Did some fun patches on the Impala's deck lid. Had to rebuild the reinforcement plate on the inside too. She's coming along.

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Maggie’s The Welding and Metalworking Thread

- Thread starter bogeybrown

- Start date

Impressive!!! Most folks just stuff in cardboard and cover it with Bondo! That, sir, is what restoration is all about!View attachment 8007746View attachment 8007745View attachment 8007747View attachment 8007748View attachment 8007749View attachment 8007750

Did some fun patches on the Impala's deck lid. Had to rebuild the reinforcement plate on the inside too. She's coming along.

Sirhr

Thanks, I keep teasing the owner that I'm gonna do that.i know these cars are gonna be well cared for so I want to make use they are still going after I'm dead and gone.Impressive!!! Most folks just stuff in cardboard and cover it with Bondo! That, sir, is what restoration is all about!

Sirhr

Fantastic bending of the front sight dovetail. Who is doing the nitre bluing on the small parts?

Engine driven welder questions for our learned compatriots here:

My Lady is talking about us looking into a welder/generator unit that we can use at our leisure to stick-weld as well as both AC and DC TIG (aluminum and stainless, etc) that will also double as an 'emergency generator' if needed here.

This is for 'hobby' and 'personal interest' use as opposed to "pipeline" or "pressure-ticket" applications. There's talk of us building a trailer or two in the next few years, as well as any personal projects that we get into (of have already started).

I'm perfectly good with 'used', and it don't have to have all the bells-and-whistles that are out there. Just the ability to do the job and not take up too much space in the garage. I'll be building our own stand with wheels for it to live on. Not in the back of our truck.

So I'm throwing that at the brain-trust here, as I know some of ya'll have some very valid opinions. I'd sure like to hear them. I was a Millwright when I was working, so there's that with regards to 'comprehension of application' and such. I know what I don't know.

Thanks, and sing-out!

My Lady is talking about us looking into a welder/generator unit that we can use at our leisure to stick-weld as well as both AC and DC TIG (aluminum and stainless, etc) that will also double as an 'emergency generator' if needed here.

This is for 'hobby' and 'personal interest' use as opposed to "pipeline" or "pressure-ticket" applications. There's talk of us building a trailer or two in the next few years, as well as any personal projects that we get into (of have already started).

I'm perfectly good with 'used', and it don't have to have all the bells-and-whistles that are out there. Just the ability to do the job and not take up too much space in the garage. I'll be building our own stand with wheels for it to live on. Not in the back of our truck.

So I'm throwing that at the brain-trust here, as I know some of ya'll have some very valid opinions. I'd sure like to hear them. I was a Millwright when I was working, so there's that with regards to 'comprehension of application' and such. I know what I don't know.

Thanks, and sing-out!

Probably be Turnbull. The engraver will send them out for finishing.Fantastic bending of the front sight dovetail. Who is doing the nitre bluing on the small parts?

Cheers,

Sirhr

Dont buy a welder/generator. Just get a generator and plug your welder into it. Especially if you plan to tig. While there are many welder/generators that CAN tig in some basic way, none are made FOR tig welding.Engine driven welder questions for our learned compatriots here:

My Lady is talking about us looking into a welder/generator unit that we can use at our leisure to stick-weld as well as both AC and DC TIG (aluminum and stainless, etc) that will also double as an 'emergency generator' if needed here.

This is for 'hobby' and 'personal interest' use as opposed to "pipeline" or "pressure-ticket" applications. There's talk of us building a trailer or two in the next few years, as well as any personal projects that we get into (of have already started).

I'm perfectly good with 'used', and it don't have to have all the bells-and-whistles that are out there. Just the ability to do the job and not take up too much space in the garage. I'll be building our own stand with wheels for it to live on. Not in the back of our truck.

So I'm throwing that at the brain-trust here, as I know some of ya'll have some very valid opinions. I'd sure like to hear them. I was a Millwright when I was working, so there's that with regards to 'comprehension of application' and such. I know what I don't know.

Thanks, and sing-out!

I will start the discussion here, so check back as I gather a few thoughts and give some examples. There are some older models that would do a good job for you. I have used them in the field on pipe hangers and light structural.Engine driven welder questions for our learned compatriots here:

My Lady is talking about us looking into a welder/generator unit that we can use at our leisure to stick-weld as well as both AC and DC TIG (aluminum and stainless, etc) that will also double as an 'emergency generator' if needed here.

This is for 'hobby' and 'personal interest' use as opposed to "pipeline" or "pressure-ticket" applications. There's talk of us building a trailer or two in the next few years, as well as any personal projects that we get into (of have already started).

I'm perfectly good with 'used', and it don't have to have all the bells-and-whistles that are out there. Just the ability to do the job and not take up too much space in the garage. I'll be building our own stand with wheels for it to live on. Not in the back of our truck.

So I'm throwing that at the brain-trust here, as I know some of ya'll have some very valid opinions. I'd sure like to hear them. I was a Millwright when I was working, so there's that with regards to 'comprehension of application' and such. I know what I don't know.

Thanks, and sing-out!

I prefer a portable machine that has DC output (not rectified).. JMHO

The Lincoln SA-200 is great but too big for your application.

Here is one that is on CL... You will not find one that is running for less than $500 - $800.. Top end they are $9k...

Lincoln DC Arc Welder / Lincwelder 225 amp Gas Engine (New Block) -...

This is an older welder, with electric start, 225 amp, runs on gas, AC auxiliary power. The engine was no good, so I recently put a new block in it, a 2 cylinder Onan. The welder worked before I put...

missoula.craigslist.org

Second one is near you, $2,000:

Lincoln welder - tools - by owner

Lincoln welder very low hours one owner 110 and 220 generator. 16 HP I/C series Briggs & Stratton very heavy perfect for the back of a pickup truck for the farm or ranch But must sell so make...

winnipeg.craigslist.org

Lincoln Gas Welder, Generator Gas Powered - tools - by owner - sale

Lincoln Welder, Generator gas powered in great condition. CASH ONLY, NO SCAMMERS, I WILL HAVE THE WELDER OUT OF THE TRUCK AND BE READY TO SELL.. Miller, Arc Welding, Gas Welding, Plasma Cutter,...

seattle.craigslist.org

Lincwelder 225 Lincoln Welder | eBay

Lincwelder 225 Lincoln Welder DC Arc Welder AS-IS CONDITION LOCAL PICKUP ONLY 225 Amp DC Arc Welder Welder Runs Good & Welds Good. Cables are included. Used batteries are included. Welder is on wheels. Wheel cart is removable.

www.ebay.com

Gas and Supply

USA's largest independent welding supply distributor. Great prices, better service. Buy online 24/7.

Lincoln Electric Ranger® 305 G EFI Engine Driven Welder (Kohler®)

Lincoln Electric Ranger® 305G EFI K3928-1 Engine Driven Welder (Kohler®) A Welder for All Seasons Make the Ranger 305 G your portable welding station - general stick and downhill pipe, Touch Start™ TIG, MIG, and flux-cored wire capability. Choose the Ranger 305 G EFI (electronic fuel injection)...

canadaweldingsupply.com

canadaweldingsupply.com

Last edited:

Here's what I did back in 2005 when the big hurricanes hit. Runs the whole house as long as I keep the water heater and clothes drier turned off. It's doubled in price since then. More fancy electronic crap now to break also.Engine driven welder questions for our learned compatriots here:

My Lady is talking about us looking into a welder/generator unit that we can use at our leisure to stick-weld as well as both AC and DC TIG (aluminum and stainless, etc) that will also double as an 'emergency generator' if needed here.

This is for 'hobby' and 'personal interest' use as opposed to "pipeline" or "pressure-ticket" applications. There's talk of us building a trailer or two in the next few years, as well as any personal projects that we get into (of have already started).

I'm perfectly good with 'used', and it don't have to have all the bells-and-whistles that are out there. Just the ability to do the job and not take up too much space in the garage. I'll be building our own stand with wheels for it to live on. Not in the back of our truck.

So I'm throwing that at the brain-trust here, as I know some of ya'll have some very valid opinions. I'd sure like to hear them. I was a Millwright when I was working, so there's that with regards to 'comprehension of application' and such. I know what I don't know.

Thanks, and sing-out!

Miller Bobcat 225 w/Remote Start/Stop 907791001

How much machine do you want?Engine driven welder questions for our learned compatriots here:

My Lady is talking about us looking into a welder/generator unit that we can use at our leisure to stick-weld as well as both AC and DC TIG (aluminum and stainless, etc) that will also double as an 'emergency generator' if needed here.

This is for 'hobby' and 'personal interest' use as opposed to "pipeline" or "pressure-ticket" applications. There's talk of us building a trailer or two in the next few years, as well as any personal projects that we get into (of have already started).

I'm perfectly good with 'used', and it don't have to have all the bells-and-whistles that are out there. Just the ability to do the job and not take up too much space in the garage. I'll be building our own stand with wheels for it to live on. Not in the back of our truck.

So I'm throwing that at the brain-trust here, as I know some of ya'll have some very valid opinions. I'd sure like to hear them. I was a Millwright when I was working, so there's that with regards to 'comprehension of application' and such. I know what I don't know.

Thanks, and sing-out!

Gas or diesel ?

How set are you on that ac tig capability ?

AC tig on an engine drive is going to be tough. I think, at one time miller made a bobcat that would, in their words, run "non critical" ac tig with no additional accessories but I never could locate one. A rig welder I know had one, a bobcat 302 I believe. He swears up and down he tigged aluminum with it without a high frequency box.

So on his word my dad bought one for the exact purpose you are wanting one and for the life of me we can't make it ac tig for nothing. It runs DC like a champ though.

Gas machine with a small footprint the Lincoln ranger 305G or a miller bobcat either one will make a fine machine for you. AC/DC stick, DC tig. You're going to need a high frequency box with either of them to ac tig to my knowledge. 10 or 11k watt generators in both of them. I have an older ranger gxt with a 10k watt generator and it'll run everything in the house except the big amp pullers. Stay away from the 305D. They've got small displacement high speed diesels in them that are loud and annoying af and they break down constantly. I use them at work. And they suck.

Diesel machines I like the Lincoln vantage 300/322 (I'll catch some hate for that one) and the miller big blue 300r pro, 2014-2017.(even more hate for that one) 2018 to current the millers have PC board problems. $2,000 dollar fix. That's coming from a united rentals mechanic that works on the welding machines. He prefers the vantage. Said they rarely do more than change the oil in those machines but the 14-18 miller's are solid according to him. And he sees a lot of them.

The millers tig amazingly well. DC only though. Both the vantage and the Miller have 11k generators I believe and both have lift arc/touch start tig settings. Which is nice. Not sure on the miller but the vantage has the capability to run 3phase power. If that matters to you.

If you're set on needing ac tig just buy an inexpensive ac tig machine and plug it in to your engine drive if you have to or your 220v outlet in your garage/ shop. For the inexpensive route you're looking at yeswelder, htp, Everlast or all out go miller dynasty.

I've welded ac tig on a diesel machine before and while it did work its not ideal.

Categorically false. I tig off of diesel welder/generators every day and they have specific tig settings.Dont buy a welder/generator. Just get a generator and plug your welder into it. Especially if you plan to tig. While there are many welder/generators that CAN tig in some basic way, none are made FOR tig welding.

The old sa-200 is a great machine, I have a 48 in my shop. DC only on the generator side though. They run a grinder good. Neighbor had one of the old weldanpower lincolns. 2 cylinder Onan iirc. He had a heck of a time sourcing parts for that thing. Cummins bought Onan so he ended up going through them I believe. It was a bad dude after he got it running though.I will start the discussion here, so check back as I gather a few thoughts and give some examples. There are some older models that would do a good job for you. I have used them in the field on pipe hangers and light structural.

I prefer a portable machine that has DC output (not rectified).. JMHO

The Lincoln SA-200 is great but too big for your application.

Here is one that is on CL... You will not find one that is running for less than $500 - $800.. Top end they are $9k...

Lincoln DC Arc Welder / Lincwelder 225 amp Gas Engine (New Block) -...

This is an older welder, with electric start, 225 amp, runs on gas, AC auxiliary power. The engine was no good, so I recently put a new block in it, a 2 cylinder Onan. The welder worked before I put...missoula.craigslist.org

View attachment 8007850View attachment 8007859

Second one is near you, $2,000:

Lincoln welder - tools - by owner

Lincoln welder very low hours one owner 110 and 220 generator. 16 HP I/C series Briggs & Stratton very heavy perfect for the back of a pickup truck for the farm or ranch But must sell so make...winnipeg.craigslist.org

Lincoln Gas Welder, Generator Gas Powered - tools - by owner - sale

Lincoln Welder, Generator gas powered in great condition. CASH ONLY, NO SCAMMERS, I WILL HAVE THE WELDER OUT OF THE TRUCK AND BE READY TO SELL.. Miller, Arc Welding, Gas Welding, Plasma Cutter,...seattle.craigslist.org

Lincwelder 225 Lincoln Welder | eBay

Lincwelder 225 Lincoln Welder DC Arc Welder AS-IS CONDITION LOCAL PICKUP ONLY 225 Amp DC Arc Welder Welder Runs Good & Welds Good. Cables are included. Used batteries are included. Welder is on wheels. Wheel cart is removable.www.ebay.com

Gas and Supply

USA's largest independent welding supply distributor. Great prices, better service. Buy online 24/7.www.gasandsupply.com

Lincoln Electric Ranger® 305 G EFI Engine Driven Welder (Kohler®)

Lincoln Electric Ranger® 305G EFI K3928-1 Engine Driven Welder (Kohler®) A Welder for All Seasons Make the Ranger 305 G your portable welding station - general stick and downhill pipe, Touch Start™ TIG, MIG, and flux-cored wire capability. Choose the Ranger 305 G EFI (electronic fuel injection)...canadaweldingsupply.com

This is a fantastic start to the conversation ya'll, and it is hugely appreciated. By-all-means, continue. Let's hear it, good or bad. That first link there that's relatively local to me, sure looks like an old machine for 2grand. One thing I'm hesitant on something like that (he's only in town for a few weeks) is what is the repair/parts availability on the welder/generator side of these units. I understand the engine side, be-it Kohler, B & S, Onan, etc. But the 'old old old electricals'.... still get-able or 'you pays yer money and you takes yer chances'?

Yes, I did say 'used' in my first post there. That thing looks 40+ years old, to me. (not a complaint, just a simple observation) and when I am left holding the bag, I want to know what that's worth.

Yes, I did say 'used' in my first post there. That thing looks 40+ years old, to me. (not a complaint, just a simple observation) and when I am left holding the bag, I want to know what that's worth.

Forgot to add:

DC TIG for doing stainless steel, and other 'odd jobs' that we come across and such.

AC TIG for doing aluminum repairs as well as the odd fabrication and such. We're boaters, and there's always something at the marina that needs to be made/tweaked/improved/repaired and such.

"high frequency box" now that is something I will need to look into more. Any of the AC welders I've used in the past have been big Miller shop units in the companies that I've worked. Then the advent of 'suitcase welders' came out afterwards, and I've got practically no experience with them at all. (comparatively speaking) I bought a chinesium DC TIG from one of my bro's fathers estate. It was working great, until all-the-sudden it didn't. But that one didn't do aluminum at all.

I want to be able to at least say 'yes', I can do it (when asked for assistance) as opposed to flat-out 'no' because I don't have the equipment.

From that point on, everything we accomplish comes with a 20/20/20 warranty.

20 minutes

20 feet

or

20 knots

DC TIG for doing stainless steel, and other 'odd jobs' that we come across and such.

AC TIG for doing aluminum repairs as well as the odd fabrication and such. We're boaters, and there's always something at the marina that needs to be made/tweaked/improved/repaired and such.

"high frequency box" now that is something I will need to look into more. Any of the AC welders I've used in the past have been big Miller shop units in the companies that I've worked. Then the advent of 'suitcase welders' came out afterwards, and I've got practically no experience with them at all. (comparatively speaking) I bought a chinesium DC TIG from one of my bro's fathers estate. It was working great, until all-the-sudden it didn't. But that one didn't do aluminum at all.

I want to be able to at least say 'yes', I can do it (when asked for assistance) as opposed to flat-out 'no' because I don't have the equipment.

From that point on, everything we accomplish comes with a 20/20/20 warranty.

20 minutes

20 feet

or

20 knots

High frequency box let's you start the arc not touching. Not lift arc. Hold the tungsten at the right spacing off the metal, turn on the arc, and it connects. Might have all of the balance controls as well. Not sure. Only done a little TIG in a college class.Forgot to add:

DC TIG for doing stainless steel, and other 'odd jobs' that we come across and such.

AC TIG for doing aluminum repairs as well as the odd fabrication and such. We're boaters, and there's always something at the marina that needs to be made/tweaked/improved/repaired and such.

"high frequency box" now that is something I will need to look into more. Any of the AC welders I've used in the past have been big Miller shop units in the companies that I've worked. Then the advent of 'suitcase welders' came out afterwards, and I've got practically no experience with them at all. (comparatively speaking) I bought a chinesium DC TIG from one of my bro's fathers estate. It was working great, until all-the-sudden it didn't. But that one didn't do aluminum at all.

I want to be able to at least say 'yes', I can do it (when asked for assistance) as opposed to flat-out 'no' because I don't have the equipment.

From that point on, everything we accomplish comes with a 20/20/20 warranty.

20 minutes

20 feet

or

20 knots

Like I said, they CAN tig, but it's missing pulse, preflow, post flow, upslope, down slope.... and 60hz sinewave AC tig?How much machine do you want?

Gas or diesel ?

How set are you on that ac tig capability ?

AC tig on an engine drive is going to be tough. I think, at one time miller made a bobcat that would, in their words, run "non critical" ac tig with no additional accessories but I never could locate one. A rig welder I know had one, a bobcat 302 I believe. He swears up and down he tigged aluminum with it without a high frequency box.

So on his word my dad bought one for the exact purpose you are wanting one and for the life of me we can't make it ac tig for nothing. It runs DC like a champ though.

Gas machine with a small footprint the Lincoln ranger 305G or a miller bobcat either one will make a fine machine for you. AC/DC stick, DC tig. You're going to need a high frequency box with either of them to ac tig to my knowledge. 10 or 11k watt generators in both of them. I have an older ranger gxt with a 10k watt generator and it'll run everything in the house except the big amp pullers. Stay away from the 305D. They've got small displacement high speed diesels in them that are loud and annoying af and they break down constantly. I use them at work. And they suck.

Diesel machines I like the Lincoln vantage 300/322 (I'll catch some hate for that one) and the miller big blue 300r pro, 2014-2017.(even more hate for that one) 2018 to current the millers have PC board problems. $2,000 dollar fix. That's coming from a united rentals mechanic that works on the welding machines. He prefers the vantage. Said they rarely do more than change the oil in those machines but the 14-18 miller's are solid according to him. And he sees a lot of them.

The millers tig amazingly well. DC only though. Both the vantage and the Miller have 11k generators I believe and both have lift arc/touch start tig settings. Which is nice. Not sure on the miller but the vantage has the capability to run 3phase power. If that matters to you.

If you're set on needing ac tig just buy an inexpensive ac tig machine and plug it in to your engine drive if you have to or your 220v outlet in your garage/ shop. For the inexpensive route you're looking at yeswelder, htp, Everlast or all out go miller dynasty.

I've welded ac tig on a diesel machine before and while it did work its not ideal.

Categorically false. I tig off of diesel welder/generators every day and they have specific tig settings.

The old sa-200 is a great machine, I have a 48 in my shop. DC only on the generator side though. They run a grinder good. Neighbor had one of the old weldanpower lincolns. 2 cylinder Onan iirc. He had a heck of a time sourcing parts for that thing. Cummins bought Onan so he ended up going through them I believe. It was a bad dude after he got it running though.

No thanks. Buy two purpose built machines.

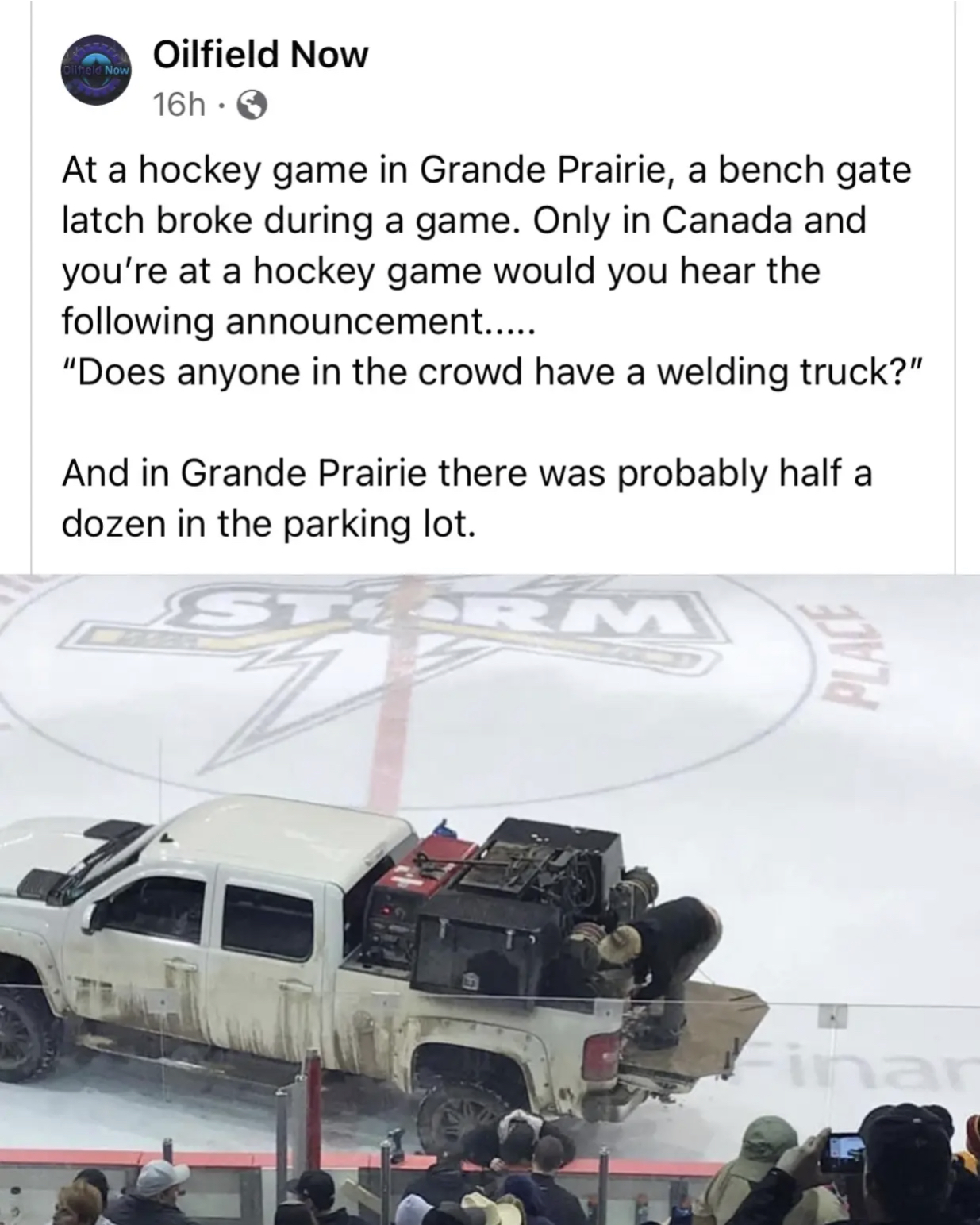

The real Reason Sean wants a welding truck…. “Here I come to save the day!” — Dudley Doright

Looks like a ranger 305.The real Reason Sean wants a welding truck…. “Here I come to save the day!” — Dudley Doright

View attachment 8008192

Yeah it's a different world as far as general pipe fabrication vs specialized tig applications. Not even all ac tig capable machines have those options. You start getting into money there.Like I said, they CAN tig, but it's missing pulse, preflow, post flow, upslope, down slope.... and 60hz sinewave AC tig?

No thanks. Buy two purpose built machines.

Those old machines like the one hobo linked to are pretty simple machines that have a pretty good service record. There's just not that much to go wrong with them. They just work.This is a fantastic start to the conversation ya'll, and it is hugely appreciated. By-all-means, continue. Let's hear it, good or bad. That first link there that's relatively local to me, sure looks like an old machine for 2grand. One thing I'm hesitant on something like that (he's only in town for a few weeks) is what is the repair/parts availability on the welder/generator side of these units. I understand the engine side, be-it Kohler, B & S, Onan, etc. But the 'old old old electricals'.... still get-able or 'you pays yer money and you takes yer chances'?

Yes, I did say 'used' in my first post there. That thing looks 40+ years old, to me. (not a complaint, just a simple observation) and when I am left holding the bag, I want to know what that's worth.

On the flipside the newer machines have way better generators in them. Especially the millers. The millers have a cleaner power output. It's even better than a comparable Lincoln. Between my ranger gxt and my dad's bobcat you can see the difference in the lights at times when using them for generator purposes.

You'll see some flutter in the lighting running on the ranger and with the bobcat you'd never know you were running off a generator. Miller even states that their generators will power sensitive electronics such as computers. It probably sounds like I'm shilling for miller but really it's just been my experience with them.

Sales rep for coastal welding supply told me when we bought my dad's bobcat, for diesel machines go Lincoln. For the smaller gas machines go Miller. And they sell both.

My choice would be a dedicated generator, and a Dynasty 300 multi process machine, you can do a bunch with the older 200DX still. Gotta watch keeping that machine clean on the inside, damn dirt daubers cost me almost $2k in repairs on that machine. If the IGBT overheats it will kill a couple boards in there.

I have the Kubota generator and a Dynasty 200DX and a Maxstar 280. If I am just stick welding I grab the Maxstar, eventually I'll sell my 200 and probably the millermatic 251 and buy the Dynasty to the 300. Thats like a $20k upgrade though....

I have the Kubota generator and a Dynasty 200DX and a Maxstar 280. If I am just stick welding I grab the Maxstar, eventually I'll sell my 200 and probably the millermatic 251 and buy the Dynasty to the 300. Thats like a $20k upgrade though....

Good thread. Have a several welders in my shop and been thinking about acquiring a gas powered welder. Have three tig machines with my favorite being a Fronius iWave 230i which is just an amazing piece of equipment. For MIG use a Millermatic 255 which has a pulse function and welds aluminum very well with the Aluma Pro gun.

Keep it up guys, I'm researching the specific machines ya'll are suggesting here on my end. There is a LOT of thinking to do, considering the budget and the limitations of their abilities.

I get the comedic reference up above, and I appreciate it. To add to that direction though, I am a Millwright. The motto (so-to-speak) of Millwrights is:

"We Can Handle It"

Just that in itself, when given a task. To that end in general, AND to coordinate that with my own abilities/issues/consolation prizes from the accident, I'm really trying hard to rejuvenate some (as many as possible) abilities/techniques that I'd once had or been able to do before. And the generator portion of this, was simply using the idea of killing 2 (or 3 or 4) birds with one stone.

I've only used a diesel generator once, years ago in the sawmill during a power outage. The 'decompression lever' makes it a LOT easier to pull-start. A number of folks here have asked/stated "gas or diesel". My own thinking is, if I were to buy a generator and plug a welder into it, I'd be better off (longevity-wise) to get a diesel generator on the smaller scale, to mainly run the house and stuff, then get a 'more specifically designed for' AC/DC TIG welder and plug in to it. There are VERY few occasions where I need to travel and weld. There are very few occasions where the power is out for longer than 2 hours here.

I've not even been able to think about entertaining this premise for a LOT of years, hence why I'm asking about 'what's-out-there-now' and with the mind-trust of ya'll, you know better as to what actually works and what is a BS pipe-dream.

Does that clarify more, of my intent?

I get the comedic reference up above, and I appreciate it. To add to that direction though, I am a Millwright. The motto (so-to-speak) of Millwrights is:

"We Can Handle It"

Just that in itself, when given a task. To that end in general, AND to coordinate that with my own abilities/issues/consolation prizes from the accident, I'm really trying hard to rejuvenate some (as many as possible) abilities/techniques that I'd once had or been able to do before. And the generator portion of this, was simply using the idea of killing 2 (or 3 or 4) birds with one stone.

I've only used a diesel generator once, years ago in the sawmill during a power outage. The 'decompression lever' makes it a LOT easier to pull-start. A number of folks here have asked/stated "gas or diesel". My own thinking is, if I were to buy a generator and plug a welder into it, I'd be better off (longevity-wise) to get a diesel generator on the smaller scale, to mainly run the house and stuff, then get a 'more specifically designed for' AC/DC TIG welder and plug in to it. There are VERY few occasions where I need to travel and weld. There are very few occasions where the power is out for longer than 2 hours here.

I've not even been able to think about entertaining this premise for a LOT of years, hence why I'm asking about 'what's-out-there-now' and with the mind-trust of ya'll, you know better as to what actually works and what is a BS pipe-dream.

Does that clarify more, of my intent?

I am needing a website that can make printable cut patterns for saddles for tubing. Would also like it for square tubing. Anyone know a good one? I had one years back that calculated based on pipe diameter being saddled, diameter being seated to and angle. It would be good to get something that easy again without resorting to SolidWorks.

I'm pretty sure I still have that bookmarked. I'll look tonight or in the morning.I am needing a website that can make printable cut patterns for saddles for tubing. Would also like it for square tubing. Anyone know a good one? I had one years back that calculated based on pipe diameter being saddled, diameter being seated to and angle. It would be good to get something that easy again without resorting to SolidWorks.

Two hour power outages ? I don't even drag mine out for that lol. I think the last time I used the ranger for a generator it ran for a week. Sucker burns about a gallon an hour with the whole house on it though. And we tried to minimize what we actually used.Keep it up guys, I'm researching the specific machines ya'll are suggesting here on my end. There is a LOT of thinking to do, considering the budget and the limitations of their abilities.

I get the comedic reference up above, and I appreciate it. To add to that direction though, I am a Millwright. The motto (so-to-speak) of Millwrights is:

"We Can Handle It"

Just that in itself, when given a task. To that end in general, AND to coordinate that with my own abilities/issues/consolation prizes from the accident, I'm really trying hard to rejuvenate some (as many as possible) abilities/techniques that I'd once had or been able to do before. And the generator portion of this, was simply using the idea of killing 2 (or 3 or 4) birds with one stone.

I've only used a diesel generator once, years ago in the sawmill during a power outage. The 'decompression lever' makes it a LOT easier to pull-start. A number of folks here have asked/stated "gas or diesel". My own thinking is, if I were to buy a generator and plug a welder into it, I'd be better off (longevity-wise) to get a diesel generator on the smaller scale, to mainly run the house and stuff, then get a 'more specifically designed for' AC/DC TIG welder and plug in to it. There are VERY few occasions where I need to travel and weld. There are very few occasions where the power is out for longer than 2 hours here.

I've not even been able to think about entertaining this premise for a LOT of years, hence why I'm asking about 'what's-out-there-now' and with the mind-trust of ya'll, you know better as to what actually works and what is a BS pipe-dream.

Does that clarify more, of my intent?

Gotta love that gulf coast living during hurricane season.

Yeah, 2 hours'ish I'm not worried either. There are other things to 'get by' with. But, with the 'harsh winter' coming and other issues, I'd rather have 'something' than nothing as a back-up. I have experienced 21hr outages and such, when I lived out West. Just trying to be pro-active. I get that numerous have stated 'get a generator' and also 'get the welder I want and plug it into the generator when needed'.Two hour power outages ? I don't even drag mine out for that lol. I think the last time I used the ranger for a generator it ran for a week. Sucker burns about a gallon an hour with the whole house on it though. And we tried to minimize what we actually used.

Gotta love that gulf coast living during hurricane season.

In everything I do, I want my limitations to be me, and not my equipment. That way I know it can be done, I just need to find a way of doing it.

There's so much that is 'new' with the TIG controllers, than when I used em in the past. Hence this tangent of questioning and such. I truly do appreciate the input.

I follow you on the TIG setup's... You almost have to decide if your work will be "production" or "prototype / maintenance"... Two different worlds. The more job specific machines are nice for production (same thing day in and day out). Prototype / maintenance it just does not pay to spend a lot of time programing a machine. That is where "Old School Craftsmanship" comes into play. If you are patching a bullet hole in an aluminum boat then the welder has to feel how the puddle is acting. Takes a few years to develop being versatile.Yeah, 2 hours'ish I'm not worried either. There are other things to 'get by' with. But, with the 'harsh winter' coming and other issues, I'd rather have 'something' than nothing as a back-up. I have experienced 21hr outages and such, when I lived out West. Just trying to be pro-active. I get that numerous have stated 'get a generator' and also 'get the welder I want and plug it into the generator when needed'.

In everything I do, I want my limitations to be me, and not my equipment. That way I know it can be done, I just need to find a way of doing it.

There's so much that is 'new' with the TIG controllers, than when I used em in the past. Hence this tangent of questioning and such. I truly do appreciate the input.

There is no one welding machine that is perfect for everything.

Also it needs to be considered if the TIG weld will be shot or not.

If Xray is required it sure is nice to run a good machine you have had

time on already.

If Xray is required it sure is nice to run a good machine you have had

time on already.

With the advances in both person generator technology as well as "at home" welders I would go with some sort of millermatic 220 machine and a generator that you can plug it into. I think the new millermatic does ac and DC.

I have run some very high tech welders off of some giant generators. What you are doing is doubling all of the current wave characteristics. The welding I was doing was called "Orbital Welding" and some of the material was 1/4" stainless tubing...With the advances in both person generator technology as well as "at home" welders I would go with some sort of millermatic 220 machine and a generator that you can plug it into. I think the new millermatic does ac and DC.

Weather was cool outside where the generator was and as the temperature warmed up the characteristics of the machine changed. The job I was on required the welders "coupon in" every morning and "coupon out" at the end of the shift. If the seeings on the machine had to be changed the QC would require a welder to run new coupons. With a generator that was changing, it was like a cat chasing it's tail.

Eventually permanent power (not temp power) was brought in. Even with that we had to install current stabilizers to run the machines.

I would not consider running a welder off of a generator. Too many variables.

Next is considering the "Duty Cycle" of both generator and welder.

Welding Machines - What is Duty Cycle & How is it Calculated

Your questions answered on duty cycle and welding machines! How is duty cycle is calculated? Is Duty-Cycle the best indication of performance? ... and more!

Last edited:

I have run some very high tech welders off of some giant generators. What you are doing is doubling all of the current wave characteristics. The welding I was doing was called "Orbital Welding" and some of the material was 1/4" stainless tubing...

Weather was cool outside where the generator was and as the temperature warmed up the characteristics of the machine changed. The job I was on required the welders "coupon in" every morning and "coupon out" at the end of the shift. If the seeings on the machine had to be changed the QC would require a welder to run new coupons. With a generator that was changing, it was like a cat chasing it's tail.

Eventually permanent power (not temp power) was brought in. Even with that we had to install current stabilizers to run the machines.

I would not consider running a welder off of a generator. Too many variables.

Next is considering the "Duty Cycle" of both generator and welder.

Welding Machines - What is Duty Cycle & How is it Calculated

Your questions answered on duty cycle and welding machines! How is duty cycle is calculated? Is Duty-Cycle the best indication of performance? ... and more!www.weldclass.com.au

Modern day inverter welders, including the orbitals I have in my rental fleet, have a wide band input capability. This means that the weld quality and output calibration are not affected by variation from generators or poor quality power.

Also, modern generators can also provide sinewave output from an inverter source. This means clean power and variable engine rpm. No longer do engines need to maintain 1800 or 3600 rpm to provide 60hz.

Even cheap Chinese welders and generators can offer these advances. With a miller, you need to buy an enpak to get an inverter generator output. I believe all other Miller and Lincoln generators only provide AC output directly coupled to rotor speed.

The AMI 207 in the video above was designed in the late 80s/ early 90s. Good at the time, not so much now. While popular with the union, it was the last successful example from AMI.

Last edited:

Does anyone here have experience setting up a laser welder? A business we partner with just bought one and is having a hell of a time setting it up. They bought it second hand, but little used. Salesmen, manufacturer etc has been zero help. I’m too dumb to have a conversation about the topic, but figured I’d throw a few lines out.

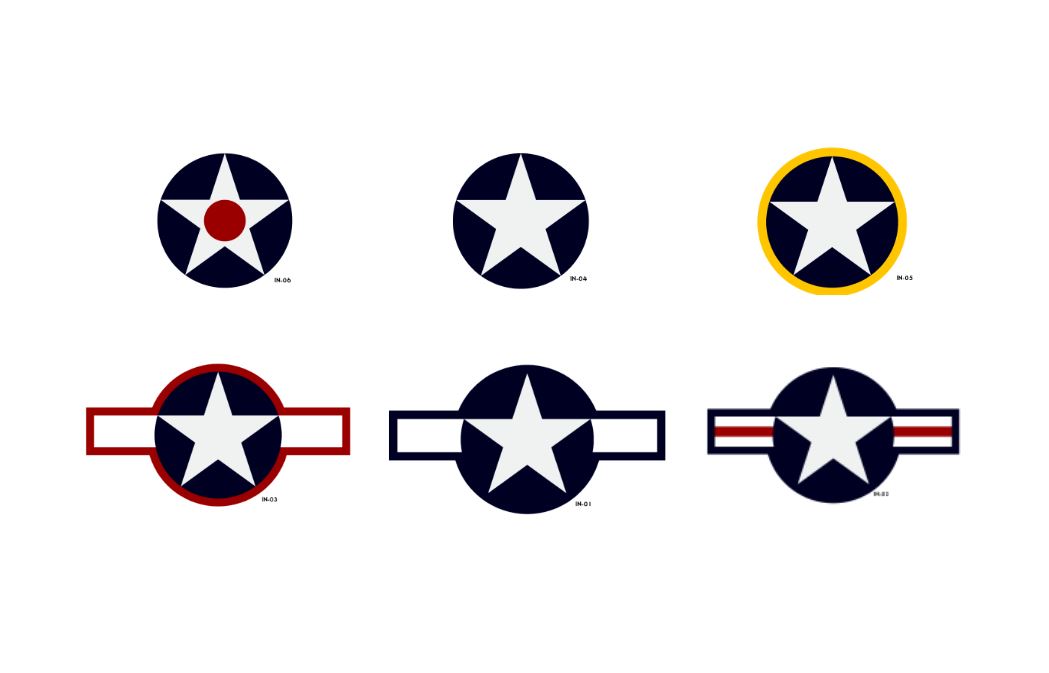

Anyone have any ideas what this tool box is known as or when it was from? Came from my grandpa to my dad to me. Might go back to my great grandpa. Dad's mom was a Stark hence the star with K. Was thinking of cleaning it up some.

Dude that’s seriously cool.Anyone have any ideas what this tool box is known as or when it was from? Came from my grandpa to my dad to me. Might go back to my great grandpa. Dad's mom was a Stark hence the star with K. Was thinking of cleaning it up some.

View attachment 8009686View attachment 8009687View attachment 8009688

Yes. I have experience with several manufacturers of YAG laser welders: Amada Miyachi, Raytheon, IPG and Liburdi.Does anyone here have experience setting up a laser welder? A business we partner with just bought one and is having a hell of a time setting it up. They bought it second hand, but little used. Salesmen, manufacturer etc has been zero help. I’m too dumb to have a conversation about the topic, but figured I’d throw a few lines out.

Anyone have any ideas what this tool box is known as or when it was from? Came from my grandpa to my dad to me. Might go back to my great grandpa. Dad's mom was a Stark hence the star with K. Was thinking of cleaning it up some.

View attachment 8009686View attachment 8009687View attachment 8009688

Other than Soap and water I would not do “too” much cleaning. Looks like the USAF (or AAC) rondele might have been done by someone who did nose art or knew their way around a brush. Look for a signature!

If there is a brand name or a mil “cage code” kind of number you could date it and get manufacturer.

Totally cool!!! Would love to find that it went back to ww2… theoretically that logo is 43-47.

Timeline for the US Air Force National Star Insignia

Information helpful to dating and identification US Air Force national insignia aircraft markings, commonly called "star & bars" or "roundels" that were first used by military aircraft of the United States before and during World War II.

There are “unit museums” that would kill

For that sort thing if it can be traced to a crewman or mechanic. And nose art collectors are all over that stuff, too!

Totally awesome! Worth some research!

Sirhr

Anyone have any ideas what this tool box is known as or when it was from? Came from my grandpa to my dad to me. Might go back to my great grandpa. Dad's mom was a Stark hence the star with K. Was thinking of cleaning it up some.

View attachment 8009686View attachment 8009687View attachment 8009688

Looks like the old tool boxes we had in England circa 1984.

Heavy mofos, but they were solid.

We used them in aircraft maintenance.

Anyone have any ideas what this tool box is known as or when it was from? Came from my grandpa to my dad to me. Might go back to my great grandpa. Dad's mom was a Stark hence the star with K. Was thinking of cleaning it up some.

View attachment 8009686View attachment 8009687View attachment 8009688

I love a good rabbit hole in the morning!!

Some info.

Sirhr

This is a deep dive thread over at G503, home to all things militaria.

What makes yours potentially incredibly special is the nose art… and a potential connection to a real WW2 unit and/or individual!

Be very careful in your conservation/cleanup!

Totally awesome piece of history!

Sirhr

Like I said, they CAN tig, but it's missing pulse, preflow, post flow, upslope, down slope.... and 60hz sinewave AC tig?

No thanks. Buy two purpose built machines.

Definitely the way to go. Miller dynasty was the machine I wanted before I had to quit welding.

We had some aluminum piping come up on a job one time and I had to test for it. Machine I used for the test was a dynasty 700. I loved that machine.Definitely the way to go. Miller dynasty was the machine I wanted before I had to quit welding.

Machine I got in the field

Was a red-d-arc 500amp ac/dc diesel machine with a miller high freq box. Man was that ever a crude setup.

Syncrowaves are old tech but they just work.I have a syncrwave 200 in my garage. Love that little bastard.

Thanks @sirhrmechanic. I figured either you or someone else would know something (or at least what direction I should look). I figured maybe just fix the handle some and some rust removal and maybe something to clear coat where the rust was. Helps that its been back in Utah for the last couple of years after being in my parents garage attic in Houston for 15 years or so.

This is a deep dive thread over at G503, home to all things militaria.

What makes yours potentially incredibly special is the nose art… and a potential connection to a real WW2 unit and/or individual!

Be very careful in your conservation/cleanup!

Totally awesome piece of history!

Sirhr

I would do nothing yet… except soap and water…. Definitely no clear coat or de-rusting. It’s original rust! ;-)Thanks @sirhrmechanic. I figured either you or someone else would know something (or at least what direction I should look). I figured maybe just fix the handle some and some rust removal and maybe something to clear coat where the rust was. Helps that its been back in Utah for the last couple of years after being in my parents garage attic in Houston for 15 years or so.

I’d research the heck out of your granddad’s units and if you don’t want to keep it, a museum would love that with the “story” and preserve your grandfathers legacy forever!

Sirhr

I want to keep it. Grandpa was domestic. Worked for Remington ammunition plant in Salt Lake. Made 30 cal and 50 cal ammo. He lived 1913-2008.I would do nothing yet… except soap and water…. Definitely no clear coat or de-rusting. It’s original rust! ;-)

I’d research the heck out of your granddad’s units and if you don’t want to keep it, a museum would love that with the “story” and preserve your grandfathers legacy forever!

Sirhr

That is cool, I have an old (i think) black & decker drill my grandfather had. All metal and still working. He really did not do much "handy" type things, but having that tool just makes me think back. I need to snap a pic of it, I bet it is 1950's.

My dad says it was my great grandpa's. No idea what he did in ww2. He lived 1890-1981.Anyone have any ideas what this tool box is known as or when it was from? Came from my grandpa to my dad to me. Might go back to my great grandpa. Dad's mom was a Stark hence the star with K. Was thinking of cleaning it up some.

View attachment 8009686View attachment 8009687View attachment 8009688

Historically, the syncrowave series has been a transformer based, SCR fired squarewave tig welder, limited to 60hz output.They tig aluminum like a champ. High frequency and it can run on 110.

Currently, Miller uses the Syncrowave name as its economy line tig welder and is an inverter, I believe. It doesnt have the options of the dynasty series but does get you out of a fixed 60hz output.

But there are many other low cost inverter AC tig welders that weld just as well, if not better without the spend of a miller.

Alphatig is a great option for a low cost AC inverter tig.The Everlast Power Tig 255 and 325 are good machines for the money. Have a 325 in my shop but rarely use it since I bought the Fronius and will probably sell it. Add a CK water cooled torch to it and you a GTG.

Made in Taiwan, too. Not China.

Similar threads

- Replies

- 0

- Views

- 533

- Replies

- 10

- Views

- 2K

- Replies

- 13

- Views

- 2K

Precision Rifle Gear

Tango Innovations FIRE4000 WMLRF Initial Impressions

- Replies

- 330

- Views

- 25K