This is 50/50 product and DIY...but I recently came across a new product called The Last Stand (www.laststands.com) and basically you buy their molded joint system and go to the hardware store to buy some #4 rebar and you have a fully adjustable, bullet resistant and very transportable target system to hang anything you want from it...been loving mine...

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

-

Quick Shot Challenge: What’s the most underrated gear you never leave home without?

Contest ends Wednesday, join now for the chance to win free Hide merch!

Join contest

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The ultimate target stand!

- Thread starter shootermcgavin

- Start date

-

- Tags

- stand target target system

Here is a system I've been working on for a couple years. I've shot thousands of rifle to include 300 WM and pistol rounds at these targets without a failure. Notice that all hardware is protected by the plate so there is nothing to break. The target sets at an angle to the ground which directs splatter downward. The free movement upon impact lessens bullet damage to the target face by re-directing energy.

This is my first prototype and I'm working on a system that will allow multiple targets to be hung on the same post and the system will be WELDLESS which will enhance durability.

Watch these videos to see how reactive the target is. It is being shot with a 223 @ 140 yards

8inchsteelplaterearmovie.mp4 Video by vinconco | Photobucket

8inchsteelplaterearmovie.mp4 Video by vinconco | Photobucket

This is my first prototype and I'm working on a system that will allow multiple targets to be hung on the same post and the system will be WELDLESS which will enhance durability.

Watch these videos to see how reactive the target is. It is being shot with a 223 @ 140 yards

8inchsteelplaterearmovie.mp4 Video by vinconco | Photobucket

8inchsteelplaterearmovie.mp4 Video by vinconco | Photobucket

All of these are great ides. If you can weld then the solutions are endless

I'm working on a weldless T-post system and will have pics up shortly. Then all you will need to do is bolt a couple pieces of 1/4" x 1" steel strap and 4 chain links to your plates and bang away. WELDS BREAK especially with rifle targets and they soften the steel around the welds.

Here is a system I've been working on for a couple years. I've shot thousands of rifle to include 300 WM and pistol rounds at these targets without a failure. Notice that all hardware is protected by the plate so there is nothing to break. The target sets at an angle to the ground which directs splatter downward. The free movement upon impact lessens bullet damage to the target face by re-directing energy.

This is my first prototype and I'm working on a system that will allow multiple targets to be hung on the same post and the system will be WELDLESS which will enhance durability.

Watch these videos to see how reactive the target is. It is being shot with a 223 @ 140 yards

8inchsteelplaterearmovie.mp4 Video by vinconco | Photobucket

8inchsteelplaterearmovie.mp4 Video by vinconco | Photobucket

I like this idea alot

Here is a front and back video of the target being shot with a .223 @ 140 yards

T Post target system - YouTube

T Post target system - YouTube

I'm working on a weldless T-post system and will have pics up shortly. Then all you will need to do is bolt a couple pieces of 1/4" x 1" steel strap and 4 chain links to your plates and bang away. WELDS BREAK especially with rifle targets and they soften the steel around the welds.

i'm not gonna disagree with you, just get technical. unless the welder is at fault the welds aren't what is breaking. the filler metal is generally a higher tensile strength than your typical mild steel. the area around the weld is usually what breaks because like said, it softens the steel around the weld. so far I've never had a weld break on me. mine have seen up to a 7mm ultra mag at 100yds or more. with all that said I try to get away from welding my targets when I can. there's aways a better way. but I do like your design, does it always return back to face the shooter?

i'm not gonna disagree with you, just get technical. unless the welder is at fault the welds aren't what is breaking. the filler metal is generally a higher tensile strength than your typical mild steel. the area around the weld is usually what breaks because like said, it softens the steel around the weld. so far I've never had a weld break on me. mine have seen up to a 7mm ultra mag at 100yds or more. with all that said I try to get away from welding my targets when I can. there's aways a better way. but I do like your design, does it always return back to face the shooter?

Watch the video I posted (above) to see the target in action....

I have welded targets that have lasted too and I've seen a lot of them fail as well. I'm trying to come up with something the average shooter that cannot weld can put together easily with tools at hand. I'm changing the T-post bracket design to be easier and cheaper to make so it could sell for around 25 bucks.

Last edited:

I take my targets and stands to the local club range and bring them back home with me; so simpler and less bulky works best.

I use Corroplast sign blanks, and their corresponding 'H' frame stakes.

They are very durable, and to a minor degree are also self healing; but when a round hits the hidden wire stake, all bets are off. I also bring along packing paper for refacing the sign blanks when the existing holes become a distraction.

Greg

I use Corroplast sign blanks, and their corresponding 'H' frame stakes.

They are very durable, and to a minor degree are also self healing; but when a round hits the hidden wire stake, all bets are off. I also bring along packing paper for refacing the sign blanks when the existing holes become a distraction.

Greg

Last edited:

JCSteel targets has a tri-corner system that is pretty cheap, and works great. I didn't want to post a direct link because I don't know if they are a site sponsor or not. They aren't hard to find though.

Jake at JCsteeltargets is a vendor here, jcvibby is his Hide name so post whatever links you like

I used EMT for my feet poles, it weighs less than rebar. It is on a pivot so when hit the plate rocks back and the red indicator pops up from behind the flat black one that normally blocks it from view.

For large paper or more than one target I generally use this one.

You can make it hold any target of any size depending on what 1x2 strips you use. Make sure to bring along two extras to slid in the feet so the wind can't blow it around. I have used it as big as 6'x8 with butchers paper as a target backer, if you get far enough away, even that looks small.

For large paper or more than one target I generally use this one.

You can make it hold any target of any size depending on what 1x2 strips you use. Make sure to bring along two extras to slid in the feet so the wind can't blow it around. I have used it as big as 6'x8 with butchers paper as a target backer, if you get far enough away, even that looks small.

I've been using the brackets for tarp covers like you see at the local bazaars. My neighbor was a distributor and hooked me up. I just run 1" conduit for the legs and center section and then run fire hose loops with chain to the targets. works great a distance. up close I have been using the t-post targets from jc steel.

I looked at the last stand and didn't want to pay $80 for two of those things. This is what I came up with. About $30 and collapses completely and is very shrapnel resistant. With a 1/2 scale ipsc on it it will handle 300wm at 200 yards no problem. The top rebar bowed slightly after about 40 shots on mine but bends right back. Here is an album Trunk Ready Target Stand - Imgur

Cremaster - You must have read incorrectly somewhere - The Last Stand target stand system retails for $39.99 per pair (not $80). Add some 1/2" rebar and some AR500 and you're good to go. They're easy to setup, adjustable to any terrain, compact to store and very durable. Look for them at Best Targets or on GunBroker.

I have been developing my own brackets from two piece of pipe and big nut to be used with a 10mm (#3<10mm<#4) rebar. Nut will make the leg angle to 60 degrees. It seems to be solid and heavy.

I might share when I get weldings done.

I might share when I get weldings done.

I might share when I get weldings done.

Works well with 22lr. Tomorrow I might try with 260rem

Attachments

My bro n law had a pvc base with a tee on each side that turned up for an upright. Instead of running a pvc pipe for the upright he just left the open tee. Then he took two 2x2s & shaved the ends down a bit to fit them in the pvc. Bring a staple gun to attach cardboard to the 2x2. They will take a few more stray hits.

Will the true Shootermcgavin please step forward?

What if Stephen hawking is the real shootermcgavin and can't step forward.

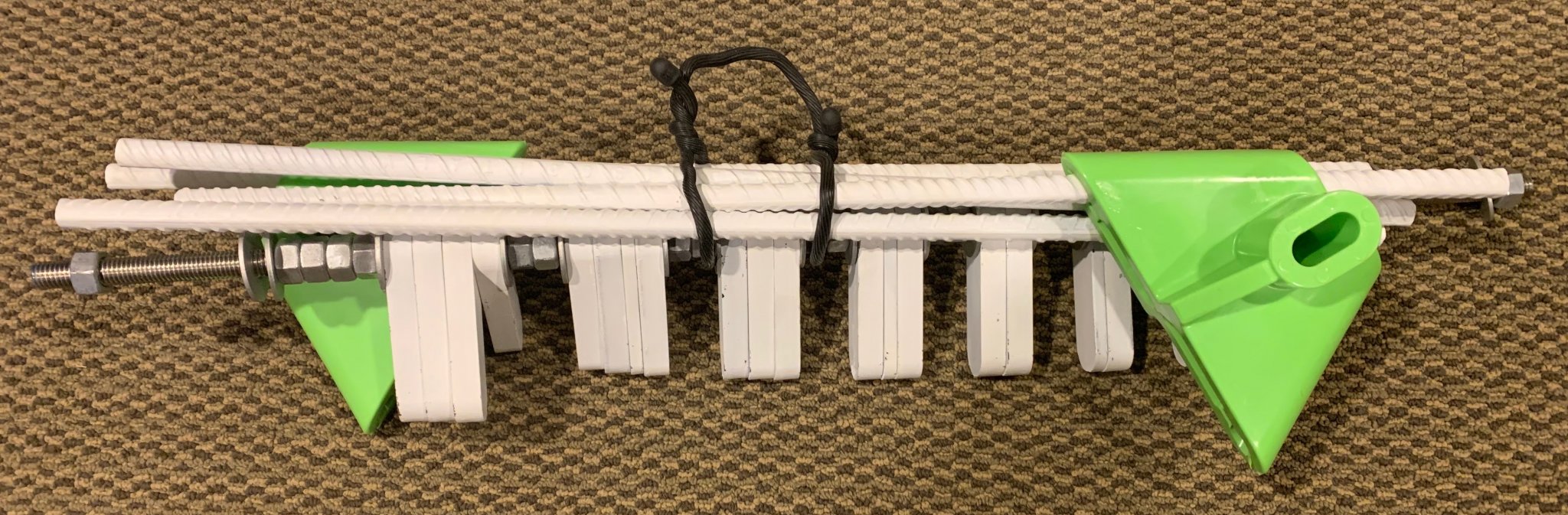

Just finished my DIY/Buy (Last Stand/Shootingtargets7/Home Depot) highly portable KYL rack. Intent was to have a KYL rack that is more compact and will easily fit in the car for range day - all with out a welder and with easily replaceable parts.

There's ~1/8 inch of space/play between the sets. I'll know tomorrow how they spin but by hand, they spin great. I know that I have another wire/flex tie around here somewhere and I'll likely find it next week after the first range session.

John

There's ~1/8 inch of space/play between the sets. I'll know tomorrow how they spin but by hand, they spin great. I know that I have another wire/flex tie around here somewhere and I'll likely find it next week after the first range session.

John

Looks great!Just finished my DIY/Buy (Last Stand/Shootingtargets7/Home Depot) highly portable KYL rack. Intent was to have a KYL rack that is more compact and will easily fit in the car for range day - all with out a welder and with easily replaceable parts.

There's ~1/8 inch of space/play between the sets. I'll know tomorrow how they spin but by hand, they spin great. I know that I have another wire/flex tie around here somewhere and I'll likely find it next week after the first range session.

John

View attachment 7143165View attachment 7143166

That's pretty cool. Great use of the LastStand kit. Have you used it yet? How did it hold up? What calibers/distances?Just finished my DIY/Buy (Last Stand/Shootingtargets7/Home Depot) highly portable KYL rack. Intent was to have a KYL rack that is more compact and will easily fit in the car for range day - all with out a welder and with easily replaceable parts.

There's ~1/8 inch of space/play between the sets. I'll know tomorrow how they spin but by hand, they spin great. I know that I have another wire/flex tie around here somewhere and I'll likely find it next week after the first range session.

John

View attachment 7143165View attachment 7143166

I might have to copy as I already have the stand.

In particular, which Shootingtargets7 parts did you use?

16x 1" wide x 1/2" thick AR500 gong targets from shootingtargets7.com.

4x 1" wide x 1/4" thick AR500 gong targets from shootingtargets7.com.

*36" threaded stainless rod (cut to size after putting together the nuts, washers, targets, etc.),

*4x 24" long by 1/2" thick pieces of rebar

*bag of 25x 2" wide galvanized washers (with a 1/2" hole in them) - from Home Depot

*bag of 25x galvanized nuts for the 1/2" stainless rod - from Home Depot

The Last Stand target stand ends - be sure to put a washer and nut on both sides of the target ends

I use Rustoleum (SP?) white primer as the paint. The "*" items are from Home Depot.

FWIW, I've only used it for 22LR from ~40 to 200 yards. It's AR500 steel, so the targets themselves should hold up to just about anything that normal AR500 steel would take (probably more) - durability for the galvanized parts are a maybe.

Lastly, it works great. I've totally shot the heck out of this target with my 22LR and after each repaint, the target still looks new.

After hitting the 1/4" targets at 50 yards (consistently) one day, I moved it to 100 yards. 2" down to 3/4" at 100 is almost too easy. Shooting the 1/2 & 1/4" targets at 100 yards is addictive.

Total fun.

John

4x 1" wide x 1/4" thick AR500 gong targets from shootingtargets7.com.

*36" threaded stainless rod (cut to size after putting together the nuts, washers, targets, etc.),

*4x 24" long by 1/2" thick pieces of rebar

*bag of 25x 2" wide galvanized washers (with a 1/2" hole in them) - from Home Depot

*bag of 25x galvanized nuts for the 1/2" stainless rod - from Home Depot

The Last Stand target stand ends - be sure to put a washer and nut on both sides of the target ends

I use Rustoleum (SP?) white primer as the paint. The "*" items are from Home Depot.

FWIW, I've only used it for 22LR from ~40 to 200 yards. It's AR500 steel, so the targets themselves should hold up to just about anything that normal AR500 steel would take (probably more) - durability for the galvanized parts are a maybe.

Lastly, it works great. I've totally shot the heck out of this target with my 22LR and after each repaint, the target still looks new.

After hitting the 1/4" targets at 50 yards (consistently) one day, I moved it to 100 yards. 2" down to 3/4" at 100 is almost too easy. Shooting the 1/2 & 1/4" targets at 100 yards is addictive.

Total fun.

John

Last edited:

That's awesome John. Thanks for the parts list and the report. I bought my kids a .22 (CZ 455 Scout) last Christmas, they would love this.

FWIW, while the KYL rack really has been great. However, I think that I’ll soon suffer buying a bunch more steel. Frankly shooting steel is addictive - in a good way.

John

John

My stand has stood up very well. It hasn’t seen much for heavy calibers, but it’s been out in the field for 12 months & still looks great.

The only downside I’ve found is that you should wear gloves to handle it as after a while shrapnel does get caught in it.

The only downside I’ve found is that you should wear gloves to handle it as after a while shrapnel does get caught in it.

You’re talking specifically about “The Last Stand” parts, correct? I’ve definitely seen the same thing, mine are full of shrapnel and will definitely cut you if not wearing gloves.The only downside I’ve found is that you should wear gloves to handle it as after a while shrapnel does get caught in it.

That’s correct, just the brackets get sharp. I have a long, repurposed bag that I put the rebar & brackets in when transporting to help with this, but it doesn’t move a lot anymore.

I also spent the extra for epoxy coated rebar to minimize how dirty my hands would get, but since I need gloves now anyway it’s not necessary.

I also spent the extra for epoxy coated rebar to minimize how dirty my hands would get, but since I need gloves now anyway it’s not necessary.

Similar threads

- Replies

- 1

- Views

- 657

- Replies

- 13

- Views

- 2K

- Replies

- 9

- Views

- 619

- Replies

- 0

- Views

- 441

- Replies

- 46

- Views

- 5K