Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

6mm Dasher

- Thread starter "HeysKSFirefighter

- Start date

It all depends on who you get your hydro-form brass from. See my recommendation above. The only place I've gotten true "load-and-shoot" brass.So concencous is after you get hydrocormed brass back you should full length size it before fire forming? Or do people just clean brass then load and finish fire forming the. Resize after that?

Thank you chad

It all depends on who you get your hydro-form brass from. See my recommendation above. The only place I've gotten true "load-and-shoot" brass.

I got mine from hunts long range and is Lapua brass. I measured the hydroformed brass and was pretty consistent but does need to be fireformed to get final fitment

https://huntslongrange.com/product/lapua-6-dasher-hydroformed-brass/?v=7516fd43adaa

Chad

Don't discount 4166 as a viable option for powder.

I have found slightly better velocity with less carbon issues using it.

Shot a 4 round group the other day at 1360 yards using 110 SMK and 4166 that had just less than 6" vertical dispersion.

The wind was kicking my ass so we won't discuss the horizontal! That was all the ammo I had left that day hence only 4 shots.

I have found slightly better velocity with less carbon issues using it.

Shot a 4 round group the other day at 1360 yards using 110 SMK and 4166 that had just less than 6" vertical dispersion.

The wind was kicking my ass so we won't discuss the horizontal! That was all the ammo I had left that day hence only 4 shots.

Attachments

I am a new guy to 6 Dasher, but have formed brass for a few wildcats in the past. My understanding is that regardless of how/where you get your hydroformed brass, it should be blown out enough to at least cause a slightly firmer than normal bolt closing. This slight crush fit will ensure the case isn't moving forward on primer strike. I believe with most hydroformed brass, this will mean running it through your sizing die to bump the rounded shoulder back slightly and testing the bolt close on the brass piece until the slight crush is just right.

If your hydroformed brass does not cause a harder bolt close before sizing, it probably didn't get blown forward enough during the hydroforming. Not optimal, but if this is the situation you find yourself in, you will definitely want to seat your bullets with high neck tension and a stiff jam into the lands before firing. (better yet, get them hydroformed right so there is at least a slight crush fit)

Thanks for everyone's posts on forming and powders for the dasher.

I saw some 4166 on the local shelves the other night, so I grabbed a bottle to throw into the testing mix.

The new barrel should be here this weekend, so hopefully will be launching projectiles down range soon. (got a great deal on some RDF 105gr blems, hoping they work as good for me as they have for some others)

If your hydroformed brass does not cause a harder bolt close before sizing, it probably didn't get blown forward enough during the hydroforming. Not optimal, but if this is the situation you find yourself in, you will definitely want to seat your bullets with high neck tension and a stiff jam into the lands before firing. (better yet, get them hydroformed right so there is at least a slight crush fit)

Thanks for everyone's posts on forming and powders for the dasher.

I saw some 4166 on the local shelves the other night, so I grabbed a bottle to throw into the testing mix.

The new barrel should be here this weekend, so hopefully will be launching projectiles down range soon. (got a great deal on some RDF 105gr blems, hoping they work as good for me as they have for some others)

Rim fire Mike

I would do a good job of sorting those blemished bullets. I have found they are in terrific condition, but they seem to come from many different lots and/or dies. Therefore lengths, base to ogive and weights vary. Because of this I’ve played hell with consistent seating depths. I gave up for now and will shoot Berger’s in my BR and use the blems for fire forming Dasher brass when I get one. I’ve had good luck with first run RDFs in 6.5 for steel banging.

I would do a good job of sorting those blemished bullets. I have found they are in terrific condition, but they seem to come from many different lots and/or dies. Therefore lengths, base to ogive and weights vary. Because of this I’ve played hell with consistent seating depths. I gave up for now and will shoot Berger’s in my BR and use the blems for fire forming Dasher brass when I get one. I’ve had good luck with first run RDFs in 6.5 for steel banging.

Rim fire Mike

I would do a good job of sorting those blemished bullets. I have found they are in terrific condition, but they seem to come from many different lots and/or dies. Therefore lengths, base to ogive and weights vary. Because of this I’ve played hell with consistent seating depths. I gave up for now and will shoot Berger’s in my BR and use the blems for fire forming Dasher brass when I get one. I’ve had good luck with first run RDFs in 6.5 for steel banging.

Thanks for the heads up on your experience with these. I got them for just over $14/100 shipped, so will be great for fireforming at least and hopefully shoot well if I sort by weight and ogive length.

So concencous is after you get hydrocormed brass back you should full length size it before fire forming? Or do people just clean brass then load and finish fire forming the. Resize after that?

Thank you chad

Chad

i hydro form my brass so the bolt is very tight on close, then I resize the brass pressing the rounded shoulder more inline to the 40 degree shoulder. Here is a picture of my just hydro form dasher on the right vs a twiced fired one on the left.

Last edited:

I believe the Hodgdon reloading page lists 6 Dasher load data.Does anyone have a load with 4166 and 105 hybrids

Yep it's on there but no 4166 with 105 or 107I believe the Hodgdon reloading page lists 6 Dasher load data.

It is just a tad faster than Varget.Yep it's on there but no 4166 with 105 or 107

Start with Varget loads and I have ended up with higher charge weights than Varget.

Enter at your own risk.

Every rifle is different.

YMMV.

Yada yada.

I did load 110 SMK over 33 gr. of 4166 and got 2880 fps.

My 105 Hornady loading is not getting posted for the above reasons.

Specs:

26 inch bartlein barrel

1.555 chamber

272 no-turn neck

104 freebore

Defiance Deviant action

Primers CCI450

False shoulder formed brass

105 hybrid seated 0.015 off the lands

32.6 gr of Varget = 2978 fps (on average) SD 4.2

33.0 gr of Varget = 3006 fps (on average) SD 5.4

On a colder day 33 gr varget 2984 fps SD 1.4 ES 4

Specs:

26 inch bartlein barrel

1.555 chamber

272 no-turn neck

104 freebore

Defiance Deviant action

Primers CCI450

False shoulder formed brass

105 hybrid seated 0.015 off the lands

32.6 gr of Varget = 2978 fps (on average) SD 4.2

33.0 gr of Varget = 3006 fps (on average) SD 5.4

On a colder day 33 gr varget 2984 fps SD 1.4 ES 4

Hi is it possible to know what the overall length is?

26'' Hawk Hill Marsksman 1/7 twist

Lapua Hydro formed brass Hunts Longrange

Impact Action

105Hyb 5 thou off

32.8 Varget @ 3001 fps

CCI 450's

I tried BR-4's, but would get a few hang fires in cold weather.

Going to give the 110's a try this week. This is my first Dasher barrel only 60 rds fired so far, I'm a 6.5 and 6 Creed guy.

Loving the Dasher so far.

Lapua Hydro formed brass Hunts Longrange

Impact Action

105Hyb 5 thou off

32.8 Varget @ 3001 fps

CCI 450's

I tried BR-4's, but would get a few hang fires in cold weather.

Going to give the 110's a try this week. This is my first Dasher barrel only 60 rds fired so far, I'm a 6.5 and 6 Creed guy.

Loving the Dasher so far.

Last edited:

26'' Hawk Hill Marsksman 1/7 twist

Lapua Hydro formed brass Hunts Longrange

Impact Action

105Hyb 5 thou off

32.8 Varget @ 3001 fps

CCI 450's

I tried BR-4's, but would get a few hang fires in cold weather.

Going to give the 110's a try this week. This is my first Dasher barrel only 60 rds fired so far, I'm a 6.5 and 6 Creed guy.

Loving the Dasher so far.

Hey Capt

How was the brass from Hunts Longrange? and if you don't mind what was your prep work once you got it, did you resize, fireform with bullet into lands? Just asking because I see a lot in here about the DJ brass but I picked mine up from Hunts as well. my action is in the 10 day jail then I have to put it together so will be acouple of weeks until I can see if the bolt closes tight on the hydroformed brass.

Thanks

Chad

Do you think if I took varget load for br and dashed and got the diff and backed off a few 10ths would that be a starting point for 4166 I also wanna try VVIt is just a tad faster than Varget.

Start with Varget loads and I have ended up with higher charge weights than Varget.

Enter at your own risk.

Every rifle is different.

YMMV.

Yada yada.

I did load 110 SMK over 33 gr. of 4166 and got 2880 fps.

My 105 Hornady loading is not getting posted for the above reasons.

In my BR 29.9 grains if 4166 and 30.0 grains of Varget are the same speed for all intents and purposes when it’s warm. Varget is slightly faster when it’s cold out.Do you think if I took varget load for br and dashed and got the diff and backed off a few 10ths would that be a starting point for 4166 I also wanna try VV

Triggs75, I just tumbled it to clean off some lube and fired it. It shot great the way it came, ready to load and go!

Triggs75, I just tumbled it to clean off some lube and fired it. It shot great the way it came, ready to load and go!

Same for me. Makes it easy. It's nice to have a few buddies spotting brass at matches to find 95-99% of your $1.55 brass.

You could have a bunch of different lots of brass that way. It would be hard to nail down tuning issues since likely you will have different case capacities and neck thicknesses.Same for me. Makes it easy. It's nice to have a few buddies spotting brass at matches to find 95-99% of your $1.55 brass.

I don't neck turn. I've had good luck with this method for the 300 hunt's cases I did this way. I never get wrapped around the axel on fine tuning a load. If it shoots .5" or better I'm happy. I'd never claim to be a great reloader though. Guess it depends on what you're seeking for accuracy.

I may end up buying hydroformed brass someday, but had to try forming my own first... just because.

Getting the hydro die and consistent technique down took a dozen or so cases, but I've got it figured out now and am actually quite pleased with how uniform the cases are turning out. See attached picture with new 6BR case on left, then case out of hydroform die, case after full length sizer die, and finally once-fired case.

I got to the range to try out some initial load work ups with H4350, Varget and IMR 4166.

H4350 grouped pretty tight across more than a 2 grain spread, but not sure if I'm willing to use a drop tube that seemingly would need to be almost ceiling high to get enough powder in to get the velocity I'm looking for. (knew this but wanted to see because I have a lot of this powder)

Varget seemed okay, but need to load more cases to get a little faster than my loads were today.

IMR 4166 was the standout in what I tested on this trip. Look to have a nice accuracy node right around 3000 fps. No pressure signs yet so will keep going up a little more to see what happens.

After this first range trip, already thinking I'm going to end up really liking this dasher thing!!

Getting the hydro die and consistent technique down took a dozen or so cases, but I've got it figured out now and am actually quite pleased with how uniform the cases are turning out. See attached picture with new 6BR case on left, then case out of hydroform die, case after full length sizer die, and finally once-fired case.

I got to the range to try out some initial load work ups with H4350, Varget and IMR 4166.

H4350 grouped pretty tight across more than a 2 grain spread, but not sure if I'm willing to use a drop tube that seemingly would need to be almost ceiling high to get enough powder in to get the velocity I'm looking for. (knew this but wanted to see because I have a lot of this powder)

Varget seemed okay, but need to load more cases to get a little faster than my loads were today.

IMR 4166 was the standout in what I tested on this trip. Look to have a nice accuracy node right around 3000 fps. No pressure signs yet so will keep going up a little more to see what happens.

After this first range trip, already thinking I'm going to end up really liking this dasher thing!!

Attachments

What 4166 load did you start withI may end up buying hydroformed brass someday, but had to try forming my own first... just because.

Getting the hydro die and consistent technique down took a dozen or so cases, but I've got it figured out now and am actually quite pleased with how uniform the cases are turning out. See attached picture with new 6BR case on left, then case out of hydroform die, case after full length sizer die, and finally once-fired case.

I got to the range to try out some initial load work ups with H4350, Varget and IMR 4166.

H4350 grouped pretty tight across more than a 2 grain spread, but not sure if I'm willing to use a drop tube that seemingly would need to be almost ceiling high to get enough powder in to get the velocity I'm looking for. (knew this but wanted to see because I have a lot of this powder)

Varget seemed okay, but need to load more cases to get a little faster than my loads were today.

IMR 4166 was the standout in what I tested on this trip. Look to have a nice accuracy node right around 3000 fps. No pressure signs yet so will keep going up a little more to see what happens.

After this first range trip, already thinking I'm going to end up really liking this dasher thing!!

DJ's brass, 32.7 Varget, CCI450, 105 VLD .010" in.

Hawkhill 7T MTU @ 26" on a Curtis Vector in MPA Chassis(not bedded). Group is 100 yards, first five-shot group after installing the scope.

This was ZERO load workup for this rifle. These five were originally loaded for one of my long range BR rifles.

The only group shot with it so far. I pulled the scope back off and took it to be bedded into a KMW Sentinel and have the barrel ceracoated.

Hawkhill 7T MTU @ 26" on a Curtis Vector in MPA Chassis(not bedded). Group is 100 yards, first five-shot group after installing the scope.

This was ZERO load workup for this rifle. These five were originally loaded for one of my long range BR rifles.

The only group shot with it so far. I pulled the scope back off and took it to be bedded into a KMW Sentinel and have the barrel ceracoated.

Attachments

What 4166 load did you start with

I started with 31.5gr of IMR 4166 in my hydroformed cases. I only loaded test rounds up to 33gr which were right around 3000 fps with no pressure signs.

Do you know what you where getting around 32.5I started with 31.5gr of IMR 4166 in my hydroformed cases. I only loaded test rounds up to 33gr which were right around 3000 fps with no pressure signs.

Generally speaking, the node long proven to provide top accuracy results in 6 Dasher is right around 3,020 FPS or so. RL15 and H4895 are two other commonly used powders for the Dasher but RL15 is just too dirty and to temp sensitive for PRS applications (IMO).

I experimented with Alliant 2000MR in late 2016 and results were promising. I was able to get the little Dasher to perform over its head, seeing as high as 3,200 FPS with 105 Hybrids from a 28" barrel. The caveat is I don't feel it a great choice for PRS type shooting either and it is very hard on barrels. I wiped the throat out of a great Bartlein in very short order with it. IMR4166 is (my best guess) very close to IMR 4064. Berger shows that to be a good power for velocity and the Enduron powders have shown to be very capable.

I experimented with Alliant 2000MR in late 2016 and results were promising. I was able to get the little Dasher to perform over its head, seeing as high as 3,200 FPS with 105 Hybrids from a 28" barrel. The caveat is I don't feel it a great choice for PRS type shooting either and it is very hard on barrels. I wiped the throat out of a great Bartlein in very short order with it. IMR4166 is (my best guess) very close to IMR 4064. Berger shows that to be a good power for velocity and the Enduron powders have shown to be very capable.

I started with 31.5gr of IMR 4166 in my hydroformed cases. I only loaded test rounds up to 33gr which were right around 3000 fps with no pressure signs.

awesome ... i really got to try some.

Do you know what you where getting around 32.5

I was getting around 2950 with 32.5gr of 4166. All testing was with the 105gr RDF's about .010 into the lands.

I appreciate the infoI was getting around 2950 with 32.5gr of 4166. All testing was with the 105gr RDF's about .010 into the lands.

Jumping aboard the Dasher train (choo choo) this year and I thought I'd share my findings so far with you all:

Gun Specs

- Defiance Deviant Elite LH

- International Barrels M24 contour, 26" long

- MDT Elite Brake 3/4-24

So far I have done 350 ish rounds of FF-ing with 90-105 gr bullets, jammed 0.030", 30 gr +/- 0.3 gr of Varget, then I started load dev.

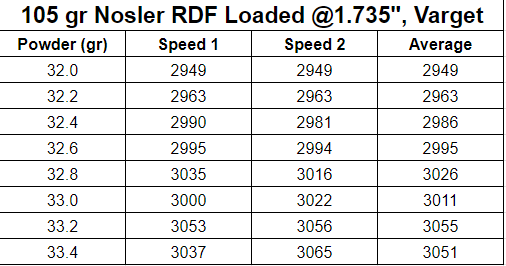

I have run the 105 Nosler RDF's at 0.040" off the lands (the 1.735" is CBTO with a custom gauge):

The 108 ELD-M's 0.020" off the lands:

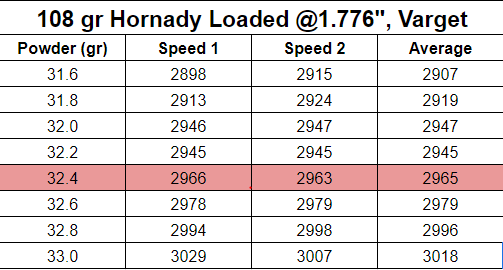

The 32.4 gr load was highlighted because that was what I ran at a club match last weekend, but more on that later.

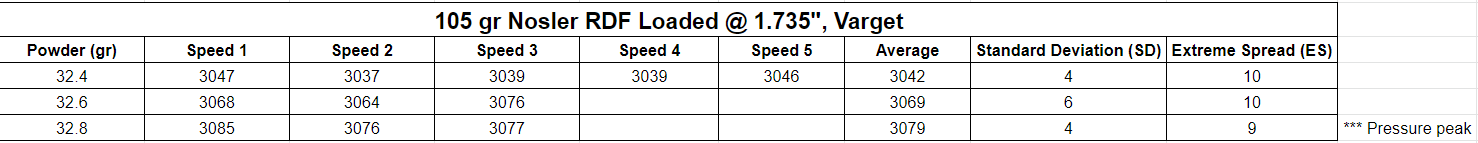

However, since running those two ladders, it appears that my barrel has further sped up another 50-75 ft/s as these are the numbers I got yesterday!

105 gr RDF:

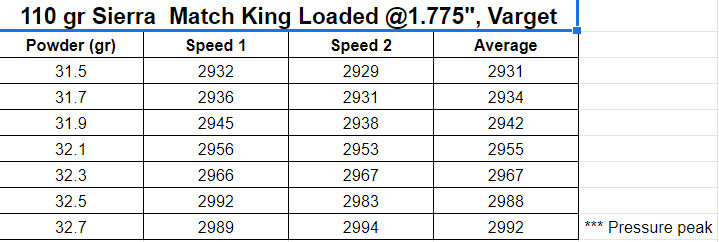

and 110 SMK:

I hope this proves useful for anyone out there It looks like I will be running the 108's this season, as 105 Hybrids and the 110 SMK's are hard to find/expensive up here!

It looks like I will be running the 108's this season, as 105 Hybrids and the 110 SMK's are hard to find/expensive up here!

Gun Specs

- Defiance Deviant Elite LH

- International Barrels M24 contour, 26" long

- MDT Elite Brake 3/4-24

So far I have done 350 ish rounds of FF-ing with 90-105 gr bullets, jammed 0.030", 30 gr +/- 0.3 gr of Varget, then I started load dev.

I have run the 105 Nosler RDF's at 0.040" off the lands (the 1.735" is CBTO with a custom gauge):

The 108 ELD-M's 0.020" off the lands:

The 32.4 gr load was highlighted because that was what I ran at a club match last weekend, but more on that later.

However, since running those two ladders, it appears that my barrel has further sped up another 50-75 ft/s as these are the numbers I got yesterday!

105 gr RDF:

and 110 SMK:

I hope this proves useful for anyone out there

Going to take the plunge and get a Dasher spun up. Just wanting to see if I am on the write path for collecting components and tools:

Brass: purchasing hydroformed Lapua brass from @Rimfiremike

Powder: Have a lead on a couple kegs of Varget

Bullets: Going to run 110SMKs has I have several thousand, could be talked into 108ELDMs if performance will be much better

Primers: Planning to use CCI 450s but also have BR4s as well.

As far as dies, is there a consensus on the best out there? I have Whidden and Redding and like them both, need micrometer seater die and would like a bushing full length die.

What bushing will I need with the lapua brass?

Any other tips or tricks would be appreciated!

Brass: purchasing hydroformed Lapua brass from @Rimfiremike

Powder: Have a lead on a couple kegs of Varget

Bullets: Going to run 110SMKs has I have several thousand, could be talked into 108ELDMs if performance will be much better

Primers: Planning to use CCI 450s but also have BR4s as well.

As far as dies, is there a consensus on the best out there? I have Whidden and Redding and like them both, need micrometer seater die and would like a bushing full length die.

What bushing will I need with the lapua brass?

Any other tips or tricks would be appreciated!

I'm not sure but from what I've read those two bullets are pretty different, as in freebore on your chambering. I'll be interested to see what others that know more than I do say.

Brass: Best I have used is from DJ's Brass Service. Shoulders are sharp and length is consistent. Brass is worked hard during the hydro-form process and his is annealed after. Best of all it shoots well right out of the gate (reduce load slightly first firing).Going to take the plunge and get a Dasher spun up. Just wanting to see if I am on the write path for collecting components and tools:

Brass: purchasing hydroformed Lapua brass from @Rimfiremike

Powder: Have a lead on a couple kegs of Varget

Bullets: Going to run 110SMKs has I have several thousand, could be talked into 108ELDMs if performance will be much better

Primers: Planning to use CCI 450s but also have BR4s as well.

As far as dies, is there a consensus on the best out there? I have Whidden and Redding and like them both, need micrometer seater die and would like a bushing full length die.

What bushing will I need with the lapua brass?

Any other tips or tricks would be appreciated!

Powder: you're right on that choice for sure. Varget is the best I've used and I've shot thousands of 6 Dasher rounds.

Bullets: If your twist is right for the 110 SMK then that is a great choice. The "new" SMK's are very good quality bullets.

Primers: I would stay with the plan to use CCI450.

Dies: Mine are Whidden and have not regretted using them over Redding. My loaded round runout, using Whidden dies on the Coax, is never more than .015 total.

Barrel is 1:7.5 twist. I have an AMP annealer and can anneal after receiving.Brass: Best I have used is from DJ's Brass Service. Shoulders are sharp and length is consistent. Brass is worked hard during the hydro-form process and his is annealed after. Best of all it shoots well right out of the gate (reduce load slightly first firing).

Powder: you're right on that choice for sure. Varget is the best I've used and I've shot thousands of 6 Dasher rounds.

Bullets: If your twist is right for the 110 SMK then that is a great choice. The "new" SMK's are very good quality bullets.

Primers: I would stay with the plan to use CCI450.

Dies: Mine are Whidden and have not regretted using them over Redding. My loaded round runout, using Whidden dies on the Coax, is never more than .015 total.

I do have a couple boxes of the 110SMK but yet to shoot any. I was merely stating that the newer SMK is a much better (more consistent) bullet than before they started pointing them at the factory. I really don't think the overall shape is any different than it was and I have always found SMKs to be very tolerant of seating depth.How sensitive to seating depth are the 110gr smk? Reason I ask is with 105 hybrids I can run from. 020 to 060 off the lands with no change in accuracy or velocity. I heard the 110gr smk can be touchy and requires a lot of adjustment as the barrel wears.

Here at my 450' ASL I felt like it would take a 7 twist to fully stabilize the 110 past 800 yards or so and have just had a 7T Hawkhill barrel done in Dasher.

Like you, I keep the Hybrid well off the lands. Also like you I find them not to require as much "chasing" as the barrel wears.

I do have a couple boxes of the 110SMK but yet to shoot any. I was merely stating that the newer SMK is a much better (more consistent) bullet than before they started pointing them at the factory. I really don't think the overall shape is any different than it was and I have always found SMKs to be very tolerant of seating depth.

Here at my 450' ASL I felt like it would take a 7 twist to fully stabilize the 110 past 800 yards or so and have just had a 7T Hawkhill barrel done in Dasher.

Like you, I keep the Hybrid well off the lands. Also like you I find them not to require as much "chasing" as the barrel wears.

I am at 2500 ASL, hopefully the 7.5 will be enough.

I would venture a guess that you would be. The 7.5 might do it here during summer but I doubt it during cooler temps.I am at 2500 ASL, hopefully the 7.5 will be enough.

How sensitive to seating depth are the 110gr smk? Reason I ask is with 105 hybrids I can run from. 020 to 060 off the lands with no change in accuracy or velocity. I heard the 110gr smk can be touchy and requires a lot of adjustment as the barrel wears.

I found them finicky in my Dasher and went back to 105 Hybrids.

Jumping aboard the Dasher train (choo choo) this year and I thought I'd share my findings so far with you all:

Gun Specs

- Defiance Deviant Elite LH

- International Barrels M24 contour, 26" long

- MDT Elite Brake 3/4-24

So far I have done 350 ish rounds of FF-ing with 90-105 gr bullets, jammed 0.030", 30 gr +/- 0.3 gr of Varget, then I started load dev.

I have run the 105 Nosler RDF's at 0.040" off the lands (the 1.735" is CBTO with a custom gauge):

View attachment 7031927

The 108 ELD-M's 0.020" off the lands:

View attachment 7031930

The 32.4 gr load was highlighted because that was what I ran at a club match last weekend, but more on that later.

However, since running those two ladders, it appears that my barrel has further sped up another 50-75 ft/s as these are the numbers I got yesterday!

105 gr RDF:

View attachment 7031938

and 110 SMK:

View attachment 7031944

I hope this proves useful for anyone out thereIt looks like I will be running the 108's this season, as 105 Hybrids and the 110 SMK's are hard to find/expensive up here!

What free bore is your barrel? That is a wide range of bullets with very different base to ogive distances.

My dasher barrel will be here tomorrow.

27” HH

.150 Freebore

7 twist m24 contour

Brass from @Rimfiremike

I’ve got 105s and 112s on hand. But will be focusing on the 112s as they have shot great in my 6BR.

I’ve got RL16, H4895, 4166 and varget on hand. Lots of H4895 so I am hoping to use that. From what I’m reading H4895 may be a bit fast for the 112. Didn’t have an issue in 6BR though.

27” HH

.150 Freebore

7 twist m24 contour

Brass from @Rimfiremike

I’ve got 105s and 112s on hand. But will be focusing on the 112s as they have shot great in my 6BR.

I’ve got RL16, H4895, 4166 and varget on hand. Lots of H4895 so I am hoping to use that. From what I’m reading H4895 may be a bit fast for the 112. Didn’t have an issue in 6BR though.

What kinds of speeds were you getting with the 112s in a BR? Barrel length? What is the BTO of the 112s?My dasher barrel will be here tomorrow.

27” HH

.150 Freebore

7 twist m24 contour

Brass from @Rimfiremike

I’ve got 105s and 112s on hand. But will be focusing on the 112s as they have shot great in my 6BR.

I’ve got RL16, H4895, 4166 and varget on hand. Lots of H4895 so I am hoping to use that. From what I’m reading H4895 may be a bit fast for the 112. Didn’t have an issue in 6BR though.

What kinds of speeds were you getting with the 112s in a BR? Barrel length? What is the BTO of the 112s?

2760 is where the node has been. H4895 29.1gr. BTO is 1.805 with a 30thou jump. my BR has a .120 Freebore

26” HH 7 twist

Sorry, I mean the base to ogive of the bullet itself.2760 is where the node has been. H4895 29.1gr. BTO is 1.805 with a 30thou jump. my BR has a .120 Freebore

26” HH 7 twist

Sorry, I mean the base to ogive of the bullet itself.

Ah, I got you. .697

Ah, I got you. .697

Damn, those are long for a VLD type bullet, almost to Hornady lengths.

What free bore is your barrel? That is a wide range of bullets with very different base to ogive distances.

I have a .104 freebore in this barrel, but may bump that up on the next one.

Similar threads

- Replies

- 13

- Views

- 550

- Replies

- 3

- Views

- 356

- Replies

- 7

- Views

- 1K

- Replies

- 15

- Views

- 1K