Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

AutoTrickler V4

- Thread starter adamjmac

- Start date

I'm glad y'all are having great results with the tip @Maurygold . Its not the first time I've designed something, but it's the first time I've gone and sold something; which originally was not my intention. I just hope that, if I were to design something like the Autotrickler V1-4 that folks would help me out with testing, possible improvements and so on. As shooters, we need to help each other and those who support/help improve the sport!

My new V4 was overthrowing H4350 by .06 -.08 grains pretty consistently and occasionally higher. I tilted the back up about .015 and recalibrated. It is now throwing dead on or .02 under and I think that is about as good as it gets - especially with kernels that weigh about .028 on average. When I added the height, I could clearly see the flow through the trickler was more even. No different than tweaking the trickler on the V3. Just my .03.

Last edited:

I tilted mine to but still think it's worked best with the @jthor tip. for $15 not a lot to lose I'd still recommendMy new V4 was overthrowing H4350 by .06 -.08 grains pretty consistently and occasionally higher. I tilted the back up about .015 and recalibrated. It is now throwing dead on or .02 under and I think that is about as good as it gets - especially with kernels that weigh about .028 on average. When I added the height, I could clearly see the flow through the trickler was more even. No different than tweaking the trickler on the V3. Just my .03.

Me too. I got it work great by tilting the scale and running at the prescribed numbers but ultimately went to a more aggressive angle (which happens to be my scale at flat) and now get between .23-.25 and throw a few seconds faster with the tip. 43g test - Staball 8 secs, Varget and H4350 at 10-12 secs. Rarely an overthrow, and when it did, .02 grains - so one kernel (.02 for Varget, .03 for H4350 but scale only does .02).I tilted mine to but still think it's worked best with the @jthor tip. for $15 not a lot to lose I'd still recommend

question about adding a light tower

i have a V3 and V4 on the way (used)

because im a moron id like to set up a light tower R,Y,G

On a V3 im thinking yellow when the machine is weighing and green when the V3 "stops"

i can just wait for the green light and pull the pan

on the V4 im thinking the same yellow, green, but include red over time

has anyone looked at what the output signal or lack of signal is on the V3 and V4

looking for the trigger without poking around so much

thanks

i have a V3 and V4 on the way (used)

because im a moron id like to set up a light tower R,Y,G

On a V3 im thinking yellow when the machine is weighing and green when the V3 "stops"

i can just wait for the green light and pull the pan

on the V4 im thinking the same yellow, green, but include red over time

has anyone looked at what the output signal or lack of signal is on the V3 and V4

looking for the trigger without poking around so much

thanks

Cant speak to the V3 but the V4 already has a green LED indicator when it is in range.question about adding a light tower

i have a V3 and V4 on the way (used)

because im a moron id like to set up a light tower R,Y,G

On a V3 im thinking yellow when the machine is weighing and green when the V3 "stops"

i can just wait for the green light and pull the pan

on the V4 im thinking the same yellow, green, but include red over time

has anyone looked at what the output signal or lack of signal is on the V3 and V4

looking for the trigger without poking around so much

thanks

thanks i saw that on a videoCant speak to the V3 but the V4 already has a green LED indicator when it is in range.

i figure that one stays put and i put a more visible one

id rather not steal the signal from that little LED and burn something out, or introduce a current messing with the scale

plan is to make a totally separate "system" just using the signalby its own power supply etc

Let us know when you start selling them. I would be interestedthanks i saw that on a video

i figure that one stays put and i put a more visible one

id rather not steal the signal from that little LED and burn something out, or introduce a current messing with the scale

plan is to make a totally separate "system" just using the signalby its own power supply etc

thanks i saw that on a video

i figure that one stays put and i put a more visible one

id rather not steal the signal from that little LED and burn something out, or introduce a current messing with the scale

plan is to make a totally separate "system" just using the signalby its own power supply etc

I understand, basically a stand alone light system with an input signal from the scale to trigger LEDs.

A quick google suggests the scale uses RS485 for communication and it seems there are already relay outputs available to buy (link). As I see it the tricky part will be connecting your LED indicator system and the stepper motors from Autotrickler at the same time (from memory there is only one output port on the scale).

Anyways, good luck with it all.

I am with you. The green light on my V4 is a nice addition but when the room is bright and I am in a hurry and loading fast I would like a brighter more obvious in your face green light.thanks i saw that on a video

i figure that one stays put and i put a more visible one

id rather not steal the signal from that little LED and burn something out, or introduce a current messing with the scale

plan is to make a totally separate "system" just using the signalby its own power supply etc

I have a PM in with jthor, I have had some slight overshooting problems with Allaint RL50...I bet his nozzle will fix my occasional overshooting.

thanks i saw that on a video

i figure that one stays put and i put a more visible one

id rather not steal the signal from that little LED and burn something out, or introduce a current messing with the scale

plan is to make a totally separate "system" just using the signalby its own power supply etc

Wanting a more obvious green light, I set an old mirror in the back of the scale under the green LED and came up with this. I'll eventually find a smaller square mirror and make a stand to set in the back of the enclosure so it doesn't look like an afterthought.I am with you. The green light on my V4 is a nice addition but when the room is bright and I am in a hurry and loading fast I would like a brighter more obvious in your face green light.

Ive been using my V4 along side my pair of V3s for a bit now. Maybe have 1,000 rounds through it. I am really liking it. I have adjusted the rates enough to be quite consistent. I would consider the error rate to be improved on the small and mid grain powders, and likely improved on the large grain powders. I currently have the gap set at 1.5 grains and keep flow at 9/8 for smaller powders and 7/6 for the larger ones. Having three machines side by side, it is more important to not over throw than to squeak out an additional 2 seconds of speed..

One big bonus for me is charges over 100 grains. The V4 is much faster there. I am very happy with the system overall. I have not added a tip or messed with angles at all and I am getting good results. I was skeptical initially because I was having a hard time believing the V3 could be improved on. Now, after some use, I am in favor of the V4.

Side bonus, it is much quieter.

For perspective, I loaded over 30,000 rounds in 2021 and am planning on 50,000 rounds in 2022.

One big bonus for me is charges over 100 grains. The V4 is much faster there. I am very happy with the system overall. I have not added a tip or messed with angles at all and I am getting good results. I was skeptical initially because I was having a hard time believing the V3 could be improved on. Now, after some use, I am in favor of the V4.

Side bonus, it is much quieter.

For perspective, I loaded over 30,000 rounds in 2021 and am planning on 50,000 rounds in 2022.

Awesome idea. I too was thinking of something like that or one of the “crystal” looking things that splits the light in all directions.Wanting a more obvious green light, I set an old mirror in the back of the scale under the green LED and came up with this. I'll eventually find a smaller square mirror and make a stand to set in the back of the enclosure so it doesn't look like an afterthought.

View attachment 7824565

All,

If I haven’t been replying to messages fast it’s cause I’ve been trying to produce more V4 tips. I haven’t been ignoring just to ignore. Took me about a week and a half to get these to produce reliably and set up a process of treatment after they are done printing. Note, I’m doing this in my free time on top of a full time job and everything else I do on the side. The design has slightly changed, but doesn’t change the function. I just change the end where the tip attaches to the tube slightly. Resin 3D printing isn’t just plug and play especially when you’re trying to produce parts in production. I’ve also gone away from using clear resin due to it being very finicky and hard to produce consistent results with from one batch of resin to another.

Video on the updated tip and install.

If I haven’t been replying to messages fast it’s cause I’ve been trying to produce more V4 tips. I haven’t been ignoring just to ignore. Took me about a week and a half to get these to produce reliably and set up a process of treatment after they are done printing. Note, I’m doing this in my free time on top of a full time job and everything else I do on the side. The design has slightly changed, but doesn’t change the function. I just change the end where the tip attaches to the tube slightly. Resin 3D printing isn’t just plug and play especially when you’re trying to produce parts in production. I’ve also gone away from using clear resin due to it being very finicky and hard to produce consistent results with from one batch of resin to another.

Video on the updated tip and install.

All,

If I haven’t been replying to messages fast it’s cause I’ve been trying to produce more V4 tips. I haven’t been ignoring just to ignore. Took me about a week and a half to get these to produce reliably and set up a process of treatment after they are done printing. Note, I’m doing this in my free time on top of a full time job and everything else I do on the side. The design has slightly changed, but doesn’t change the function. I just change the end where the tip attaches to the tube slightly. Resin 3D printing isn’t just plug and play especially when you’re trying to produce parts in production. I’ve also gone away from using clear resin due to it being very finicky and hard to produce consistent results with from one batch of resin to another.

Video on the updated tip and install.

Thanks for doing this again. I have literally referred your invention to every shooter (12+) that continues to have overthrow issues with the V4. To add, your tip has made the reloading experience much better on the V4. Not playing with shims, levels, etc.

As a way to save on shipping, I would suggest you check out PirateShip.com if you already haven't.

Can confirm, @NiteQwill sent me your way and I have been very happy with the tip. Its also probably the first resin printed part that I have knowingly played with, and I am surprised with the print quality compared to my FDM printer. I get pretty darn good prints, but not quite as smooth as yours. Maybe I'll have to pick up a resin printer hah. Nice work, and thanks!Thanks for doing this again. I have literally referred your invention to every shooter (12+) that continues to have overthrow issues with the V4. To add, your tip has made the reloading experience much better on the V4. Not playing with shims, levels, etc.

As a way to save on shipping, I would suggest you check out PirateShip.com if you already haven't.

I haven't. I'll have to take a look. I went with USPS just cause it was easy with Click-n-ship and it tracks all the packages i've sent out. Also flat rate keeps things consistent which is easy for me doing this in my free time.Thanks for doing this again. I have literally referred your invention to every shooter (12+) that continues to have overthrow issues with the V4. To add, your tip has made the reloading experience much better on the V4. Not playing with shims, levels, etc.

As a way to save on shipping, I would suggest you check out PirateShip.com if you already haven't.

FDM and Resin printers have their place. Resin printing can push out really accurate results and smooth too. A lot of folks use them for printing models. Cool part with resin printers is it can take you the same amount of time to 1 part or 30 parts of the same thing if you can fit 30 of them on the print bed.Can confirm, @NiteQwill sent me your way and I have been very happy with the tip. Its also probably the first resin printed part that I have knowingly played with, and I am surprised with the print quality compared to my FDM printer. I get pretty darn good prints, but not quite as smooth as yours. Maybe I'll have to pick up a resin printer hah. Nice work, and thanks!

Last edited:

PirateShip uses USPS or UPS services at discount. Saves a significant amount of money. Pretty common method for people to ship small items because you can take advantage of USPS' commercial pricing without any fees like stamps dot com. And your receivers get email notifications of shipment. Good luck!I haven't. I'll have to take a look. I went with USPS just cause it was easy with Click-n-ship and it tracks all the packages i've sent out. Also flat rate keeps things consistent which is easy for me doing this in my free time.

I'll give it a serious look this weekend when I have free time. I'm working 12-14 hour days this week. The weekends is when I stop shipping and processing orders other than Sunday night. Been debating on shipping only monday, wednesday and friday just to keep things to a certain schedule vs dropping stuff off at the post office every day during the work week.PirateShip uses USPS or UPS services at discount. Saves a significant amount of money. Pretty common method for people to ship small items because you can take advantage of USPS' commercial pricing without any fees like stamps dot com. And your receivers get email notifications of shipment. Good luck!

Yea I've always associated resin printing with action figures and the like.. I mostly print small functional parts and I assumed resin printing wouldn't produce strong enough parts. I stand corrected!FDM and Resin printers have their place. Resin printing can push out really accurate results and smooth too. A lot of folks use them for printing models. Cool part with resin printers is it can take you the same amount of time to 1 part or 30 parts of the same thing if you can fit 30 of them on the print bed.

Yup from 3D Printed mag kits, V4 Tips to SpaceX Merlin Rocket engine parts! Pretty sure the Raptor engine has 3D printed parts as well.People generally don't know much about additive manufacturing. It's an amazing technology.

Glad I could find the time to meet you on base!I added the jthor tip to my V4 and it is awesome. It made a good machine better.

Well done.

How do I order this v4 tip?Yup from 3D Printed mag kits, V4 Tips to SpaceX Merlin Rocket engine parts! Pretty sure the Raptor engine has 3D printed parts as well.

PM jthor. See post 730 above.How do I order this v4 tip?

V4 works pretty well with Reloder 50. Do not need to tip forward as with N570, but the last kernel can be a wait.

I've been doing a lot of testing over the past month or two and I had a bit of a breakthrough yesterday. It's too early to say much right now but I am excited and I think V4 can potentially go about twice as fast as it does now, with only software changes.

The speed sliders in the app right now are controlling around a dozen numbers under the hood. The gains come from tweaking how they change in relation to each other. Different powders have very different flow characteristics at high and low speeds so one size does not fit all. Also the density of powder in the tube is hugely affected by how fast the tube has been spinning over the last few seconds. Starting and stopping at low speeds for a while allows powder to settle in and fill up the tube which leads to more flow.

The best possible performance is found by understanding what each number means, and individually adjusting them to improve each part of the process, for that powder, for that tilt angle, for that target weight.

To give you an idea, dispense 2 grains of Varget repeatedly (press Re-Zero). It probably takes 15-20 seconds. You will hear it ramping down smoothly and the last 0.5 grains will flow cautiously to avoid overshooting. Sometimes you will get lucky and finish quickly and other times it will take 20 or even 30 seconds once in a while. The speed slider has a pretty minor effect on the overall result and even at speed 10 it's still pretty conservative.

With more tuning, the powder be made to flow basically at full speed directly to the target and stop. From the point where the motor starts to slow down to when it stops is under 5 seconds. Tweaking specific parts of the process in more detail lets you minimize the risk of overshooting without compromising much overall speed. It's actually not super sensitive. There is a lot of wiggle room and it's possible to get very close to optimal speed with almost zero overshooting.

I have an objective to understand this more completely and bring the potential to everyone in the simplest possible way. It won't be 10 separate sliders. It will be a step by step guide which anyone can follow without frustration. There needs to be an "easy mode" for getting decent results and then the power to optimize beyond that. This is my project. It will take some time but it is a high priority.

The speed sliders in the app right now are controlling around a dozen numbers under the hood. The gains come from tweaking how they change in relation to each other. Different powders have very different flow characteristics at high and low speeds so one size does not fit all. Also the density of powder in the tube is hugely affected by how fast the tube has been spinning over the last few seconds. Starting and stopping at low speeds for a while allows powder to settle in and fill up the tube which leads to more flow.

The best possible performance is found by understanding what each number means, and individually adjusting them to improve each part of the process, for that powder, for that tilt angle, for that target weight.

To give you an idea, dispense 2 grains of Varget repeatedly (press Re-Zero). It probably takes 15-20 seconds. You will hear it ramping down smoothly and the last 0.5 grains will flow cautiously to avoid overshooting. Sometimes you will get lucky and finish quickly and other times it will take 20 or even 30 seconds once in a while. The speed slider has a pretty minor effect on the overall result and even at speed 10 it's still pretty conservative.

With more tuning, the powder be made to flow basically at full speed directly to the target and stop. From the point where the motor starts to slow down to when it stops is under 5 seconds. Tweaking specific parts of the process in more detail lets you minimize the risk of overshooting without compromising much overall speed. It's actually not super sensitive. There is a lot of wiggle room and it's possible to get very close to optimal speed with almost zero overshooting.

I have an objective to understand this more completely and bring the potential to everyone in the simplest possible way. It won't be 10 separate sliders. It will be a step by step guide which anyone can follow without frustration. There needs to be an "easy mode" for getting decent results and then the power to optimize beyond that. This is my project. It will take some time but it is a high priority.

I've been doing a lot of testing over the past month or two and I had a bit of a breakthrough yesterday. It's too early to say much right now but I am excited and I think V4 can potentially go about twice as fast as it does now, with only software changes.

The speed sliders in the app right now are controlling around a dozen numbers under the hood. The gains come from tweaking how they change in relation to each other. Different powders have very different flow characteristics at high and low speeds so one size does not fit all. Also the density of powder in the tube is hugely affected by how fast the tube has been spinning over the last few seconds. Starting and stopping at low speeds for a while allows powder to settle in and fill up the tube which leads to more flow.

The best possible performance is found by understanding what each number means, and individually adjusting them to improve each part of the process, for that powder, for that tilt angle, for that target weight.

To give you an idea, dispense 2 grains of Varget repeatedly (press Re-Zero). It probably takes 15-20 seconds. You will hear it ramping down smoothly and the last 0.5 grains will flow cautiously to avoid overshooting. Sometimes you will get lucky and finish quickly and other times it will take 20 or even 30 seconds once in a while. The speed slider has a pretty minor effect on the overall result and even at speed 10 it's still pretty conservative.

With more tuning, the powder be made to flow basically at full speed directly to the target and stop. From the point where the motor starts to slow down to when it stops is under 5 seconds. Tweaking specific parts of the process in more detail lets you minimize the risk of overshooting without compromising much overall speed. It's actually not super sensitive. There is a lot of wiggle room and it's possible to get very close to optimal speed with almost zero overshooting.

I have an objective to understand this more completely and bring the potential to everyone in the simplest possible way. It won't be 10 separate sliders. It will be a step by step guide which anyone can follow without frustration. There needs to be an "easy mode" for getting decent results and then the power to optimize beyond that. This is my project. It will take some time but it is a high priority.

Interesting.

I know this is still a work in progress but based on what you have found is the goal a new updated version of the app (possibly with additional settings / sliders) and a PDF guide on how to tune the system?

My V4 has been working pretty good (I didnt have a V3 to compare to like some other folks) but if this improves the overall operation I'm interested.

Interesting.

I know this is still a work in progress but based on what you have found is the goal a new updated version of the app (possibly with additional settings / sliders) and a PDF guide on how to tune the system?

My V4 has been working pretty good (I didnt have a V3 to compare to like some other folks) but if this improves the overall operation I'm interested.

Yes, to clarify, I expect this is an app update and a guide which includes clear instructions for tuning sliders as well as tilt angle.

There may be upgrades to mechanical parts for other reasons but specifically for what I'm talking about now, I am using the stock hardware and only a free app update is required because the app can control all of the parameters I am adjusting and the mechanics are not holding back performance (at least with Varget).

Yes, to clarify, I expect this is an app update and a guide which includes clear instructions for tuning sliders as well as tilt angle.

There may be upgrades to mechanical parts for other reasons but specifically for what I'm talking about now, I am using the stock hardware and only a free app update is required because the app can control all of the parameters I am adjusting and the mechanics are not holding back performance (at least with Varget).

As someone who uses lots of Varget this is very welcome news!

I look forward to any developments (particularly if they make the system faster, dropping repeatable precise amounts is #1 for me but a faster system is always a plus).

Thank you for your efforts with this.

Taking an already great product and making it even better. I didnt think the V3 could get much better, but prefer the V4 now. An improved V4 will be spectacular.I've been doing a lot of testing over the past month or two and I had a bit of a breakthrough yesterday. It's too early to say much right now but I am excited and I think V4 can potentially go about twice as fast as it does now, with only software changes.

The speed sliders in the app right now are controlling around a dozen numbers under the hood. The gains come from tweaking how they change in relation to each other. Different powders have very different flow characteristics at high and low speeds so one size does not fit all. Also the density of powder in the tube is hugely affected by how fast the tube has been spinning over the last few seconds. Starting and stopping at low speeds for a while allows powder to settle in and fill up the tube which leads to more flow.

The best possible performance is found by understanding what each number means, and individually adjusting them to improve each part of the process, for that powder, for that tilt angle, for that target weight.

To give you an idea, dispense 2 grains of Varget repeatedly (press Re-Zero). It probably takes 15-20 seconds. You will hear it ramping down smoothly and the last 0.5 grains will flow cautiously to avoid overshooting. Sometimes you will get lucky and finish quickly and other times it will take 20 or even 30 seconds once in a while. The speed slider has a pretty minor effect on the overall result and even at speed 10 it's still pretty conservative.

With more tuning, the powder be made to flow basically at full speed directly to the target and stop. From the point where the motor starts to slow down to when it stops is under 5 seconds. Tweaking specific parts of the process in more detail lets you minimize the risk of overshooting without compromising much overall speed. It's actually not super sensitive. There is a lot of wiggle room and it's possible to get very close to optimal speed with almost zero overshooting.

I have an objective to understand this more completely and bring the potential to everyone in the simplest possible way. It won't be 10 separate sliders. It will be a step by step guide which anyone can follow without frustration. There needs to be an "easy mode" for getting decent results and then the power to optimize beyond that. This is my project. It will take some time but it is a high priority.

Received my V4 yesterday. Loaded 200 rounds of dasher with Varget today. I was very impressed. Easy setup, ran calibration, then was off to the races with 8-12 seconds throws. 3 overthrows out of 200. Didn’t have to mess with it at all. Couldn’t be happier. Fyi: Used Jthor’s plastic tip from the get go.

Last edited:

I agree with Adam’s assessment. Most of the fine ball powders and small stick flow great. The larger stick powders become very sensitive to the tube speed. Likely why so many people have better success running the small tube fast. The trickle rate becomes more predictable/uniform. Excited to see where this ends up.

Making excellent progress.

I have a question.

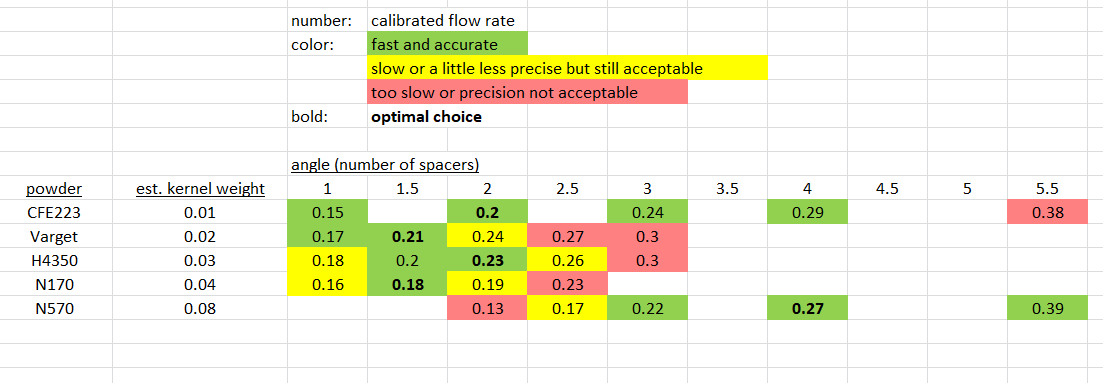

N570 appears to be an outlier. I expected N170 to fall in between in terms of tuning but it doesn't. It flows much more like the other powders despite having large kernels.

Can anyone suggest another common, easily obtainable powder, similar to N570, which has issues flowing at normal tilt angles, which I should be considering?

I already have some H1000 and H50BMG and will test these soon.

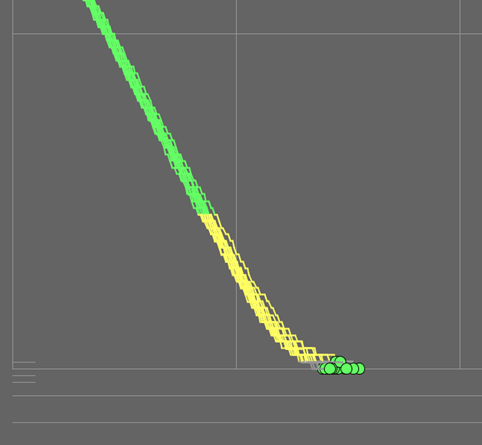

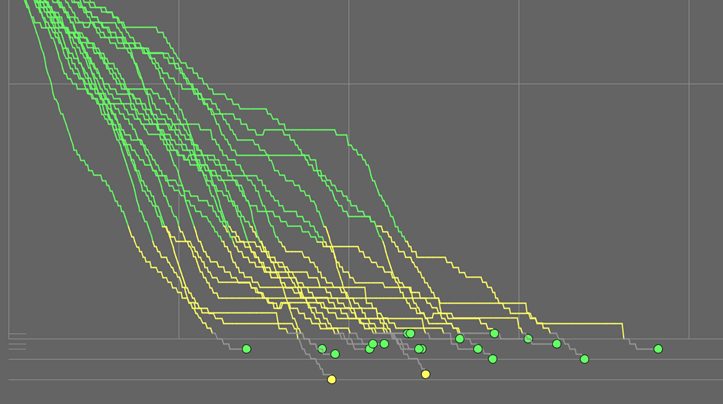

I'll be writing this all up soon in a document but for now here's two opposite ends of the spectrum of how powder can flow. Just look at what we have to work with...

I have a question.

N570 appears to be an outlier. I expected N170 to fall in between in terms of tuning but it doesn't. It flows much more like the other powders despite having large kernels.

Can anyone suggest another common, easily obtainable powder, similar to N570, which has issues flowing at normal tilt angles, which I should be considering?

I already have some H1000 and H50BMG and will test these soon.

I'll be writing this all up soon in a document but for now here's two opposite ends of the spectrum of how powder can flow. Just look at what we have to work with...

To me the key will be the slow tube flow, H1000 and 4350 are the reason I bought this unit, clumping appears to be the only reason for overthrows, thus jthors tip and the sawtooth McDonald's straw in a chargemaster, have you considered other pitchs (courser) for the slow tube.

Making excellent progress.

I have a question.

N570 appears to be an outlier. I expected N170 to fall in between in terms of tuning but it doesn't. It flows much more like the other powders despite having large kernels.

Can anyone suggest another common, easily obtainable powder, similar to N570, which has issues flowing at normal tilt angles, which I should be considering?

I already have some H1000 and H50BMG and will test these soon.

View attachment 7838370

I'll be writing this all up soon in a document but for now here's two opposite ends of the spectrum of how powder can flow. Just look at what we have to work with...

View attachment 7838373

View attachment 7838372

what about RL33? I have not tried it but it is close to N570. I agree with those #s though. Mine runs better with tilt that produces a calibrated flow from .18 to .23, I am keeping it at .2 - .21 for now. The tip helps too, allows me to turn the speed up a little. I am running 9-12 seconds per charge without issue or over throws.

Similar threads

- Replies

- 20

- Views

- 589