldn't have done the consistency of my shooting any good either. Worried me having a DBM rifle, and only one mag that works right, so I ended up going back to the Hunter stock. I'm betting I could order 20 more mags, and they'd all work fine in the Magpul factory stock because they were engineered to go together, even though they're all inexpensive plastic ones.

I'm always complaining about my limited budget because I'm living on VA disability, but I'm also building a CJ7 from the frame up in the garage, a project that I've been working on for 2 years now, so that takes precedence right now. Any rather expensive gun builds will have to wait till the Jeep gets finished... another 2 years probably.

Glad to have at least learned of a good smith I may be able to make use of one day if funds ever come available... I love his bottom metal ideas... Would be nice to have the action blueprinted as well. My rifle (a .243) is pretty much a factory gun, but she'll do right at .75" if I do my part with the 95gr Deer Season XP.

Thinking of getting into hand loading one day, and maybe trying some of the VLD bullets if I don't just rebarrel to .308, but again, bad timing. Jeep build... Besides, you can't really buy anything these days, loaded rounds, or components.

I took the Magpul bottom metal (plastic) to him and had him modify the stock for it, along with one of the magazines. $75 later I was very pleased to have a wood stocked DBM rifle.

Then I got it home to find out my other 2 mags dragged on the bolt. Oh, it fed fine. Everything worked, but it wasn't as it should have been. Differences in the molded plastic mags...? Who knows. It's just that there was a drag as you worked the bolt. The mag I gave him worked fine. Bolt operated smooth as factory. Not so my other 2. Probably wouldn't have hurt anything having the bottom of the bolt rubbing on the top of a plastic magazine slightly, but I'm sure it wouldn't have done the consistency of my shooting any good either. Worried me having a DBM rifle, and only one mag that works right, so I ended up going back to the Hunter stock. I'm betting I could order 20 more mags, and they'd all work fine in the Magpul factory stock because they were engineered to go together, even though they're all inexpensive plastic ones.

I'm always complaining about my limited budget because I'm living on VA disability, but I'm also building a CJ7 from the frame up in the garage, a project that I've been working on for 2 years now, so that takes precedence right now. Any rather expensive gun builds will have to wait till the Jeep gets finished... another 2 years probably.

Glad to have at least learned of a good smith I may be able to make use of one day if funds ever come available... I love his bottom metal ideas... Would be nice to have the action blueprinted as well. My rifle (a .243) is pretty much a factory gun, but she'll do right at .75" if I do my part with the 95gr Deer Season XP.

Thinking of getting into hand loading one day, and maybe trying some of the VLD bullets if I don't just rebarrel to .308, but again, bad timing. Jeep build... Besides, you can't really buy anything these days, loaded rounds, or components.

Last edited:

Glad to have found this thread. Being new to the precision shooting game, this is one of the places where I learn how things are done. I tried to have my local gunsmith do something similar not long ago (on a much less ambitious scale) and it didn't work out as well. After putting my Remington 700 in a Magpul Hunter stock I did see an increase in accuracy (small one) but I really enjoyed having the convenience of the DBM. What I missed, however, was the soul of the very nice wood stock the rifle came out of.

I took the Magpul bottom metal (plastic) to him and had him modify the stock for it, along with one of the magazines. $75 later I was very pleased to have a wood stocked DBM rifle.

View attachment 7514390

Then I got it home to find out my other 2 mags dragged on the bolt. Oh, it fed fine. Everything worked, but it wasn't as it should have been. Differences in the molded plastic mags...? Who knows. It's just that there was a drag as you worked the bolt. The mag I gave him worked fine. Bolt operated smooth as factory. Not so my other 2. Probably wouldn't have hurt anything having the bottom of the bolt rubbing on the top of a plastic magazine slightly, but I'm sure it wouldn't have done the consistency of my shooting any good either. Worried me having a DBM rifle, and only one mag that works right, so I ended up going back to the Hunter stock. I'm betting I could order 20 more mags, and they'd all work fine in the Magpul factory stock because they were engineered to go together, even though they're all inexpensive plastic ones.

I'm always complaining about my limited budget because I'm living on VA disability, but I'm also building a CJ7 from the frame up in the garage, a project that I've been working on for 2 years now, so that takes precedence right now. Any rather expensive gun builds will have to wait till the Jeep gets finished... another 2 years probably.

Glad to have at least learned of a good smith I may be able to make use of one day if funds ever come available... I love his bottom metal ideas... Would be nice to have the action blueprinted as well. My rifle (a .243) is pretty much a factory gun, but she'll do right at .75" if I do my part with the 95gr Deer Season XP.

Thinking of getting into hand loading one day, and maybe trying some of the VLD bullets if I don't just rebarrel to .308, but again, bad timing. Jeep build... Besides, you can't really buy anything these days, loaded rounds, or components.

Man that looks great.

Measure up the mags is there just a tolerance issue? Can you sand lightly the other mags to get them working.

My idea that I needed a mag feed was from taking classes watching everyone else bottom load while I was individually top loading.

Never slowed me down or prevented me doing a drill just meant I had to be a hair more prepared and ambidextrous.

Instructors at Sig were good naturedly ribbing me yesterday because I brought a 1911 to class.

The only .45 and everyone else had Sig of at least 13 round capacity.

I had 10 mags. 7 rounders as JMB ordained it to be. I was getting my mag change drills in.

Found it funny that in one drill just before lunch the instructors had us do the excercise until all of our mags were clear.

Everyone with their 3 high cap mags went dry and I still had some mags left.......Instructors were like "Great the last century guy is putting you all to shame."

Tried sanding a bit, but was worried about the mags being plastic, and possible damage to the feed lips. I may try to shim the bottom metal out a few thousands, see what that does. Could be it without all 3 there to work with he just set it in too far.Man that looks great.

Measure up the mags is there just a tolerance issue? Can you sand lightly the other mags to get them working.

My idea that I needed a mag feed was from taking classes watching everyone else bottom load while I was individually top loading.

Never slowed me down or prevented me doing a drill just meant I had to be a hair more prepared and ambidextrous.

Instructors at Sig were good naturedly ribbing me yesterday because I brought a 1911 to class.

The only .45 and everyone else had Sig of at least 13 round capacity.

I had 10 mags. 7 rounders as JMB ordained it to be. I was getting my mag change drills in.

Found it funny that in one drill just before lunch the instructors had us do the excercise until all of our mags were clear.

Everyone with their 3 high cap mags went dry and I still had some mags left.......Instructors were like "Great the last century guy is putting you all to shame."

Nice job on the range drills by the way. Often (most times) it boils down to the man behind the gun...

Here’s the stock (far left Gods Plaid) my LRI build will drop into. Should have it this week and can post more pics.

(

(

Just waiting on bipod lug for Harris bipod, but she’s ready to fire away.

First, I sincerely appreciate all the encouragement and support from the folks who have mentioned us on this thread. I am very flattered, to say the least.

Now, down to business.

View attachment 7212533

The DBM setup LRI is making was born out of necessity. There are issues I've encountered for a number of years that annoyed the hell out of me.

1. A DBM with a bit of elegance to hopefully appeal to the sporting community.

2. AI magazine compliance* (rant to follow)

3. Obendorf style latch for hunting applications (goes in/out of a scabbard, vehicle, case easily)

4. Lightweight

5. Crowned trigger guard with hips. -an attempt at a respectful nod to how guns used to be made.

6. Full support to gunsmiths and end-users. (more on that in a minute)

View attachment 7212534

View attachment 7212545

*AI set a standard with magazines that began almost two decades ago. When you look at any attempt at a "sporter" DBM what do you find? You find a corner that you become boxed into the moment you get your wallet out. Now, you are locked into the magazine configuration they offer. The stuff you've already spent thousands of dollars on has no use. It's a big reset button and you have to start all over again. Then add insult to injury when you later learn that the magazines are almost always poorly made. Rubber O rings and other things to bandaid problems that shouldn't exist to begin with.

I am of the opinion that this approach is both dumb and stupid from a manufacturer's standpoint.

It doesn't take a 30 round magazine to go shoot a deer or an elk. -Least it shouldn't. Hunting guns demand some compromise to suit the task as a whole. ( A light gun that's easy to shoot and built to deliver good accuracy from a cold bore shot.) That's really all it has to do. Now, that said, it is nice to not have to destroy your thumbs loading (3 round) magazines at the range when you just want to go shooting or while working up a load. That is where this trinket I'm making starts to get a little traction. Grab some (AI, ARC, Alpha, Accurate) 10 rounders and go to the range.

Our floor metal works with all of them.

View attachment 7212543View attachment 7212541

View attachment 7212538

View attachment 7212535

So, OP, at this point it might be a good time to review your setup and make sure I'm the right guy for your project and your application.

The next facet of this project that I wanted to work on was the "after purchase" side of things. A big company has been the dominant force in this particular product for a long, long time. YET, the best you get from them when it comes to fitting the thing is either a photocopy void of any meaningful dimensions or a telephone call where the person on the phone says, "send it to us and we'll do it for "x" amount of dollars.

LRI supports the product for both gunsmiths and end-users. Anyone can go to the product listing and download prints, setup sheets, tool packages, AND the ACTUAL CODE that we use to fit the parts to the stock. You may have to change a bit of the syntax to suit your machine, but the meat and potatoes of the process are lined out in detail.

I've been on a crusade for the last 15+ years to change this side of the industry. When I can go to McMaster Carr's website and download a Solid Works Part file of a bolt, screw, pump, assembly, whatever, then we should be able to do it here as well.

the days of being treated as though I'm asking for access to National Security matters needs to die a quick and painful death. It is just a floormetal. . .

You can find more on our stuff here:

LRI DETACHABLE BOTTOM METAL SYSTEM FOR REMINGTON TYPE M700 SA

Anyone who has used or fitted a detachable magazine setup on a rifle has inevitably run into the situation where a particular brand of magazine doesn't work. The problem is there is no standard. No hall of records where you anoint yourself in Hoppes and pay homage to gain the magic answer. We...www.longriflesinc.com

LRI, those are absolutely pristine!! Is your DBM "drop in" ready for stocks that were in letted for R700 BDLs? I have a McMillan M40A1 stock that I ordered and is inletted with the BDL hinge place magazine setup. I would love to purchase your DBM configuration but wasn't sure if it would work or drop in with the way my fiberglass McMillan stock is inletted. There is a little bit of play with the bottom metal already.

I love wooden stocks.

Too rough on my kit though.

Rough = Character

Here’s the stock (far left Gods Plaid) my LRI build will drop into. Should have it this week and can post more pics. View attachment 7518965(

Man Im not getting notifications and this is my favorite thread of the moment...

Is LRI cutting the inlet from an un-inletted blank or did the maker inlet and LRI will skim bed?

Just waiting on bipod lug for Harris bipod, but she’s ready to fire away.

View attachment 7522619

Looks very competent.

Love that Tiger Stripe pattern in the middle.Here’s the stock (far left Gods Plaid) my LRI build will drop into. Should have it this week and can post more pics. View attachment 7518965(

Grayboe actually sells their stocks pre-inletted. This is actually my third from them and they haven’t let me down yet.Man Im not getting notifications and this is my favorite thread of the moment...

Is LRI cutting the inlet from an un-inletted blank or did the maker inlet and LRI will skim bed?

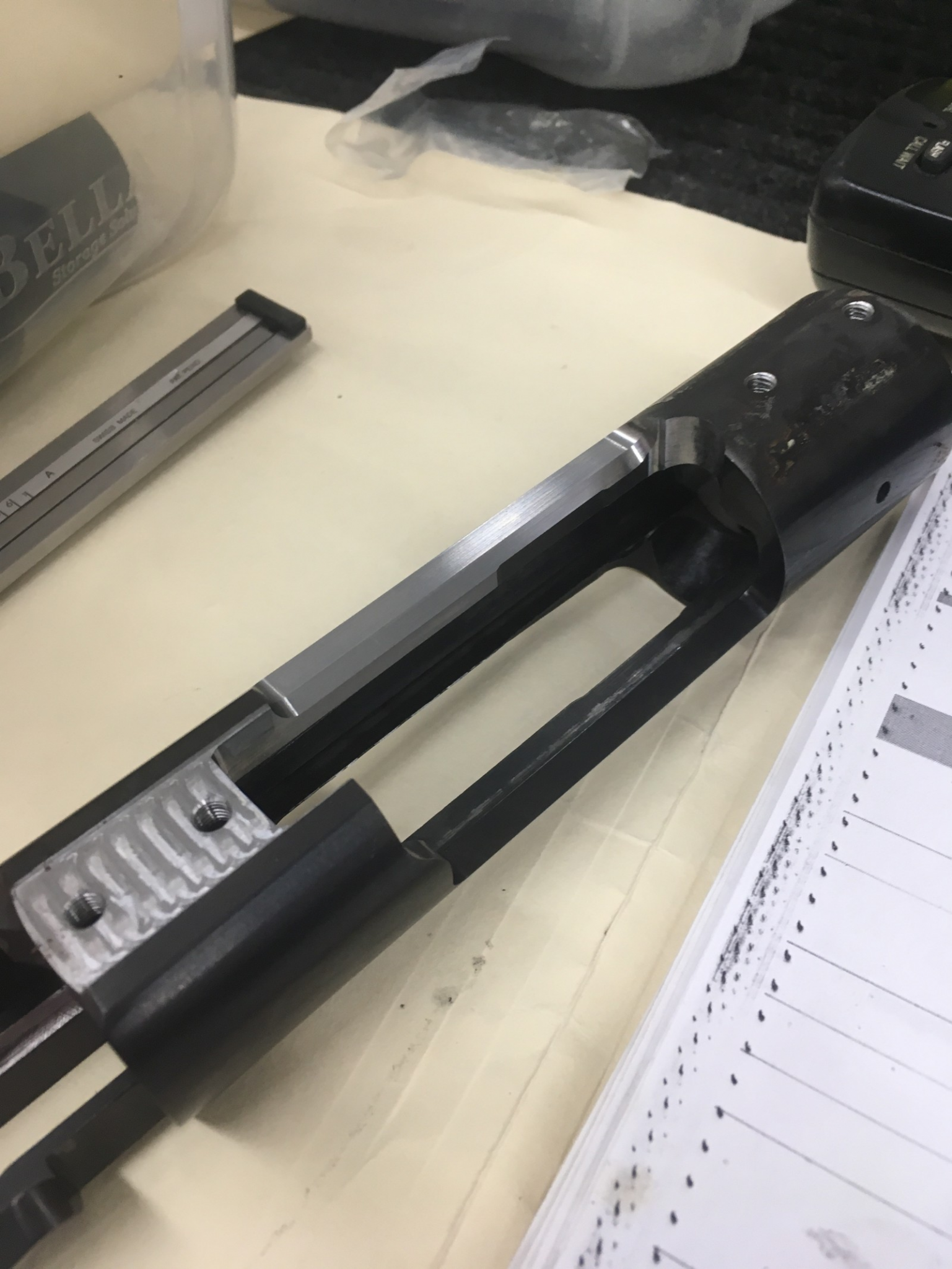

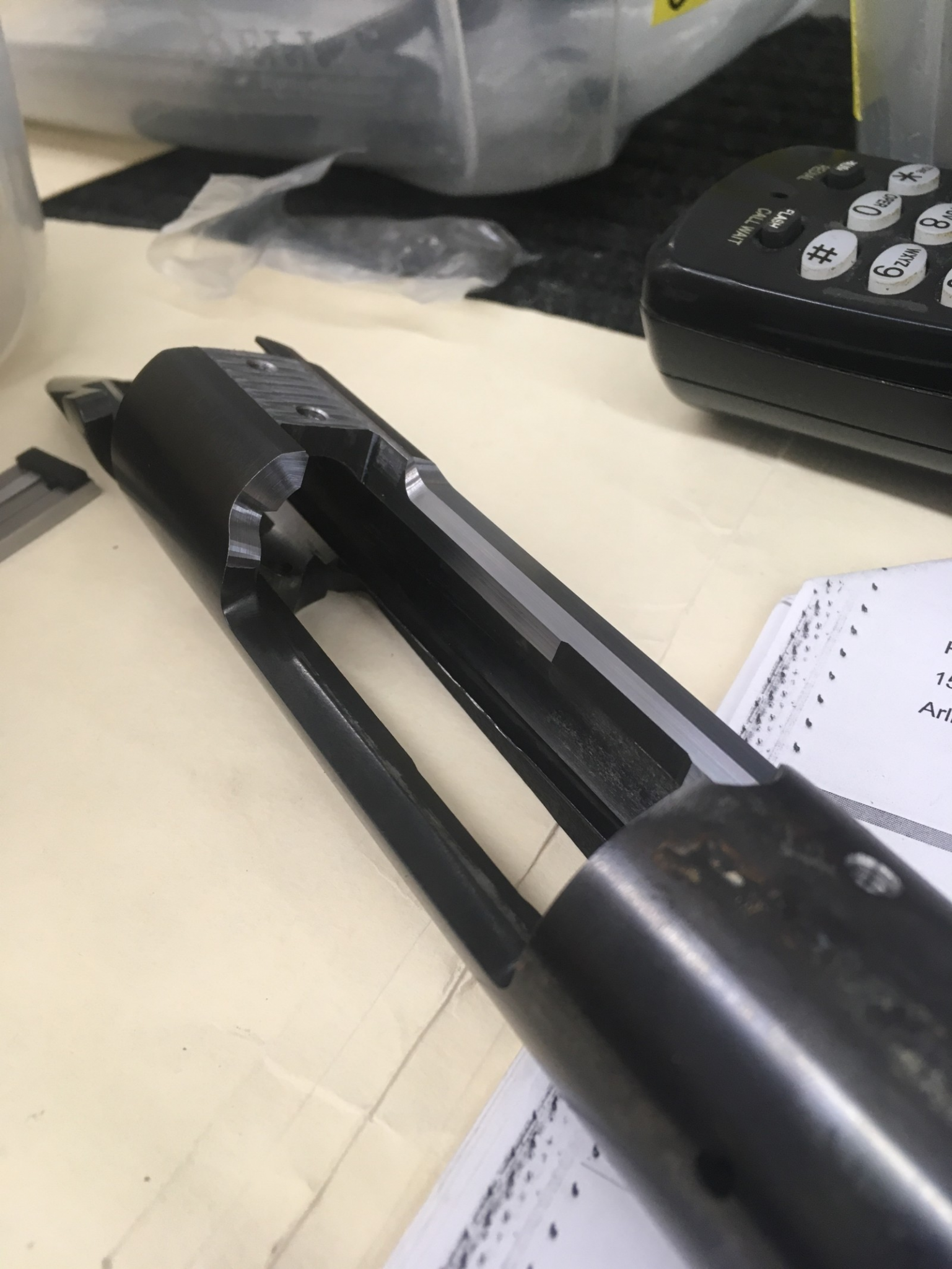

I got antsy and requested some pictures even of the work in progress and LRI was willing to oblige. Just waiting for the stock work to come on line and they will be wrapping it up.

The stock work is going to be really interesting to see...

The stock work is going to be really interesting to see...

pmclaine - any updates from LRI?

I just received these yesterday:

I just received these yesterday:

pmclaine - any updates from LRI?

I just received these yesterday:

View attachment 7609273View attachment 7609274View attachment 7609275

Patiently waiting........

Damn! They put your bolt on the wrong side.

Is that Parkerizing?

I know, weird right? - it's happened on ever one of my bolt action.Patiently waiting........

Damn! They put your bolt on the wrong side.

Is that Parkerizing?

It's Cerakote on a stainless action. Just told Tanner to do his thing. Believe I even verbalized "something along the lines of a parkerized finish". Guess he mixed up some custom grey, but I don't have the specifics on it.

I know, weird right? - it's happened on ever one of my bolt action.

It's Cerakote on a stainless action. Just told Tanner to do his thing. Believe I even verbalized "something along the lines of a parkerized finish". Guess he mixed up some custom grey, but I don't have the specifics on it.

I think it looks great!

I like parkerizing for coming home, getting out the Marsh ink brush full of Ballistol, and lubing everything metal down.....

Its like curry combing a Horse shiny.

Thanks for sharing.... In today's world it's hard to beat craftsmanship and customer service.... At any price.

I've always known I wanted to send a rifle to Chad.

After reading through this. Now I need too.

That's what's being an adult is right? Knowing the difference between wants and needs?

After reading through this. Now I need too.

That's what's being an adult is right? Knowing the difference between wants and needs?

Similar threads

- Replies

- 7

- Views

- 1K

- Replies

- 33

- Views

- 5K