How much resizing is always going to be a balance between the desire for the most consistent alignment round-to-round of cartridge to chamber and the desire to ensure reliable chambering and extraction.

Additionally, it depends on how you are using the system and where. I.E. Will everything always be perfectly clean and how detrimental would failure to chamber or extract be for how you are using the system.

After considering those areas, and testing your approach proceed according to your needs.

A side note, there are certainly other reasons to load than having brass that fits "perfectly" in your chamber. Such as neck tension control/consistency, charge weight control/consistency, bullet seating depth control/consistency to name a few.

You’re right and my comment about reloading vs. not was a little tongue in cheek. It just seems a little counter intuitive to bump the shoulder .002” below what unfired brass is measuring at. I was however surprised to see the bug holes this barrel was shooting with unfired brass. The rounds were not concentric AT ALL due to some apparently banana shaped brass, which made it all the more of a head scratcher.

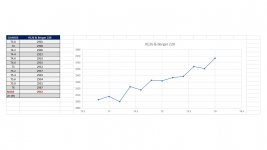

There’s 8 rounds in here at exactly an inch at 100 yards, and the left most one was all me. Charges in the group started at 74.1 and ended at 76.2. Probably not impressive to most of you guys but for me I was expecting to see a larger spread.

My purposes are hunting and shooting steel. For this reason my final load won’t be jammed into the lands, but dirty ammunition and chamber is not really an issue I run into in my pursuits.